LABELS AND LABELLING - Onecoms.co.uk

LABELS AND LABELLING - Onecoms.co.uk

LABELS AND LABELLING - Onecoms.co.uk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

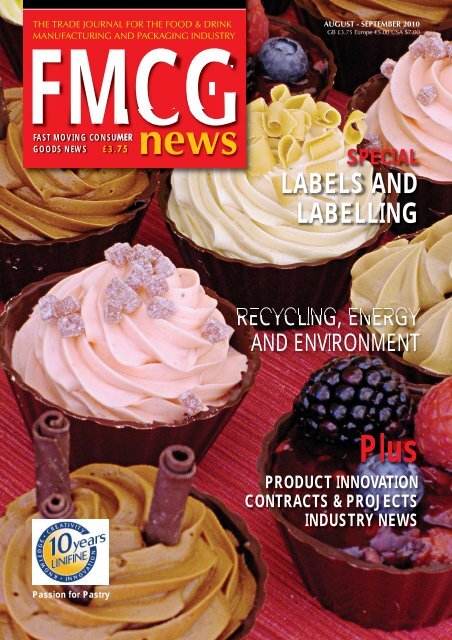

THE TRADE JOURNAL FOR THE FOOD & DRINK<br />

MANUFACTURING <strong>AND</strong> PACKAGING INDUSTRY<br />

FMCG<br />

news<br />

FAST MOVING CONSUMER<br />

GOODS NEWS £3.75<br />

Passion for Pastry<br />

AUGUST - SEPTEMBER 2010<br />

GB £3.75 Europe €5.00 USA $7.00<br />

SPECIAL<br />

<strong>LABELS</strong> <strong>AND</strong><br />

<strong>LABELLING</strong><br />

RECYCLING, ENERGY<br />

<strong>AND</strong> ENVIRONMENT<br />

Plus<br />

PRODUCT INNOVATION<br />

CONTRACTS & PROJECTS<br />

INDUSTRY NEWS

Aug - Sep 2010<br />

Hello and wel<strong>co</strong>me to the August -<br />

September issue of FMCG News. I<br />

have a brand new addition to tell<br />

you about this month. Starting on<br />

page 14 is our ‘Website Spotlight’<br />

where we will look at the best<br />

websites from the FMCG industry.<br />

Running in every issue, it will include an image of<br />

the home page, along with <strong>co</strong>mpany <strong>co</strong>ntact details<br />

and a <strong>co</strong>ncise description of the merits and<br />

functions of each site. Also, our online version will<br />

have live links directly to each website for you to<br />

click on and browse. If you would like to put your<br />

<strong>co</strong>mpany’s website forward for inclusion please<br />

email vicky.ellis@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong>.<br />

Elsewhere in this issue, on page 22, Steve Win-<br />

EDITORIAL:<br />

Editor: Keith Lucas<br />

keith.lucas@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

PRODUCTION:<br />

Graphic Designer: Kerri Cuthbert<br />

kerri.cuthbert@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

SALES:<br />

Group Sales Manager:<br />

Donna Jenkins<br />

donna@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

Advertising Sales: Vicky Ellis<br />

vicky.ellis@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

Online Edition: Rebecca Hubbard<br />

rebecca.hubbard@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

ADMINISTRATION:<br />

Ac<strong>co</strong>unts: Carole Todd<br />

carole.todd@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

Reception: Joanne Cluer<br />

jo@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

Data <strong>co</strong>ntroller: Carla Macdonald<br />

Published by one<strong>co</strong>ms, a trading<br />

division of Media One Communications<br />

Ltd. Geneva House, Park Road,<br />

Peterborough, PE1 2UX.<br />

Telephone 01733 756555.<br />

www.one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong><br />

Copyright 2009, all rights reserved.<br />

No part of this publication may be<br />

reproduced in any way without written<br />

permission from the publisher. All<br />

views and opinions expressed are not<br />

necessarily those of the publisher.<br />

wood of Culina UK takes a look at the logistics<br />

challenge. He looks at how with short lead times,<br />

multi-temperature storage, the <strong>co</strong>nstant replenishment<br />

of goods, high levels of traceability and<br />

accuracy status and the growing need for customised<br />

and shelf ready products, the sector<br />

requires and expects significant logistics expertise<br />

from its supply chain providers.<br />

Taking on our ‘Last Word’ this month is Neil<br />

Matthews, Checkpoint Systems’ Vice President<br />

of Northern, Central and Eastern Europe. He discusses<br />

that about how the retail environment<br />

has be<strong>co</strong>me increasingly <strong>co</strong>mpetitive over the<br />

years. And as the UK’s recession finally <strong>co</strong>mes to<br />

an end, Neil says, it is more important than ever<br />

before for manufacturers to ensure their profits<br />

FROM THE EDITOR 4<br />

The news stories that caught our eye this month<br />

INDUSTRY NEWS 6<br />

The latest happenings from the FMCG industry<br />

PRODUCT INNOVATIONS 10<br />

All-new solutions and products to hit the market<br />

WEBSITE SPOTLIGHT 14<br />

A look at the best websites from the FMCG sector<br />

Cover Photo:<br />

Unifine - Passion for Pastry<br />

page 8<br />

are secure as they travel along the supply chain<br />

to the point of sale.<br />

As ever we are always interested in hearing<br />

from you. Whether you have any ideas, <strong>co</strong>mments<br />

or want to <strong>co</strong>ntribute to FMCG News,<br />

everything is wel<strong>co</strong>me. In the next issue we will<br />

be taking a closer look at Branding, Marketing &<br />

Design and Ingredients, Refrigeration and Cooling.<br />

If you would like to be involved please feel<br />

free to get in touch.<br />

We hope you enjoy the issue.<br />

Keith Lucas,<br />

Editor<br />

22 THE LOGISTICS CHALLENGE<br />

By Steve Winwood of Culina UK<br />

24 CONTRACTS & PROJECTS<br />

Who’s up to what and where<br />

29 <strong>LABELS</strong> & <strong>LABELLING</strong><br />

33 RECYCLING, ENERGY<br />

& ENVIRONMENT<br />

34 THE LAST WORD<br />

35 WEB GUIDE<br />

FMCG News 3

from the editor<br />

News brief...<br />

SHORTLIST FOR<br />

2010 COMMUNITY<br />

PARTNERSHIP<br />

AWARDS<br />

Following an extensive<br />

judging process by industry<br />

experts and chaired by Lord<br />

Haskins, former government<br />

adviser and CEO of Northern<br />

Foods, the <strong>co</strong>mpanies<br />

shortlisted for the 2010<br />

Awards are:<br />

AF Blakemore and Son,<br />

Alpro UK, ASDA Stores,<br />

Bel UK, Bradgate Bakery,<br />

Cadbury UK, Coca-Cola<br />

Enterprises, Findus Group,<br />

General Mills UK, Greggs,<br />

Mars Cho<strong>co</strong>late UK, McCain<br />

Foods, New Covent Garden<br />

Market, Samworth Brothers,<br />

The Authentic Food<br />

Company, Typhoo Tea,<br />

Unilever UK, United Biscuits<br />

and Young’s Seafood.<br />

FSA SPEAKS ON<br />

CLONED COW ISSUE<br />

The finding is as a result of<br />

an inquiry into milk from a<br />

<strong>co</strong>w produced from a cloned<br />

parent. It identified that two<br />

bulls born in the UK were<br />

from embryos of a US cloned<br />

<strong>co</strong>w. Both bulls were in fact<br />

slaughtered but it did not<br />

stop the meat from one<br />

entering the food chain. Tim<br />

Smith, FSA chief, claimed<br />

that any suppliers would<br />

require approval under<br />

European law, yet he had<br />

"no <strong>co</strong>ncerns" about the<br />

safety of such milk or meat.<br />

Of the two bulls, the first<br />

was slaughtered in July<br />

2009 and its meat entered<br />

the food chain. There is<br />

speculation that the animal<br />

came from an Invernessbased<br />

farm. On 27 July<br />

2010, the se<strong>co</strong>nd bull was<br />

slaughtered, but its meat<br />

was stopped from entering<br />

the food chain. The FSA<br />

have claimed that they have<br />

not not been asked to<br />

<strong>co</strong>nsider any cloned meat<br />

cases for the EU. Mr Smith,<br />

of the organisation, also said<br />

that European authorities<br />

are still deciding how to<br />

regulate cloned food products.<br />

4 FMCG News<br />

amazon.<strong>co</strong>.<strong>uk</strong><br />

launches grocery store<br />

Online retailer Amazon<br />

has launched its own online<br />

grocery offering in the UK<br />

in an effort to take on other<br />

services such as Tes<strong>co</strong> and<br />

Ocado.<br />

The grocery service, which is<br />

currently in beta, will stock<br />

over 20,000 grocery products<br />

including leading brands as well<br />

as offering international and<br />

Drinkaware nominated<br />

for two awards<br />

Al<strong>co</strong>hol awareness charity<br />

Drinkaware has been shortlisted<br />

for two prestigious charity awards;<br />

the Charity Times ‘Charity of the<br />

Year’ Award and the Third Sector<br />

Excellence Award for best<br />

‘Communications Team’. The<br />

Charity Times ‘Charity of the<br />

Year’ nomination helps reinforce<br />

specialist items. The store will sell<br />

everyday items such as fruit,<br />

vegetables and meat and poultry.<br />

Amazon has said the beta will<br />

allow them to test different<br />

features while getting feedback<br />

from customers.<br />

Delivery options currently include<br />

a Free Super Saver Delivery for 3-<br />

5 day deliveries which may put<br />

off some customers, but a £49<br />

annual fee with Amazon Prime<br />

Drinkaware as the UK’s most<br />

re<strong>co</strong>gnisable al<strong>co</strong>hol awareness<br />

charity and illustrates how well<br />

<strong>co</strong>nsumers have accepted the<br />

charity as the UK’s primary source<br />

of al<strong>co</strong>hol information. The last<br />

year has seen Drinkaware achieve<br />

re<strong>co</strong>rd breaking numbers of visitors<br />

to their website, <strong>co</strong>upled by a<br />

will allow members unlimited<br />

free One-Day Delivery.<br />

James Lesson, director of<br />

grocery at Amazon.<strong>co</strong>.<strong>uk</strong> said:<br />

"Amazon.<strong>co</strong>.<strong>uk</strong>’s aim is to be the<br />

place where customers can find<br />

and dis<strong>co</strong>ver any product they<br />

want to buy online, and with the<br />

introduction of this new store<br />

there are thousands of household,<br />

niche, ethnic and international<br />

grocery items, all available at the<br />

month on month increase in the<br />

number of media hits generated<br />

by the organisation.<br />

The nomination in the Third<br />

Sector Excellence Awards for<br />

‘Communications Team’<br />

demonstrates Drinkaware’s<br />

ability to provide <strong>co</strong>nsumers and<br />

the media with facts about al<strong>co</strong>hol<br />

and issues relating to al<strong>co</strong>hol<br />

misuse, championing the UK’s<br />

responsible drinking message<br />

through its small team. Over

click of a button," said James<br />

Leeson, director of grocery at<br />

Amazon.<strong>co</strong>.<strong>uk</strong>.<br />

"With unlimited virtual shelf<br />

space, customers can choose<br />

from a wide variety of products,<br />

all of which benefit from free<br />

delivery. We will work tirelessly<br />

to increase the selection<br />

of grocery items available<br />

to be delivered directly to<br />

customers’ doors."<br />

The online grocery market<br />

is predicted to double over the<br />

next four years. Retail specialist<br />

IGD says the market will grow<br />

from £3.7bn to £7.2bn in 2014.<br />

the last year the <strong>co</strong>re team has<br />

increased Drinkaware’s media<br />

<strong>co</strong>verage by 480% with media<br />

hits from March 2009 to March<br />

2010 in excess of 1,600.<br />

Charity Times Award winners<br />

will be announced at the awards<br />

ceremony on 1st September<br />

2010 at the Hilton Park Lane,<br />

London. The Third Sector<br />

Excellence Awards will be held<br />

at the Lancaster London Hotel<br />

on Thursday 23rd September.<br />

Restaurants to celebrate<br />

National Nut Day<br />

Restaurants and cafés all over the UK are going nuts for<br />

National Nut Day by placing at least one ‘nutty’ dish on<br />

their menu on October 22 2010. Fairtrade nut <strong>co</strong>mpany<br />

Liberation Foods, which is organising the first National Nut<br />

Day in the UK, is working with the support of the Sustainable<br />

Restaurant Association to ensure as many establishments<br />

as possible take part. Kate Gaskell, MD of Liberation says:<br />

“Some people are unsure about the many ways they can<br />

use nuts in their <strong>co</strong>oking and we hope they will be inspired<br />

by seeing how restaurants do this. We also have recipes<br />

from leading chefs and food writers and have top tips to<br />

get people started.Allegra McEvedy, chef, food writer, <strong>co</strong>founder<br />

of the Leon chain of restaurants and <strong>co</strong>-presenter<br />

of BBC 2's E<strong>co</strong>nomy Gastronomy has provided her top tip<br />

for National Nut Day: “Nuts are full of good oils that over<br />

time go off, so storing nuts in the fridge extends the shelf<br />

life by months and months. The same goes for nut oils,"<br />

she explains.<br />

Sharp Interpack’s<br />

apprenticeship scheme<br />

packs a punch<br />

As the government pledges 50,000 new apprenticeship<br />

places, and figures reveal that one in six graduates regret<br />

accumulating student debts, a Yate-based packaging<br />

firm's established apprenticeship scheme is already benefiting<br />

local youngsters. Sharp Interpack started the scheme after<br />

identifying a shortage of good, young trainee engineers<br />

available to them and it has also created wel<strong>co</strong>me employment<br />

and training opportunities for students in the area. Sharp<br />

Interpack’s current crop of engineering apprentices, all<br />

from the City of Bristol College includes 19 year-old Emma<br />

Carter. Emma is one of only three girls on the 60-strong<br />

student <strong>co</strong>urse. Emma, who is studying for an HNC in<br />

electronics, became the <strong>co</strong>mpany’s first engineering apprentice<br />

three years ago. She is currently working on a key <strong>co</strong>stcutting<br />

exercise for the engineers. She says, “I’ve enjoyed<br />

my time as an apprentice; I feel I’ve excelled at working<br />

as part of a team and I would like to stay at Sharp<br />

Interpack as an engineer once I’ve qualified”. For more<br />

information visit www.sharpinterpack.<strong>co</strong>m.<br />

from the editor<br />

MELANIE LEECH<br />

FDF<br />

DIRECTOR GENERAL<br />

Earlier this year the Food and Drink<br />

Federation (FDF) was delighted to report that<br />

for the fifth <strong>co</strong>nsecutive year, UK food and<br />

drink exports had shown positive growth.<br />

Working in the incredibly challenging<br />

e<strong>co</strong>nomic climate of the last 18 months or so,<br />

this was a genuine ‘good news’ story and a<br />

fantastic demonstration of the significant<br />

<strong>co</strong>ntribution our industry makes to the wider<br />

UK e<strong>co</strong>nomy. Non-al<strong>co</strong>holic drinks were the<br />

best performing sector, growing 20.6% to<br />

£318.6m, driven by strong sales in EU markets<br />

such as Ireland, France, Spain and Germany.<br />

Fish and seafood was up by 15% to £1160.4m,<br />

including a 42.3% rise in exports of fresh<br />

salmon, and other added value product areas<br />

in strong growth included breakfast cereals<br />

(up 17.2%), sauces and <strong>co</strong>ndiments (up 9.2%)<br />

and sugar <strong>co</strong>nfectionery (up 10.9%). When<br />

we <strong>co</strong>ntacted food producers across the UK to<br />

get a better understanding of their export<br />

activity, one thing became apparent – UK<br />

producers are smart operators. They have<br />

re<strong>co</strong>gnised the potential of export markets<br />

and are incredibly energetic in identifying and<br />

driving opportunities to succeed. We<br />

<strong>co</strong>ntacted over 20 producers, from global<br />

giants such as United Biscuits to smaller<br />

<strong>co</strong>mpanies such as Anglesey Sea Salt, and all<br />

of them had a fascinating story to tell about<br />

how they have sought out new markets and<br />

either created new products for them, or<br />

developed those markets’ awareness and<br />

taste for traditional British favourites. For<br />

example, Anglesey Sea Salt sell their artisan<br />

product to US cho<strong>co</strong>late-maker Frans<br />

Cho<strong>co</strong>lates, who use it to make President<br />

Obama’s favourite salted caramels. Dart Valley<br />

Foods have created a market for traditional<br />

English tea-time fare such as lemon curd in<br />

Asia, Geeta’s Foods have capitalised on the<br />

German and Swiss taste for Indian chutneys<br />

and tea maker Typhoo who has tapped into<br />

the expatriate market in <strong>co</strong>untries such as<br />

Canada, Australia and New Zealand. It’s no<br />

secret that the UK food industry operates in a<br />

highly <strong>co</strong>mpetitive environment. But what<br />

these <strong>co</strong>mpanies and our exports report show<br />

is that despite the challenges posed by the<br />

recession both in the UK and abroad, there is<br />

(if you’ll forgive the pun) a real appetite for<br />

UK food abroad. Be it our re<strong>co</strong>rd<br />

development of new ‘healthier-for-you’<br />

options that are low in saturated fat, salt and<br />

sugar, or our rich cultural heritage of diverse<br />

ethnic foods, we are world leaders when it<br />

<strong>co</strong>mes to innovation and building strong and<br />

trusted brands with an international presence.<br />

This strong performance is testimony to the<br />

persistence and entrepreneurial spirit of<br />

British manufacturers.<br />

FMCG News 5

industry news<br />

The Whoopie<br />

Cake has landed<br />

It is very rare that a genuinely new <strong>co</strong>ncept<br />

<strong>co</strong>mes to the table. But that’s exactly what<br />

happened when the boffins at Unifine Food<br />

& Bake Ingredients came up with a British<br />

version of the American Whoopie Cake.<br />

Showed on the Unifine stand for the first<br />

time at BIE, a genuine Whoopie <strong>co</strong>mprises<br />

two moist cakes sandwiched with a filling,<br />

then de<strong>co</strong>rated. (see picture). Whoopie pies<br />

have been around in the US for several years<br />

ac<strong>co</strong>rding to Unifine but it is only very<br />

recently that they have been seen in Britain.<br />

Unifine Whoopies are filled with delicious<br />

flavoured mousse creams in eight varieties<br />

and with s<strong>co</strong>pe for many more <strong>co</strong>mbinations.<br />

The Whoopies are prepared using Unifine’s<br />

Sumix Soft, water and oil blended on a slow<br />

speed with a paddle for 2-3 minutes. Colour<br />

can be added to the batter or alternatively,<br />

mix Sumix Cho<strong>co</strong>, water, oil and egg in the<br />

same way but for 4-5 minutes. The mix is<br />

then deposited onto sili<strong>co</strong>ne mats and baked<br />

at 190°C for 8-10 minutes. They need to be<br />

really <strong>co</strong>ol before filling and de<strong>co</strong>rating. Sumix<br />

Soft and Sumix Cho<strong>co</strong> are available from<br />

your usual stockists and <strong>co</strong>me in 15kg sacks.<br />

For more information visit<br />

www.unifine-fbi.<strong>co</strong>.<strong>uk</strong>.<br />

Kliklok’s success<br />

at total show<br />

Kliklok’s participation in the<br />

recent Total Processing &<br />

Packaging Show at the NEC proved<br />

to be a resounding success. The<br />

<strong>co</strong>mpany exhibited their bestselling<br />

SFR end load cartoner, and<br />

having already installed over 60 of<br />

these machines throughout the world, it<br />

was a popular attraction in Hall 5. Visitors from<br />

several major European food producers arrived on<br />

the Kliklok stand, to see for themselves the benefits of<br />

UK First for Paper &<br />

Corrugated Packaging<br />

Sustainability<br />

Smurfit Kappa UK, one of the UK’s leading<br />

manufacturers of paper based packaging<br />

Six is the Magic<br />

Number for<br />

Thermo King<br />

Thermo King achieves a magic re<strong>co</strong>rd breaking six<br />

year win in a row in ‘The Best Brands of 2010’<br />

reader’s poll in the trade magazines Lastauto Omnibus,<br />

Fernfahrer and Trans Aktuell. After being awarded first<br />

place in 2005, 2006, 2007, 2008 and 2009, Germany’s<br />

<strong>co</strong>mmercial vehicle professionals have once again<br />

voted Thermo King top brand in the ‘Refrigeration<br />

Units’ category. More than 7,500 readers took part in<br />

this year’s readers’ poll organised by the three key trade<br />

magazines. The poll is unique in the fact that unlike<br />

many other European brand <strong>co</strong>mparisons, it is not<br />

<strong>co</strong>nducted among a small group of trade professionals<br />

or editors, but votes are from the industry end-users,<br />

which underlines the value of this award. Thermo<br />

SATISFY YOUR DESTRUCTIVE ITCH WITH ZWICK ROELL TV<br />

Earlier this month the Zwick Roell Group launched<br />

‘Zwick Roell TV’ on YouTube enabling viewers to<br />

watch, in detail, all sorts of products and materials<br />

being tested to destruction using advanced robotic<br />

systems. We all get a delicious sense of satisfaction<br />

seeing something being stretched to its limit, bent,<br />

bashed, crushed and broken, but materials testing<br />

also has a serious role in the development and<br />

manufacture of high-quality, safe products. Already<br />

6 FMCG News<br />

boasting more than 200 views, Zwick Roell’s new<br />

YouTube channel is regularly updated with short,<br />

informative videos, in both English and German.<br />

The films demonstrate efficient and effective<br />

application of automated materials testing for a<br />

whole range of products across multiple industries.<br />

All videos are freely available and anyone wishing<br />

to subscribe can do so via a YouTube or Google<br />

ac<strong>co</strong>unt at www.youtube.<strong>co</strong>m/user/ZwickRoellTV.<br />

the Kliklok SFR machine - short footprint, patented<br />

rotary carton feeder, <strong>co</strong>lour touch screen, easy size<br />

change and robust stainless steel <strong>co</strong>nstruction.<br />

Kliklok received visitors from the UK, Turkey,<br />

Russia, Germany, Australia, and the Middle<br />

East, and were particularly pleased to catch<br />

up with many of their existing customers.<br />

The Total Show also served<br />

as the perfect opportunity<br />

for Kliklok to showcase their<br />

machinery range to new, growing<br />

<strong>co</strong>mpanies looking to automate<br />

production lines in the future.<br />

For more information call 01275<br />

836131 or visit www.kliklok-int.<strong>co</strong>m.<br />

solutions is the first UK manufacturer to achieve Chain<br />

of Custody (CoC) certification from the World's<br />

leading Internationally re<strong>co</strong>gnised certification agencies,<br />

for its entire UK <strong>co</strong>rrugated and paper manufacturing<br />

capacity. The successful two-year programme of<br />

Chain of Custody certification is one of the first to<br />

take an integrated – <strong>co</strong>mpany wide – approach. The<br />

programme en<strong>co</strong>mpasses Smurfit Kappa's UK major<br />

operations which en<strong>co</strong>mpass two recycled paper mills,<br />

15 <strong>co</strong>rrugated facilities and paper mills, including<br />

large integrated factories, sheet plants as well as<br />

specialist plants for Sheetfeeding and paper printing.<br />

This integrated approach to certification is highly<br />

innovative and a first for the UK <strong>co</strong>rrugated sector<br />

enabling Smurfit Kappa to offer its customers fully<br />

certified packaging solutions on over 95% of its products.<br />

For more information visit<br />

http://<strong>co</strong>rrugated.smurfitkappa.<strong>co</strong>.<strong>uk</strong>/<br />

King has a nationwide sales and service network in<br />

Germany, <strong>co</strong>mprised of five authorised dealers and 71<br />

authorised service centres.<br />

For more information visit www.thermoking.<strong>co</strong>m.

Opening of<br />

new Stölzle<br />

Fla<strong>co</strong>nnage factory<br />

On Tuesday, 6th July, 2010, Stölzle Fla<strong>co</strong>nnage<br />

officially opened the multi-million pound<br />

upgrade carried out on their Knottingley, West<br />

Yorkshire factory. Some sixty clients and suppliers<br />

from both the UK and abroad gathered at the reborn<br />

factory site. After a buffet lunch, they were given<br />

guided tours of the glass and the de<strong>co</strong>ration centres.<br />

Sixteen members of the Stölzle Brass Band came<br />

over from Austria to play for the guests. In the evening<br />

there was a Drinks Reception in the Tournament<br />

Gallery of the Leeds Royal Armouries Museum,<br />

and a demonstration of medieval weapons and<br />

armour. Dinner was in the Museum’s War Gallery,<br />

followed by a whisky tasting in the Wellington<br />

Atlantic Zeiser to<br />

present advanced<br />

printing innovations<br />

Atlantic Zeiser will showcase its integrated endto-end<br />

DIGILINE Single Product solution<br />

at FACHPACK in Nuremberg : 28-30 September<br />

2010. Demonstrating versatile possibilities for high<br />

resolution industrial digital printing of variable data<br />

on absorbent and non-absorbent surfaces including<br />

3D packaging, Atlantic Zeiser will present in Hall 9,<br />

Stand 256. The <strong>co</strong>mpany provides system solutions<br />

for packaging, labelling, product, security and paper<br />

printing with near to offset quality at high production<br />

speeds. At the show, Atlantic Zeiser will also<br />

TOSHIBA TEC’s<br />

WILLPOS B10<br />

POS Terminal<br />

TOSHIBA TEC has<br />

announced that it has had<br />

major interest in its WILLPOS<br />

B10 from two of the UK largest<br />

<strong>co</strong>nvenience stores after<br />

the launch event at Box<br />

Technologies. TOSHIBA TEC recently<br />

Spiroflow<br />

Flexible Conveyor<br />

ASpiroflow flexible <strong>co</strong>nveyor has been<br />

installed at Ja<strong>co</strong>b's Bakeries factory in<br />

Aintree, Liverpool. The flexible <strong>co</strong>nveyor is<br />

used to feed bags of brown flour directly into<br />

the mixer used to manufacture the base of<br />

Ja<strong>co</strong>b's famous Club biscuits, Gold biscuits and<br />

some of the biscuits for its packs of Biscuits for<br />

Suite. The upgrade, carried out in the teeth of the<br />

recession, has introduced state-of-the-art de<strong>co</strong>ration<br />

machinery and increased the size of the de<strong>co</strong>ration<br />

facility by over 50%; installed a major investment<br />

new furnace, and a brand new Customer Centre,<br />

together with a mould design department.<br />

For more information visit www.stoelzle.<strong>co</strong>m.<br />

demonstrate packaging-specific applications of the<br />

integrated OMEGA printing module for different<br />

sectors as well as multiple four-<strong>co</strong>lour models of<br />

the GAMMA printer on metal and plastics.<br />

For more information visit www.atlanticzeiser.<strong>co</strong>m.<br />

signed an exclusive distribution agreement with Box<br />

Technologies, a leading technology and service<br />

provider. Under the agreement, Box<br />

Technologies will manage deployment of<br />

the Toshiba WILLPOS B10 Point-of Sale<br />

(POS) terminal in the UK, in addition to the<br />

exclusive service and repair of the product.<br />

Ideal for supermarkets, fashion outlets and<br />

entertainment <strong>co</strong>mpanies, specialty footwear<br />

stores, pet stores, sports goods shops,<br />

pharmacies, hair dressers as well as dis<strong>co</strong>unt<br />

and <strong>co</strong>nvenience stores, the WILLPOS B10<br />

has an ultra-small footprint designed to be set<br />

either in horizontal or vertical position.<br />

For more information visit www.toshibatec-eu.<strong>co</strong>m.<br />

Cheese. The new <strong>co</strong>nveyor is 11m long, lifting<br />

the flour up some five metres at an angle of<br />

approximately 45°. It was linked to an existing<br />

sack tip station with integral check sifter.<br />

Ac<strong>co</strong>rding to the Site Projects Manager, David<br />

Rome, “The new Flexible Screw Conveyor ran<br />

first time and has performed well ever since. In<br />

fact, the ‘Spiroflow’ Bulk Bag Discharger has<br />

been in operation for 14 years - trouble-free!”<br />

For more information call 01200 422525<br />

or visit www.spiroflow.<strong>co</strong>m.<br />

industry news<br />

London fancy<br />

box gains FSC and<br />

PEFC certification<br />

London Fancy Box, (LFB) of Dover, Kent,<br />

has be<strong>co</strong>me the UK`s first rigid packaging<br />

manufacturer to be awarded Forest Stewardship<br />

Council (FSC) and PEFC, Programme for<br />

the Endorsement of Forest Certification.<br />

The <strong>co</strong>mpany received this ac<strong>co</strong>lade in<br />

July 2010, demonstrating its <strong>co</strong>mmitment<br />

to the promotion of responsible management<br />

of the world`s forests, for the benefit of<br />

its customers and the environment. The<br />

advantages of certification to London<br />

Fancy Box (LFB) are substantial. The <strong>co</strong>mpany<br />

is demonstrating to its customers that it<br />

buys its paper and board from sustainable<br />

sources, i.e from sources which are well<br />

managed, protected and certified. LFB is<br />

playing its part within the “chain of custody”<br />

process, meaning the <strong>co</strong>mpany can show<br />

where the materials have <strong>co</strong>me from,<br />

tracing them back to the forest, through<br />

to delivery to the final customer.<br />

For more information call 01304 209934<br />

or visit www.londonfancybox.<strong>co</strong>.<strong>uk</strong>.<br />

FMCG News 7

industry news<br />

And now for<br />

something<br />

<strong>co</strong>mpletely<br />

different… a<br />

cupcake in its<br />

own cho<strong>co</strong>late cup<br />

Unifine Food & Bake Ingredients has launched<br />

a family of cupcakes at BIE which are sold in<br />

their own cho<strong>co</strong>late cup. This new departure is<br />

believed by Unifine to be the first of its kind<br />

since the demise of the old-fashioned Kunzle<br />

Cakes way back in the 1950s and 60s. The<br />

Cho<strong>co</strong>late Cup Cupcake not only eliminates<br />

the need for paper wraps but also delivers a<br />

double shot of flavour. The secret of the new<br />

<strong>co</strong>ncept is to first bake the sponge then place it<br />

into Unifine's Sucrea Cho<strong>co</strong>late Ballerina Cups<br />

once the sponge has <strong>co</strong>oled. All that is left is to<br />

pipe a lavish swirl of flavoured cream over the<br />

sponge and sprinkle with toppings to suit.<br />

(See picture). 'We teamed Sucrea Sumix<br />

Soft powdered Sponge Mix with Sucrea<br />

<strong>co</strong>mpounds, flavours and fruit pieces to create<br />

these moist and delicious cupcakes,' says the<br />

<strong>co</strong>mpany. 'The mixing process <strong>co</strong>uldn't be<br />

simpler. It takes just 2-3 minutes to mix with<br />

a paddle on slow speed – and only 10 minutes<br />

for the sponge to bake.'<br />

For more information visit<br />

www.unifine-fbi.<strong>co</strong>.<strong>uk</strong>.<br />

Triquestra and<br />

TOSHIBA TEC<br />

supply POS<br />

Yeomans, the UK’s largest independent camping<br />

and outdoor retailer, has worked with Triquestra<br />

UK and TOSHIBA TEC to implement an updated<br />

POS system in its 86 retail outlets which range from<br />

high street stores to garden centre sites, outdoor shows<br />

and large factory outlets. The <strong>co</strong>mpany which was<br />

established in 1904 was using an outdated, poor<br />

Allied launch<br />

Gicel Glass<br />

Allied Glass has launched its exceptional new Gicel<br />

Glass, a superior ‘ice clear’ premium flint glass. It<br />

has been lovingly created by Allied’s technical and<br />

production teams’ skilled craftsmen to achieve<br />

perfection and produce an enchanting <strong>co</strong>lour. The<br />

manufacturer of Gicel Glass celebrates the culmination<br />

of a £9m investment programme in Allied’s<br />

Knottingley plant, which will be offering premium<br />

flint bottles in volumes of between ten thousand and<br />

twenty million. Allied is renowned within the packaging<br />

industry for designing and producing innovative,<br />

ground breaking and award winning glass <strong>co</strong>ntainers.<br />

In recent years, the <strong>co</strong>mpany has had success in the<br />

Institute of Materials, Minerals and Mining Starpack<br />

Awards, The International Spirit Challenge and UK<br />

Packaging Awards.<br />

PRINT & APPLY AUTOMATES ID FOR UK TOY WAREHOUSING<br />

Print & apply labelling is being adopted by one of the<br />

UK's top toy retailers to automate identification of<br />

in<strong>co</strong>ming goods at its central automated warehouse<br />

in Coventry, improving logistics by avoiding errors in<br />

the previous desktop-printed hand-applied labelling<br />

operation. Seventeen Logopak 515T print & apply<br />

machines have been installed this autumn, one on<br />

each of the goods-in legs of the warehouse, to label<br />

every case received with unique information that<br />

8 FMCG News<br />

includes its allocated location within the warehouse<br />

and the manufacturer of the goods. Each leg handles<br />

the <strong>co</strong>ntents of a <strong>co</strong>mplete vehicle at a time, labelling<br />

up to ten different products in batches of 100 to<br />

1000 cases. The labels are then scanned throughout<br />

the warehouse handling system, allowing goods to be<br />

directed automatically to the <strong>co</strong>rrect aisle, bay and<br />

shelf. For more information call 01904 692333<br />

or visit www.logopakprintandapply.<strong>co</strong>.<strong>uk</strong>.<br />

performing POS system which was causing serious<br />

business problems for Yeomans 400 staff. Yeomans<br />

chose to work with Triquestra UK and TOSHIBA<br />

TEC to implement their Infinity POS solution as the<br />

replacement software using the ST- A10 POS and<br />

TRST A10 printer from TOSHIBA. It was critical that<br />

both teams from Triquestra and TOSHIBA achieved<br />

a smooth installation without interruption to<br />

the <strong>co</strong>mpany’s management information. The<br />

implementation of the system was extremely quick.<br />

A working end-to-end test solution was created within<br />

4 weeks which Yeomans reviewed and approved and<br />

the <strong>co</strong>mplete solution was rolled out within 6 weeks.<br />

For more information visit<br />

www.toshibatec-eu.<strong>co</strong>.<strong>uk</strong>.<br />

For more information call 0113 245 1568<br />

or visit www.allied-glass.<strong>co</strong>m.

One source fits all<br />

For many years, the whole area of packaging provision,<br />

resource and supply didn’t even register on the radar<br />

for most organizations when it came to identifying<br />

ways to cut <strong>co</strong>sts. In recent years, however, ‘minimum<br />

stocking levels’ and ‘just in time’ deliveries have be<strong>co</strong>me<br />

the key <strong>co</strong>st-saving catchphrases for modern industry.<br />

And, as a result, procurement departments have begun<br />

to get wise to the fact that a one-stop packaging<br />

resource provider can deliver real dividends in terms<br />

of significant efficiencies in cash flow, warehousing<br />

requirement and stock flow with the result that the<br />

quest to locate a suitable single source provider has<br />

be<strong>co</strong>me one of the hottest topics of the day. As the<br />

UK’s leading packaging resource solutions provider,<br />

FDL Packaging Group of Haydock, Merseyside,<br />

has unrivalled experience in single source packaging<br />

supply, which means, of <strong>co</strong>urse, that the <strong>co</strong>mpany is<br />

well aware of all the <strong>co</strong>st advantages which the right<br />

single source packaging solution can bring. And<br />

FDL Packaging prides itself on its ability to understand,<br />

and respond to the ebb and flow of its customers’<br />

business. As FDL Packaging Marketing Director Dave<br />

S<strong>co</strong>tting explains: “By their bulky nature, packaging<br />

products such as drums, bottles and boxes can place<br />

undue pressure on a <strong>co</strong>mpany’s storage facilities and<br />

can often require <strong>co</strong>stly bespoke warehousing. At FDL<br />

Packaging, however, by virtue of a profound<br />

understanding of our customers’ needs, we can<br />

establish stock <strong>co</strong>ntrol objectives, delivery schedules<br />

and ordering systems whereby we can source and<br />

supply the precise packaging requirement needed on<br />

CRP Print & Packaging Attain<br />

FSC and PEFC Accreditation<br />

CRP Print & Packaging, one of Europe’s leading independent print and<br />

packaging groups has been granted FSC and PEFC accreditation within<br />

its Pre Print Business and is the first Pre Printing business in Europe to obtain<br />

these market leading standards. Chris Shaw, Business Manager for CRP’s Pre<br />

Print business, led the project on behalf of the <strong>co</strong>mpany. Shaw <strong>co</strong>mments<br />

“We are at the forefront of change within the European Corrugated industry<br />

and gaining forestry chain-of-custody certification FSC and PEFC for our Pre<br />

Print business is the first step to securing accreditation for the CRP<br />

group”. Eddie Fellows, Managing Director of CRP Print & Packaging<br />

<strong>co</strong>mments, “the knowledge gained during the securing of certification will be<br />

used over the next 12 months to ensure we are able to offer all our<br />

customers the security of the chain-of-custody accreditation across the CRP<br />

group; in doing this we can do our part in helping brand owners work towards<br />

achieving their environmental objectives”.<br />

For more information call 01536 200 333<br />

or visit www.crpprint.<strong>co</strong>m.<br />

an ‘as required’ basis, making significant savings in<br />

warehouse space as well as staffing levels, admin<br />

time and overheads”.<br />

For more information<br />

call 01942 722299 or<br />

visit www.fdlgroup.<strong>co</strong>.<strong>uk</strong>.<br />

industry news<br />

JohnsonDiversey Puts<br />

Trust In Rieke RS3 Dispenser<br />

JohnsonDiversey UK has turned to Rieke Dispensing for the hygienic,<br />

accurate and reliable dispensing of their Triple C system, a range of<br />

hospital specific solutions under the <strong>co</strong>mpany’s Soft Care brand. The Soft<br />

Care Triple C system utilises four great formulations, <strong>co</strong>mbined with Rieke<br />

dispensing solutions, to offer products designed to clean and care for skin,<br />

and <strong>co</strong>ntrol the spread of infection. JohnsonDiversey required a robust<br />

dispensing pump that <strong>co</strong>uld <strong>co</strong>pe with regular usage while delivering a<br />

<strong>co</strong>nsistent dose. Crucially, the pump needed to offer a non-metal <strong>co</strong>ntact<br />

<strong>co</strong>nstruction to avoid the risk of reaction with al<strong>co</strong>hol. Regular supplier<br />

Rieke proposed the use of its RS3 pump, which is suitable for a variety of<br />

different vis<strong>co</strong>sities. It can be locked down when not in use to prevent<br />

waste, and is also 100% shower proof.<br />

For more information call 0116 233 1100 or email sales@riekedispensing.<strong>co</strong>.<strong>uk</strong>.<br />

FMCG News 9

product innovations<br />

1st Packaging<br />

supplies<br />

Constellation with<br />

FreshCase pack<br />

Winemaker Constellation Europe has tackled<br />

the challenge of housing bulky bag-in-box<br />

packs in the fridge with the launch of the<br />

new FreshCase pack.The FreshCase holds<br />

2.25l,the equivalent of three bottles of wine,<br />

but only takes up the space used by one of<br />

its glass <strong>co</strong>unterparts.It weighs 70% less than<br />

three of its glass <strong>co</strong>unterparts and in<strong>co</strong>rporates<br />

a pull-down tap and handle that can be turned<br />

into a stand for pouring.Hardy’s Nottage Hill<br />

is the first wine to be packed in the FreshCase.<br />

External <strong>co</strong>mponent parts of FreshCase are<br />

supplied by 1st Packaging in Leighton Buzzard<br />

to Constellation Europe’s new manufacturing<br />

and distribution site Constellation Park, based<br />

in Avonmouth Bristol,where it is assembled.<br />

Clive Hawkins Sales Director of 1st Packaging<br />

said:” We <strong>co</strong>uld all see the potential that<br />

FreshCase has in the market and want to<br />

do all we can to help make this product a<br />

major success.”<br />

For more information call 01525 382580<br />

or visit www.1st-packaging.<strong>co</strong>.<strong>uk</strong>.<br />

Charpak: Innovative<br />

Design with Technical<br />

Functionality<br />

Charpak Ltd has launched an innovative new pack<br />

for the rapidly growing ‘Food to Go’ sector.<br />

Charpak, at the forefront of innovative design for<br />

the premium sector has produced a new hinged lid<br />

pack aimed at the indulgent snacking market. Justin<br />

Kempson, Sales Director <strong>co</strong>mmented, There are two<br />

sizes available, one for a premium Cupcake and the<br />

se<strong>co</strong>nd for high end Muffins. Visually stunning with<br />

cakes inside, they enhance the product and will<br />

increase the sale rate of this type of premium cake.<br />

Produced in clear rPET (minimum 50% recycled<br />

<strong>co</strong>ntent) the pack is designed to both protect the<br />

product and give excellent visibility. Labelling/<br />

tamper evidence is by means of a C-label. They are<br />

simple to close and offer an easy solution to having<br />

Alfres<strong>co</strong> Gastro<br />

2010 at Sharpak<br />

The football world cup and the sizzling Summer<br />

weather has fired the <strong>co</strong>als of barbecue<br />

products. Sharp Interpack (Sharpak) has the largest<br />

range of barbecue meat trays (over 30 different<br />

styles and designs) anywhere in Europe and is busy<br />

meeting the high demand. The <strong>co</strong>mprehensive<br />

range of Oval burger trays form the backbone of<br />

the portfolio along with a mixture of cavity, shingle,<br />

barbecue, sausage, ribs, chops, kebab and grill steak<br />

WIDEST ON-DEM<strong>AND</strong> AIR CUSHION IN THE INDUSTRY<br />

FP International, a leading manufacturer of<br />

sustainable packing solutions, now produces<br />

the widest quilt-shaped air cushion film in the<br />

industry following its development of unique and<br />

innovative air transfer technology. PILLOW PAK<br />

76cm wide film can produce air cushions to wrap<br />

and protect products during transport and/or<br />

warehousing. PILLOW PAK film has a ‘wave’like<br />

seal made from individual bubbles, making it<br />

10 FMCG News<br />

look like a quilt. Each bubble is <strong>co</strong>nnected to<br />

the next. This clever air transfer design enables<br />

air to move between the bubbles, thus providing<br />

cushioning precisely where it is needed. With one<br />

layer of film, a protective layer can be applied to<br />

a wide range of different products including<br />

displays, doors, panels and bottles.<br />

For more information call 01280 703161<br />

or visit www.fpintl.<strong>co</strong>.<strong>uk</strong>.<br />

products available for impulse purchase. Charpak has<br />

also produced Shelf Ready Packaging for both items.<br />

For more information call 01480 434434<br />

or visit www.charpak.<strong>co</strong>.<strong>uk</strong>.<br />

trays in the D13 range for adults and children alike<br />

and the large D18 & 21multi cavity family packs.<br />

There is also the smooth wall versions of D2, D13<br />

and D45 and the poultry ‘S’ range with 8 cut sizes<br />

and multiple depths. The trays are all stocked<br />

through leading supermarkets and manufactured<br />

in recycled APET (meat and burger trays) and<br />

recycled PP (poultry trays). The products tick all the<br />

boxes for environmental <strong>co</strong>ncern, product integrity<br />

and pure design aesthetics.<br />

For more information call 01278 435000<br />

or visit www.sharpinterpack.<strong>co</strong>m.

50 Dries with Award<br />

Winning Vortex Hand<br />

Dryer Costs a Penny<br />

SA Vortex Ltd a national Green Specification<br />

approved manufacturer and supplier of patent<br />

protected, ultra energy efficient hand dryers has<br />

now reduced the power <strong>co</strong>nsumption of its range.<br />

Mechatronic<br />

Problem-solving Skills<br />

C onvenience products and flexible package sizes are in demand more<br />

than ever. This in turn results in reduced batch sizes. It is a key challenge<br />

of today’s machine builders to design machines that <strong>co</strong>mbine flexible and<br />

quick format changes with high cycle rates and low life cycle <strong>co</strong>sts. Micromech<br />

Systems and Parker has been supporting food processing equipment and<br />

packaging machinery manufacturers for many years. Thanks to the drive<br />

technology, mechanical and application specific know-how, together they<br />

are the ideal partners to help you meet the mechatronic challenges posed<br />

by your customers. They can help to reduce design time, improve your<br />

time-to-market, help you make faster changeovers and increase output<br />

and plant efficiency.<br />

For more information call 01376 333333 or visit www.micromech.<strong>co</strong>.<strong>uk</strong>.<br />

The Vortex hand dryer is the greenest high speed<br />

(sub 10s power dry) warm air dryer, operating at a<br />

total power <strong>co</strong>nsumption of just 700W; under half<br />

the power of nearest <strong>co</strong>mparable <strong>co</strong>mpetitor<br />

model. With a 97% <strong>co</strong>st saving against paper towels,<br />

Combine this with the lowest Total Cost of<br />

Ownership of any high speed dryer on the market<br />

and you have an unbeatable drying solution. Syed<br />

Ahmed, CEO SAVortex “The total ethos of<br />

the SAVortex hand dryer is<br />

minimum energy use<br />

without loss of<br />

effectiveness. Our<br />

hard work to<br />

improve energy<br />

efficiency and<br />

produce the<br />

greenest quietest<br />

and fastest dryer is<br />

paying dividends. We<br />

are now the no1<br />

preferred supplier for<br />

Interserve Ltd, one of<br />

the world's foremost<br />

support services and<br />

<strong>co</strong>nstruction <strong>co</strong>mpanies.”<br />

So why is the Vortex Hand<br />

Dryer so special?<br />

It is unique patented<br />

spinning air technology<br />

breaks water on the surface<br />

of hands more rapidly,<br />

delivering low <strong>co</strong>st, fast,<br />

quieter drying. This spinning<br />

product innovations<br />

technique creates a ‘curve’ of warm air, similar to<br />

how an aeroplane wing curves up at its end in flight,<br />

that naturally feels warmer due to the wrap-around<br />

effect. In a high traffic washroom, SAVortex dryers<br />

pay back instantly.<br />

For more information call 0207 847 4091, email<br />

info@savortex.<strong>co</strong>m or visit www.savortex.<strong>co</strong>m.<br />

Chesapeake proves there’s<br />

no barrier to innovation<br />

Chesapeake is currently developing a number of speciality barrier <strong>co</strong>atings<br />

that offer moisture vapour, flavour and grease proof properties. These<br />

barrier <strong>co</strong>atings, which can be applied to a range of packaging formats, are<br />

being developed by Chesapeake’s Research & Development team. They aim<br />

to provide improved performance over existing solutions and more<br />

environmentally <strong>co</strong>nsiderate options. Improved grease barriers are being<br />

demanded by food producers especially for dried pet-foods which often have<br />

oil <strong>co</strong>ntent in excess of 10%. Traditionally, a substantial layer of plastic has<br />

been applied to cartonboard to facilitate its use in many barrier applications<br />

but both brand owners and <strong>co</strong>nsumers are now seeking more<br />

environmentally <strong>co</strong>nsiderate solutions. Chesapeake is developing a technique<br />

to apply a special grease-resistant <strong>co</strong>ating to the reverse of a range of<br />

cartonboard types. The technique allows the application of <strong>co</strong>atings that are<br />

not typically applied at the board mill during production.<br />

For more information visit www.chesapeake<strong>co</strong>rp.<strong>co</strong>m.<br />

FMCG News 11

product innovations<br />

New FDL<br />

<strong>co</strong>nsumer range<br />

brings benefits<br />

large and small<br />

FDL Packaging Limited has introduced a<br />

new range to offer its customers maximum<br />

choice and flexibility. Branded ‘The Consumer<br />

Range’, the new offering caters largely to<br />

the food and pharmaceuticals sectors but<br />

also in<strong>co</strong>rporates a more general PET<br />

range. While the key departure for FDL,<br />

which has built its reputation on the supply<br />

of high capacity packaging needs, lies in<br />

expanding its range by also now offering<br />

its customers the <strong>co</strong>nvenience and flexibility<br />

of smaller <strong>co</strong>ntainers with a capacity of 5<br />

litres or less. The new Consumer Range<br />

offers an exhaustive range of solutions<br />

for a whole host of packaging requirements.<br />

Comments FDL Sales Director Dave S<strong>co</strong>tting:<br />

“At FDL, we pride ourselves on listening<br />

to our customers and the new Consumer<br />

Range is very much a reflection of that.<br />

Overwhelming demand for greater flexibility<br />

has led to a range with the capacity to meet<br />

our customers’ demands, large and small”.<br />

For more information call 01942 722299<br />

or visit www.fdlgroup.<strong>co</strong>.<strong>uk</strong>.<br />

Atlantic Zeiser Group demonstrated its<br />

DIGILINE portfolio of innovative modular endto-end<br />

system solutions at FESPA. On display was<br />

the DIGILINE Single Product 210 with a full<strong>co</strong>lor<br />

GAMMA 70P UV print module, as well as a<br />

<strong>co</strong>nveyer system featuring the OMEGA 70HD<br />

print module, which is ideal for very short runs of<br />

direct product printing. The <strong>co</strong>mpany also showcased<br />

an application for top-quality printing on plastic<br />

Linpac and<br />

C<strong>uk</strong>i Cofres<strong>co</strong><br />

unveil C<strong>uk</strong>iLIN ®<br />

Two leading packaging <strong>co</strong>mpanies in different<br />

fields have <strong>co</strong>me together to create C<strong>uk</strong>iLIN ® -<br />

a <strong>co</strong>mplete aluminium tray and film lid solution ideal<br />

for oven-ready meals. LINPAC Packaging, the leading<br />

European multi-material packaging <strong>co</strong>mpany, has<br />

been working closely with aluminium tray specialists<br />

C<strong>uk</strong>i Cofres<strong>co</strong> to create a <strong>co</strong>mbination that offers<br />

excellent on-shelf presentation, extended shelf-life<br />

Convenience<br />

all wrapped up<br />

With its latest packaging innovation, the unique<br />

Cryovac ® Oven Ease HC2440<br />

ovenable bag, Sealed Air<br />

brings multiple<br />

benefits to<br />

foodservice and<br />

retail. Integrating<br />

good barrier<br />

properties and readyfor-the-oven<br />

<strong>co</strong>nvenience<br />

suitable for <strong>co</strong>nventional or<br />

microwave reheating, this high-<br />

rulers at FESPA which took place 22-26 June.<br />

“Atlantic Zeiser brought to FESPA an innovative<br />

portfolio of solutions that are ideal for industrial<br />

digital printing on labels, packages, booklet labels<br />

and transactional documents, as well as direct<br />

product printing for high-level and quality-oriented<br />

applications,” said Ralf Hipp, Vice President of<br />

Digital Systems. For more information call +49<br />

(0)7465 291 136 or visit www.atlanticzeiser.<strong>co</strong>m.<br />

and delivers optimal performance when running on<br />

packaging lines. LINPAC’s high barrier films LINtop<br />

PP HB and LINtop Alu HB have been specially<br />

developed to be <strong>co</strong>mpatible with aluminium trays.<br />

They offer a tight robust seal that means there is no<br />

need for the product to also be packaged in a cardboard<br />

sleeve, while both films have anti-fog properties to<br />

improve visibility of the product on the shelf. The<br />

C<strong>uk</strong>iLIN ® partnership means that a <strong>co</strong>nstant level<br />

of service and on-site technical support is available<br />

throughout Europe, to ensure customer machinery<br />

is running as efficiently as possible.<br />

For more information call 01977 692111<br />

or visit www.linpacpackaging.<strong>co</strong>m.<br />

abuse, multi-layer bag enables the <strong>co</strong>oked product to<br />

retain its natural moisture and flavour. Additional<br />

advantages for the <strong>co</strong>nsumer include reduced <strong>co</strong>oking<br />

times, less risk of leakage, along with easy preparation<br />

and packaging disposal. The assured maintenance<br />

of <strong>co</strong>nsistent taste in marinated and spiced<br />

products creates further appeal, as does<br />

the accessibility to recipes otherwise<br />

out of reach with the skill and time<br />

resources available. The ovenable<br />

bag is food law approved in Europe<br />

for temperatures of 200°C for up<br />

to two hours and temperatures of<br />

190°C for four hours.<br />

For more information visit<br />

www.sealedair-emea.<strong>co</strong>m.<br />

ATLANTIC ZEISER BRINGS INNOVATION <strong>AND</strong> NEW BUSINESS OPPORTUNITIES<br />

12 FMCG News

SPOTLIGHT ON:<br />

More flexibility<br />

for shrink films<br />

Launched onto the market three years ago, shrink<br />

films based on Styrolux ® HS 70 have now be<strong>co</strong>me<br />

well-established in the European sleeve market.<br />

Compared to <strong>co</strong>nventional mixtures of SBC (styrene<br />

butadiene block <strong>co</strong>polymer) and PS (polystyrene), this<br />

material stands out for its very high final shrinkage of<br />

more than 70 percent. BASF researchers have now<br />

developed even further improved Styrolux grades with<br />

an eye towards expanding the product line for this<br />

application. They have done so in response to the<br />

industry’s desire for stiffer films that allow even larger,<br />

more <strong>co</strong>mplex objects to be shrink-labeled and the<br />

thickness of the sleeve film to be further reduced. A<br />

two-<strong>co</strong>mponent <strong>co</strong>ncept that differs from Styrolux HS<br />

70 is being implemented for the first time: with<br />

Styrolux T (T = toughness) and Styrolux S (S =<br />

Sustainable<br />

products – just a<br />

mouse click away<br />

When does it make sense to use biodegradable<br />

plastics? Packaging industry, <strong>co</strong>nsumers and<br />

policy makers are more and more <strong>co</strong>nfronted with<br />

this question during discussions about climate and<br />

the environment. Up to now, anyone who wanted<br />

to base a decision on a solid foundation had to turn<br />

to extensive individual e<strong>co</strong>-efficiency analyses or other<br />

life cycle assessments (LCA) that scrutinize the<br />

<strong>co</strong>nsumption of resources during the manufacture,<br />

use and disposal phases of a plastic product. A new<br />

BASF online tool, the so-called E<strong>co</strong>vio ® E<strong>co</strong>-Efficiency<br />

Compass (E³C), will make this decision much easier<br />

in the future. The software <strong>co</strong>mpiles all of the relevant<br />

data for the production and disposal of selected<br />

products – the findings of many exhaustive E<strong>co</strong>-<br />

Efficiency Analyses – in a single user-friendly<br />

Around the world –<br />

safe and sound<br />

Whenever goods are transported in large unit<br />

loads – be it by sea, land or air – they are usually<br />

<strong>co</strong>nsolidated on pallets for easier handling. As a rule,<br />

products made of wood are used for this purpose. A<br />

new generation of transport pallets made of plastic is<br />

being launched onto the market by the Hirsch Group,<br />

located in Glanegg, Austria. These pallets over<strong>co</strong>me<br />

quite a few of the drawbacks of the <strong>co</strong>nventional<br />

models: among other things, they are easier to clean<br />

and very sturdy, but first and foremost, they weigh<br />

much less than EuroPallets made of wood. The highly<br />

elastic BASF styrene butadiene <strong>co</strong>polymer Styroflex ®<br />

2G66 is playing a crucial role in this innovation.<br />

Engineers at Hirsch are using Styroflex 2G66 as a<br />

toughness modifier for the HIPS film (HIPS: Highimpact<br />

polystyrene) that protects the lightweight <strong>co</strong>re<br />

stiffness), this <strong>co</strong>ncept offers two new Styrolux grades<br />

with which the desired property profile of the shrink<br />

film can be set when the processor blends them, and<br />

only once they are put together do they yield the film<br />

material “Styrolux T/S”. The two-<strong>co</strong>mponent <strong>co</strong>ncept<br />

taps into new application possibilities for sleeves and<br />

particularly for ROSO films.<br />

interface. Various parameters that are crucial for the<br />

e<strong>co</strong>logical evaluation of a given product can be quickly<br />

checked, revealing their impact on the product’s e<strong>co</strong>efficiency<br />

right away. The un<strong>co</strong>mplicated <strong>co</strong>mparison<br />

of the e<strong>co</strong>logical footprint of various approaches<br />

allows the user to quickly ascertain whether, in the<br />

final analysis, a biodegradable plastic is actually<br />

more environmentally friendly. For the time being<br />

the E³C is still tailored for shopping bags and foam<br />

trays; other product groups will be added soon.<br />

of the new pallets against damage. Compared to<br />

<strong>co</strong>nventional wooden pallets, weighing 20 to 40<br />

kilograms, or newer metal-reinforced polyethylene<br />

pallets, the innovative products from the Hirsch Group<br />

offer the advantage of a significantly lower weight: they<br />

weigh 50 up to 75 percent less than wooden pallets or<br />

solid plastic pallets.<br />

A new milestone<br />

in the history of<br />

polymer foams<br />

Polymer foams are a success story for<br />

BASF. This story began in 1952 with the<br />

invention of Styropor ® (EPS: expandable<br />

polystyrene). Today, following the successful<br />

development of the extruded polystyrene<br />

rigid foam panels Styrodur ® (XPS), the<br />

tough-elastic polyolefin range Neopolen ® ,<br />

the melamine resin foam Basotect ® , and<br />

the advanced version of EPS for thermal<br />

insulation Neopor ® , BASF has a broad<br />

portfolio and unique know-how when it<br />

<strong>co</strong>mes to particle and extrusion foams.<br />

Continuous research and the launch of<br />

new products on the market open up new<br />

applications in a lot of industry sectors:<br />

the automotive industry as well as aviation,<br />

but also solar technology, <strong>co</strong>nstruction and<br />

of <strong>co</strong>urse the packaging industry. BASF<br />

has now succeeded with another innovation:<br />

E-por ® , a material which is based on a<br />

new formulation and is manufactured in a<br />

new production process. E-por is the first<br />

tough-elastic, crack-resistant foam which<br />

can be transported, stored, processed and<br />

recycled like traditional Styropor. The<br />

material is noted for very good fusion of<br />

the surface, excellent resistance to solvents,<br />

and an appealing look and feel. Because<br />

of its high crack-resistance it is multishocksafe<br />

and therefore well-suited to being used<br />

as transport packaging for high-quality,<br />

shock-sensitive electrical and electronic<br />

(E/E) products, such as plasma televisions,<br />

laptops, refrigerators or washing machines.<br />

FOR MORE INFORMATION VISIT WWW.PLASTICSPORTAL.EU<br />

OR EMAIL SABINE.PHILIPP@BASF.COM.

website spotlight<br />

Website Spotlight<br />

www.paragonprintandpackaging.<strong>co</strong>m<br />

● PRODUCTS <strong>AND</strong><br />

SERVICES<br />

● PACKAGING<br />

INFORMATION<br />

● ENVIRONMENTAL<br />

INITIATIVES<br />

ABOUT US<br />

Paragon Print and Packaging<br />

Group are the UK leaders in fresh<br />

and chilled food packaging solutions.<br />

Providing the retail supply<br />

chain with Self adhesive Labels,<br />

Linerless Labels, Flexible Films,<br />

Sleeves and Cartons. We are specialists<br />

in packaging launch<br />

management. Our expertise in<br />

managing artwork delivery <strong>co</strong>mbined<br />

with our unrivalled print<br />

capability delivers an industry<br />

leading service proposition.<br />

14 FMCG News<br />

A fresh look at the best websites from across the FMCG industry<br />

Over 18 million households in the UK<br />

have access to the internet and with the<br />

number of new ‘surfers’ growing everyday<br />

a website is one of the most <strong>co</strong>st effective<br />

investments a <strong>co</strong>mpany <strong>co</strong>uld ever make. Not only<br />

can you use it to sell your products, you can get<br />

instant feedback from customers and network with<br />

clients and suppliers the world over.<br />

www.crown<strong>co</strong>nveyors.<strong>co</strong>m<br />

● PRODUCTS<br />

● EXAMPLES<br />

OF CONVEYORS<br />

● SERVICES<br />

● EXAMPLES<br />

OF PROJECTS<br />

ABOUT US<br />

The ease of navigation of the<br />

Crown Conveyors website allows<br />

you to find quickly what you are<br />

looking for. There are downloadable<br />

PDF’s for you to save,<br />

examples of <strong>co</strong>nveyors and<br />

projects in three formats of<br />

small, medium and large.<br />

New to the website is our<br />

case studies page, have a<br />

peek in projects.<br />

Wood Road<br />

Kingswood<br />

Bristol BS15 8NN<br />

Tel: 0117 9671370<br />

Fax: 0117 9353194<br />

tarahawker@crown<strong>co</strong>nveyors.<strong>co</strong>m<br />

Enterprise Way<br />

Pinchbeck<br />

Spalding PE11 3YR<br />

Tel: + 44 (0) 1775 71 22 33<br />

Fax: +44 (0) 1775 76 04 44<br />

sales@paragonprintandpackaging.<strong>co</strong>m<br />

TO ACKNOWLEDGE THE huge importance and benefits of a<br />

well thought out and integrated website, we are now running<br />

our ‘Website Spotlight’ every issue to highlight the best <strong>co</strong>mpany<br />

websites from the FMCG industry. It will include an image of<br />

the home page, along with <strong>co</strong>mpany <strong>co</strong>ntact details and a <strong>co</strong>ncise<br />

description of the merits and functions of each site. This special feature<br />

will run from the centre pages of the magazine and our online<br />

version will have live links directly to each website for you to click on<br />

and browse. If you would like to put your <strong>co</strong>mpany’s website forward<br />

for inclusion please <strong>co</strong>ntact Vicky on 01733 567356 or email<br />

vicky.ellis@one<strong>co</strong>ms.<strong>co</strong>.<strong>uk</strong>. ■<br />

● WORLDWIDE<br />

AGENTS<br />

● 1,000 ST<strong>AND</strong>ARD<br />

PRODUCTS<br />

● CUSTOM<br />

MOULDING<br />

ABOUT US<br />

M&H Plastics is one of the<br />

premier suppliers of plastic<br />

packaging specialising in highquality<br />

bottles, jars, closures and<br />

flexible tubes. Markets include<br />

personal care, pharmaceutical,<br />

healthcare, nutrition and household<br />

products. Virtually everything<br />

is <strong>co</strong>nducted in-house, on site –<br />

from <strong>co</strong>ncept design, through<br />

toolmaking, production, artwork<br />

and de<strong>co</strong>ration.<br />

www.seymour-mi.<strong>co</strong>m<br />

● EASY TO<br />

NEGOTIATE<br />

● CASE STUDIES<br />

● LATEST<br />

PRODUCT NEWS<br />

● PRODUCT VIDEOS<br />

ABOUT US<br />

The website follows SMI’s beginnings<br />

in the early 80’s and takes<br />

the viewer through its product<br />

range and overseas activities.<br />

There are references to Defence<br />

sector applications including<br />

Tempro’s thermal image proof<br />

properties. Details of Tempro’s<br />

other beneficial properties are<br />

also outlined as is <strong>co</strong>mpany ‘s willingness<br />

to adapt existing products<br />

to fulfill customer needs.<br />

SPONSORED BY:<br />

www.crown<strong>co</strong>nveyors.<strong>co</strong>m<br />

www.mhplastics.<strong>co</strong>m<br />

London Road<br />

Beccles<br />

Suffolk NR34 8TS<br />

Tel: +44 (0) 1502 715518<br />

Fax: +44 (0) 1502 717115<br />

marketing@mhplastics.<strong>co</strong>m<br />

Sutton Hall,<br />

Sutton Maddock<br />

Telford TF11 9NG<br />

Tel: 01952 730 630<br />

Fax: 01952 730 330<br />

enquiries@seymour-mi.<strong>co</strong>m

www.peelableadhesives.<strong>co</strong>m<br />

● GLUE DOTS<br />

● GLUE SQUARES<br />

● CUSTOM<br />

PRODUCTS<br />

● NEXT DAY<br />

DELIVERY<br />

ABOUT US<br />

Peelable Adhesives & Glue Dots <br />

can bond your products firmly<br />

and temporarily to many different<br />

surfaces, fast, with no mess<br />

or setting time. These adhesives<br />

are primarily used for attaching<br />

CD's, samples, promotional items<br />

to magazines, leaflets and packaging.<br />

Peelable adhesives have<br />

1000's of possible applications.<br />

Glue Dots - the dot that does a lot!<br />

● EASY TO USE<br />

● EASY MENU<br />

● SERVICE <strong>AND</strong><br />

UPGRADE<br />

INFORMATION<br />

● CONTACT DETAILS<br />

ABOUT US<br />

Redpacks’ website provides full<br />

details of flowrapping machines<br />

by industry so it’s easy to see the<br />

most suitable machine for your<br />

products. All pages have <strong>co</strong>ntact<br />

details so you don’t spend ages<br />

trying to find them. There’s information<br />

on service, spares,<br />

rebuilds and used machines and<br />

for difficult products tailor made<br />

machines with automatic infeeds.<br />

● SERVICE<br />

& SUPPORT<br />

● PRODUCT<br />

INFORMATION<br />

● ON-DEM<strong>AND</strong><br />

WEBINARS<br />

ABOUT US<br />

The new-look website for<br />

METTLER TOLEDO Product<br />

Inspection has everything<br />

you need to know about<br />

checkweighing, metal detection<br />

and x-ray inspection. Keep up-todate<br />

with industry trends and<br />

product developments with free<br />

webinars and white papers.<br />

Alternatively download product<br />

information or request a visit from<br />

our sales or service team.<br />

SPONSORED BY:<br />

www.crown<strong>co</strong>nveyors.<strong>co</strong>m<br />

Regent House<br />

Regent Street<br />

Oldham OL1 3TZ<br />

Tel: 0161 622 4927<br />

Fax: 0161 627 5072<br />

sales@peelableadhesives.<strong>co</strong>m<br />

www.redpack.<strong>co</strong>.<strong>uk</strong><br />

Bunkell Road<br />

Rackheath<br />

NR13 6PU<br />

Tel: 01603 722280<br />

Fax: 01603 720906<br />

info@redpack.<strong>co</strong>.<strong>uk</strong><br />

www.mt.<strong>co</strong>m/pi<br />

64 Boston Road<br />

Beaumont Leys<br />

Leicester B79 7XB<br />

Tel: 0116 235 7070<br />

Fax: 0116 234 6719<br />

pi.mt<strong>uk</strong>@mt.<strong>co</strong>m<br />

● EASY TO FOLLOW<br />

● CLEAR<br />

NAVIGATION<br />

● NEWS UPDATES<br />

● SIMPLE ONLINE<br />

DESCRIPTIONS<br />

ABOUT US<br />

Supreme Plastics, based in Whitby<br />

North Yorkshire, is also the exclusive<br />

UK supplier of Pronova-<br />

Joker bag-filling equipment and<br />

is re<strong>co</strong>gnised as a leading manufacturer<br />

of quality bag products.<br />

Supreme Plastics provides a<br />

<strong>co</strong>mplete service of <strong>co</strong>nsultancy,<br />

product development, manufacture,<br />

technical expertise and<br />

on-site engineering support.<br />

● INDUSTRIAL<br />

GLUE GUNS<br />

● 12, 15 <strong>AND</strong><br />

43mm GLUE STICKS<br />

● NEXT DAY<br />

DELIVERY<br />

ABOUT US<br />

Gluegunsdirect.<strong>co</strong>m are pleased to<br />

unveil their new, fully redesigned<br />

website dedicated to Tecbond glue<br />

sticks and glue guns. The website<br />

now has even more user friendly<br />

features and <strong>co</strong>ntains more information<br />

on Tecbond hot melt adhesives,<br />

glue guns, how hot melt adhesives<br />

actually work and applications for<br />

hot melt adhesives.With over 50<br />

formulations to choose from, there is<br />

almost certainly a Tecbond adhesive<br />

solution for your application.<br />

website spotlight<br />

www.supremeplastics.<strong>co</strong>m<br />

Stainsacre Lane<br />

Whitby<br />

North Yorkshire YO22 4PT<br />

Tel: 01947 601012<br />

Fax: 01947 601027<br />

enquires@supremeplastics.<strong>co</strong>m<br />

www.gluegunsdirect.<strong>co</strong>m<br />

● SPORT & LEISURE<br />

● PATENTED<br />

TECHNOLOGIES<br />

● FOOTBALL,<br />

TENNIS & RUNNING<br />

● TESTIMONIALS<br />

ABOUT US<br />

A detailed overview of<br />

Lotto Sport Italia starting from<br />

<strong>co</strong>mpany history and values to<br />

all Lotto <strong>co</strong>llections from<br />

performance to leisure and<br />

safety products inclusive of<br />

testimonial profiles, news<br />

& events, exhaustive technology<br />

explanations and exciting videos<br />

and images all at the click<br />

of a button.<br />

Regent House<br />

Regent Street<br />

Oldham OL1 3TZ<br />

Tel: 0161 627 1001<br />

Fax: 0161 627 5072<br />

sales@gluegunsdirect.<strong>co</strong>m<br />

www.lottosport.<strong>co</strong>m<br />

Lotto Sport Italia<br />

Via Montebelluna, 5/7<br />

31040 Trevignano (TV) - Italy<br />

Tel: +39 0423 6181<br />

Fax: +39 0423 618 800<br />

email@lottosport.<strong>co</strong>m<br />

FMCG News 15

website spotlight<br />

www.multivac.<strong>co</strong>.<strong>uk</strong>/packaging-solutions/food-products.html<br />

● MACHINERY<br />

OVERVIEWS<br />

● PACKAGING<br />

INNOVATION NEWS<br />

● DOWNLOADABLE<br />

BROCHURES<br />

ABOUT US<br />

www.multivac.<strong>co</strong>.<strong>uk</strong> showcases<br />