Cincom Sliding Headstock Type Automatic CNC ... - Maci-mag.com

Cincom Sliding Headstock Type Automatic CNC ... - Maci-mag.com

Cincom Sliding Headstock Type Automatic CNC ... - Maci-mag.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Metal Finishing/Plating/Coating Issue:<br />

Legacy Technologies Inc., Mission, KS Offers Contract<br />

Plating and Stamping<br />

Micro Medical Instruments, St. Louis: New Citizen K16<br />

Microfinish, St. Louis, MO, Continues To Expand<br />

& Improve Its Operations & Services<br />

SourceOne, Lincoln, NE, Strives To Be A One Source<br />

Manufacturing Partner<br />

Heartland Fabrication & Machine, Independence,<br />

MO, Installs Mori Seiki NLX 2500Y <strong>CNC</strong> Lathe<br />

Wichita ISM & APICS Chapter Hold Joint Meeting<br />

Ernest-Spencer Metals, Meriden, KS: KSAFE Award<br />

Prsrt Std<br />

U.S. POSTAGE<br />

PAID<br />

Lawrence, KS<br />

66044<br />

Permit No. 34<br />

January, 2012<br />

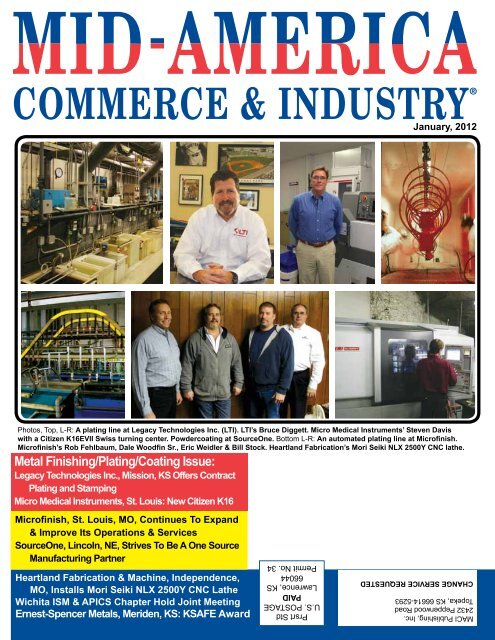

Photos, Top, L-R: A plating line at Legacy Technologies Inc. (LTI). LTI’s Bruce Diggett. Micro Medical Instruments’ Steven Davis<br />

with a Citizen K16EVII Swiss turning center. Powdercoating at SourceOne. Bottom L-R: An automated plating line at Microfinish.<br />

Microfinish’s Rob Fehlbaum, Dale Woodfin Sr., Eric Weidler & Bill Stock. Heartland Fabrication’s Mori Seiki NLX 2500Y <strong>CNC</strong> lathe.<br />

CHANgE SERVICE REquESTED<br />

MACI Publishing, Inc.<br />

2432 Pepperwood Road<br />

Topeka, KS 66614-5293

Supported by MCC’s legendary, full service, distributor network.<br />

Experience the difference.<br />

The Evolution Continues.<br />

Same quality you’ve <strong>com</strong>e to expect with<br />

more tools, more fl exibility, more value.<br />

McClain Tool & Technology, Inc.<br />

106 Weldon Parkway, St. Louis, MO 63043<br />

(P) 1-800-886-5839 (F) 1-314-432-1180<br />

The World Leader in <strong>CNC</strong> Swiss Turning<br />

Serving: Kansas • Missouri • So. Illinois<br />

www.mcclaintool.<strong>com</strong><br />

Allendale, NJ<br />

(201) 818-0100<br />

Elk Grove Village, IL<br />

(847) 364-9060<br />

Fountain Valley, CA<br />

(714) 434-6224<br />

<strong>Cin<strong>com</strong></strong> <strong>Sliding</strong> <strong>Headstock</strong> <strong>Type</strong> <strong>Automatic</strong> <strong>CNC</strong> Lathe<br />

Machine specifi cations<br />

2-YEAR Machine and<br />

Control Limited Warranty<br />

www.marucit.<strong>com</strong><br />

Maximum machining diameter (D) ∅ 16 mm (.63")<br />

Maximum machining length (L) 200 mm (7.87") / 1 chucking<br />

Main spindle speed 15,000 rpm<br />

Back spindle speed 10,000 rpm<br />

Live tools 7 standard

Mid-America Commerce & Industry is<br />

published 11 times a year (June and July<br />

are <strong>com</strong>bined) by:<br />

MACI Publishing, Inc.<br />

2432 SW Pepperwood Rd.<br />

Topeka, KS 66614-5293<br />

David Lippe, managing editor; Ray Lippe,<br />

editor. Published since 1973. Mid-America<br />

Commerce & Industry is a registered<br />

trademark of MACI Publishing, Inc.<br />

A one year subscription is $20.00.<br />

Phone: 785-272-5280<br />

Fax: 785-272-3729<br />

Email: maci@maci-<strong>mag</strong>.<strong>com</strong><br />

Web site:<br />

www.maci-<strong>mag</strong>.<strong>com</strong><br />

Mid-America is sent to industrial<br />

purchasing managers, plant managers,<br />

industrial engineers, and <strong>com</strong>pany<br />

presidents in Missouri, Kansas, Oklahoma,<br />

Nebraska, Arkansas and Iowa.<br />

Index- January, 2012<br />

Vol. 39 - No. 05<br />

Micro Medical Instruments Installs<br />

Citizen K16EVII .....................5<br />

Heartland Fab & Machine:<br />

Installs Mori Seiki .........................6<br />

Microfinish Continues To Expand<br />

and Improve ..........................8<br />

SourceOne: A One Source Manufacturing<br />

Partner .................10<br />

Legacy Technologies Offers<br />

Contract Plating & Stamping ..12<br />

Wichita ISM & APICS Meet .......14<br />

Ernest-Spencer: KSAFE Award .15<br />

FMA Starts Green Mfg Network ..16<br />

Editorial......................................18<br />

St. Louis NTMA: Healthcare Reform .22<br />

Paulo Products Names Rassieur .. 24<br />

SWIC Faculty: AWS Award ........25<br />

Paulo Products Receives GM<br />

Powertrain Approval ...............26<br />

Up<strong>com</strong>ing Issues .......................27<br />

Carr Lane Names Frost President .28<br />

Up<strong>com</strong>ing Trade Shows ............30<br />

4 MID-AMERICA COMMERCE & INDUSTRY

St. Louis, Missouri<br />

Micro Medical Instruments<br />

Installs Citizen K16EVII Swiss<br />

Micro Medical Instruments,<br />

Inc., St. Louis, Missouri, has<br />

recently installed a new Citizen<br />

K16EVII Swiss turning center.<br />

The 22-year-old firm<br />

specializes in producing micro<br />

surgical instruments for the field<br />

of opthamology. Founded by<br />

Steven Davis, a 37-year industry<br />

veteran, the firm started out in a<br />

Above: Steven Davis.<br />

2-car garage and has grown to<br />

its current 7,000+-sq.-ft. facility<br />

with 14 employees. Micro<br />

Medical Instruments’ products<br />

are distributed worldwide. Most<br />

of its instruments are produced<br />

out of stainless steel or titanium<br />

and many require a microscope<br />

for final finishing and inspection.<br />

Tight tolerances are the norm for<br />

the <strong>com</strong>pany.<br />

The new Citizen K16EVII<br />

(purchased through McClain Tool<br />

& Technology) was needed to<br />

improve the <strong>com</strong>pany’s speed and<br />

efficiency.<br />

Micro Medical Instruments<br />

had purchased a Citizen L25<br />

Turning Center<br />

Above: Micro Medical Instruments’ new Citizen K16 Swiss turning center.<br />

(through McClain Tool &<br />

Technology) in 1996, which is still<br />

in use. “The McClain people are<br />

great to work with,” stated Davis.<br />

“When it came time to add another<br />

turning center there was no need to<br />

think about where to buy it.”<br />

The K16EVII features a 15,000rpm<br />

main spindle, a 10,000-rpm<br />

pickoff spindle, 7-axis, 23 tools<br />

including seven live and a 12’<br />

barfeeder. “The K16 has been a<br />

big plus all the way around,” noted<br />

Davis. “It can run unattended and<br />

takes us so much further in our<br />

instrument production and even to<br />

finished parts. Its capabilities with<br />

smaller parts are amazing.”<br />

“We concentrate on quality<br />

and on-time delivery,” continued<br />

Davis. “Combine that with our<br />

great people (the average tenure<br />

at the firm is over 12 years) and<br />

you can see the reasons for our<br />

success.”<br />

Micro Medical Instruments can<br />

be contacted at (314) 845-3663.<br />

JANUARY, 2012 5

Independence, Missouri<br />

Heartland Fabrication & Machine Installs<br />

Mori Seiki NLX 2500Y <strong>CNC</strong> Lathe<br />

Heartland Fabrication<br />

& Machine (HFM), Inc.,<br />

Independence, Missouri, has<br />

recently installed a new Mori Seiki<br />

NLX 2500 Y <strong>CNC</strong> lathe, the first of<br />

its kind in the region.<br />

The <strong>com</strong>pany, a <strong>CNC</strong> machine<br />

and fabrication shop, offers <strong>CNC</strong><br />

turning (including y-axis), milling,<br />

drilling, tapping, welding (MIG &<br />

TIG), <strong>CNC</strong> sawing, tube bending<br />

and light punching.<br />

“We’ve always focused<br />

on well-qualified, well-trained<br />

employees and utilizing the latest<br />

technology, which is why we got<br />

the NLX 2500 Y,” stated owner<br />

Mike Hudson. “It is a kick-ass<br />

machine,” <strong>com</strong>mented Hudson.<br />

“This expands our machining<br />

Above: HFM’s new Mori Seiki NLX 2500Y <strong>CNC</strong> lathe.<br />

capabilities and will be<br />

great for some of our new<br />

projects.”<br />

The NLX 2500 features<br />

a 10” chuck, 12 tool stations<br />

with 24 positions, live milling<br />

and can handle parts up to 18”<br />

in diameter and 28” in length.<br />

6 MID-AMERICA COMMERCE & INDUSTRY

It has taken over the work of a<br />

10-year-old <strong>CNC</strong> lathe. “The<br />

performance improvement over<br />

the older machine is amazing,”<br />

noted Hudson.<br />

HFM serves a wide<br />

range of industries in mid-<br />

America including: elevator/<br />

lift equipment; architectural/<br />

ornamental; construction;<br />

<strong>com</strong>munications; trucking;<br />

railroad; agriculture; lawn<br />

and garden; defense and food<br />

processing.<br />

HFM’s fabrication<br />

department has grown recently<br />

as new structural steel work has<br />

<strong>com</strong>e.<br />

The <strong>com</strong>pany, which has<br />

DBE and MBE designations, can<br />

be contacted at: (816) 778-0766;<br />

Fax (816) 778-0799; 3345 East<br />

Geospace Drive, Independence,<br />

Missouri 64056; www.<br />

heartlandfab.<strong>com</strong>.<br />

quaLity is our <strong>com</strong>mitment.<br />

Your Kansas City regional supplier of:<br />

Powder Coating<br />

Wet Coating<br />

Architectural<br />

816.554.6710 | advancedcoatings.<strong>com</strong> | 2300 ne independence ave. | Lee’s summit, mo 64064<br />

JANUARY, 2012 7

Greater St. Louis Area<br />

Microfinish Continues To Expand and<br />

Improve Its Operations and Services<br />

Microfinish, a 52-year<br />

metal finishing <strong>com</strong>pany with<br />

four locations in the Greater St.<br />

Louis area, continues to expand<br />

and improve its operations and<br />

services.<br />

The firm offers a wide range of<br />

metal finishing services including<br />

zinc plating, nickel/chrome plating,<br />

e-coating, powder coating and<br />

mechanical finishing (deburring,<br />

burnishing, blasting and washing).<br />

Recently the firm has had<br />

its powder-coating operation<br />

designated as a PACCAR Certified<br />

Quality supplier (for the rail and<br />

truck industries); added a new<br />

sales manager, Rob Fehlbaum;<br />

expanded its nickel and e-coating<br />

capacity at its Gratiot facility and<br />

will be adding to its Warrenton<br />

facility later this year.<br />

The ISO-certified firm has<br />

four locations that specialize in<br />

particular processes/sizes.<br />

The 125,000-sq.-ft. Gratiot<br />

facility features a RoHS <strong>com</strong>pliant<br />

high production nickel/chrome<br />

plating line; an E-coating line and<br />

a new larger zinc plating line for<br />

larger parts and assemblies.<br />

The 15,000-sq.-ft. Sunset Hills<br />

facility offers vibratory finishing,<br />

deburring, ball-burnishing and<br />

pre-plate finishing. Both automated<br />

and manual cabinets are available<br />

to clean parts of almost any metal<br />

and configuration.<br />

The 35,000-sq.-ft. Warrenton<br />

facility houses two highproduction,<br />

variable speed, powder<br />

coating lines. One includes a<br />

climate-controlled booth for tight<br />

quality control. Custom racking,<br />

masking, labeling and packaging<br />

are available.<br />

The 20,000-sq.-ft. St. Louis<br />

Zinc plating location offers two<br />

fully-automated rack lines and<br />

Above (l-r): Rob Fehlbaum, Dale Woodfin Sr., Eric Weidler & Bill Stock.<br />

Above: Powdercoating at Microfinish.<br />

one barrel line. It offers yellow<br />

and black chromate and RoHs<br />

<strong>com</strong>pliant blue-bright finishes.<br />

Two ovens for baking and<br />

hydrogen embrittlement relief are<br />

also on site.<br />

Microfinish’s plating is<br />

certified to ASTM, CAT, Ford,<br />

John Deere, GM and Toyota<br />

specs.<br />

Tractor trailer and van<br />

transportation are also available.<br />

“Having good people is key<br />

to our success,” stated Bill Stock,<br />

president and long-time industry<br />

veteran. “Our Berkeley plant was<br />

Above: Plating at Microfinish.<br />

heavily da<strong>mag</strong>ed by a tornado last<br />

spring. Our crew stepped up and<br />

took charge of the situation and we<br />

only missed six processing days.<br />

We care about our people and they<br />

care about Microfinish.”<br />

“We are really focused on<br />

meeting or exceeding customer<br />

needs,” added Eric Weidler, “We<br />

know that quality, delivery and<br />

pricing are critical, no matter the<br />

size of the customer.<br />

Microfinish can be contacted at:<br />

(314) 849-8181; Fax (314) 849-<br />

5149; www.microfinishco.<strong>com</strong>.<br />

8 MID-AMERICA COMMERCE & INDUSTRY

Precision Made Parts<br />

<strong>CNC</strong> Milling<br />

Welded Assemblies<br />

Since 1979<br />

Your Single Source Machine Shop<br />

for Quality and Dependable Service<br />

A Modern Machine Shop <strong>mag</strong>azine<br />

“Top 10 Shop”<br />

<strong>CNC</strong> Turning<br />

Custom J-I-T Assembly<br />

manufacturing, inc.<br />

6790 Martindale • Shawnee, KS 66218<br />

(P) 913.441.4120 • (F) 913.441.0330<br />

(TF) 888.441.4500 • www.c-rmfg.<strong>com</strong><br />

� e Talent to Perform with the Technology to Excel

Your One Source<br />

Manufacturing<br />

Partner<br />

Engineering Services<br />

• Design & Prototyping<br />

• Process Engineering<br />

• In-Plant Consultation<br />

• Rebuilding of Machines<br />

• Specialty Machine Build<br />

• Plant Automation<br />

Sheet Metal Fabrication<br />

• Laser Cutting<br />

• Punching<br />

• Bending & Tube Bending<br />

• Pin Insertion<br />

Machining<br />

• <strong>CNC</strong> & Tool Room<br />

Welding<br />

• Induction<br />

• Resistance<br />

• Robotic<br />

• TIG & MIG<br />

• Pressure Vessel<br />

Powder Coating<br />

• Automated Line<br />

• Batch Booth<br />

• Sandblasting<br />

• Any Size or Volume<br />

Added Services<br />

• Assembly & Packaging<br />

• Warehousing & Shipping<br />

Specialized Services<br />

• Artistic Fabrication<br />

• DuPont® Star Coater<br />

Certified<br />

• ASME Certified Pressure<br />

Vessel Welding<br />

• Maintenance Machine<br />

Work & Repair<br />

1030 SW 6th Street<br />

Lincoln, NE 68522<br />

(P) 402-474-6603<br />

(F) 402-474-6605<br />

(W) www.sourceonex.<strong>com</strong><br />

(E) sales@sourceonex.<strong>com</strong><br />

Request a quote online<br />

or e-mail us at<br />

quotes@sourceonex.<strong>com</strong><br />

SourceOne Strives<br />

Be A One Source<br />

Manufacturing Partner<br />

SourceOne, Lincoln, Nebraska<br />

was started in 1974 as Industrial<br />

Machine Specialties by former<br />

high school friends Elmer Wessel<br />

and Nick Cusick in a garage with<br />

very limited machine capabilities.<br />

Throughout the 38 years of<br />

continual ownership, the diverse<br />

multi-process manufacturer has<br />

grown internally and spawned<br />

successful sister <strong>com</strong>panies due<br />

in large part to the creativity of its<br />

staff and the entrepreneurial spirit<br />

of its owners.<br />

SourceOne offers engineering<br />

services, sheet metal fabrication,<br />

machining, welding, powder<br />

coating, heat treating, sand blasting<br />

and other value-added services<br />

to customers across the U.S.<br />

with a focus on the Midwest. Its<br />

staff of 75 operates in a modern<br />

50,000-sq.-ft. facility.<br />

The firm’s powder coating<br />

operation, which includes two<br />

powder lines, an automated 5-stage<br />

wash system and a batch booth,<br />

is Dupont ‘Star Coater’ Certified.<br />

This certification, which is only<br />

held by a handful of <strong>com</strong>panies<br />

in the U.S., requires a rigorous<br />

certification process. SourceOne<br />

is also a member of the DuPont<br />

Twenty Group that works together<br />

to improve the industry.<br />

The <strong>com</strong>pany has a wide range<br />

of <strong>CNC</strong> and manual equipment<br />

that includes <strong>CNC</strong> lasers (up to<br />

4,000-watt), lathes, mills, press<br />

brakes, turret punches, and tube<br />

benders as well as manual mills,<br />

lathes, shears, grinders and<br />

welding stations (MIG & TIG).<br />

Design services at SourcOne<br />

include: prototyping; tooling<br />

and product design; industrial<br />

Above: Powder coating at SourceOne.<br />

Above: Laser cutting at SourceOne.<br />

10 MID-AMERICA COMMERCE & INDUSTRY

Above: A welder at work at SourceOne in Lincoln NE.<br />

automation and special machine design and building.<br />

The firm offers full assembly capabilities for<br />

subassemblies to <strong>com</strong>plete product assembly with<br />

packaging and drop shipping.<br />

“We best serve those customers who seek to maximize<br />

the benefit of outsourcing by engaging SourceOne at<br />

the earliest possible time in the planning, design and<br />

implementation of automation, tooling, and production<br />

projects that require the widest range of <strong>com</strong>petencies,”<br />

stated Elmer Wessel, president.<br />

SourceOne can be contacted at: (888) 418-7547; Fax<br />

(402) 474-6605; 1030 SW 6 th Street, Lincoln, Nebraska<br />

68522; sales@sourceonex.<strong>com</strong>; www.sourceonex.<strong>com</strong>.<br />

Metals<br />

• Hot Rolled<br />

• Cold Finished<br />

• Structural<br />

• Plate<br />

Plastics<br />

• Acetal<br />

• Acrylic<br />

• Delrin ®<br />

• Sheet<br />

• Aluminum<br />

• Stainless<br />

• Pipe<br />

Processing Services<br />

• Laser Cutting<br />

• Hi Definition Plasma Cutting<br />

• Flame Cutting<br />

Other Services<br />

• Same day cutting and/or shipping<br />

• Competitive prices on a wide variety of products<br />

• Extensive inventory<br />

Alro Steel<br />

Metals • Industrial Supplies • Plastics<br />

• Tubing<br />

• Brass<br />

• Copper<br />

• Bronze<br />

• Extren ®<br />

• Fiberglass Grating<br />

• Nylatron ®<br />

• Nylon<br />

• Phenolics<br />

• Polycarbonate<br />

• Tube Laser Cutting<br />

• Production/Precision Saw Cutting<br />

• Precision Aluminum Plate Cutting<br />

• Quality assurance programs<br />

• Electronic data order entry<br />

• Polypropylene<br />

• PVC<br />

• Teflon ®<br />

Contact Your Alro Steel Representative Today!!!<br />

8000 Hall St. Bldg #4 • St. Louis, MO 63147-2422<br />

Pho: (314) 726-3080 • Fax: (314) 726-5017<br />

Toll Free:(800) 325-0978<br />

• Cast Iron<br />

• Tool Steel<br />

• Alloys<br />

• Mold Steel<br />

• High Speed<br />

• Drill Rod<br />

• Precision Ground Flat Stock<br />

• Steel Grating<br />

alro.<strong>com</strong><br />

• Expanded Metal<br />

• Threaded Rod<br />

• Tivar ®<br />

• UHMW-PE<br />

• Urethane<br />

• Shearing/Forming<br />

• Grinding<br />

• Packaging to Customer Specifications<br />

• Bar code order entry<br />

• Exceptional technical assistance<br />

8600 S. 89th W. Avenue • Tulsa, OK 74131-3649<br />

Pho: (918) 227-1456 • Fax: (918) 227-1455<br />

Toll Free:(800) 722-4973<br />

Alro delivers ... everyday<br />

JANUARY, 2012 11

Mission, Kansas<br />

Legacy Technologies Offers<br />

Contract Plating and Stamping<br />

Legacy Technologies Inc. (LTI),<br />

Mission, Kansas, offers contract<br />

plating and stamping.<br />

The 38-year-old firm produces<br />

its own product line of Glass-<br />

To-Metal seals for electronic<br />

<strong>com</strong>ponents such as crystals,<br />

oscillators and sensors for a variety<br />

of Electronic applications. It<br />

operates in a newly built, specific<br />

use 4-year-old, 30,000-sq.-ft.<br />

facility with 75 employees. LTI,<br />

Above: LTI’s Bruce Diggett.<br />

which is ISO <strong>com</strong>pliant, serves<br />

customers across the globe in<br />

such industries as aerospace,<br />

tele<strong>com</strong>munications, automotive<br />

and defense.<br />

Its plating operation includes<br />

six lines (barrel and rack) for<br />

electroless nickel, electrolytic<br />

nickel, electrolytic gold and<br />

electrolytic tin-lead. Parts up to<br />

15” in diameter can be plated. Post<br />

baking processing is also available<br />

as needed. State-of-the-art XRF<br />

(X-ray flourescence) equipment<br />

is used to precisely measure the<br />

thickness of the plating. Other<br />

quality testing performed at LTI<br />

includes: solderability, thermal<br />

cycling and adhesion testing.<br />

Where applicable, all baths meet<br />

RoHS Standards.<br />

“We have <strong>com</strong>plete analytical<br />

Above: Examples of LTI’s plating and stamping work.<br />

tracking of all baths in the plating<br />

operation for traceability and<br />

meet all quality standards for the<br />

industries we serve,” stated Bruce<br />

Diggett, president and 26-year<br />

industry veteran. “We can offer<br />

quick turnaround ranging from two<br />

days to two weeks.”<br />

The stamping area specializes<br />

in extremely small parts (.003”<br />

x .030” up to .020” x 4.750”)<br />

in thin metals, with thicknesses<br />

from .003” - .500. Prototypes<br />

to production runs are available.<br />

“We specialize in small lot<br />

production,” states Diggett. The<br />

<strong>com</strong>pany utilizes both progressive<br />

and single-station dies in its 12<br />

stamping presses. Reel to reel<br />

Above: Two of LTI’s six plating lines.<br />

stamping is also available.<br />

LTI’s tooling area offers die<br />

design, die making and can also<br />

develop, design and build fixtures,<br />

jigs and gages. In-house heat<br />

treating and tempering is also<br />

available.<br />

“Our unique capabilities and<br />

experience (the average tenure at<br />

LTI is over 10 years) give us the<br />

ability to work with customers<br />

and deliver high quality parts and<br />

plating,” <strong>com</strong>mented Diggett.<br />

LTI can be contacted at (913)<br />

432-2487 X224; Fax (913)<br />

432-0570; 6700 W 47 th Terrace,<br />

Mission, Kansas 66203; bdiggett@<br />

legacytechnologies.<strong>com</strong><br />

www.legacytechnologies.<strong>com</strong>.<br />

12 MID-AMERICA COMMERCE & INDUSTRY

Tomorrow’s manufacturing solutions, today<br />

The premier provider of<br />

High quality<br />

High tech<br />

Machine solutions<br />

From Hartwig<br />

Don’t face your machining development challenges alone. With a<br />

rich history of providing top quality, the highest technology and<br />

best-in-class service, let Hartwig show you the latest manufacturing<br />

technology and solutions.<br />

Visit us at one of our three Midwest locations<br />

Hartwig St. Louis Hartwig Kansas City Hartwig Wichita<br />

10617 Trenton Avenue 6110 Deramus Avenue 4959 S. Lulu Court<br />

St. Louis, MO 63132 Kansas City, MO 64120 Wichita, KS 67216<br />

314-426-5300 816-231-1850 316-522-5500

Above (l-r): Wichita APICS’ President, Brian Ferris; Kevin Kohls and ISM-<br />

Wichita’s President Tim Strobel at the joint January meeting in Wichita.<br />

Midwest Tool, Inc.<br />

COMPLETE JOB SHOP<br />

Milling & Turning (<strong>CNC</strong> & Manual)<br />

Boring Grinding<br />

Sawing Welding<br />

Sheet Metal Work Inspection Lab<br />

Midwest Tool, Inc.<br />

3637 Enterprise Ave. • Joplin, Mo 64801<br />

(P) 417-623-6872 • (F) 417-623-6998<br />

www.midwest-tool-inc.<strong>com</strong><br />

(E) sales@midwest-tool-inc.<strong>com</strong><br />

Wichita ISM<br />

and APICS<br />

Chapters Hold<br />

Joint Meeting<br />

The Wichita Chapters of the<br />

Institute for Supply Management<br />

(ISM) and APICS-The Society for<br />

Operations Management held a<br />

joint meeting on January 10 th at the<br />

Wichita Area Technical College in<br />

Wichita.<br />

The featured speaker was<br />

Kevin Kohls of Kohls Consulting<br />

and his topic was “Comparing the<br />

Toyota Way and the Theory of<br />

Contraints.”<br />

Kohl provides improvement<br />

training and services to industry.<br />

His presentation covered the<br />

14 management principles outlined<br />

in the book The Toyota Way, by<br />

Jeffery Liker. He <strong>com</strong>pared this<br />

with the Theory of Constaint<br />

introduced by the late management<br />

guru Eli Goldratt.<br />

As <strong>com</strong>panies implement<br />

Lean or continuous improvement<br />

programs, it is important to<br />

understand these concepts. This<br />

can change the way one looks at<br />

these programs.<br />

ISM-Wichita can be contacted<br />

at www.napmwichita.org.<br />

APICS can be contacted at:<br />

www.apics-wichita.org.<br />

Above: Part of the crowd at the<br />

joint January meeting in Wichita.<br />

14 MID-AMERICA COMMERCE & INDUSTRY

Ernest-Spencer<br />

Metals Earns<br />

KSAFE Award<br />

Ernest-Spencer Metals,<br />

Meriden, Kansas, has earned the<br />

prestigious KSAFE Award from the<br />

Kansas Department of Labor.<br />

Ernest-Spencer Metals is a<br />

metal fabrication <strong>com</strong>pany that<br />

fabricates and supplies parts to<br />

many different manufacturing<br />

sectors. Ernest-Spencer Metals is an<br />

ISO 9001-certified <strong>com</strong>pany with<br />

over 150 employees.<br />

The KSAFE Award is<br />

presented to <strong>com</strong>panies that have<br />

demonstrated a safe environment<br />

for their employees by having over<br />

100,000 hours without a lost time<br />

accident and that have a safety<br />

training plan, a formal safety<br />

program, and an employee involved<br />

safety <strong>com</strong>mittee. In 2011 there<br />

was only one other recipient of the<br />

KSAFE award.<br />

Since 1922, the Ernest-Spencer <strong>com</strong>panies have been providing first quality products and services to the<br />

Midwest industrial and agricultural <strong>com</strong>munities. We have continued to invest in our facilities, technology and people<br />

so that we may serve as a single-source supplier for all of your fabrication, coatings and construction needs.<br />

FABRICATION COATINGS CONSTRUCTION<br />

The ernesT-spencer <strong>com</strong>panies<br />

3323 East 82nd Street Meriden, KS 66512 Phone: 785/484-3165 Fax: 785/484-2032<br />

Email: sales@esmetals.<strong>com</strong> www.ernestspencer.<strong>com</strong><br />

JANUARY, 2012 15

FMA Starts Green Manufacturing Network<br />

The Fabricators & Manufacturers Association,<br />

Intl. (FMA) invites manufacturing executives to join<br />

its new Green Manufacturer Network, a professional<br />

organization of individual members working together<br />

to drive the transition toward environmentally friendly<br />

manufacturing.<br />

“The mission of the Green Manufacturer Network<br />

is to be the principal resource to advance sustainable<br />

manufacturing,” said Edward Youdell, president<br />

and CEO of the FMA. “By joining this network,<br />

executives throughout the entire supply chain can learn<br />

North topeka FabricatioN<br />

Sheet Metal Fabrication<br />

• Laser Cutting • Forming<br />

• Punching • Welding<br />

MaterialS<br />

• Steel<br />

• Stainless Steel • Aluminum<br />

• Galvanized • Galvannealed<br />

up to 5’x10’, 1/4” thick<br />

Flexibility from<br />

quote to production<br />

NOW in our NEW LOCATION!<br />

Triple the space and equipment<br />

to serve our customers better!<br />

North topeka FabricatioN<br />

3801 NW 14th Street • Topeka, KS 66618<br />

(P) 785.234.2111 • (F) 785.234.2141<br />

practical strategies and affordable measures to run<br />

sustainable operations, as well as discover new business<br />

opportunities in the green marketplace.”<br />

Members of the group receive discounts on<br />

conferences, workshops, and webinars; helpful event<br />

announcements and topical discussions; as well as access<br />

to sustainability resources.<br />

Jim Warren, FMA membership and education<br />

director said, “They’ve recognized that being green<br />

directly impacts the bottom line in a positive way.<br />

Further, good environmental stewardship sends a<br />

powerful message to current<br />

and potential customers of one’s<br />

dedication to sustainability in their<br />

<strong>com</strong>munities.”<br />

The cost to join the Green<br />

Manufacturer Network is $150. Call<br />

(888) 394-4362 or email network@<br />

greenmanufacturer.net to learn more.<br />

Based in Rockford, Ill., FMA<br />

is a professional organization with<br />

nearly 2,300 members working<br />

together to improve the metal<br />

fabricating and forming industry.<br />

Superior<br />

Aluminum<br />

Castings, Inc. YEARS<br />

Your Casting Connection<br />

From drawing or concepts...<br />

to <strong>com</strong>plete tooling development...<br />

to supplying quality castings...<br />

to adding value where you need it.<br />

• Sand Casting•<br />

•Air-Set No-Bake•<br />

•Heat Treat•<strong>CNC</strong> Machining•<br />

•Painting•<br />

Made in the USA<br />

Superior Aluminum Castings, Inc.<br />

1211 South Powell Road • Independence, MO 64057<br />

(P) 816-796-5775 (F) 816-796-5776<br />

Email: David@supalum.<strong>com</strong><br />

16 MID-AMERICA COMMERCE & INDUSTRY

Hurry! Hurry! Hurry! Step right<br />

up! For only a few dollars you can rid<br />

yourself of rheumatism, backaches,<br />

gout, dizziness, etc. Today we marvel<br />

that people would actually buy medicine<br />

from these traveling hucksters and<br />

then be surprised when it didn’t work.<br />

Now, we’re so much wiser. Or are we?<br />

First, we must acknowledge that<br />

while the United States has been a<br />

world leader in manufacturing, inventions<br />

and new technology, it was<br />

enterprising salespeople that raised our<br />

standard of living so fast.<br />

They weren’t selling snake oil.<br />

Thousands of peddlers fanned out over<br />

the country offering products and<br />

services that could benefit the public.<br />

They knocked on doors and explained<br />

to housewives how new appliances,<br />

such as the washing machine, could<br />

reduce their work load at home.<br />

They demonstrated how the automobile<br />

could replace the horse, allowing<br />

millions of people to move about<br />

the country as they wished. Stores displayed<br />

television sets that entertained,<br />

informed and at the same time caused<br />

an even greater demand for these wonderful<br />

new work-savers, machines,<br />

drugs and thousands of other things.<br />

The point we want to make is that<br />

these promoters were selling things<br />

that were of real value to the buyer.<br />

Therefore, they had no need to scream<br />

Hurry! Hurry! Hurry!<br />

As most of you have probably<br />

discovered, when the seller must have<br />

your answer NOW; When you only get<br />

this one chance to buy today and there<br />

is no time for you to think this over or<br />

do some fact checking, you know it’s<br />

probably a bad deal.<br />

So, how did today’s supposedly<br />

smart generations get conned into buy-<br />

18 MID-AMERICA COMMERCE & INDUSTRY

ing the concept that any rise in the<br />

earth’s temperature is the result<br />

of an increase in carbon dioxide?<br />

And, that it is specifically caused<br />

by today’s humans? Or even if<br />

any slight warming is really a bad<br />

thing?<br />

We have no solid knowledge<br />

that an increase in temperature<br />

today is any different than it’s been<br />

as the earth warmed and cooled<br />

over the years when there were no<br />

humans burning coal or gasoline.<br />

Perhaps we wouldn’t have so<br />

many reservations about the facts<br />

on global warming or “climate<br />

change” as some call it (in case<br />

the earth starts cooling) if it hadn’t<br />

<strong>com</strong>e as a proclamation chiseled in<br />

stone. There was to be no questioning<br />

of this new development,<br />

even by skeptical scientists. Those<br />

scientists who dared to suggest<br />

we needed more tests or found<br />

serious flaws in the studies have<br />

(Continued on next page)<br />

machining & fabricating<br />

<strong>CNC</strong> Milling<br />

<strong>CNC</strong> Turning from Swiss to Large 35” x 129”<br />

Fully Automated Emco Cell<br />

High Speed Mills<br />

Grinding<br />

Weldments<br />

1050 E. “H” HIGHWAY<br />

Liberty, MO 64068<br />

Phone: (816) 781-6765<br />

Fax: (816) 415-8044<br />

sales@pridemfgkc.<strong>com</strong><br />

www.pridemfgkc.<strong>com</strong><br />

ISO 9001:2008<br />

ISO 13485: 2003 Medical<br />

precision manufactured parts<br />

JANUARY, 2012 19

DESIGN & FABRICATION<br />

OF CABINETS AND COMPONENTS FOR<br />

ELECTRONICS & INDUSTRY<br />

SINCE<br />

1972<br />

THESE PANELS AND BOXES ARE MADE IN QUANTITIES OF 1 TO 20,000<br />

Our <strong>com</strong>plete service can deliver a cabinet to you ready for final assembly.<br />

Specializing in the design and fabrication of low cost metal cabinets<br />

and <strong>com</strong>ponents for new electronic and mechanical equipment. All<br />

new products go through several stages of development before<br />

being launched full scale. Venture can do it all, and adjust the price<br />

according to volume. Let us work for you on your next project!<br />

DESIGN - Matching to your <strong>com</strong>ponents and style specifications. Minimizing tool cost.<br />

SINGLE PROTOTYPES - To check Form, Fit, Function.<br />

SMALL LOTS - For the field test.<br />

SHORT RUN PRODUCTION - From 1 to 20,000.<br />

CONTINUOUS PRODUCTION - Timely lots shipped to meet your on going schedule.<br />

CALL TODAY AT (800)588-0441<br />

Visit our website at: www.ventureindustrial.<strong>com</strong><br />

®<br />

VENTURE INDUSTRIAL PRODUCTS, INC.<br />

5 2 5 S E O L D H A M PA R K WAY<br />

LEE’S SUMMIT, MISSOURI 64081<br />

TEL: (816)524-0441 FAX: (816)524-0836<br />

...Editorial<br />

From Previous Page<br />

been chastised and ridiculed by the<br />

group that is dedicated to “saving<br />

our planet.”<br />

And, while they didn’t actually<br />

say Hurry! Hurry! Hurry! They did<br />

say time was of the essence and<br />

that our coast cities and thousands<br />

of islands would be submerged in a<br />

few short decades if we didn’t start<br />

spending billions of dollars either<br />

reducing our carbon footprint or<br />

giving other countries billions of<br />

dollars to stop burning fossil fuels.<br />

With few serious discussions<br />

about the facts, the United Nations,<br />

the European countries and the islands<br />

that might be flooded, knew<br />

immediately what must be done.<br />

We were to start the distribution of<br />

money through Cap and Trade programs,<br />

begin shutting down coal<br />

mines with strict regulations, raise<br />

gas prices and increase subsidies<br />

for anything related to renewable<br />

energy sources.<br />

Fortunately, we’ve been unable<br />

to enact Cap and Trade legislation<br />

so far. However, Congress’s doubts<br />

about sending billions of dollars to<br />

other countries has not prevented<br />

a rash of new government regulations<br />

based on the “fact” that<br />

carbon dioxide is now a poisonous<br />

gas. As a result of this “rush<br />

to judgment,” our government<br />

can now regulate just about every<br />

aspect of our lives since CO2 is<br />

everywhere.<br />

In November, the Heritage<br />

Foundation published an article by<br />

Nicolas D. Loris titled “New EPA<br />

Inspector General Report: One<br />

More Reason to Reject Climate-<br />

Change Regulation.”<br />

Loris writes that “In April<br />

2009, the EPA proposed an endangerment<br />

finding that stated<br />

that global warming and climate<br />

change pose a serious threat to<br />

20 MID-AMERICA COMMERCE & INDUSTRY

public health and safety, and that,<br />

thus, almost any entity that emits<br />

carbon dioxide and other greenhouse<br />

gases could be regulated<br />

under the Clean Air Act.” (This<br />

statement is a dictator’s dream,<br />

giving him or her unlimited power<br />

over people under the guise of saving<br />

their lives.)<br />

“The agency has since begun<br />

the process of regulating greenhouse-<br />

gas emissions, targeting<br />

fossil-fuel power plants and petroleum<br />

refineries first. Climatologists<br />

and industry groups petitioned the<br />

EPA, arguing that scientific evidence<br />

was not conclusive enough<br />

to issue the endangerment finding.<br />

“In 2010, the EPA rejected<br />

these petitions to reconsider the<br />

finding... In fact, Section 202(a)<br />

(1) of the Clean Air Act states that<br />

the EPA administrator must use<br />

independent ‘judgment’ when determining<br />

causes and contributors<br />

to air pollution that may endanger<br />

human health and public safety.”<br />

Loris concludes that, “Placing<br />

the regulation of greenhouse-gas<br />

emissions in the hands of unelected<br />

bureaucrats would be an immense<br />

and unacceptable expansion of<br />

government power with monumental<br />

cost and few benefits for<br />

anyone.”<br />

The good news is that many<br />

more groups around the world are<br />

speaking out about this unscientific<br />

“hurry-up, ask no questions”<br />

policy of the global warming<br />

proponents.<br />

So, as we get into 2012, why<br />

not take a few minutes to ask your<br />

representatives to check into this<br />

dictatorial attitude at the EPA and<br />

to take responsibility for returning<br />

the U.S. to a democracy.<br />

8a, SDB and MBE Certified<br />

Native American Owned<br />

A <strong>CNC</strong> Fabrication & Machine Shop Offering:<br />

• <strong>CNC</strong> Turning (including Y-axis)<br />

• Milling (4 Axis) • Welding (MIG & TIG)<br />

• Drilling • <strong>CNC</strong> Sawing<br />

• Tapping • Tube Bending<br />

• Welding • Light Punching<br />

Heartland Fabrication & MacHine<br />

3345 East Geospace Drive, Independence, MO 64056<br />

P: 816-778-0766 • F: 816-778-0799<br />

Website: www.heartlandfab.<strong>com</strong> • E-mail: mike@heartlandfab.<strong>com</strong><br />

Paxton & Vierling Steel 800-831-9252<br />

Omaha, NE<br />

sales@pvsteel.<strong>com</strong><br />

JANUARY, 2012 21

St. Louis NTMA Learns More About<br />

up<strong>com</strong>ing Healthcare Reform Details<br />

Above (l-r): Darrell Songer & Chad Kunze. Above: Steelville Mfg.’s crew with Bill Bachmann (far right).<br />

The St. Louis Chapter of the<br />

National Tooling & Machining<br />

Association (NTMA) held a<br />

meeting at the Sheraton Westport<br />

in St. Louis on January 10th.<br />

The featured speakers were<br />

Chad Kunze and Darrell Songer,<br />

both CPAs and partners with<br />

Clifton LarsonAllen a top 10<br />

accounting and consulting firm.<br />

The topic for the presentation<br />

was “Healthcare Reform-Hashing<br />

Out the Details.” The duos goal<br />

was to attempt to clarify the main<br />

issues related to healthcare reform.<br />

The presentation and<br />

subsequent discussions covered<br />

a wide range of topics about the<br />

impact of the reform on small<br />

businesses and manufacturers.<br />

Much is still unknown about this<br />

MISSOURI<br />

PLATING<br />

COMPANY<br />

® Since<br />

1888<br />

NICKEL<br />

BARREL ZINC • RACK ZINC<br />

Trivalent Conversion Coatings<br />

Our 40,000 sq. ft. Plant Offers Fully<br />

Automated Production Plating Lines<br />

To Ac<strong>com</strong>modate Your Plating Needs.<br />

Missouri Plating Company<br />

(P) 816-483-0333 (F) 816-483-1096<br />

7001 EAST 13TH STREET<br />

KANSAS CITY, MISSOURI 64126<br />

www.missouriplating.<strong>com</strong><br />

22 MID-AMERICA COMMERCE & INDUSTRY

Above (l-r): Herb Homeyer receives<br />

an appreciation plaque from Bill<br />

Bachman for his year as president.<br />

legislation.<br />

In other chapter business,<br />

Steelville Manufacturing, Steelville,<br />

Missouri, was presented a new<br />

member plaque.<br />

The St. Louis NTMA can be<br />

contacted at: (314) 974-6418 or<br />

ntmastl@aol.<strong>com</strong>.<br />

Custom Powder Coating Solutions<br />

Conveyorized & Batch Paint Lines<br />

• Conveyorized Powder Coating Line<br />

with 3-Stage Pretreatment,<br />

30” x 60” x 120” Part Window<br />

• Aluminum Oxide Blasting for<br />

Paint, Rust & Scale Removal<br />

• Quick 3-5 Day Turnaround<br />

• Flat Bed & Box Delivery Services<br />

• New-High Volume Batch Powder Line with Iron Phosphate<br />

Pretreatment, 8’ x 9’ x 21’ Part Window & 2000# Capacity<br />

• New-Automated Steel Shot Blasting for High Volume Scale<br />

& Rust Removal<br />

816-221-9700 • Fax 816-221-9701 • nfinney@ihdkc.<strong>com</strong><br />

1201 Burlington, North Kansas City, Missouri 64116<br />

JANUARY, 2012 23

<strong>CNC</strong> FABRICATION & METALFORMING MACHINERY<br />

St. Louis Kansas City Wichita<br />

Al Colby Don Patterson Mitch Brown<br />

314.422.2178 913.558.2121 316.640.5893<br />

www.blackrockmachinery.<strong>com</strong><br />

LASERS • PLASMA • PRESS BRAKES • SHEARS • FOLDERS • PLATE ROLLS • PRESSES<br />

Paulo Products<br />

Names Rassieur<br />

Sales Manager,<br />

Special Projects<br />

Left:<br />

Paulo<br />

Products<br />

Will<br />

Rassieur.<br />

Paulo Products Company, St. Louis,<br />

Missouri, is pleased to announce<br />

the appointment of Will Rassieur<br />

as Sales Manager, Special Projects.<br />

Rassieur joined Paulo in 2010<br />

and has held the position of Sales<br />

Engineer, primarily supporting the St<br />

Louis facility. In his new role as part<br />

of Paulo’s Corporate Sales effort, he<br />

will support the sales and marketing<br />

effort at each of the Paulo facilities<br />

as well as develop new business with<br />

selected major accounts.<br />

“Will brings wel<strong>com</strong>e new<br />

ideas, skills, and energy to Paulo’s<br />

Corporate Sales and Marketing<br />

effort. He has contributed to Paulo’s<br />

growth over the past year as a Sales<br />

Engineer and I’m confident that he<br />

will continue to contribute at a high<br />

level toward achieving our goals”<br />

states Jim Heman, VP, Sales and<br />

Marketing.<br />

One of the largest heat treating<br />

<strong>com</strong>panies in North America, Paulo<br />

offers a wide variety of heat treating,<br />

brazing and metal finishing solutions<br />

to key industries such as aerospace,<br />

automotive, agriculture and tooling<br />

as well as providing a broad range<br />

of metallurgical and engineering<br />

services. Paulo operates plants in St.<br />

Louis, Kansas City, Nashville, TN,<br />

Murfreesboro, TN, and Cleveland,<br />

OH.<br />

For more information about Paulo<br />

Products visit www.paulo.<strong>com</strong>.<br />

24 MID-AMERICA COMMERCE & INDUSTRY

SWIC Faculty<br />

Member Receives<br />

AWS Award<br />

Southwestern Illinois College<br />

(SWIC) Heating, Ventilation, Air<br />

Conditioning and Refrigeration<br />

Program Coordinator Keith Otten was<br />

recently awarded the American Welding<br />

Society’s Section Educator Award for<br />

the St. Louis Area.<br />

“I’m very honored to receive this<br />

award,” Otten said. “It’s always an<br />

honor to take a student who may have<br />

little to no experience in this field and<br />

expose them to the opportunity to do a<br />

certain trade and get them started in a<br />

career of their choice.”<br />

The AWS is a national organization<br />

that promotes welding technology and<br />

associated fields.<br />

“We congratulate Keith on his<br />

success and are proud to call him a<br />

faculty member at SWIC,” said SWIC<br />

Tech Ed Dean Brad Sparks. For more<br />

information on SWIC and the HVAR<br />

program call (618) 931-0600 ext. 7420.<br />

Master3DGage is the future of<br />

inprocess model-based inspection.<br />

Accurate, reliable and cost effective. Call<br />

to arrange your in-house demo today.<br />

Ask about special limited-time offers!<br />

PLATING:<br />

• Electroless Nickel<br />

• Electrolytic Nickel<br />

• Electrolytic Gold<br />

• Electrolytic Tin Lead<br />

• Rack And Barrel Plating<br />

• XRF Measuring<br />

• Baking<br />

• Adhesion Testing<br />

• Quick Turn Around<br />

We can help with your CAD/CAM needs:<br />

• 21+ years of Mastercam experience<br />

• 25+ years of machine shop experience<br />

We also offer Mastercam:<br />

Solids • Design • Mill • Lathe • Wire • Router<br />

Multi-Axis • Maintenance • Art • Add-ins<br />

For the most important job...yours!<br />

Certified<br />

MasterCam<br />

Trainer<br />

HIGH QUALITY PRODUCTS<br />

AND SERVICES<br />

FOR OVER 30 YEARS<br />

PLATING, HERMETIC SEALS, METAL STAMPINGS, ASSEMBLY/SECONDARY OPERATIONS<br />

METAL STAMPING:<br />

• Progressive And Single Station<br />

Die Capabilities<br />

• Precision Thin Metal Stamping<br />

Specialists<br />

• .003-.500 Material Thicknesses<br />

• Prototype - Production Quantities<br />

• In House Tooling<br />

Legacy Technologies Inc<br />

6700 W 47 TH Terrace, Mission, KS 66203 (P) 913-432-2020 (F) 913-432-O570<br />

E-mail: bdiggett@legacytechnologies.<strong>com</strong> | www..legacytechnologies.<strong>com</strong><br />

205 W 2nd Street<br />

Wichita KS 67202<br />

316.262.0076<br />

Fax: 316.262.0347<br />

redbird@iwichita.<strong>com</strong><br />

www.redbirdinc.<strong>com</strong><br />

JANUARY, 2012 25

Paulo Products Receives Approval As<br />

A Heat Treat Source For gM Powertrain<br />

The St Louis, Missouri, facility<br />

of Paulo Products Company<br />

has successfully <strong>com</strong>pleted all<br />

necessary testing and has received<br />

provisional approval as a supplier<br />

to the Powertrain Division of<br />

General Motors. This approval<br />

authorizes Paulo to heat treat per<br />

Machining / Fabrication (Sheet, Plate, & Structural) / Welding<br />

Turning, Milling, Punching, Cutting, Stamping, & Forming<br />

High-Definition Plasma Cutting / Blanchard Grinding<br />

816 E. Callan Road • Monett, MO 65708<br />

Phone: 417-235-7182 • Fax: 417-235-8262<br />

Email: general@clark-ind.<strong>com</strong> Web: www.Clark-ind.<strong>com</strong><br />

Recognized for our Quality, Service & On-Time Delivery<br />

GM Casting Tooling Standard<br />

HPDC-G-2 for GM tooling sources<br />

and others who utilize the GM<br />

Spec. GM Powertrain primarily<br />

makes <strong>com</strong>ponents for GM cars<br />

and trucks. The division also sells<br />

engines, transmissions, castings,<br />

and <strong>com</strong>ponents to many other<br />

automotive, marine, and industrial<br />

customers.<br />

In order to heat treat<br />

<strong>com</strong>ponents for GM suppliers,<br />

the heat treater must successfully<br />

pass furnace performance tests<br />

as well as material testing. This<br />

achievement demonstrates Paulo’s<br />

capability and <strong>com</strong>mitment to<br />

meet the requirements of GM’s<br />

Specifications. Paulo – St Louis<br />

joins Paulo – Nashville as two of<br />

the select few heat treaters who<br />

have the GM approval. “We<br />

are extremely pleased with this<br />

ac<strong>com</strong>plishment. It reflects the<br />

capability and quality of our<br />

equipment and our people. It<br />

will benefit us as well as our<br />

customers.” says Bob Innes, St<br />

Louis Plant Manager. Paulo<br />

plants in St Louis and Nashville<br />

feature vacuum heat treating with<br />

10-bar quench capability.<br />

Paulo provides heat treating,<br />

brazing, and metal finishing. The<br />

St Louis plant is a full-service<br />

heat treat facility offering batch<br />

and continuous atmosphere heat<br />

treating, vacuum, induction,<br />

press and plug quenching,<br />

hot flattening, straightening,<br />

cryogenics, blasting, brazing and<br />

black oxiding. Paulo also offers<br />

a broad range of metallurgical<br />

services and extensive engineering<br />

resources. Paulo has a plant and<br />

headquarters in St Louis as well as<br />

plants in Kansas City, Nashville,<br />

TN, Murfreesboro, TN, and<br />

Willoughby, OH.<br />

For more information on Paulo<br />

Products visit: www.paulo.<strong>com</strong>.<br />

26 MID-AMERICA COMMERCE & INDUSTRY

UPCOMING<br />

ISSUES<br />

FEBRuARY 2012<br />

Foundry, Castings,<br />

Molding<br />

MARCH 2012<br />

Powder Coating,<br />

Industrial Services<br />

APRIL 2012<br />

Metals<br />

MAY 2012<br />

Machine Shop and<br />

Custom Fabrication<br />

Advertising deadline is the<br />

1st business day of each<br />

month. The issue is published<br />

and distributed the last week<br />

of the month.<br />

For more<br />

information<br />

contact:<br />

DavID LIPPE at<br />

785-272-5280 or<br />

maci@maci-<strong>mag</strong>.<strong>com</strong><br />

ON-LINE<br />

BuYER’$ guIDE<br />

Available 24/7, 365<br />

days a year at:<br />

www.maci-<strong>mag</strong>.<strong>com</strong><br />

RSS FEED<br />

Add http://www.<br />

maci-<strong>mag</strong>.<strong>com</strong>/feed.<br />

xml to the “Add New<br />

Channel” section of<br />

your RSS reader.<br />

<strong>CNC</strong> FABRICATION & METALFORMING MACHINERY<br />

St. Louis Kansas City Wichita<br />

Al Colby Don Patterson Mitch Brown<br />

314.422.2178 913.558.2121 316.640.5893<br />

www.blackrockmachinery.<strong>com</strong><br />

LASERS • PLASMA • PRESS BRAKES • SHEARS • FOLDERS • PLATE ROLLS • PRESSES<br />

JANUARY, 2012 27

Carr Lane Mfg.<br />

Names Frost<br />

President<br />

The Board of Directors of<br />

Carr Lane Manufacturing Co., St.<br />

Louis, Missouri, has named Alan<br />

K. Frost as President, succeeding<br />

the late CEO Earl E. Walker.<br />

Frost holds a law degree and<br />

MBA from Washington University<br />

in St. Louis, MO. He has extensive<br />

experience in process improvement<br />

through ISO 9001:2008 and as<br />

a Malcolm Baldrige National<br />

Quality Award Examiner. Het has<br />

37 years of experience at Carr<br />

Lane, having managed virtually all<br />

areas of the <strong>com</strong>pany during that<br />

time, including his most recent<br />

responsibilities as Vice President<br />

of Operations.<br />

Carr Lane Manufacturing<br />

Co. is a leading manufacturer of<br />

tooling <strong>com</strong>ponents and related<br />

products utilized by manufacturers<br />

28 MID-AMERICA COMMERCE & INDUSTRY

Left:<br />

Carr<br />

Lane<br />

Mfg.’s<br />

Alan<br />

Frost.<br />

in all types of industry, including<br />

aerospace, automotive, agriculture<br />

and heavy equipment. The<br />

<strong>com</strong>pany is enjoying a successful<br />

year in 2011, and is optimistic<br />

about prospects for 2012, as well.<br />

It is the intention of the Board<br />

and the President to continue<br />

to grow the <strong>com</strong>pany through<br />

enhanced customer service and<br />

process improvements across the<br />

<strong>com</strong>pany, including Carr Lane<br />

Drill Bushing Company, a division<br />

located in Austin, TX.<br />

Carr Lane can be contacted at<br />

www.carrlane.<strong>com</strong>.<br />

Manufacturing Solutions<br />

Providers of Software, Training & Contract Services for Manufacturers<br />

“Our Experience Guarantees Your Success”<br />

Software for <strong>CNC</strong> Machining and Inspecting your Products<br />

Now you can create Mastercam World Famous Toolpaths inside SolidWorks!<br />

Associative - Parametric - Replaceable Part Models<br />

NC Programming Software<br />

Computer Aided Inspection Software<br />

Helping You Make Better Products Faster!<br />

877-429-5708 www.qtemfg.<strong>com</strong><br />

JANUARY, 2012 29

• Late model injection<br />

molding machines<br />

to 1500 ton.<br />

• Gas assist technology.<br />

• Servo robotics.<br />

• Climate controlled<br />

facility.<br />

• In-house tooling<br />

PM and repair.<br />

Plastic Injection Molding<br />

A <strong>com</strong>mitment to continuous<br />

process improvement since 1974<br />

2130 Industrial Drive • McPherson, KS 67460<br />

(620) 241-2400<br />

info@fergusonproduction.<strong>com</strong><br />

www.fergusonproduction.<strong>com</strong><br />

CERTIFIED<br />

ISO 9001-2000<br />

Up<strong>com</strong>ing<br />

Trade<br />

Shows<br />

October 3-4, 2012<br />

Nebraska Products<br />

Show, Grand Island<br />

Event Center, Grand<br />

Island, NE, Mid-<br />

America Expositions,<br />

Inc, 800-475-<br />

SHOW (7469) www.<br />

showofficeonline.<strong>com</strong><br />

October 24-25, 2012<br />

Sioux Falls Products<br />

Show, Sioux Falls<br />

Convention Center,<br />

Sioux Falls, SD Mid-<br />

America Expositions,<br />

Inc, 800-475-<br />

SHOW (7469) www.<br />

showofficeonline.<strong>com</strong><br />

___________________<br />

Visit our website for<br />

up-to-date information<br />

on up<strong>com</strong>ing trade<br />

shows in Mid-<br />

America.<br />

30 MID-AMERICA COMMERCE & INDUSTRY

Zinc Plating Division<br />

8353 Courtney<br />

St. Louis, MO 63140<br />

Phone 314-521-4142 • Fax 314-521-9637<br />

This Facility Provides<br />

Hydrogen Embrittlement Relief RoHS Trivalent Clear<br />

Yellow Chromate Black Chromate<br />

Barrel Plating Rack Plating<br />

MICROFINISH IPC, LLC<br />

4001 Gratiot<br />

St. Louis, MO 63110<br />

Phone 314-652-5200 • Fax 314-652-5202<br />

This Facility Provides<br />

Nickel/Chrome Plating Trivalent Zinc Plating<br />

Zinc Phosphate E-Coating<br />

Hydrogen Embrittlement Relief<br />

Metal Finishing Division-Main Office<br />

11048 Gravois Ind. Ct.<br />

St. Louis, MO. 63128<br />

Phone 314-849-8181 • Fax 314-849-5149<br />

This Facility Provides<br />

Glass Bead Blasting Vibratory Deburring<br />

Vapor Degreasing Ball Burnishing<br />

Derusting<br />

Powder Coating Division<br />

7000 S. Spoede Lane<br />

Warrenton, MO. 63383<br />

Phone 636-456-1787 • Fax 636-456-1789<br />

This Facility Provides<br />

Climate Controlled Powder Room<br />

High Gloss--Low Gloss<br />

<strong>Automatic</strong> Reciprocating Guns UV Resistant Powders<br />

Textured and Wrinkle A Rainbow of Colors<br />

FOUR LOCATIONS, ONE GREAT FINISH!<br />

www.microfinishco.<strong>com</strong> microfinishco@aol.<strong>com</strong>

Small lathes are either light-duty machines,<br />

or ultra-<strong>com</strong>plex and expensive.<br />

Haas is Different.<br />

Utilizing simple designs, <strong>com</strong>mon <strong>com</strong>ponents, and clever manufacturing<br />

techniques, we build a small-footprint lathe that’s quick, rugged, reliable,<br />

easy to use, and affordable.<br />

A Division of NYMAT Machine Tool Corp.<br />

Kansas City<br />

15661 South Mahaffie Street<br />

Olathe, KS 66062<br />

Phone: (913) 768-HAAS (4227)<br />

Fax: (314) 567-0220<br />

Haas Automation<br />

St. Louis<br />

136 Weldon Parkway<br />

St. Louis, MO 63043<br />

Phone: (314) 567-HAAS (4227)<br />

Fax: (314) 567-0220