State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rolldown<br />

Rolldown was developed in the late 1980s by Subterra (a division <strong>of</strong> Daniels Contractors Ltd., UK) as a<br />

complement to Swagelining and was used in the British Gas renovation program. Rolldown uses<br />

standard grade PE (PE3408) and is available in diameters from 4 to 20 inches (100 to 500 mm).<br />

Depending on diameter and starting DR <strong>of</strong> the stock liner, pressure ratings up to 232 psi (16 bar) are<br />

achievable. Rolldown has been installed up to 5,000 feet (1,524 meters) in one insertion. The PE pipe<br />

holds its reduced diameter indefinitely prior to reversion, which allows <strong>for</strong> interruptions during the<br />

insertion process which is not possible with a tension-based system. The string <strong>of</strong> PE pipes can be pulled<br />

through a bend <strong>of</strong> up to 11.25 degrees. After insertion, the line is reverted to its original diameter by<br />

water pressure. Standard couplings are attached to the ends <strong>of</strong> the PE pipe and used to reconnect to<br />

fittings or the existing main.<br />

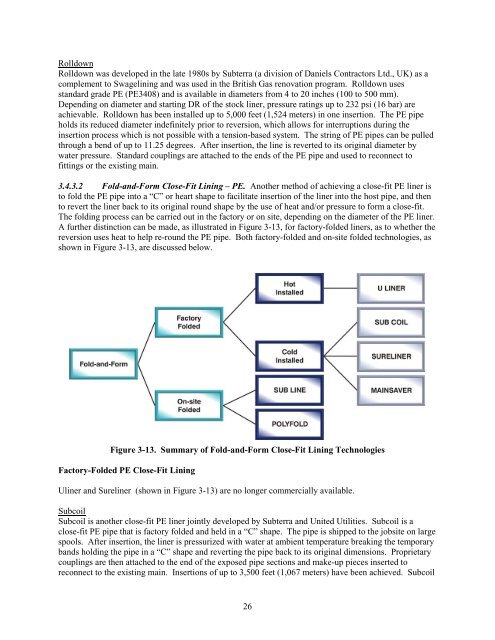

3.4.3.2 Fold-and-Form Close-Fit Lining – PE. Another method <strong>of</strong> achieving a close-fit PE liner is<br />

to fold the PE pipe into a “C” or heart shape to facilitate insertion <strong>of</strong> the liner into the host pipe, and then<br />

to revert the liner back to its original round shape by the use <strong>of</strong> heat and/or pressure to <strong>for</strong>m a close-fit.<br />

The folding process can be carried out in the factory or on site, depending on the diameter <strong>of</strong> the PE liner.<br />

A further distinction can be made, as illustrated in Figure 3-13, <strong>for</strong> factory-folded liners, as to whether the<br />

reversion uses heat to help re-round the PE pipe. Both factory-folded and on-site folded technologies, as<br />

shown in Figure 3-13, are discussed below.<br />

Figure 3-13. Summary <strong>of</strong> Fold-and-Form Close-Fit Lining Technologies<br />

Factory-Folded PE Close-Fit Lining<br />

Uliner and Sureliner (shown in Figure 3-13) are no longer commercially available.<br />

Subcoil<br />

Subcoil is another close-fit PE liner jointly developed by Subterra and United Utilities. Subcoil is a<br />

close-fit PE pipe that is factory folded and held in a “C” shape. The pipe is shipped to the jobsite on large<br />

spools. After insertion, the liner is pressurized with water at ambient temperature breaking the temporary<br />

bands holding the pipe in a “C” shape and reverting the pipe back to its original dimensions. Proprietary<br />

couplings are then attached to the end <strong>of</strong> the exposed pipe sections and make-up pieces inserted to<br />

reconnect to the existing main. Insertions <strong>of</strong> up to 3,500 feet (1,067 meters) have been achieved. Subcoil<br />

26