State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

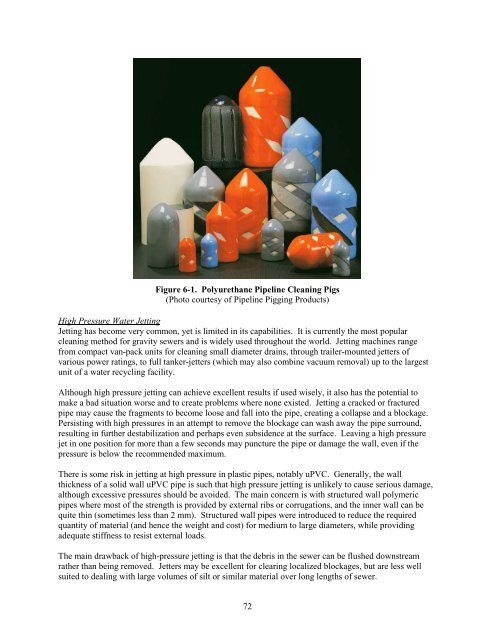

Figure 6-1. Polyurethane Pipeline Cleaning Pigs<br />

(Photo courtesy <strong>of</strong> Pipeline Pigging Products)<br />

High Pressure Water Jetting<br />

Jetting has become very common, yet is limited in its capabilities. It is currently the most popular<br />

cleaning method <strong>for</strong> gravity sewers and is widely used throughout the world. Jetting machines range<br />

from compact van-pack units <strong>for</strong> cleaning small diameter drains, through trailer-mounted jetters <strong>of</strong><br />

various power ratings, to full tanker-jetters (which may also combine vacuum removal) up to the largest<br />

unit <strong>of</strong> a water recycling facility.<br />

Although high pressure jetting can achieve excellent results if used wisely, it also has the potential to<br />

make a bad situation worse and to create problems where none existed. Jetting a cracked or fractured<br />

pipe may cause the fragments to become loose and fall into the pipe, creating a collapse and a blockage.<br />

Persisting with high pressures in an attempt to remove the blockage can wash away the pipe surround,<br />

resulting in further destabilization and perhaps even subsidence at the surface. Leaving a high pressure<br />

jet in one position <strong>for</strong> more than a few seconds may puncture the pipe or damage the wall, even if the<br />

pressure is below the recommended maximum.<br />

There is some risk in jetting at high pressure in plastic pipes, notably uPVC. Generally, the wall<br />

thickness <strong>of</strong> a solid wall uPVC pipe is such that high pressure jetting is unlikely to cause serious damage,<br />

although excessive pressures should be avoided. The main concern is with structured wall polymeric<br />

pipes where most <strong>of</strong> the strength is provided by external ribs or corrugations, and the inner wall can be<br />

quite thin (sometimes less than 2 mm). Structured wall pipes were introduced to reduce the required<br />

quantity <strong>of</strong> material (and hence the weight and cost) <strong>for</strong> medium to large diameters, while providing<br />

adequate stiffness to resist external loads.<br />

The main drawback <strong>of</strong> high-pressure jetting is that the debris in the sewer can be flushed downstream<br />

rather than being removed. Jetters may be excellent <strong>for</strong> clearing localized blockages, but are less well<br />

suited to dealing with large volumes <strong>of</strong> silt or similar material over long lengths <strong>of</strong> sewer.<br />

72