BLACkMER PUMPS - National Energy Equipment

BLACkMER PUMPS - National Energy Equipment

BLACkMER PUMPS - National Energy Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

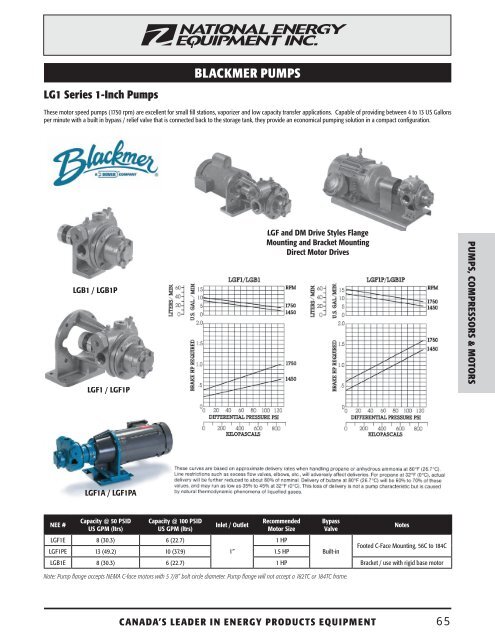

LG1 Series 1-Inch Pumps<br />

<strong>BLACkMER</strong> <strong>PUMPS</strong><br />

These motor speed pumps (1750 rpm) are excellent for small fi ll stations, vaporizer and low capacity transfer applications. Capable of providing between 4 to 13 US Gallons<br />

per minute with a built in bypass / relief valve that is connected back to the storage tank, they provide an economical pumping solution in a compact confi guration.<br />

NEE #<br />

lgB1 / lgB1P<br />

lgF1 / lgF1P<br />

lgF1a / lgF1Pa<br />

Capacity @ 50 PSId<br />

uS gPm (ltrs)<br />

Capacity @ 100 PSId<br />

uS gPm (ltrs)<br />

LGF1E 8 (30.3) 6 (22.7)<br />

Inlet / Outlet<br />

lgF and dm drive Styles Flange<br />

mounting and Bracket mounting<br />

direct motor drives<br />

recommended<br />

motor Size<br />

LGF1PE 13 (49.2) 10 (37.9) 1”<br />

1.5 HP<br />

Bypass<br />

Valve<br />

Note: Pump fl ange accepts NEMA C-face motors with 5 7/8” bolt circle diameter. Pump fl ange will not accept a 182TC or 184TC frame.<br />

1 HP<br />

Built-in<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 65<br />

Notes<br />

Footed C-Face Mounting, 56C to 184C<br />

LGB1E 8 (30.3) 6 (22.7) 1 HP Bracket / use with rigid base motor<br />

<strong>PUMPS</strong>, COMPRESSORS & MOTORS

<strong>PUMPS</strong>, COMPRESSORS & MOTORS<br />

66<br />

<strong>BLACkMER</strong> <strong>PUMPS</strong><br />

LGL and LGRL 1 1/4-Inch and 1 1/2-Inch Pumps<br />

Designed for small to medium capacity requirements such as auto propane dispensers and multiple scale bottle fi lling applications. Capacities range from 14 to 33 US Gallons<br />

per minute. These pumps have a built in relief valve to protect the downstream piping system but they require the use of an external bypass valve to set the discharge<br />

pressure and protect the pump from premature wear.<br />

Features a redesigned cavitation suppression liner. Various motor confi gurations are available and are sized based<br />

on the pressure and fl ow requirements of the application as well as the electrical power available on site. Pump<br />

assemblies can be provided by NEE and would include the pump and motor, mounted on a base plate with couplings<br />

and coupling guard ready to be connected to your piping and electrical system.<br />

lgrl1.25 / lgl1.25 / lgl1.5<br />

NEE #<br />

Capacity @ 50 PSId<br />

uS gPm (ltrs)<br />

lgrlF1.25 / lglF1.25<br />

Capacity @ 100 PSId<br />

uS gPm (ltrs)<br />

Note: Maximum differential pressure rating with a 2 HP motor is 80 PSID.<br />

Inlet / Outlet<br />

lgF and dm drive Styles Flange<br />

mounting and Foot mounting<br />

direct motor drives<br />

recommended<br />

motor Size<br />

LGRLF1.25A 16 (60.6) 14 (53.0) 1-1/4” 2 HP / 3 HP BV34<br />

Bypass<br />

Valve<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

Notes<br />

Footed C-Face Mounting<br />

56C to 184C<br />

LGL1.25 21 (79.5) 18 (68.1) 1-1/4” 2 HP / 3 HP BV34 Foot / base mounted pump<br />

LGL1.5 33 (124.9) 29 (109.8) 1-1/2” 3 HP BV1 Foot / base mounted pump

LGL 2-Inch, 3-Inch and 4-Inch Plant Pumps<br />

<strong>BLACkMER</strong> <strong>PUMPS</strong><br />

High capacity pumps for bulk plant, cylinder filling, bobtail and transport truck loading. These pumps are available in V-Belt or gear drive speed reduction configurations.<br />

Motor selection and speed determines the capacities, please contact NEE for performance curves and application requirements. Weld connection flanges are available<br />

as an option. Complete base mounted assemblies include: pump, base, motor slider base, belts, sheaves, pulleys, belts and a motor selected based on your application<br />

requirements.<br />

NEE #<br />

VB drive Style<br />

V-Belt drive<br />

Capacity @ 50 PSId uS<br />

gPm (ltrs)<br />

Capacity @ 100 PSId<br />

uS gPm (ltrs)<br />

Inlet / Outlet<br />

lgld4<br />

Cutaway<br />

recommended<br />

motor Size<br />

hr drive Style helical<br />

gear reduction drive<br />

LGLD2E 67 (254) 57 (216) 2” NPT 3 HP / 7.5 HP BV 114 / BV112 Foot / base mounted pump<br />

LGLD3E 133 (503) 112 (428) 3” NPT 10 HP / 15 HP BV 114 / BV112 / BV2 Foot / base mounted pump<br />

LGLD4A 270 (1022) 220 (823) 4” / 3” Weld 20 HP / 30 HP BV112 / BV2 Foot / base mounted pump<br />

Bypass<br />

Valve<br />

Note: Capacities listed are approximate and will vary based on the speed selected and variables in your piping system as well ambient temperatures.<br />

Contact NEE and request a copy of Blackmer Bulletin 501 for performance details<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 67<br />

Notes<br />

<strong>PUMPS</strong>, COMPRESSORS & MOTORS

<strong>PUMPS</strong>, COMPRESSORS & MOTORS<br />

LGLH2A-N High Pressure LPG Pump<br />

Suited for High differential delivery requirements the LGLH2A-N is ideal for<br />

Aerosol filling, vaporizer feed and any other high differential pressure applications<br />

requiring capacities up to 100 USGPM.<br />

Features:<br />

n 165 psid capabilities<br />

n Sliding Vane, positive displacement design for<br />

consistent performance<br />

n Dimensionally interchangeable with LGLD2<br />

n Operates at speeds up to 980 rpm<br />

n Patented cavitaion suppression liner<br />

n Replaceable liner and end plate discs<br />

n Flanged inlet and outlet connections<br />

68<br />

lglh2a-N<br />

Cutaway<br />

Autogas LGL158 Pump<br />

Blackmer’s Continuous Duty High<br />

Pressure LPG Pump is ideally suited<br />

for applications requiring high<br />

differential pressures. This motor<br />

speed, sliding vane pump features a<br />

cavitation supression liner, flanged<br />

inlet / outlet connections, replaceable<br />

liner and end plates. With suction lift<br />

up to 4 meters, this pump is ideal for<br />

underground applications.<br />

NEE #<br />

Capacity @ 150 PSId<br />

uS gPm (ltrs)<br />

<strong>BLACkMER</strong> <strong>PUMPS</strong><br />

U.S. GALLONS PER MINUTE<br />

MOTOR HORSEPOWER REQUIRED<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

CHARACTERISTIC CURVES<br />

Models: Capacity LGH2 @ 145 PSId Inlet /<br />

NEE #<br />

uS gPm (ltrs) Outlet<br />

recommended<br />

motor Size<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

Page Number 501-025<br />

Effective July 2005<br />

recommended<br />

Bypass Valve<br />

Replaces new<br />

Section 501<br />

LGLH2A-N 47 (182) at 640 RPM 2” 10 HP BV1.25 / BV1.5<br />

LGLH2<br />

(KILOPASCALS)<br />

0 200 400 600 800 1,000 1,200<br />

0 200 400 600 800 1,000 1,200<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200<br />

DIFFERENTIAL PRESSURE - PSI<br />

Blackmer Characteristic Curves are based on Brake Horsepower (BHp). To determine Motor Horsepower, drive<br />

train inefficiencies must be added to the BHp.<br />

These curves are based on approximate delivery rates when handling propane or anhydrous ammonia at 80ºF<br />

(26.7ºC). Line restrictions such as excess flow valves, elbows, etc., will adversely effect deliveries. For propane<br />

at 32ºF (0ºC), actual delivery will be further reduced to about 80% of nominal. Delivery of butane at 80ºF (26.7ºC)<br />

will be 60 to 70% of these values, and may run as low as 35 to 45% at 32ºF (0ºC). This loss of delivery is not a<br />

pump characteristic but is caused by natural thermodynamic phenomena of liquefied gases.<br />

Motor speeds listed are nominal. Actual pump speed and performance may very depending on conditions.<br />

Inlet Outlet<br />

recommended<br />

motor Size<br />

LGL158 33.3 (122) 2” ANSI 300# RF Flange 1 1/2” ANSI 300# RF Flange 5HP / 10HP BV34 / BV1<br />

980<br />

RPM<br />

980<br />

RPM<br />

780<br />

780<br />

640<br />

520<br />

420<br />

350<br />

640<br />

520<br />

420<br />

350<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

LITERS PER MINUTE<br />

KILOWATTS<br />

Bypass Valve Notes<br />

www.blackmer.com<br />

Foot / base mounted pump 225<br />

PSI relief valve setting, 1750<br />

rpm operating speed

Truck Pumps<br />

<strong>BLACkMER</strong> <strong>PUMPS</strong><br />

Blackmer’s TLG series truck pumps feature a double pump shaft for left or right hand PTO rotation, integral safety relief valve and<br />

auxiliary intake ports for emergency unloading of another tank or truck. These pumps are excellent workhorses for bobtail and<br />

transport trucks. Maximum differential pressure on the older 3 and 4 inch truck pumps is 650 psid, but the TLGLF3C and TLGLF4B<br />

are capable of differential pressures up to 870 psid.<br />

TlglF3<br />

Cutaway<br />

CHARACTERISTIC CURVES<br />

LG, LD and TLG Series Pumps<br />

NOTE: Blackmer Characteristic Curves are based on Brake Horsepower (BHp). To determine Motor Horsepower, drive train inefficiencies<br />

must be added to the BHp.<br />

These curves are based on approximate delivery rates when handling propane or anhydrous ammonia at 80ºF (26.7ºC). Line restrictions such<br />

as excess flow valves, elbows, etc., will adversely effect deliveries. For propane at 32ºF (0ºC), actual delivery will be further reduced to about<br />

80% of nominal. Delivery of butane at 80ºF (26.7ºC) will be 60 to 70% of these values, and may run as low as 35 to 45% at 32ºF (0ºC). This<br />

loss of delivery is not a pump characteristic but is caused by natural thermodynamic phenomena of liquefied gases.<br />

NEE #<br />

Capacity @ 50 PSId<br />

uS gPm (ltrs)<br />

Capacity @ 100 PSId<br />

uS gPm (ltrs)<br />

Inlet<br />

auxiliary<br />

Inlet /Outlet<br />

TlglF4<br />

Cutaway<br />

Bypass<br />

Valve<br />

TLGLF3C 93 (352) 81 (307) 3” ANSI Flange 2” / 2” NPT BV112 / BV2<br />

Notes Pump gasket to<br />

Fisher ISC Valves<br />

C404-24 - 1P8777699152 /<br />

C403-24 - T10561138992<br />

TLGLF4B 400 (1511) 329 (1244) 4” ANSI Flange 3” / 2” NPT BV2 C404-32 T1118299152<br />

* Capacity of TLGLF4B is based on pump speed of 870 RPM.<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 69<br />

<strong>PUMPS</strong>, COMPRESSORS & MOTORS