EBP 500 - voran Maschinen GmbH

EBP 500 - voran Maschinen GmbH

EBP 500 - voran Maschinen GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fruit processing M<strong>500</strong> line 2/12<br />

Fruit processing M<strong>500</strong> line<br />

Our solutions today set the standards for tomorrow.

Provided by nature.<br />

2<br />

Emptying Washing & mashing Pressing<br />

Fruit processing M<strong>500</strong> line

Filtering & settling Pasteurisation Filling<br />

°F °C<br />

www.<strong>voran</strong>.at<br />

3

Optimised by <strong>voran</strong> ®<br />

.<br />

4<br />

Filling<br />

3 integrated buffer with<br />

overflow protection<br />

3 takes 3, 5, 10 or 20 litre bags<br />

3 pre-programmed filling weight<br />

Pasteurisation<br />

3 fully-automatic operation<br />

3 filling not started until pasteurisation<br />

temperature has been reached<br />

3 plate-type heat exchanger suitable<br />

for juice<br />

°F °C<br />

Filtering & settling<br />

3 screens can be cleaned during<br />

processing (not shown)<br />

3 drain for clear and residue (tanks)<br />

3 optimum stability<br />

Fruit processing M<strong>500</strong> line

Pressing<br />

3 continuous operation<br />

3 high yield<br />

3 minimum space requirements<br />

www.<strong>voran</strong>.at<br />

Washing & mashing<br />

3 controlled automatically by press<br />

3 adjustable mash quality<br />

3 space-saving, flexible construction<br />

Emptying<br />

3 controlled feed from bulk bins<br />

3 high stability<br />

3 easy operation<br />

5

Implemented together.<br />

<strong>voran</strong> ® – Our solutions today set<br />

the standards for tomorrow.<br />

The modular configuration of the <strong>voran</strong> ® M<strong>500</strong> fruit<br />

processing line is a future-safe solution for producing and<br />

packaging high quality, natural, tasty, long-life products.<br />

As the industry leader in commercial fruit processing,<br />

<strong>voran</strong> ® has brought together the advantages of modular<br />

technology based on decades of experience, continuous<br />

development and consideration of market needs to bring<br />

you a customer-oriented, optimised overall concept.<br />

Our industry-specific knowledge on production processes,<br />

quality factors, hygiene specifications for raw materials and<br />

operation of the plant contribute to the unrivalled quality of<br />

the final product as much as our high standards regarding<br />

production technology and mechanical engineering.<br />

Our innovative overall solutions are geared towards the very<br />

highest level of technology, modular design and exceptional<br />

cost effectiveness for our customers.<br />

With the <strong>voran</strong> ® business model and our comprehensive<br />

support service you can concentrate on what matters most.<br />

Let <strong>voran</strong> ® worry about the rest.<br />

6<br />

<strong>voran</strong> ® – We supply the recipe<br />

as well as the kitchen.<br />

It is really important to us that we have an opportunity<br />

to talk to customers about the processes they need to<br />

implement so that we can ensure we design and deliver<br />

the perfect system.<br />

From the installation plan to utilities required and the<br />

necessary connection points through to assisting in setting<br />

up the pressing room, we have a great deal of experience<br />

to input.<br />

You can also benefit from the collective know-how gleaned<br />

from hundreds of reference projects that have already been<br />

implemented in a wide range of applications, capacities and<br />

countries.<br />

Thanks to our comprehensive experience in storage and<br />

logistics we can guarantee rapid service, fast delivery of<br />

spare parts and straightforward, expert advice on processing,<br />

operation and any malfunctions that occur.<br />

<strong>voran</strong> ® – Where top quality is standard.<br />

Proven <strong>voran</strong> ® quality is based primarily on the decades of<br />

experience as a specialist one-stop-shop for fruit processing<br />

systems. With hundreds of plug-and-play systems supplied,<br />

ongoing development to processing technology and a vast<br />

knowledgebase on quality indicators, <strong>voran</strong> ® is your professional<br />

partner.<br />

Maintaining hygiene when handling raw materials and operating<br />

the system are important factors. That is why <strong>voran</strong> ®<br />

places great value on the ease of cleaning and compatibility<br />

for food contact of all components that come into contact<br />

with the product.<br />

All modular components implemented by <strong>voran</strong> ® ensure a<br />

long service life, high value retention and low maintenance<br />

costs. When our service team starts up a system for the first<br />

time, all function parameters are recorded in the handover<br />

check sheet to ensure reliable operation - so you can concentrate<br />

on your production.<br />

The highest quality support and service is also standard<br />

at <strong>voran</strong> ® . Detailed documentation including operating<br />

instructions and comprehensive functional description and<br />

troubleshooting/remedying instructions go without saying.<br />

Thanks to the use of standardised parts in manufacturing,<br />

we are also able to guarantee expert technical support and<br />

rapid availability of spares and wear parts. As part of our<br />

comprehensive service concept we offer pre-season preventive<br />

maintenance to ensure your system operates smoothly<br />

over the long-term.<br />

Fruit processing M<strong>500</strong> line

Stationary when you need it.<br />

Mobile when you want it to be.<br />

<strong>voran</strong> ® M<strong>500</strong> fruit processing line<br />

The <strong>voran</strong> ® M<strong>500</strong> fruit processing lines features machines<br />

that are perfectly matched to achieve a capacity of up to<br />

<strong>500</strong> litres per hour, depending on the fruit quality.<br />

The M<strong>500</strong> line has been implemented many times and is<br />

a modular system so that it can be perfectly adapted to your<br />

needs and specification to guarantee minimum manual<br />

work thanks to its high degree of automation.<br />

The M<strong>500</strong> mobil version offers the high capacity and all the<br />

advantages of the M<strong>500</strong> line installed ready for operation<br />

on an aluminium-clad trailer.<br />

www.<strong>voran</strong>.at<br />

<strong>voran</strong> ® – Experience meets innovation.<br />

For decades <strong>voran</strong> ® <strong>Maschinen</strong> <strong>GmbH</strong> has stood for<br />

quality, dynamic and professionalism in food and<br />

drink processing as part of the <strong>voran</strong> ® Holding.<br />

As a financially stable medium-sized company we<br />

currently employ around 160 people in Pichl bei Wels –<br />

at the heart of the province of Upper Austria.<br />

Always at the leading edge, we continue to develop<br />

proven systems as well as pioneer new ways, where<br />

experience and expertise count.<br />

Transparency and a sprit of innovation motivate <strong>voran</strong> ®<br />

to realise economically viable solutions featuring advanced<br />

technology in close cooperation with our customers.<br />

Visit us at www.<strong>voran</strong>.at to learn more<br />

today about the standards for tomorrow.

WALC<br />

8<br />

Space-saving and flexible<br />

The washing and mashing systems are controlled<br />

completely automatically depending on the requirements<br />

of the belt press. They are designed with a rotating turret<br />

so that they can be installed flexibly without taking up<br />

too much space, and yet they are still easy to access for<br />

cleaning.<br />

The raw material is cleaned in the integrated washing<br />

vessel, which is continuously fed with fresh water.<br />

The cleaned material is conveyed to the inline centrifugal<br />

mill by a vertical auger-type elevator.<br />

The quality of the mash can be adjusted if required using<br />

replaceable screens - no tools required.<br />

The <strong>voran</strong> ® WALC highlights:<br />

3 up to 2,000 kg of fruit per hour<br />

3 automatic operation (controlled by belt press)<br />

3 interchangeable screens for adjustable mash quality -<br />

no tools required<br />

3 pip and stone protection tool<br />

3 rotating turret for space-saving installation and<br />

easy cleaning<br />

3 auger elevator features soft-start<br />

3 service-friendly design - e.g. split bearing on auger shaft<br />

3 integrated floor drain<br />

3 processes wide range of fruit and vegetables<br />

3 stainless steel construction<br />

Fruit processing M<strong>500</strong> line

<strong>EBP</strong> <strong>500</strong><br />

Continuous high yield<br />

Optimum juice quality and yield are guaranteed thanks to<br />

the variable speed and pressure control for the <strong>EBP</strong> <strong>500</strong> belt<br />

press. The press is operated completely automatically and<br />

continuously.<br />

The rate at which mash is fed to the press can be regulated<br />

individually for each product. The juice flows to the left or<br />

right virtually free of oxidation. The pomace is wiped away<br />

from the belt at the end of the pressing sequence. The efficient<br />

high-pressure belt cleaning system and optional brush<br />

system ensure optimum cleaning results.<br />

The <strong>voran</strong> ® <strong>EBP</strong> <strong>500</strong> highlights:<br />

3 up to 700 kg of mash per hour<br />

3 high yield of up to 75 percent<br />

3 automatic continuous operation<br />

3 automatic belt regulation<br />

3 processes wide range of fruit, vegetables and herbs<br />

3 best juice quality<br />

3 low proportion of cloudy juice<br />

3 good accessibility - easy to clean<br />

3 minimum space requirements<br />

3 juice and waste water drain to left or right<br />

3 sealed roller bearings<br />

3 stainless steel construction<br />

www.<strong>voran</strong>.at<br />

9

PA <strong>500</strong>-Gas<br />

Fully automatic and safe<br />

The high quality control<br />

system of the PA <strong>500</strong> Gas<br />

pasteurisation system<br />

ensures that juice is fed<br />

to the filling unit only<br />

after it has reached the<br />

preset temperature. The<br />

whole system runs completely<br />

automatically -<br />

no operator required.<br />

After the required temperature<br />

has been reached,<br />

the juice is fed from the<br />

buffer tank through the<br />

heat exchanger. If the<br />

temperature falls below<br />

the filling unit set point<br />

then the juice is fed back<br />

into the buffer tank. As soon as the juice has reached filling<br />

temperature the system switches over automatically to filling<br />

mode. The temperature<br />

of the juice can be<br />

regulated within +/– 0.4<br />

degrees Celsius by modulating<br />

the power of the<br />

gas heater and the flow<br />

rate of the product. The<br />

system automatically<br />

switches over to standby<br />

mode if the filling unit<br />

buffer tank is full.<br />

10<br />

The <strong>voran</strong> ® PA <strong>500</strong>-Gas highlights:<br />

3 up to <strong>500</strong> litres of juice per hour<br />

3 adjustable pasteurising and filling temperature<br />

3 fully automatic - no operator required<br />

3 precise temperature control<br />

3 reliable pasteurisation to protect product<br />

3 rapid availability thanks to short heating up time<br />

3 can be used to process small volumes<br />

3 heated buffer tank ensures continuity when<br />

stopping and starting<br />

3 system can be flushed using commercially<br />

available detergents<br />

3 plate-type heat exchanger suitable for juice<br />

3 product is conveyed carefully using stainless steel<br />

juice pump with neoprene impeller<br />

and dry running protection<br />

3 tight-welded stainless steel frame<br />

Fruit processing M<strong>500</strong> line

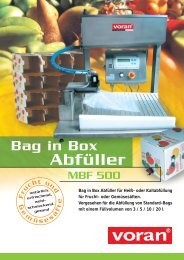

MBF <strong>500</strong><br />

Exact and compact<br />

The MBF <strong>500</strong> fills bags almost free of bubbles and with no<br />

dripping thanks to its electronically-controlled filling valve.<br />

A weighing system guarantees precise metering of the<br />

filling amount.<br />

The integrated buffer tank is fed directly from the pasteurising<br />

system. The filling system is able to remember two<br />

different filling weights that can be selected directly so that<br />

it is easy to change between different sizes of bag. After filling,<br />

the bag is closed manually and placed inside the box.<br />

www.<strong>voran</strong>.at<br />

The <strong>voran</strong> ® MBF <strong>500</strong> highlights:<br />

3 up to <strong>500</strong> litres of juice per hour (with 10 litre bags)<br />

3 takes 3, 5, 10 or 20 litre bags<br />

3 minimal foam in bag thanks to pump-free filling<br />

3 exact filling weight<br />

3 weighing system (can be calibrated to Austrian standards)<br />

3 2 filling weights can be stored and selected directly<br />

3 quick change between different volumes of bag<br />

3 2 automatic counters that can be reset individually<br />

to zero<br />

3 integrated buffer tank with level indicator monitored<br />

by pasteurising system<br />

3 buffer tank can be drained completely empty<br />

3 efficient cleaning<br />

3 compact and space-saving construction<br />

3 stainless steel construction<br />

11

GKE Juice collection tank 65 l<br />

The bulk bin tipper is designed to empty standard and<br />

special format large boxes of fruit at a controlled rate.<br />

Bulk boxes can be positioned on tipping system by hand<br />

truck or forklift. The whole tipping process takes around<br />

20 seconds and can easily be stopped in any position.<br />

The complete system is built in stainless steel and<br />

features an integrated hydraulic power unit.<br />

12<br />

The collection basin is perfectly matched for connection to the <strong>EBP</strong> <strong>500</strong>.<br />

The juice runs directly from the belt press through a removable, large surface<br />

1 mm coarse screen to be collected in a 65 litre buffer tank. A stainless steel<br />

level switch automatically controls the impeller-type pump that is designed to<br />

carefully convey the product at flow rates of up to 1,800 litres per hour. The<br />

pump can also be switched on and off manually if the tank needs to be drained.<br />

Fruit processing M<strong>500</strong> line

Tanks Pipe-screen Accessories<br />

The tanks are mainly used as buffer tanks with optional<br />

tanks available to allow cloudy product to settle prior to<br />

pasteurisation. Two connections at different heights for<br />

clear product and drain, an external measuring scale, three<br />

support legs for optimum stability and easy cleaning thanks<br />

to top surface finish quality of the stainless steel tank.<br />

www.<strong>voran</strong>.at<br />

Efficient and<br />

cost-effective filtering<br />

with a mesh size of<br />

0.25 mm. By implementing<br />

two gap screens in parallel<br />

it is possible to clean<br />

the screens without<br />

interrupting operation.<br />

Compressor<br />

Kaeser Classic Mini<br />

For belt tensioning and regulating<br />

<strong>EBP</strong> <strong>500</strong> and actuating filling<br />

valve on optional MBF 750.<br />

High pressure cleaner<br />

Kärcher HD7/18C<br />

For cleaning belt on the <strong>EBP</strong> <strong>500</strong><br />

automatically.<br />

13

Options<br />

WAR 65<br />

The WAR 65 combines power and extreme<br />

robustness with a space saving design and easy<br />

cleaning thanks to the rotating turret. The flow rate<br />

of mash is controlled depending on the requirements<br />

of the belt press. The quality of the mash can be<br />

adjusted to the type and quality of fruit being processed<br />

using replaceable screens - no tools required.<br />

The <strong>voran</strong> ® WAR 65 highlights:<br />

3 up to 6,000 kg of fruit per hour<br />

3 automatic operation (controlled by belt press)<br />

3 adjustable mash quality with replaceable screens -<br />

no tools required<br />

3 pip and stone protection tool<br />

3 thick plate construction - robust and reduces noise<br />

3 rotating turret for space-saving installation and<br />

easy cleaning<br />

3 auger elevator features soft-start<br />

3 service-friendly design<br />

3 integrated floor drain<br />

3 processes wide range of fruit and<br />

vegetables<br />

3 easily transportable<br />

14<br />

<strong>EBP</strong> <strong>500</strong><br />

Add-on supports can be fitted to the <strong>EBP</strong> <strong>500</strong> belt press<br />

so that it can easily be adjusted to the mash outlet height<br />

of the WAR 65. This means that standard size big boxes<br />

can be used for collecting pomace.<br />

Fruit processing M<strong>500</strong> line

Line filler 6-positions<br />

The inline filling unit is designed for semi-automatic hot<br />

filling of fruit and vegetable juice from an integrated buffer<br />

tank into bottles between 0.25 and 2 litres. The filling height<br />

is individually adjustable and it is easy to switch bottle sizes<br />

without using any tools. A range of filling nozzle sizes are<br />

available for different bottle openings. Capacity is up to<br />

600 litres per hour with 1 litre bottles.<br />

www.<strong>voran</strong>.at<br />

MBF 750-R6<br />

All features on the MBF <strong>500</strong> also apply to the MBF 750-R6.<br />

The main highlights are a capacity of up to 900 litres<br />

per hour with 10 litre bags and the optional 6-nozzle<br />

inline filling unit.<br />

15

Options<br />

Berries & Stone fruit<br />

The combination of slanting conveyor and de-stoning unit<br />

is the right choice for the production of de-stoned mash<br />

from berries and stone fruit.<br />

The high quality and homogenous mash with optimum<br />

aroma containment can be used directly for distilling or<br />

further processing with the belt press.<br />

SA<br />

The slanting conveyor offers high flexibility in raw materials<br />

handling because it is ideal for all types of pomaceous fruit,<br />

stone fruit, berries and vegetables.<br />

An integrated inspection screen is provided for hand<br />

selection. Rinsing takes place inside the wash tank while<br />

post cleaning is performed by a fresh water spray on the<br />

conveyor belt. The speed of the conveyor is infinitely<br />

variable.<br />

The conveyor is available in three configurations:<br />

3 without centrifugal mill<br />

3 with centrifugal mill<br />

3 with pivoting centrifugal mill (shown)<br />

16<br />

EP 1000<br />

The flow of raw material is regulated by a belt-driven<br />

central auger. The DN65 connection for the mash outlet<br />

leads directly to the mash pump or mash basin.<br />

Stones are ejected separately.<br />

The main cover can be removed without tools so that the<br />

screen for straining berries can quickly<br />

and easily be replaced with a screen<br />

for processing cherries, plums,<br />

apricots and other types of<br />

stone fruit.<br />

Accessories<br />

Mash pump: self-priming eccentric screw pump that can<br />

be connected directly to the EP 1000 or fitted with a mash<br />

funnel and feed auger.<br />

Fruit processing M<strong>500</strong> line

M<strong>500</strong> mobil<br />

Mobile and complete<br />

The M<strong>500</strong> mobil system combines high capacity and all the<br />

advantages of the M<strong>500</strong> on an aluminium-clad trailer. The<br />

M<strong>500</strong> mobil is pre-installed ready for operation, fitted with<br />

central utility supply point and equipped to each customer‘s<br />

individual specifications.<br />

The <strong>voran</strong> ® M<strong>500</strong> mobil highlights:<br />

3 installed ready for operation<br />

3 central utility supply point (power, water)<br />

3 central control cabinet<br />

3 intuitive layout; robust construction<br />

3 proven standardised components<br />

3 individually designed<br />

3 effective intermediate and final cleaning<br />

3 high mobility with whole system on one trailer<br />

3 reach more customers<br />

3 rapid return on investment<br />

3 positive carbon balance thanks to shorter<br />

transport routes<br />

3 fruit is manipulated less often<br />

3 special trailer with pressing lines including<br />

EU certification for straightforward approval<br />

in Austria and Germany<br />

www.<strong>voran</strong>.at<br />

17

Installation plans<br />

Washing & mashing<br />

18<br />

Emptying Washing & mashing<br />

De-stoning & straining<br />

Pressing<br />

Filling<br />

Pasteurisation<br />

°F °C<br />

Filtering & settling<br />

The installation layout shown here is one of the proven<br />

setups that has been implemented many times using the<br />

<strong>voran</strong> ® M<strong>500</strong> fruit processing line.<br />

Of course the installation can be configured to perfectly<br />

match the layout of your site and your individual requirements.<br />

Tanks<br />

PA <strong>500</strong><br />

MBF <strong>500</strong><br />

Juice collection<br />

tank<br />

9.000<br />

WALC<br />

<strong>EBP</strong> <strong>500</strong><br />

GKE<br />

EP 1000<br />

SA<br />

Fruit processing M<strong>500</strong> line<br />

9.000

Technical data<br />

Total weight in kg 305 250 520 29 400<br />

Height / Width / Depth in mm 1.317/ 1.697/ 1.466 (1.666) 2.419/ 1.826/ 616 1.300/ 1.940/ 1.161 290/ 1.327/ 508 1.900/ 1.830/ 1.100<br />

Total weight in kg 125 40 420 180 210<br />

Height / Width / Depth in mm 1.704/ 1.350/ 700 1.490/910/420 2.450/ 1.751 / 873 2.080/2 .614 (2.463)/ 662 1.670/ 1.650/820<br />

www.<strong>voran</strong>.at<br />

1.317<br />

1.704<br />

GKE<br />

1.697<br />

1.945<br />

MBF <strong>500</strong><br />

900<br />

1.350<br />

2.530<br />

MBF 918<br />

Tisch 785<br />

825<br />

1.490<br />

WALC<br />

Line filler<br />

6-positions<br />

910<br />

900<br />

1.826<br />

1.578<br />

2.450<br />

1.480<br />

2.419<br />

1.300<br />

<strong>EBP</strong> <strong>500</strong><br />

WAR 65<br />

1.751<br />

1.940<br />

800<br />

540<br />

2.080<br />

SA without RM 1.747<br />

1.238<br />

Juice collection<br />

tank<br />

SA<br />

1.327<br />

1.060<br />

SA without RM 2.463<br />

2.614<br />

840<br />

290<br />

1.670<br />

1.585<br />

1.900<br />

PA <strong>500</strong>-GAS<br />

EP 1000<br />

525<br />

1.830<br />

1.650<br />

1.030<br />

615<br />

19<br />

Technical updates and any errors expressly excepted.

<strong>voran</strong>.at<br />

How to reach us<br />

Munich<br />

Innsbruck<br />

Bozen<br />

q Passau<br />

q Salzburg<br />

Kufstein<br />

Pichl bei Wels<br />

A 8<br />

Passau<br />

Salzburg<br />

Udine<br />

Edt bei Lambach<br />

Lambach<br />

A 1<br />

B 134<br />

r Graz<br />

Wels<br />

Villach<br />

w Prague<br />

Linz<br />

Klagenfurt<br />

q after <strong>500</strong> m<br />

Wels interchange<br />

A 25<br />

B 1<br />

Steyrermühl<br />

<strong>voran</strong> ® <strong>Maschinen</strong> <strong>GmbH</strong><br />

Sales<br />

Linzer Straße 30<br />

A 4650 Edt bei Lambach<br />

T +43 (0) 72 49 / 444-0<br />

F +43 (0) 72 49 / 444-888<br />

office@<strong>voran</strong>.at<br />

www.<strong>voran</strong>.at<br />

Bad Schallerbach<br />

A 9<br />

Wels<br />

Voralpenkreuz<br />

w Prague<br />

A 7<br />

Linz<br />

Graz<br />

A 1<br />

Maribor<br />

Vienna e<br />

Linz interchange<br />

Traun interchange<br />

Production<br />

Inn 7<br />

A 4632 Pichl bei Wels<br />

Brno<br />

Vienna<br />

Eisenstadt<br />

Bratislava<br />

<strong>voran</strong> ® <strong>GmbH</strong> business sectors<br />

machinery<br />

manufacturing<br />

plant construction<br />

facades