State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

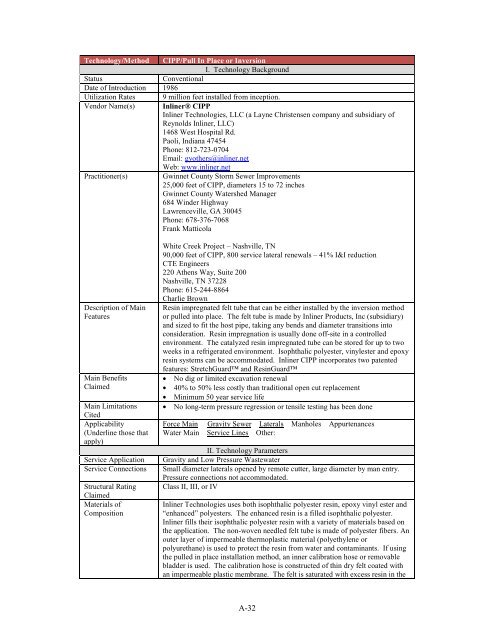

<strong>Technology</strong>/Method CIPP/Pull In Place or Inversion<br />

I. <strong>Technology</strong> Background<br />

Status Conventional<br />

Date <strong>of</strong> Introduction 1986<br />

Utilization Rates 9 million feet installed from inception.<br />

Vendor Name(s) Inliner® CIPP<br />

Inliner Technologies, LLC (a Layne Christensen company and subsidiary <strong>of</strong><br />

Reynolds Inliner, LLC)<br />

1468 West Hospital Rd.<br />

Paoli, Indiana 47454<br />

Phone: 812-723-0704<br />

Email: gyothers@inliner.net<br />

Web: www.inliner.net<br />

Practitioner(s) Gwinnet County Storm Sewer Improvements<br />

25,000 feet <strong>of</strong> CIPP, diameters 15 to 72 inches<br />

Gwinnet County Watershed Manager<br />

684 Winder Highway<br />

Lawrenceville, GA 30045<br />

Phone: 678-376-7068<br />

Frank Matticola<br />

Description <strong>of</strong> <strong>Main</strong><br />

Features<br />

<strong>Main</strong> Benefits<br />

Claimed<br />

White Creek Project – Nashville, TN<br />

90,000 feet <strong>of</strong> CIPP, 800 service lateral renewals – 41% I&I reduction<br />

CTE Engineers<br />

220 Athens Way, Suite 200<br />

Nashville, TN 37228<br />

Phone: 615-244-8864<br />

Charlie Brown<br />

Resin impregnated felt tube that can be either installed by the inversion method<br />

or pulled into place. The felt tube is made by Inliner Products, Inc (subsidiary)<br />

and sized to fit the host pipe, taking any bends and diameter transitions into<br />

consideration. Resin impregnation is usually done <strong>of</strong>f-site in a controlled<br />

environment. The catalyzed resin impregnated tube can be stored <strong>for</strong> up to two<br />

weeks in a refrigerated environment. Isophthalic polyester, vinylester and epoxy<br />

resin systems can be accommodated. Inliner CIPP incorporates two patented<br />

features: StretchGuard and ResinGuard<br />

• No dig or limited excavation renewal<br />

• 40% to 50% less costly than traditional open cut replacement<br />

• Minimum 50 year service life<br />

• No long-term pressure regression or tensile testing has been done<br />

<strong>Main</strong> Limitations<br />

Cited<br />

Applicability<br />

<strong>Force</strong> <strong>Main</strong> Gravity Sewer Laterals Manholes Appurtenances<br />

(Underline those that<br />

apply)<br />

Water <strong>Main</strong> Service Lines Other:<br />

Service Application<br />

II. <strong>Technology</strong> Parameters<br />

Gravity and Low Pressure Wastewater<br />

Service Connections Small diameter laterals opened by remote cutter, large diameter by man entry.<br />

Pressure connections not accommodated.<br />

Structural Rating<br />

Claimed<br />

Class II, III, or IV<br />

Materials <strong>of</strong><br />

Inliner Technologies uses both isophthalic polyester resin, epoxy vinyl ester and<br />

Composition<br />

“enhanced” polyesters. The enhanced resin is a filled isophthalic polyester.<br />

Inliner fills their isophthalic polyester resin with a variety <strong>of</strong> materials based on<br />

the application. The non-woven needled felt tube is made <strong>of</strong> polyester fibers. An<br />

outer layer <strong>of</strong> impermeable thermoplastic material (polyethylene or<br />

polyurethane) is used to protect the resin from water and contaminants. If using<br />

the pulled in place installation method, an inner calibration hose or removable<br />

bladder is used. The calibration hose is constructed <strong>of</strong> thin dry felt coated with<br />

an impermeable plastic membrane. The felt is saturated with excess resin in the<br />

A-32