State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

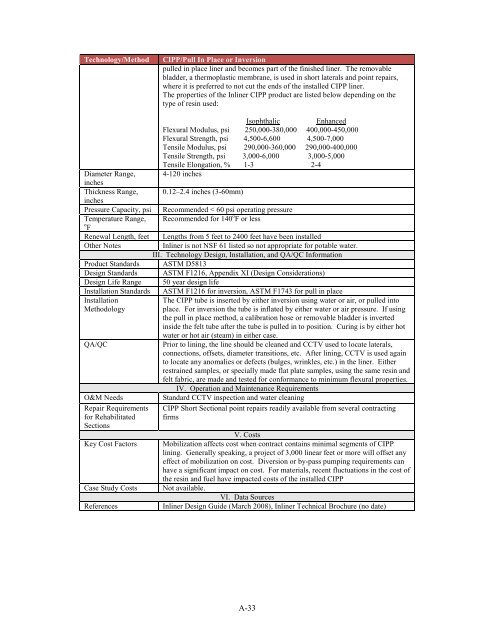

<strong>Technology</strong>/Method CIPP/Pull In Place or Inversion<br />

pulled in place liner and becomes part <strong>of</strong> the finished liner. The removable<br />

bladder, a thermoplastic membrane, is used in short laterals and point repairs,<br />

where it is preferred to not cut the ends <strong>of</strong> the installed CIPP liner.<br />

The properties <strong>of</strong> the Inliner CIPP product are listed below depending on the<br />

type <strong>of</strong> resin used:<br />

Isophthalic Enhanced<br />

Flexural Modulus, psi 250,000-380,000 400,000-450,000<br />

Flexural Strength, psi 4,500-6,600 4,500-7,000<br />

Tensile Modulus, psi 290,000-360,000 290,000-400,000<br />

Tensile Strength, psi 3,000-6,000 3,000-5,000<br />

Tensile Elongation, % 1-3 2-4<br />

Diameter Range,<br />

inches<br />

4-120 inches<br />

Thickness Range,<br />

inches<br />

0.12–2.4 inches (3-60mm)<br />

Pressure Capacity, psi Recommended < 60 psi operating pressure<br />

Temperature Range,<br />

o<br />

F<br />

Recommended <strong>for</strong> 140 o F or less<br />

Renewal Length, feet Lengths from 5 feet to 2400 feet have been installed<br />

Other Notes Inliner is not NSF 61 listed so not appropriate <strong>for</strong> potable water.<br />

Product Standards<br />

III. <strong>Technology</strong> Design, Installation, and QA/QC In<strong>for</strong>mation<br />

ASTM D5813<br />

Design Standards ASTM F1216, Appendix XI (Design Considerations)<br />

Design Life Range 50 year design life<br />

Installation Standards ASTM F1216 <strong>for</strong> inversion, ASTM F1743 <strong>for</strong> pull in place<br />

Installation<br />

Methodology<br />

The CIPP tube is inserted by either inversion using water or air, or pulled into<br />

place. For inversion the tube is inflated by either water or air pressure. If using<br />

the pull in place method, a calibration hose or removable bladder is inverted<br />

inside the felt tube after the tube is pulled in to position. Curing is by either hot<br />

water or hot air (steam) in either case.<br />

QA/QC Prior to lining, the line should be cleaned and CCTV used to locate laterals,<br />

connections, <strong>of</strong>fsets, diameter transitions, etc. After lining, CCTV is used again<br />

to locate any anomalies or defects (bulges, wrinkles, etc.) in the liner. Either<br />

restrained samples, or specially made flat plate samples, using the same resin and<br />

felt fabric, are made and tested <strong>for</strong> con<strong>for</strong>mance to minimum flexural properties.<br />

IV. Operation and <strong>Main</strong>tenance Requirements<br />

O&M Needs Standard CCTV inspection and water cleaning<br />

Repair Requirements<br />

<strong>for</strong> Rehabilitated<br />

Sections<br />

CIPP Short Sectional point repairs readily available from several contracting<br />

firms<br />

V. Costs<br />

Key Cost Factors Mobilization affects cost when contract contains minimal segments <strong>of</strong> CIPP<br />

lining. Generally speaking, a project <strong>of</strong> 3,000 linear feet or more will <strong>of</strong>fset any<br />

effect <strong>of</strong> mobilization on cost. Diversion or by-pass pumping requirements can<br />

have a significant impact on cost. For materials, recent fluctuations in the cost <strong>of</strong><br />

the resin and fuel have impacted costs <strong>of</strong> the installed CIPP<br />

Case Study Costs Not available.<br />

VI. Data Sources<br />

References Inliner Design Guide (March 2008), Inliner Technical Brochure (no date)<br />

A-33