diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10<br />

Under lock and key<br />

Oil-cracking facility redeveloped in the Stralsund industrial park<br />

A new industrial park is being developed nearby to the road to the Rügen embankment.<br />

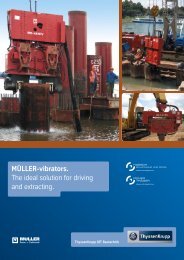

No matter whether it is a question of constructing<br />

docks or roads, reconstructing embankments or<br />

safeguarding waste sites, the HOESCH steel sheet<br />

piles manufactured by <strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong><br />

are used in a whole variety of ways. No wonder,<br />

as the walls carry conviction thanks to their enormous<br />

load-bearing capability and their long life.<br />

The steel sheet piles are also used in the construction<br />

of a new industrial park in the hanseatic city<br />

of Stralsund. As early as 1999, two consolidating<br />

walls were constructed on the site of the former<br />

oil-cracking facility, marking the route for the construction<br />

of the Stralsund bypass and the Rügen<br />

access road. The contaminated earth was removed<br />

at that time.<br />

“In the course of the current building phase, an<br />

approx. 140 metre long new sealing sheet pile wall<br />

is being constructed around the grounds on one<br />

section of the southern sheet pile wall for consolidating<br />

the former tank farm site,” says Dr. Wolfgang<br />

Kruse, specialist consultant at the Rostock<br />

service point, explaining the current construction<br />

work.<br />

Since the old pile foundations in the heavily contaminated<br />

grounds were not to be subject to waste<br />

disposal, they had to be surrounded by sheet pile<br />

walls. “Although it was not easy, we achieved it<br />

by ideal interlocking,” Kruse explains.<br />

The HOESCH sheet pile interlocks, which are provided<br />

with the HOESCH sheet pile wall (DBP 44<br />

27 561, EP 0 695 832) interlocking seal system,<br />

create almost complete seals by compressing the<br />

sheet pile interlocks, making them resistant toward<br />

mineral oils as well as numerous acids and alkalis.<br />

In Stralsund, HOESCH H 3600n +1.0 steel sheet<br />

piles in S355GP quality were used for reasons of<br />

economy. The lengths varied between 17 and 18<br />

metres.<br />

The sections were used as double piles in the northern<br />

area of the sheet pile box section. H 1700<br />

sections in S240GP quality were sufficient in the<br />

southern area because of the higher marl horizon.<br />

These sections were between six and nine metres<br />

long. The respective section lengths were the<br />

result of wide-ranging geotechnical investigations.<br />

Economic Z-profile<br />

By using the most economic H3600n Z-profile, the<br />

constructor was able to save a total of 35 tonnes<br />

of sheet piles in comparison with the tender, thereby<br />

securing the delivery order.<br />

A new industrial park for Stralsund is being developed<br />

in the immediate vicinity of this construction<br />

site at a location which is favourable for transportation.<br />

Here too, confidence is again being shown<br />

in the reliability of <strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong>.<br />

The contractor and principal, TLG Immobilien<br />

GmbH, required a comprehensive quality assurance<br />

plan with monitoring quality management<br />

also for the installation of the sheet piles. In addition,<br />

the interlocking system was being monitored<br />

in the ground, into which it could only be driven<br />

with difficulty. The piles were positioned without<br />

incident, and all interlocks resisted. The sheet<br />

piles were positioned using a type S 35 drop ham-