Graphene Sheets from Graphitized Anthracite Coal: Preparation ...

Graphene Sheets from Graphitized Anthracite Coal: Preparation ...

Graphene Sheets from Graphitized Anthracite Coal: Preparation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Energy & Fuels Article<br />

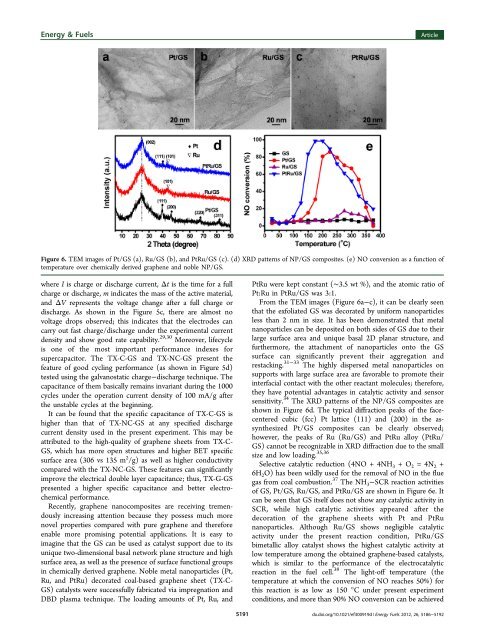

Figure 6. TEM images of Pt/GS (a), Ru/GS (b), and PtRu/GS (c). (d) XRD patterns of NP/GS composites. (e) NO conversion as a function of<br />

temperature over chemically derived graphene and noble NP/GS.<br />

where I is charge or discharge current, Δt is the time for a full<br />

charge or discharge, m indicates the mass of the active material,<br />

and ΔV represents the voltage change after a full charge or<br />

discharge. As shown in the Figure 5c, there are almost no<br />

voltage drops observed; this indicates that the electrodes can<br />

carry out fast charge/discharge under the experimental current<br />

density and show good rate capability. 29,30 Moreover, lifecycle<br />

is one of the most important performance indexes for<br />

supercapacitor. The TX-C-GS and TX-NC-GS present the<br />

feature of good cycling performance (as shown in Figure 5d)<br />

tested using the galvanostatic charge−discharge technique. The<br />

capacitance of them basically remains invariant during the 1000<br />

cycles under the operation current density of 100 mA/g after<br />

the unstable cycles at the beginning.<br />

It can be found that the specific capacitance of TX-C-GS is<br />

higher than that of TX-NC-GS at any specified discharge<br />

current density used in the present experiment. This may be<br />

attributed to the high-quality of graphene sheets <strong>from</strong> TX-C-<br />

GS, which has more open structures and higher BET specific<br />

surface area (306 vs 135 m 2 /g) as well as higher conductivity<br />

compared with the TX-NC-GS. These features can significantly<br />

improve the electrical double layer capacitance; thus, TX-G-GS<br />

presented a higher specific capacitance and better electrochemical<br />

performance.<br />

Recently, graphene nanocomposites are receiving tremendously<br />

increasing attention because they possess much more<br />

novel properties compared with pure graphene and therefore<br />

enable more promising potential applications. It is easy to<br />

imagine that the GS can be used as catalyst support due to its<br />

unique two-dimensional basal network plane structure and high<br />

surface area, as well as the presence of surface functional groups<br />

in chemically derived graphene. Noble metal nanoparticles (Pt,<br />

Ru, and PtRu) decorated coal-based graphene sheet (TX-C-<br />

GS) catalysts were successfully fabricated via impregnation and<br />

DBD plasma technique. The loading amounts of Pt, Ru, and<br />

5191<br />

PtRu were kept constant (∼3.5 wt %), and the atomic ratio of<br />

Pt:Ru in PtRu/GS was 3:1.<br />

From the TEM images (Figure 6a−c), it can be clearly seen<br />

that the exfoliated GS was decorated by uniform nanoparticles<br />

less than 2 nm in size. It has been demonstrated that metal<br />

nanoparticles can be deposited on both sides of GS due to their<br />

large surface area and unique basal 2D planar structure, and<br />

furthermore, the attachment of nanoparticles onto the GS<br />

surface can significantly prevent their aggregation and<br />

restacking. 31−33 The highly dispersed metal nanoparticles on<br />

supports with large surface area are favorable to promote their<br />

interfacial contact with the other reactant molecules; therefore,<br />

they have potential advantages in catalytic activity and sensor<br />

sensitivity. 34 The XRD patterns of the NP/GS composites are<br />

shown in Figure 6d. The typical diffraction peaks of the facecentered<br />

cubic (fcc) Pt lattice (111) and (200) in the assynthesized<br />

Pt/GS composites can be clearly observed;<br />

however, the peaks of Ru (Ru/GS) and PtRu alloy (PtRu/<br />

GS) cannot be recognizable in XRD diffraction due to the small<br />

size and low loading. 35,36<br />

Selective catalytic reduction (4NO + 4NH 3 +O 2 =4N 2 +<br />

6H 2O) has been wildly used for the removal of NO in the flue<br />

gas <strong>from</strong> coal combustion. 37 The NH 3−SCR reaction activities<br />

of GS, Pt/GS, Ru/GS, and PtRu/GS are shown in Figure 6e. It<br />

can be seen that GS itself does not show any catalytic activity in<br />

SCR, while high catalytic activities appeared after the<br />

decoration of the graphene sheets with Pt and PtRu<br />

nanoparticles. Although Ru/GS shows negligible catalytic<br />

activity under the present reaction condition, PtRu/GS<br />

bimetallic alloy catalyst shows the highest catalytic activity at<br />

low temperature among the obtained graphene-based catalysts,<br />

which is similar to the performance of the electrocatalytic<br />

reaction in the fuel cell. 38 The light-off temperature (the<br />

temperature at which the conversion of NO reaches 50%) for<br />

this reaction is as low as 150 °C under present experiment<br />

conditions, and more than 90% NO conversion can be achieved<br />

dx.doi.org/10.1021/ef300919d | Energy Fuels 2012, 26, 5186−5192