State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

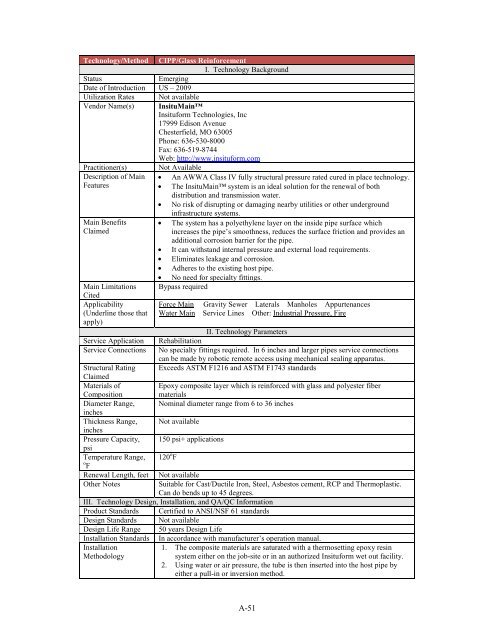

<strong>Technology</strong>/Method CIPP/Glass Rein<strong>for</strong>cement<br />

I. <strong>Technology</strong> Background<br />

Status Emerging<br />

Date <strong>of</strong> Introduction US – 2009<br />

Utilization Rates Not available<br />

Vendor Name(s) Insitu<strong>Main</strong><br />

Insitu<strong>for</strong>m Technologies, Inc<br />

17999 Edison Avenue<br />

Chesterfield, MO 63005<br />

Phone: 636-530-8000<br />

Fax: 636-519-8744<br />

Web: http://www.insitu<strong>for</strong>m.com<br />

Practitioner(s) Not Available<br />

Description <strong>of</strong> <strong>Main</strong><br />

Features<br />

<strong>Main</strong> Benefits<br />

Claimed<br />

• An AWWA Class IV fully structural pressure rated cured in place technology.<br />

• The Insitu<strong>Main</strong> system is an ideal solution <strong>for</strong> the renewal <strong>of</strong> both<br />

distribution and transmission water.<br />

• No risk <strong>of</strong> disrupting or damaging nearby utilities or other underground<br />

infrastructure systems.<br />

• The system has a polyethylene layer on the inside pipe surface which<br />

increases the pipe’s smoothness, reduces the surface friction and provides an<br />

additional corrosion barrier <strong>for</strong> the pipe.<br />

• It can withstand internal pressure and external load requirements.<br />

• Eliminates leakage and corrosion.<br />

• Adheres to the existing host pipe.<br />

• No need <strong>for</strong> specialty fittings.<br />

Bypass required<br />

<strong>Main</strong> Limitations<br />

Cited<br />

Applicability <strong>Force</strong> <strong>Main</strong> Gravity Sewer Laterals Manholes Appurtenances<br />

(Underline those that<br />

apply)<br />

Water <strong>Main</strong> Service Lines Other: Industrial Pressure, Fire<br />

II. <strong>Technology</strong> Parameters<br />

Service Application <strong>Rehabilitation</strong><br />

Service Connections No specialty fittings required. In 6 inches and larger pipes service connections<br />

can be made by robotic remote access using mechanical sealing apparatus.<br />

Structural Rating<br />

Claimed<br />

Exceeds ASTM F1216 and ASTM F1743 standards<br />

Materials <strong>of</strong><br />

Epoxy composite layer which is rein<strong>for</strong>ced with glass and polyester fiber<br />

Composition materials<br />

Diameter Range,<br />

inches<br />

Nominal diameter range from 6 to 36 inches<br />

Thickness Range,<br />

inches<br />

Not available<br />

Pressure Capacity,<br />

psi<br />

150 psi+ applications<br />

Temperature Range,<br />

o<br />

F<br />

120 o F<br />

Renewal Length, feet Not available<br />

Other Notes Suitable <strong>for</strong> Cast/Ductile Iron, Steel, Asbestos cement, RCP and Thermoplastic.<br />

Can do bends up to 45 degrees.<br />

III. <strong>Technology</strong> Design, Installation, and QA/QC In<strong>for</strong>mation<br />

Product Standards Certified to ANSI/NSF 61 standards<br />

Design Standards Not available<br />

Design Life Range 50 years Design Life<br />

Installation Standards In accordance with manufacturer’s operation manual.<br />

Installation<br />

1. The composite materials are saturated with a thermosetting epoxy resin<br />

Methodology<br />

system either on the job-site or in an authorized Insitu<strong>for</strong>m wet out facility.<br />

2. Using water or air pressure, the tube is then inserted into the host pipe by<br />

either a pull-in or inversion method.<br />

A-51