- Page 3 and 4:

ADVANCES IN PSYCHOLOGY 104 Editors:

- Page 5 and 6:

NORTH-HOLLAND ELSEVIER SCIENCE B.V.

- Page 7 and 8:

vi THE GRASPING HAND including comp

- Page 9 and 10:

viii THE GRASPING HAND Finally, all

- Page 11 and 12:

X THE GRASPING HAND 4.2 Task Plans

- Page 13 and 14:

xii THE GRASPING HAND Part I11 CONS

- Page 15 and 16:

xiv Figure 1.1 Figure 1.2 Figure 1.

- Page 17 and 18:

XVi THE GRASPING HAND Figure 6.12 F

- Page 19 and 20:

This Page Intentionally Left Blank

- Page 21 and 22:

This Page Intentionally Left Blank

- Page 23 and 24:

4 WHAT IS PREHENSION? The hand itse

- Page 25 and 26:

6 WHAT IS PREHENSION? continue in t

- Page 27 and 28:

8 WHAT IS PREHENSION? movement. Dom

- Page 29 and 30:

10 WHAT IS PREHENSION? Today, with

- Page 31 and 32:

12 WHAT IS PREHENSION? prehensile b

- Page 33 and 34:

This Page Intentionally Left Blank

- Page 35 and 36:

16 WHAT IS PREHENSION? (1988) refer

- Page 37 and 38:

18 WHAT IS PREHENSION? in Table 2.1

- Page 39 and 40:

20 WHAT IS PREHENSION? Table 2.1 Pr

- Page 41 and 42:

22 WHAT IS PREHENSION? Schlesinger

- Page 43 and 44:

24 WHAT IS PREHENSION? A. POWER GRA

- Page 45 and 46:

emphasis on Grasp emphasis on secur

- Page 47 and 48:

28 WHAT IS PREHENSION? (screwing on

- Page 49 and 50:

30 WHAT IS PREHENSION? suggested th

- Page 51 and 52:

Figure 2.5 Prehensile postures cons

- Page 53 and 54:

Figure 2.7 Oppositions can be descr

- Page 55 and 56:

36 WHAT IS PREHENSION? Many posture

- Page 57 and 58:

38 WHAT IS PREHENSION? and unwieldy

- Page 59 and 60:

40 WHAT IS PREHENSION? d Figure 2.9

- Page 61 and 62:

42 WHAT IS PREHENSION? quired oppos

- Page 63 and 64:

44 WHAT IS PREHENSION? sion; i.e.,

- Page 65 and 66:

46 WHAT IS PREHENSION? impossible t

- Page 67 and 68:

This Page Intentionally Left Blank

- Page 69 and 70:

50 THE PHASES OF PREHENSION V cm/s

- Page 71 and 72:

52 THE PHASES OF PREHENSION - 0 200

- Page 73 and 74:

54 THE PHASES OF PREHENSION recogni

- Page 75 and 76:

56 THE PHASES OF PREHENSION Executi

- Page 77 and 78:

58 THE PHASES OF PREHENSION untary

- Page 79 and 80:

60 THE PHASES OF PREHENSION isting

- Page 81 and 82:

This Page Intentionally Left Blank

- Page 83 and 84:

64 THE PHASES OF PREHENSION ence, w

- Page 85 and 86:

66 THE PHASES OF PREHENSION being p

- Page 87 and 88:

68 (sticks up) THE PHASES OF PREHEN

- Page 89 and 90:

70 THE PHASES OF PREHENSION (right

- Page 91 and 92:

72 THE PHASES OF PREHENSION organiz

- Page 93 and 94:

74 THE PHASES OF PREHENSION movemen

- Page 95 and 96:

76 THE PHASES OF PREHENSION and bas

- Page 97 and 98:

78 THE PHASES OF PREHENSION Figure

- Page 99 and 100:

80 THE PHASES OF PREHENSION Again,

- Page 101 and 102:

82 THE PHASES OF PREHENSION c Oppos

- Page 103 and 104:

84 THE PHASES OF PREHENSION the mac

- Page 105 and 106:

86 THE PHASES OF PREHENSION (surfac

- Page 107 and 108:

88 THE PHASES OF PREHENSION influen

- Page 109 and 110:

90 THE PHASES OF PREHENSION able to

- Page 111 and 112:

92 THE PHASES OF PREHENSION A Pfing

- Page 113 and 114:

94 THE PHASES OF PREHENSION forces,

- Page 115 and 116:

- Computed activation of arm muscle

- Page 117 and 118:

98 THE PHASES OF PREHENSION were in

- Page 119 and 120:

100 THE PHASES OF PREHENSION Figure

- Page 121 and 122:

102 THE PHASES OF PREHENSION same t

- Page 123 and 124:

104 THE PHASES OF PREHENSION OBJECT

- Page 125 and 126:

106 THE PHASES OF PREHENSION planni

- Page 127 and 128:

This Page Intentionally Left Blank

- Page 129 and 130:

110 THE PHASES OF PREHENSION antici

- Page 131 and 132:

112 THE PHASES OF PREHENSION and te

- Page 133 and 134:

114 THE PHASES OF PREHENSION presen

- Page 135 and 136:

116 THE PHASES OF PREHENSION determ

- Page 137 and 138:

118 THE PHASES OF PREHENSION 5.3 Co

- Page 139 and 140:

120 THE PHASES OF PREHENSION tance

- Page 141 and 142:

122 THE PHASES OF PREHENSION where

- Page 143 and 144:

124 THE PHASES OF PREHENSION Figure

- Page 145 and 146:

126 THE PHASES OF PREHENSION A B 18

- Page 147 and 148:

128 THE PHASES OF PREHENSION where

- Page 149 and 150:

130 THE PHASES OF PREHENSION SR = .

- Page 151 and 152:

132 THE PHASES OF PREHENSION MODEL

- Page 153 and 154:

134 THE PHASES OF PREHENSION A B Fi

- Page 155 and 156:

136 THE PHASES OF PREHENSION to mus

- Page 157 and 158:

138 THE PHASES OF PREHENSION method

- Page 159 and 160:

140 THE PHASES OF PREHENSION tire b

- Page 161 and 162:

142 THE PHASES OF PREHENSION torque

- Page 163 and 164:

144 THE PHASES OF PREHENSION relate

- Page 165 and 166:

146 THE PHASES OF PREHENSION the ob

- Page 167 and 168:

148 THE PHASES OF PREHENSION abilit

- Page 169 and 170:

150 THE PHASES OF PREHENSION +60 1

- Page 171 and 172:

152 THE PHASES OF PREHENSION result

- Page 173 and 174:

154 THE PHASES OF PREHENSION the di

- Page 175 and 176:

156 THE PHASES OF PREHENSION crease

- Page 177 and 178:

158 THE PHASES OF PREHENSION betwee

- Page 179 and 180: 160 50 1 THE PHASES OF PREHENSION 1

- Page 181 and 182: 162 THE PHASES OF PREHENSION positi

- Page 183 and 184: - Velocity - Acceleration s-L 1400

- Page 185 and 186: 166 THE PHASES OF PREHENSION vocal

- Page 187 and 188: 168 THE PHASES OF PREHENSION C z3Oo

- Page 189 and 190: 170 THE PHASES OF PREHENSION 150 T

- Page 191 and 192: 172 THE PHASES OF PREHENSION T 150

- Page 193 and 194: 174 THE PHASES OF PREHENSION grasp

- Page 195 and 196: 176 AREA 7 (IPS) THE PHASES OF PREH

- Page 197 and 198: 178 THE PHASES OF PREHENSION books

- Page 199 and 200: 180 THE PHASES OF PREHENSION h .r?.

- Page 201 and 202: 182 THE PHASES OF PREHENSION A B C

- Page 203 and 204: 184 THE PHASES OF PREHENSION (1982b

- Page 205 and 206: 186 THE PHASES OF PREHENSION _ - B

- Page 207 and 208: 188 THE PHASES OF PREHENSION A +6 1

- Page 209 and 210: 190 THE PHASES OF PREHENSION activa

- Page 211 and 212: 192 THE PHASES OF PREHENSION shape,

- Page 213 and 214: 194 THE PHASES OF PREHENSION the st

- Page 215 and 216: 196 THE PHASES OF PREHENSION collap

- Page 217 and 218: 198 THE PHASES OF PREHENSION Obi& T

- Page 219 and 220: 200 THE PHASES OF PREHENSION might

- Page 221 and 222: This Page Intentionally Left Blank

- Page 223 and 224: 204 THE PHASES OF PREHENSION about

- Page 225 and 226: 206 THE PHASES OF PREHENSION hands

- Page 227 and 228: 208 THE PHASES OF PREHENSION Epider

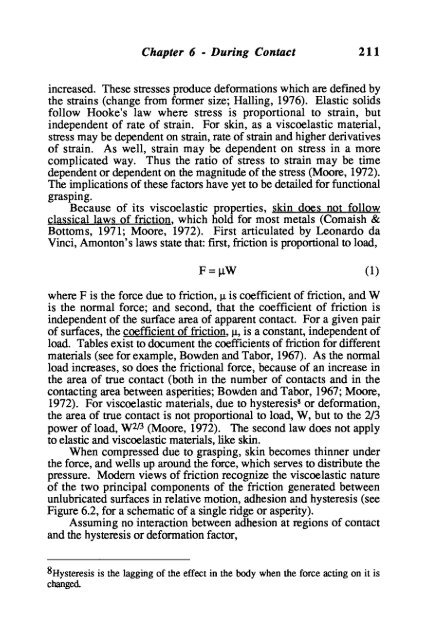

- Page 229: 210 THE PHASES OF PREHENSION the pe

- Page 233 and 234: 214 THE PHASES OF PREHENSION focusi

- Page 235 and 236: 216 THE PHASES OF PREHENSION thermo

- Page 237 and 238: 218 THE PHASES OF PREHENSION nonner

- Page 239 and 240: 220 THE PHASES OF PREHENSION hot-wa

- Page 241 and 242: 222 THE PHASES OF PREHENSION which,

- Page 243 and 244: 224 THE PHASES OF PREHENSION which

- Page 245 and 246: 226 THE PHASES OF PREHENSION for FA

- Page 247 and 248: 228 THE PHASES OF PREHENSION differ

- Page 249 and 250: 230 THE PHASES OF PREHENSION (see C

- Page 251 and 252: 232 THE PHASES OF PREHENSION LATERA

- Page 253 and 254: 234 THE PHASES OF PREHENSION more a

- Page 255 and 256: 236 THE PHASES OF PREHENSION A Poin

- Page 257 and 258: 238 THE PHASES OF PREHENSION Figure

- Page 259 and 260: 240 THE PHASES OF PREHENSION 6.3.2

- Page 261 and 262: 242 THE PHASES OF PREHENSION equati

- Page 263 and 264: 244 THE PHASES OF PREHENSION necess

- Page 265 and 266: 246 THE PHASES OF PREHENSION graspi

- Page 267 and 268: 248 A THE PHASES OF PREHENSION Figu

- Page 269 and 270: 250 z J 2 0 c .- Q el X A THE PHASE

- Page 271 and 272: 252 THE PHASES OF PREHENSION respec

- Page 273 and 274: 254 THE PHASES OF PREHENSION Z 151

- Page 275 and 276: 256 THE PHASES OF PREHENSION mechan

- Page 277 and 278: 258 THE PHASES OF PREHENSION see He

- Page 279 and 280: 260 THE PHASES OF PREHENSION might

- Page 281 and 282:

262 THE PHASES OF PREHENSION long a

- Page 283 and 284:

264 THE PHASES OF PREHENSION with u

- Page 285 and 286:

266 THE PHASES OF PREHENSION Table

- Page 287 and 288:

268 THE PHASES OF PREHENSION system

- Page 289 and 290:

270 THE PHASES OF PREHENSION In cla

- Page 291 and 292:

Table 6.6 Elliott & Connolly (1984)

- Page 293 and 294:

274 THE PHASES OF PREHENSION shape

- Page 295 and 296:

276 THE PHASES OF PREHENSION In imp

- Page 297 and 298:

278 THE PHASES OF PREHENSION cause

- Page 299 and 300:

aie3 INTRINSIC - mughnesn aspect of

- Page 301 and 302:

This Page Intentionally Left Blank

- Page 303 and 304:

284 THE PHASES OF PREHENSION percei

- Page 305 and 306:

286 THE PHASES OF PREHENSION Figure

- Page 307 and 308:

288 THE PHASES OF PREHENSION approa

- Page 309 and 310:

290 5. 6. 7. 8. 9. 10. 11. 12. 13.

- Page 311 and 312:

292 THE PHASES OF PREHENSION Fitts

- Page 313 and 314:

294 THE PHASES OF PREHENSION accele

- Page 315 and 316:

296 THE PHASES OF PREHENSION 27. Ce

- Page 317 and 318:

298 THE PHASES OF PREHENSION charac

- Page 319 and 320:

300 THE PHASES OF PREHENSION are se

- Page 321 and 322:

This Page Intentionally Left Blank

- Page 323 and 324:

This Page Intentionally Left Blank

- Page 325 and 326:

306 CONSTRAINTS AND PHASES Table 8.

- Page 327 and 328:

308 CONSTRAINTS AND PHASES the inde

- Page 329 and 330:

310 CONSTRAINTS AND PHASES While th

- Page 331 and 332:

312 CONSTRAINTS AND PHASES for a gi

- Page 333 and 334:

314 CONSTRAINTS AND PHASES fine, su

- Page 335 and 336:

316 CONSTRAINTS AND PHASES level fi

- Page 337 and 338:

318 CONSTRAINTS AND PHASES spent in

- Page 339 and 340:

z I l l I 0 Y "K ' ,------ Sensorim

- Page 341 and 342:

322 CONSTRAINTS AND PHASES componen

- Page 343 and 344:

324 CONSTRAINTS AND PHASES and the

- Page 345 and 346:

326 CONSTRAINTS AND PHASES 8.6 Summ

- Page 347 and 348:

This Page Intentionally Left Blank

- Page 349 and 350:

330 CONSTRAINTS AND PHASES 9.1 The

- Page 351 and 352:

332 CONSTRAINTS AND PHASES b) impar

- Page 353 and 354:

334 CONSTRAINTS AND PHASES The defi

- Page 355 and 356:

336 CONSTRAINTS AND PHASES less pre

- Page 357 and 358:

338 CONSTRAINTS AND PHASES transpor

- Page 359 and 360:

Opposition Space level Sensorimotor

- Page 361 and 362:

342 CONSTRAINTS AND PHASES 9.3 Futu

- Page 363 and 364:

344 CONSTRAINTS AND PHASES scientif

- Page 365 and 366:

This Page Intentionally Left Blank

- Page 367 and 368:

This Page Intentionally Left Blank

- Page 369 and 370:

350 Appendices Anterior (ventral):

- Page 371 and 372:

352 Appendices =!- / Scapula Acromi

- Page 373 and 374:

354 A pp e n dices Table A.l Degree

- Page 375 and 376:

356 Appendices Table A.l Degrees of

- Page 377 and 378:

358 Appendices Flexion: to bend or

- Page 379 and 380:

360 A pp e n dic e s Table A.2 Join

- Page 381 and 382:

362 A pp e It dices Elbow flex ext

- Page 383 and 384:

364 A pp e n dices Table A.2 Joints

- Page 385 and 386:

366 A pp e n dic e s Table A.3 Inne

- Page 387 and 388:

This Page Intentionally Left Blank

- Page 389 and 390:

370 Appendices Table B.l Prehensile

- Page 391 and 392:

372 Appendices ...... ........... t

- Page 393 and 394:

374 Appendices features of the huma

- Page 395 and 396:

376 Appendices fingers (Kamakura et

- Page 397 and 398:

378 Appendices Table B.3 Postures c

- Page 399 and 400:

380 Appendices opposition, is Napie

- Page 401 and 402:

382 A pp e n dic e s relationships

- Page 403 and 404:

384 A pp e n dic e s C.2 Artificial

- Page 405 and 406:

386 A pp e n dic e s thresholding f

- Page 407 and 408:

388 A pp e n dices processing. This

- Page 409 and 410:

390 Appendices between two units in

- Page 411 and 412:

392 A pp e n dic e s where q is a s

- Page 413 and 414:

394 A pp e It d ic e s training set

- Page 415 and 416:

396 A pp e It dic e s units. Also,

- Page 417 and 418:

398 Appendices only sense is vision

- Page 419 and 420:

400 A pp e n dices of computations

- Page 421 and 422:

402 A pp e n dic e s satisfy active

- Page 423 and 424:

404 Appendices biceps, and shoulder

- Page 425 and 426:

406 Appendices Table D.l Commercial

- Page 427 and 428:

408 Appendices Table D.2 Commercial

- Page 429 and 430:

410 Appendices Sears et al., 1989).

- Page 431 and 432:

412 A ppe It dic e s are active, wh

- Page 433 and 434:

414 A ppen die es automatic lock wh

- Page 435 and 436:

416 A pp e n dices between the thum

- Page 437 and 438:

418 Appendices D.3.1 Stanford/JPL h

- Page 439 and 440:

420 A pp e n dices D.3.3 Belgrade/U

- Page 441 and 442:

This Page Intentionally Left Blank

- Page 443 and 444:

424 THE GRASPING HAND Arbib, M.A. (

- Page 445 and 446:

426 THE GRASPING HAND Bullock, D.,

- Page 447 and 448:

428 THE GRASPING HAND Cutkosky, M.R

- Page 449 and 450:

430 THE GRASPING HAND Focillon, H.

- Page 451 and 452:

432 THE GRASPING HAND Gordon, A.M.,

- Page 453 and 454:

434 THE GRASPING HAND Hollerbach, J

- Page 455 and 456:

436 THE GRASPING HAND Jeannerod, M.

- Page 457 and 458:

438 THE GRASPING HAND Kamakura, N.,

- Page 459 and 460:

440 THE GRASPING HAND Landsmeer, J.

- Page 461 and 462:

442 THE GRASPING HAND MacKenzie, C.

- Page 463 and 464:

444 THE GRASPING HAND Moore, D.F. (

- Page 465 and 466:

446 THE GRASPING HAND Phillips, C.G

- Page 467 and 468:

448 THE GRASPING HAND Rumelhart, D.

- Page 469 and 470:

450 THE GRASPING HAND disconnection

- Page 471 and 472:

452 THE GRASPING HAND Weir, P.L. (1

- Page 473 and 474:

This Page Intentionally Left Blank

- Page 475 and 476:

456 THE GRASPING HAND Childress, D.

- Page 477 and 478:

458 THE GRASPING HAND Johansson, R.

- Page 479 and 480:

460 THE GRASPING HAND Proteau, L.,

- Page 481 and 482:

This Page Intentionally Left Blank

- Page 483 and 484:

464 THE GRASPING HAND level, of map

- Page 485 and 486:

466 THE GRASPING HAND a h Generaliz

- Page 487 and 488:

468 THE GRASPING HAND Forces. Force

- Page 489 and 490:

470 THE GRASPING HAND han& Robotics

- Page 491 and 492:

472 THE GRASPING HAND and force coo

- Page 493 and 494:

474 THE GRASPING HAND and task requ

- Page 495 and 496:

476 THE GRASPING HAND Pen, as grasp

- Page 497 and 498:

478 THE GRASPING HAND Screwdriver,

- Page 499 and 500:

480 THE GRASPING HAND and oppositio

- Page 501:

482 THE GRASPING HAND and grasping,