Alco Controls

Alco Controls Alco Controls

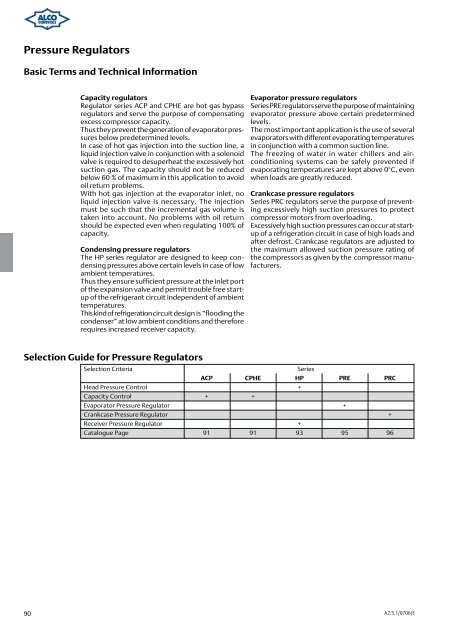

Pressure Regulators Basic Terms and Technical Information 90 Capacity regulators Regulator series ACP and CPHE are hot gas bypass regulators and serve the purpose of compensating excess compressor capacity. Thus they prevent the generation of evaporator pressures below predetermined levels. In case of hot gas injection into the suction line, a liquid injection valve in conjunction with a solenoid valve is required to desuperheat the excessively hot suction gas. The capacity should not be reduced below 60 % of maximum in this application to avoid oil return problems. With hot gas injection at the evaporator inlet, no liquid injection valve is necessary. The injection must be such that the incremental gas volume is taken into account. No problems with oil return should be expected even when regulating 100% of capacity. Condensing pressure regulators The HP series regulator are designed to keep condensing pressures above certain levels in case of low ambient temperatures. Thus they ensure sufficient pressure at the inlet port of the expansion valve and permit trouble free startup of the refrigerant circuit independent of ambient temperatures. This kind of refrigeration circuit design is “flooding the condenser” at low ambient conditions and therefore requires increased receiver capacity. Selection Guide for Pressure Regulators Evaporator pressure regulators Series PRE regulators serve the purpose of maintaining evaporator pressure above certain predetermined levels. The most important application is the use of several evaporators with different evaporating temperatures in conjunction with a common suction line. The freezing of water in water chillers and airconditioning systems can be safely prevented if evaporating temperatures are kept above 0°C, even when loads are greatly reduced. Crankcase pressure regulators Series PRC regulators serve the purpose of preventing excessively high suction pressures to protect compressor motors from overloading. Excessively high suction pressures can occur at startup of a refrigeration circuit in case of high loads and after defrost. Crankcase regulators are adjusted to the maximum allowed suction pressure rating of the compressors as given by the compressor manufacturers. Selection Criteria Series ACP CPHE HP PRE PRC Head Pressure Control + Capacity Control + + Evaporator Pressure Regulator + Crankcase Pressure Regulator + Receiver Pressure Regulator + Catalogue Page 91 91 93 95 96 A2.5.1/0706/E

Hot Gas Bypass Regulators Series ACP Technical Data Capacity Data A2.5.1/0706/E Features • High quality materials and processes for high reliability and long lifetime • Internal equalization • Compact size Adjustment Range: 0 ... 5 bar Factory Setting: 2,7 bar Max. operating Pressure PS: 31 bar Operating Temperature Range TS: –40°C ... 120°C Ambient Temperature Range: -40 ... 50°C Transport Temperature Range: -40 ... 70°C Type Part Connection, Angle Nominal Bypass Capacity* Qn No. Solder/ODF kW inch R 134a R 22 R 407C R 404A / R 507 ACP 1 047 680 1 /4 x 3 / ” 8 0.21 0.35 0.41 0.30 ACP 3 047 283 1 /4 x 3 / ” 8 0.50 0.77 0.89 0.68 ACP 5 053 374 3 /8 x 3 / ” 8 1.18 1.83 2.12 1.59 Hot Gas Bypass Regulators Series CPHE Technical Data *) Nominal capacities at +38°C condensing temperature, +4°C evaporating temperature (saturated temperatures / dew point) and 1 K liquid subcooling at the inlet of the expansion valve. Features • High quality materials and processes for high reliability and long lifetime • Superior partial load performance due to double seat orifice design (CPHE-3 to CPHE-6) • Modular design for economical logistics and easy assembly and servicing • External equalization Specific connection sizes and flanges available on request. Selection see page 80. Adjustment Range: -0,4 ... 5 bar Factory Setting: 1,4 bar Max. operating Pressure PS: 28 bar Operating Temperature Range TS: –40°C ... 120°C Ambient Temperature Range: -40 ... 50°C Transport Temperature Range: -40 ... 70°C ACP CPHE 91

- Page 41 and 42: Coldroom Controller Series EC3 Temp

- Page 43 and 44: Block Diagram EC3-33x Coldroom Cont

- Page 45 and 46: Selection table TCP/IP LON Descript

- Page 47 and 48: Rack and Condenser Controllers Seri

- Page 49 and 50: Block Diagrams EC3-81x Dual Ciruit

- Page 51 and 52: Network Accessories Description Cab

- Page 53 and 54: Pressure Transmitter Series PT4 A2.

- Page 55 and 56: Electronic Fan Speed Power Module F

- Page 57 and 58: A2.5.1/0706/E Thermo ® -Expansion

- Page 59 and 60: A2.5.1/0706/E Example Cooling capac

- Page 61 and 62: TIS(E) Valve bodies - solder type m

- Page 63 and 64: Capacity kW Valve Type TI..-M.... C

- Page 65 and 66: Condensing Temperature R 22 Capacit

- Page 67 and 68: R 407C Nominal less MOP with Standa

- Page 69 and 70: A2.5.1/0706/E Available upon specia

- Page 71 and 72: Liquid Correction Factor K t Temper

- Page 73 and 74: Thermo ® -Expansion Valve Series Z

- Page 75 and 76: Liquid Correction Factor K t Temper

- Page 77 and 78: Accessories A2.5.1/0706/E Available

- Page 79 and 80: Accessories Description Type Part N

- Page 81 and 82: Liquid Correction Factor K t Temper

- Page 83 and 84: A2.5.1/0706/E Solenoid Valves 81

- Page 85 and 86: Coils ASC Type Part No. Voltage Pow

- Page 87 and 88: 2-Way Solenoid Valves Series 540 No

- Page 89 and 90: 2. Liquid Application Liquid Correc

- Page 91: A2.5.1/0706/E Mechanical Pressure R

- Page 95 and 96: Head Pressure Control Valves Series

- Page 97 and 98: Evaporator and Crankcase Pressure R

- Page 99 and 100: A2.5.1/0706/E Fan Speed Controllers

- Page 101 and 102: Technical Data Function Diagram A2.

- Page 103 and 104: Selection Dependent on Product Comb

- Page 105 and 106: A2.5.1/0706/E Pressure Controls and

- Page 107 and 108: A2.5.1/0706/E Standards and Regulat

- Page 109 and 110: Single Pressure Controls Series PS1

- Page 111 and 112: Dual Pressure Controls PS2 TÜV / E

- Page 113 and 114: Pressure Controls Series PS3 / Stan

- Page 115 and 116: Differential Pressure Controls Seri

- Page 117 and 118: Function of contacts A2.5.1/0706/E

- Page 119 and 120: Type Part No. Adjustment Range Lowe

- Page 121 and 122: A2.5.1/0706/E System Protectors, Mo

- Page 123 and 124: Bi-flow Filter Driers Series BFK he

- Page 125 and 126: Nominal Operating Conditions Nomina

- Page 127 and 128: Connections Type Part Connection A2

- Page 129 and 130: Filter-Drier Shells With Quick-Cap

- Page 131 and 132: Correction Tables for Filter Driers

- Page 133 and 134: Suction Line Filters and Filter Dri

- Page 135 and 136: BTAS - Water and Acid Adsorption Ca

- Page 137 and 138: Moisture Liquid Indicators Series A

- Page 139 and 140: A2.5.1/0706/E Oil Management Compon

- Page 141 and 142: Electronic Oil Level Management Sys

Pressure Regulators<br />

Basic Terms and Technical Information<br />

90<br />

Capacity regulators<br />

Regulator series ACP and CPHE are hot gas bypass<br />

regulators and serve the purpose of compensating<br />

excess compressor capacity.<br />

Thus they prevent the generation of evaporator pressures<br />

below predetermined levels.<br />

In case of hot gas injection into the suction line, a<br />

liquid injection valve in conjunction with a solenoid<br />

valve is required to desuperheat the excessively hot<br />

suction gas. The capacity should not be reduced<br />

below 60 % of maximum in this application to avoid<br />

oil return problems.<br />

With hot gas injection at the evaporator inlet, no<br />

liquid injection valve is necessary. The injection<br />

must be such that the incremental gas volume is<br />

taken into account. No problems with oil return<br />

should be expected even when regulating 100% of<br />

capacity.<br />

Condensing pressure regulators<br />

The HP series regulator are designed to keep condensing<br />

pressures above certain levels in case of low<br />

ambient temperatures.<br />

Thus they ensure sufficient pressure at the inlet port<br />

of the expansion valve and permit trouble free startup<br />

of the refrigerant circuit independent of ambient<br />

temperatures.<br />

This kind of refrigeration circuit design is “flooding the<br />

condenser” at low ambient conditions and therefore<br />

requires increased receiver capacity.<br />

Selection Guide for Pressure Regulators<br />

Evaporator pressure regulators<br />

Series PRE regulators serve the purpose of maintaining<br />

evaporator pressure above certain predetermined<br />

levels.<br />

The most important application is the use of several<br />

evaporators with different evaporating temperatures<br />

in conjunction with a common suction line.<br />

The freezing of water in water chillers and airconditioning<br />

systems can be safely prevented if<br />

evaporating temperatures are kept above 0°C, even<br />

when loads are greatly reduced.<br />

Crankcase pressure regulators<br />

Series PRC regulators serve the purpose of preventing<br />

excessively high suction pressures to protect<br />

compressor motors from overloading.<br />

Excessively high suction pressures can occur at startup<br />

of a refrigeration circuit in case of high loads and<br />

after defrost. Crankcase regulators are adjusted to<br />

the maximum allowed suction pressure rating of<br />

the compressors as given by the compressor manufacturers.<br />

Selection Criteria Series<br />

ACP CPHE HP PRE PRC<br />

Head Pressure Control +<br />

Capacity Control + +<br />

Evaporator Pressure Regulator +<br />

Crankcase Pressure Regulator +<br />

Receiver Pressure Regulator +<br />

Catalogue Page 91 91 93 95 96<br />

A2.5.1/0706/E