State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

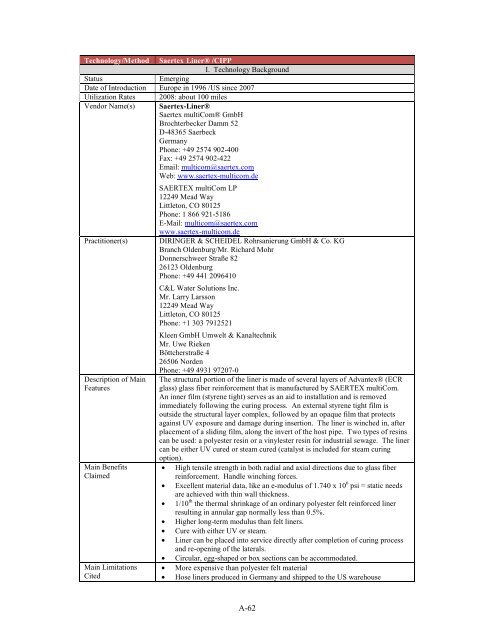

<strong>Technology</strong>/Method Saertex - Liner® /CIPP<br />

I. <strong>Technology</strong> Background<br />

Status Emerging<br />

Date <strong>of</strong> Introduction Europe in 1996 /US since 2007<br />

Utilization Rates 2008: about 100 miles<br />

Vendor Name(s) Saertex-Liner®<br />

Saertex multiCom® GmbH<br />

Brochterbecker Damm 52<br />

D-48365 Saerbeck<br />

Germany<br />

Phone: +49 2574 902-400<br />

Fax: +49 2574 902-422<br />

Email: multicom@saertex.com<br />

Web: www.saertex-multicom.de<br />

SAERTEX multiCom LP<br />

12249 Mead Way<br />

Littleton, CO 80125<br />

Phone: 1 866 921-5186<br />

E-Mail: multicom@saertex.com<br />

www.saertex-multicom.de<br />

Practitioner(s) DIRINGER & SCHEIDEL Rohrsanierung GmbH & Co. KG<br />

Branch Oldenburg/Mr. Richard Mohr<br />

Donnerschweer Straße 82<br />

26123 Oldenburg<br />

Phone: +49 441 2096410<br />

C&L Water Solutions Inc.<br />

Mr. Larry Larsson<br />

12249 Mead Way<br />

Littleton, CO 80125<br />

Phone: +1 303 7912521<br />

Kleen GmbH Umwelt & Kanaltechnik<br />

Mr. Uwe Rieken<br />

Böttcherstraße 4<br />

26506 Norden<br />

Description <strong>of</strong> <strong>Main</strong><br />

Features<br />

Phone: +49 4931 97207-0<br />

The structural portion <strong>of</strong> the liner is made <strong>of</strong> several layers <strong>of</strong> Advantex® (ECR<br />

glass) glass fiber rein<strong>for</strong>cement that is manufactured by SAERTEX multiCom.<br />

An inner film (styrene tight) serves as an aid to installation and is removed<br />

immediately following the curing process. An external styrene tight film is<br />

outside the structural layer complex, followed by an opaque film that protects<br />

against UV exposure and damage during insertion. The liner is winched in, after<br />

placement <strong>of</strong> a sliding film, along the invert <strong>of</strong> the host pipe. Two types <strong>of</strong> resins<br />

can be used: a polyester resin or a vinylester resin <strong>for</strong> industrial sewage. The liner<br />

can be either UV cured or steam cured (catalyst is included <strong>for</strong> steam curing<br />

option).<br />

<strong>Main</strong> Benefits • High tensile strength in both radial and axial directions due to glass fiber<br />

Claimed rein<strong>for</strong>cement. Handle winching <strong>for</strong>ces.<br />

• Excellent material data, like an e-modulus <strong>of</strong> 1.740 x 10 6 psi = static needs<br />

are achieved with thin wall thickness.<br />

• 1/10 th the thermal shrinkage <strong>of</strong> an ordinary polyester felt rein<strong>for</strong>ced liner<br />

resulting in annular gap normally less than 0.5%.<br />

• Higher long-term modulus than felt liners.<br />

• Cure with either UV or steam.<br />

• Liner can be placed into service directly after completion <strong>of</strong> curing process<br />

and re-opening <strong>of</strong> the laterals.<br />

<strong>Main</strong> Limitations<br />

Cited<br />

• Circular, egg-shaped or box sections can be accommodated.<br />

• More expensive than polyester felt material<br />

• Hose liners produced in Germany and shipped to the US warehouse<br />

A-62