Proceedings World Bioenergy 2010

Proceedings World Bioenergy 2010

Proceedings World Bioenergy 2010

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Figure 3: Accumulated emissions from the boiler during<br />

first 12 hours operation in the realistic sequence.<br />

Figure 4: Accumulated emissions from the stove during<br />

first 12 hours operation in the realistic sequence.<br />

Accumulated total emissions during the six-days test<br />

are plotted together with CO emission to show operating<br />

cycles in figure 3 for the boiler and in figure 4 for the<br />

stove. The boiler had higher number of start-up and stop<br />

within the same time interval due to its higher nominal<br />

power and smaller heat storage. Sudden rises of CO and<br />

TOC emissions are shown during start-up and stop.<br />

The NO emissions emitted during the stop period was<br />

small in relation to the accumulated NO emission.<br />

Particles during start and stop periods are not as<br />

dominating as for CO and TOC although emissions peaks<br />

occur. The contribution of start-up and stop phases to<br />

total accumulated emissions are shown in figure 5. The<br />

start-up and stop phases contribute 39% of the total PM<br />

emission for the boiler and 23% of PM for the stove. The<br />

amount of start-up and stop emissions are dominating for<br />

CO and TOC emissions contributing by 95% and 89%<br />

respectively at the 20kW boiler and 82% and 89 %<br />

respectively at the 12 kW stove.<br />

Figure 5: Accumulated start-up and stop emissions<br />

during six days test<br />

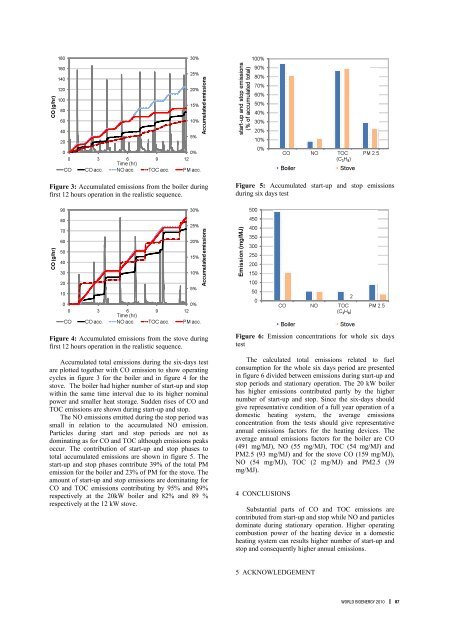

Figure 6: Emission concentrations for whole six days<br />

test<br />

The calculated total emissions related to fuel<br />

consumption for the whole six days period are presented<br />

in figure 6 divided between emissions during start-up and<br />

stop periods and stationary operation. The 20 kW boiler<br />

has higher emissions contributed partly by the higher<br />

number of start-up and stop. Since the six-days should<br />

give representative condition of a full year operation of a<br />

domestic heating system, the average emissions<br />

concentration from the tests should give representative<br />

annual emissions factors for the heating devices. The<br />

average annual emissions factors for the boiler are CO<br />

(491 mg/MJ), NO (55 mg/MJ), TOC (54 mg/MJ) and<br />

PM2.5 (93 mg/MJ) and for the stove CO (159 mg/MJ),<br />

NO (54 mg/MJ), TOC (2 mg/MJ) and PM2.5 (39<br />

mg/MJ).<br />

4 CONCLUSIONS<br />

Substantial parts of CO and TOC emissions are<br />

contributed from start-up and stop while NO and particles<br />

dominate during stationary operation. Higher operating<br />

combustion power of the heating device in a domestic<br />

heating system can results higher number of start-up and<br />

stop and consequently higher annual emissions.<br />

5 ACKNOWLEDGEMENT<br />

world bioenergy <strong>2010</strong><br />

87