Proceedings World Bioenergy 2010

Proceedings World Bioenergy 2010

Proceedings World Bioenergy 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

form of heat and constitutes 0.65% in UA’s total primary<br />

energy supply (TPES) [20]. UA utilises biomass mainly<br />

as firewood [21]. Wood pellet production is primarily<br />

export oriented [22,23]. Crop residues are burnt in<br />

converted and specifically designed boilers [20,24,25].<br />

There exist up to 25 straw-fired boilers in rural areas in<br />

UA [26]. A few farms operate small-scale individual<br />

biogas units [20]. Among larger biogas installations a few<br />

pilot projects were carried out in 2004-2009 [27,28].<br />

Today only a few large-scale plantations of energy crops<br />

(i.e. coppice crops and perennial grasses) exist in UA<br />

[23]. All of them have been introduced quite recently,<br />

and have not been harvested yet. There exist six first<br />

generation bioethanol production plants with a total<br />

capacity of 135 000 million tonnes per year [29] and<br />

eight big oil-extracting plants that produce rapeseed oil<br />

[24] in the country.<br />

2.2 Potentials for energy from biomass and straw<br />

Total technical potential of biomass and peat is<br />

estimated at 1062 PJ per year or 18.11% in the country’s<br />

TPES [14]. Annual potentials for agricultural residues<br />

and energy crops constitute the main share equalling<br />

739 PJ (or 69.5% in the country’s overall biomass<br />

potential).<br />

Straw has the highest potential among all agricultural<br />

residues - 175 PJ per year (or 16.5% of total biomass<br />

potential). Every year from 6-8 [13] to 10.2 [17] million<br />

tonnes of straw can be used for energy production in UA<br />

without putting other needs in straw under pressure. In<br />

addition, straw is also considered to be one of the easiest<br />

and the cheapest biomass options that can be developed<br />

in Ukrainian conditions [13,15,30]. For the farms with<br />

their own straw resources a straw-fired boiler payback is<br />

1-2 years while for those that purchase straw at USD 26-<br />

33 per tonne it is about 3 years [15].<br />

Current total annual fuel consumption in all boiler<br />

houses in rural areas of UA constitutes about 84 PJ,<br />

which can be fully supplied with straw resources<br />

available in the country [31]. At present the main share of<br />

straw use for energy is performed in UTEM boilers [32],<br />

the total installed capacity of which is about 8.9 MW.<br />

Annual use of straw in these boilers is about 14 100<br />

tonnes (or 0.2 PJ) [33,16].<br />

2.3 Technology for crop residue use for energy<br />

Straw combustion technology in UA is represented<br />

with a few companies that produce straw-fired boilers<br />

and their parts, heat generators and grain-drying units that<br />

use straw and/or other crop residues as a fuel.<br />

The biggest straw-fired boiler manufacturer and the<br />

only one that produces water-based straw-fired boilers<br />

with the capacity of up to 1 MW that can be used for the<br />

heating of premises is OJSC UTEM [26,32]. UTEM<br />

produces boilers under the license of Danish company<br />

Passat Energi A/S; it also provides design works,<br />

arranges heat works and service maintenance [32].<br />

Currently up to 25 UTEM boilers are installed in<br />

different regions in UA [26], which in most cases<br />

produce heat for municipal buildings in the villages (i.e.<br />

schools, kindergartens, premises of village councils,<br />

cultural centres, multi-storeyed living houses, etc.) or/and<br />

for local agricultural enterprises.<br />

Scientific Engineering Centre (SEC) Biomass carries<br />

out research and development of straw-fired heat<br />

generators [34]. OJSC Bryg is one of the few companies<br />

that produce biomass-fired heat generators and grain-<br />

drying units on biomass [35]. Currently about 20 Bryg<br />

products are installed in the country [36]. There are also a<br />

few manufacturers of heat generators and boilers that<br />

work on a mixture of solid fuels [37-40].<br />

2.4 Market potential for crop residues<br />

SEC Biomass estimated technical and commercial<br />

potential for biomass boilers and suggests that by 2015<br />

total thermal capacity of wood-, straw- and peat-fired<br />

boilers in UA can reach 9000 MW [21]. This would<br />

allow to reduce GHG emissions by 11 million tonnes per<br />

year and substitute 5.44 billion m 3 of natural gas<br />

annually. The total estimated investment cost is about<br />

USD 0.64 billion [21].<br />

In October 2009 97% of briquettes from sunflower<br />

husk and 100% straw briquettes produced in UA were<br />

sold outside the country [41]. The main markets can be<br />

found in Poland with smaller amount sold in Germany,<br />

Czech Republic, Hungary and Lithuania.<br />

2.5 Support schemes and mechanisms<br />

Ukrainian government accepted a number of<br />

documents supporting bioenergy development in the<br />

country. The State Development Programme of Biofuel<br />

Production and Consumption is the framework policy. It<br />

aims to increase the share of biofuels in the national<br />

energy balance to 5-7% [42]. Other important laws in this<br />

area include the Law of UA On Amendments to Some<br />

Laws of Ukraine on Support of Biofuel Production and<br />

Consumption, which sets a target to increase the share of<br />

biofuel use to 20% in total fuel consumption in the<br />

country by 2020 [43]; the so called Law On Green<br />

Electricity Tariff, and a set of Laws On Minimisation of<br />

Financial Crisis Impact. The latter laws set specific<br />

economic support mechanisms. <strong>Bioenergy</strong> projects in UA<br />

can also be developed as joint implementation (JI)<br />

projects under Kyoto Protocol [44].<br />

3 METHODOLOGY<br />

3.1 General approach<br />

This work presents results on straw use for energy in<br />

UA and compares them to similar experiences in SE and<br />

DK. A detailed analysis of nine initiatives (Table I) on<br />

straw for energy is applied to underpin the proposal of<br />

three types of ABFs for organisation and action in<br />

Ukrainian setting. ABFs are developed for each case, and<br />

then contrasted and compared in a cross-case analysis<br />

and a broader cross-country context.<br />

Coverage topics that have driven case study selection<br />

are given in Table II.<br />

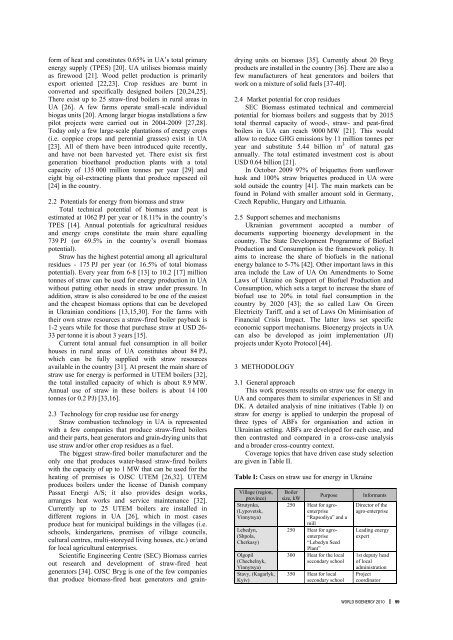

Table I: Cases on straw use for energy in Ukraine<br />

Village (region,<br />

province)<br />

Strutynka,<br />

(Lypovetsk,<br />

Vinnytsya)<br />

Lebedyn,<br />

(Shpola,<br />

Cherkasy)<br />

Olgopil<br />

(Chechelnyk,<br />

Vinnytsya)<br />

Stavy, (Kagarlyk,<br />

Kyiv)<br />

Boiler<br />

size, kW<br />

Purpose Informants<br />

250 Heat for agro- Director of the<br />

enterprise<br />

“Rapsodiya” and a<br />

mill<br />

agro-enterprise<br />

250 Heat for agro- Leading energy<br />

enterprise<br />

“Lebedyn Seed<br />

Plant”<br />

expert<br />

300 Heat for the local 1st deputy head<br />

secondary school of local<br />

administration<br />

350 Heat for local Project<br />

secondary school coordinator<br />

world bioenergy <strong>2010</strong><br />

99