State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

State of Technology Report for Force Main Rehabilitation, Final ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

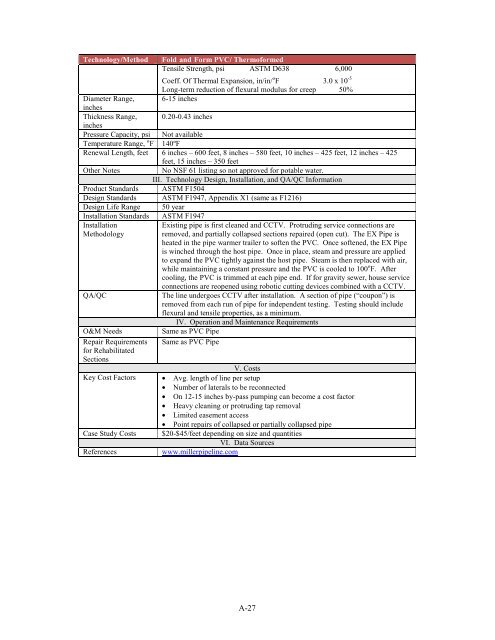

<strong>Technology</strong>/Method Fold -and - Form PVC/ Therm<strong>of</strong>ormed<br />

Tensile Strength, psi ASTM D638 6,000<br />

Coeff. Of Thermal Expansion, in/in/ o F 3.0 x 10 -5<br />

Long-term reduction <strong>of</strong> flexural modulus <strong>for</strong> creep 50%<br />

Diameter Range,<br />

inches<br />

6-15 inches<br />

Thickness Range, 0.20-0.43 inches<br />

inches<br />

Pressure Capacity, psi Not available<br />

Temperature Range, o F 140ºF<br />

Renewal Length, feet 6 inches – 600 feet, 8 inches – 580 feet, 10 inches – 425 feet, 12 inches – 425<br />

feet, 15 inches – 350 feet<br />

Other Notes No NSF 61 listing so not approved <strong>for</strong> potable water.<br />

III. <strong>Technology</strong> Design, Installation, and QA/QC In<strong>for</strong>mation<br />

Product Standards ASTM F1504<br />

Design Standards ASTM F1947, Appendix X1 (same as F1216)<br />

Design Life Range 50 year<br />

Installation Standards ASTM F1947<br />

Installation<br />

Methodology<br />

Existing pipe is first cleaned and CCTV. Protruding service connections are<br />

removed, and partially collapsed sections repaired (open cut). The EX Pipe is<br />

heated in the pipe warmer trailer to s<strong>of</strong>ten the PVC. Once s<strong>of</strong>tened, the EX Pipe<br />

is winched through the host pipe. Once in place, steam and pressure are applied<br />

to expand the PVC tightly against the host pipe. Steam is then replaced with air,<br />

while maintaining a constant pressure and the PVC is cooled to 100 o F. After<br />

cooling, the PVC is trimmed at each pipe end. If <strong>for</strong> gravity sewer, house service<br />

connections are reopened using robotic cutting devices combined with a CCTV.<br />

QA/QC The line undergoes CCTV after installation. A section <strong>of</strong> pipe (“coupon”) is<br />

removed from each run <strong>of</strong> pipe <strong>for</strong> independent testing. Testing should include<br />

flexural and tensile properties, as a minimum.<br />

IV. Operation and <strong>Main</strong>tenance Requirements<br />

O&M Needs Same as PVC Pipe<br />

Repair Requirements<br />

<strong>for</strong> Rehabilitated<br />

Sections<br />

Same as PVC Pipe<br />

Key Cost Factors •<br />

V. Costs<br />

Avg. length <strong>of</strong> line per setup<br />

• Number <strong>of</strong> laterals to be reconnected<br />

• On 12-15 inches by-pass pumping can become a cost factor<br />

• Heavy cleaning or protruding tap removal<br />

• Limited easement access<br />

• Point repairs <strong>of</strong> collapsed or partially collapsed pipe<br />

Case Study Costs $20-$45/feet depending on size and quantities<br />

VI. Data Sources<br />

References www.millerpipeline.com<br />

A-27