Achieve More Productivity with OPTIMASS - Krohne

Achieve More Productivity with OPTIMASS - Krohne Achieve More Productivity with OPTIMASS - Krohne

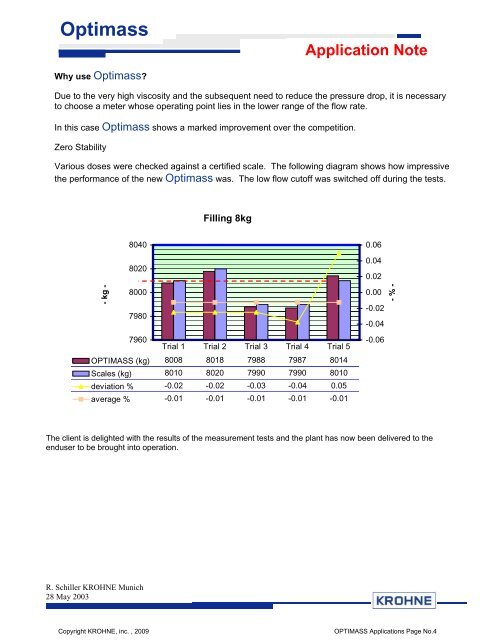

Optimass Why use Optimass? Application Note Due to the very high viscosity and the subsequent need to reduce the pressure drop, it is necessary to choose a meter whose operating point lies in the lower range of the flow rate. In this case Optimass shows a marked improvement over the competition. Zero Stability Various doses were checked against a certified scale. The following diagram shows how impressive the performance of the new Optimass was. The low flow cutoff was switched off during the tests. - kg - 8040 8020 8000 7980 7960 Filling 8kg Trial 1 Trial 2 Trial 3 Trial 4 Trial 5 OPTIMASS (kg) 8008 8018 7988 7987 8014 Scales (kg) 8010 8020 7990 7990 8010 deviation % -0.02 -0.02 -0.03 -0.04 0.05 average % -0.01 -0.01 -0.01 -0.01 -0.01 The client is delighted with the results of the measurement tests and the plant has now been delivered to the enduser to be brought into operation. R. Schiller KROHNE Munich 28 May 2003 Copyright KROHNE, inc. , 2009 OPTIMASS Applications Page No.4 0.06 0.04 0.02 0.00 -0.02 -0.04 -0.06 - % -

Optimass Through local representative Control Engineering S.A., KROHNE beat E+H, ABB and Siemens (Danfoss) with the best technology; the lowest pressure drop on process and a reasonable price. But what really impressed LEONA was the wide flow range Optimass could handle, because production will be doubled over the next 5 years, and our meters could make the transition. Application Note INDUSTRY: BEVERAGE COUNTRY: COLOMBIA METER: OPTIMASS 80S CERVECERÍA BAVARIA S.A. is a beer monopoly in Colombia which ranks number 10 of the largest breweries world wide. They have seven plants in Colombia, dominate the beer market in Ecuador and Panama, and produce more than 60% of beer consumed in Peru. Among their plants in Colombia, they have CERVECERÍA LEONA, one of the more modern plants in South America, built in 1994. Because BAVARIA is focused on increasing efficiency, they want to measure several points of the process to detect process loss. So at LEONA they instigated a pilot trial using mass flow meters for wort in kitchens as well as for bright beer after filtration. Copyright KROHNE, inc. , 2009 OPTIMASS Applications Page No.5

- Page 1 and 2: Straight to the heart of the matter

- Page 3: Optimass Application Note Brewing B

- Page 7 and 8: Optimass Application Note Tequila i

- Page 9 and 10: Application Story Application STRAI

- Page 11 and 12: Coriolis Mass Flow Application Stor

- Page 13 and 14: Process Parameters Product: Salad D

- Page 15 and 16: Above: Our KROHNE Service Engineer

- Page 17 and 18: Application Story - Bio-Ethanol Pro

- Page 19 and 20: Biodiesel in Germany The photo at r

- Page 21 and 22: Application Story - Chemical Indust

- Page 23 and 24: Tanker loading using 6 OPTIMASS met

- Page 25 and 26: Application Story - Chemical Dosing

- Page 27 and 28: Application Story: Liquid Sulphur m

- Page 29 and 30: Application Story Akzo Nobel UK Wor

- Page 31 and 32: Application Story - Petrochemicals

- Page 33 and 34: Coriolis Mass Flow Application Stor

- Page 35 and 36: Optimas Sand Separation Application

- Page 37 and 38: The Adaptive Sensor Technology of O

- Page 39 and 40: Changing to KROHNE Coriolis meters.

- Page 41 and 42: Application Stories Density Measure

- Page 43 and 44: Application Story Enzyme Production

- Page 45 and 46: The Forgotten Meters? …. continue

- Page 47 and 48: Application Story - Carbon Black Pr

- Page 49 and 50: Application Story - 1 st Optimass 2

- Page 51 and 52: Application: Loading Station Why KR

- Page 53 and 54: Application Story - Siemens Gasific

Optimass<br />

Why use Optimass?<br />

Application Note<br />

Due to the very high viscosity and the subsequent need to reduce the pressure drop, it is necessary<br />

to choose a meter whose operating point lies in the lower range of the flow rate.<br />

In this case Optimass shows a marked improvement over the competition.<br />

Zero Stability<br />

Various doses were checked against a certified scale. The following diagram shows how impressive<br />

the performance of the new Optimass was. The low flow cutoff was switched off during the tests.<br />

- kg -<br />

8040<br />

8020<br />

8000<br />

7980<br />

7960<br />

Filling 8kg<br />

Trial 1 Trial 2 Trial 3 Trial 4 Trial 5<br />

<strong>OPTIMASS</strong> (kg) 8008 8018 7988 7987 8014<br />

Scales (kg) 8010 8020 7990 7990 8010<br />

deviation % -0.02 -0.02 -0.03 -0.04 0.05<br />

average % -0.01 -0.01 -0.01 -0.01 -0.01<br />

The client is delighted <strong>with</strong> the results of the measurement tests and the plant has now been delivered to the<br />

enduser to be brought into operation.<br />

R. Schiller KROHNE Munich<br />

28 May 2003<br />

Copyright KROHNE, inc. , 2009 <strong>OPTIMASS</strong> Applications Page No.4<br />

0.06<br />

0.04<br />

0.02<br />

0.00<br />

-0.02<br />

-0.04<br />

-0.06<br />

- % -