diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12<br />

Tour de France<br />

A 28 autoroute widened between Tours and Le Mans<br />

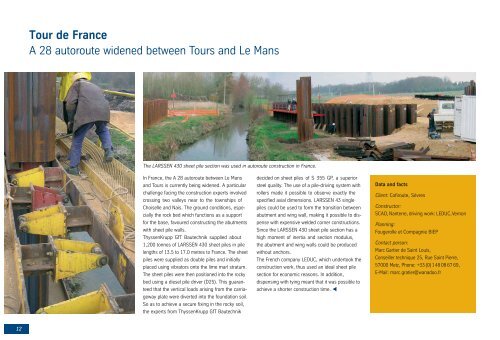

The LARSSEN 430 sheet pile section was used in autoroute construction in France.<br />

In France, the A 28 autoroute between Le Mans<br />

and Tours is currently being widened. A particular<br />

challenge facing the construction experts involved<br />

crossing two valleys near to the townships of<br />

Choiselle and Nais. The ground conditions, especially<br />

the rock bed which functions as a support<br />

for the base, favoured constructing the abutments<br />

with sheet pile walls.<br />

<strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong> supplied about<br />

1,200 tonnes of LARSSEN 430 sheet piles in pile<br />

lengths of 13.5 to 17.0 metres to France. The sheet<br />

piles were supplied as double piles and initially<br />

placed using vibrators onto the lime marl stratum.<br />

The sheet piles were then positioned into the rocky<br />

bed using a diesel pile driver (D25). This guaranteed<br />

that the vertical loads arising from the carriageway<br />

plate were diverted into the foundation soil.<br />

So as to achieve a secure fixing in the rocky soil,<br />

the experts from <strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong><br />

decided on sheet piles of S 355 GP, a superior<br />

steel quality. The use of a pile-driving system with<br />

rollers made it possible to observe exactly the<br />

specified axial dimensions. LARSSEN 43 single<br />

piles could be used to form the transition between<br />

abutment and wing wall, making it possible to dispense<br />

with expensive welded corner constructions.<br />

Since the LARSSEN 430 sheet pile section has a<br />

high moment of inertia and section modulus,<br />

the abutment and wing walls could be produced<br />

without anchors.<br />

The French company LEDUC, which undertook the<br />

construction work, thus used an ideal sheet pile<br />

section for economic reasons. In addition,<br />

dispensing with tying meant that it was possible to<br />

achieve a shorter construction time. �<br />

Data and facts<br />

Client: Cofiroute, Sèvres<br />

Constructor:<br />

SCAO,Nanterre, driving work: LEDUC,Vernon<br />

Planning:<br />

Fougerolle et Compagnie BIEP<br />

Contact person:<br />

Marc Gartier de Saint Louis,<br />

Conseiller technique 25, Rue Saint Pierre,<br />

57000 Metz, Phone: +33 (0)148 08 67 69,<br />

E-Mail: marc.gratier@wanadoo.fr