State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

more appropriate to a water main where the cleaning solution can be easily re-circulated. More<br />

in<strong>for</strong>mation on cleaning methods and technologies is covered in Section 6.<br />

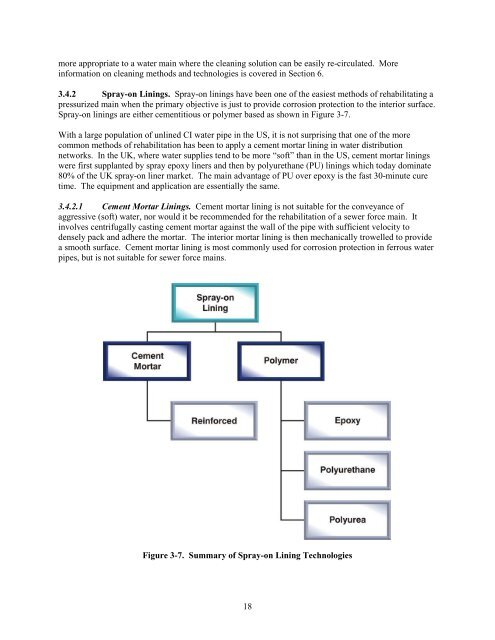

3.4.2 Spray-on Linings. Spray-on linings have been one <strong>of</strong> the easiest methods <strong>of</strong> rehabilitating a<br />

pressurized main when the primary objective is just to provide corrosion protection to the interior surface.<br />

Spray-on linings are either cementitious or polymer based as shown in Figure 3-7.<br />

With a large population <strong>of</strong> unlined CI water pipe in the US, it is not surprising that one <strong>of</strong> the more<br />

common methods <strong>of</strong> rehabilitation has been to apply a cement mortar lining in water distribution<br />

networks. In the UK, where water supplies tend to be more “s<strong>of</strong>t” than in the US, cement mortar linings<br />

were first supplanted by spray epoxy liners and then by polyurethane (PU) linings which today dominate<br />

80% <strong>of</strong> the UK spray-on liner market. The main advantage <strong>of</strong> PU over epoxy is the fast 30-minute cure<br />

time. The equipment and application are essentially the same.<br />

3.4.2.1 Cement Mortar Linings. Cement mortar lining is not suitable <strong>for</strong> the conveyance <strong>of</strong><br />

aggressive (s<strong>of</strong>t) water, nor would it be recommended <strong>for</strong> the rehabilitation <strong>of</strong> a sewer <strong>for</strong>ce main. It<br />

involves centrifugally casting cement mortar against the wall <strong>of</strong> the pipe with sufficient velocity to<br />

densely pack and adhere the mortar. The interior mortar lining is then mechanically trowelled to provide<br />

a smooth surface. Cement mortar lining is most commonly used <strong>for</strong> corrosion protection in ferrous water<br />

pipes, but is not suitable <strong>for</strong> sewer <strong>for</strong>ce mains.<br />

Figure 3-7. Summary <strong>of</strong> Spray-on Lining Technologies<br />

18