case studies - Dresser-Rand

case studies - Dresser-Rand

case studies - Dresser-Rand

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DRESSER-RAND<br />

AT A GLANCE<br />

<strong>Dresser</strong>-<strong>Rand</strong> Group Inc. is among the largest suppliers of custom-engineered<br />

rotating equipment solutions for the worldwide energy infrastructure, including<br />

oil, gas, petrochemical, power generation, and process industries. Our high-speed<br />

rotating equipment is also supplied to the environmental solutions markets within<br />

the energy infrastructure.<br />

Our products—centrifugal and reciprocating gas compressors, gas and steam<br />

turbines, gas expanders, gas and diesel engines, and associated control panels—<br />

are used in oil and gas production, high-pressure field injection and oil recovery,<br />

gas liquefaction, gas transmission, refinery processes, natural gas processing,<br />

petrochemical production, general industry (including paper, steel, sugar,<br />

and distributed power), power generation, and military applications. Our<br />

custom-engineered products are also used in other advanced applications in<br />

the environmental markets we serve, where they reduce carbon footprint and<br />

increase energy efficiency. These include, among others, hot gas turbo-expanders<br />

for energy recovery in refineries; co- and tri-generation combined heat and<br />

power (CHP) packages for institutional and other clients; and a large number<br />

of steam turbine applications to generate power using steam produced by<br />

recovering exhaust heat from a multitude of sources. Biomass and biogas<br />

applications for our steam turbine product line include gasification of<br />

municipal solid waste or incineration of wood, palm oil, sugar, or pulp<br />

and paper residues to generate power. Our equipment is used in compressed<br />

air energy storage (CAES) applications for utility-sized power generation that is<br />

environmentally friendly and provides unique grid management features.<br />

We have the largest installed base in the world of our class of equipment,<br />

encompassing a legacy of more than 40 reputable brands.<br />

<strong>Dresser</strong>-<strong>Rand</strong> has one of the most extensive global service and support organizations<br />

in the industry. The company offers a full range of original equipment manufacturer<br />

(OEM) parts, field solutions, revamps and rerates, remanufacturing, product<br />

training, and upgrades.<br />

Our clients know us best for our ability to bring equipment solutions and premier<br />

service for rotating equipment to the energy infrastructure markets. We continue<br />

to widen our markets by investing in new technologies and companies that offer<br />

exceptional environmental benefits and the economic value propositions that allow<br />

our clients’ facilities to operate more efficiently or help them to be more competitive<br />

in their markets.<br />

Our worldwide client base consists of oil and gas producers and distributors,<br />

national oil companies (NOC), and chemical and industrial companies in<br />

more than 150 countries. We have long-term supplier alliance agreements with<br />

approximately 50 of our clients.<br />

<strong>Dresser</strong>-<strong>Rand</strong> has headquarters in Houston, Texas, and Paris, France. The company<br />

has approximately 7,500 employees and operates 13 manufacturing facilities in<br />

seven countries (United States, France, United Kingdom, Germany, Spain, Norway,<br />

and India), 49 service and support centers, including six engineering and research<br />

and development centers, and 76 sales offices in 32 countries.<br />

<strong>Dresser</strong>-<strong>Rand</strong> Group Inc. is a publicly traded company listed on the New York<br />

Stock Exchange (symbol: DRC).

TABLE OF CONTENTS<br />

Overview<br />

<strong>Dresser</strong>-<strong>Rand</strong> at a Glance ...............................IFC<br />

Overview ........................................................... 1<br />

CEO Letter ......................................................... 2<br />

Corporate Vision, Mission,<br />

Guiding Principles, and Values ........................... 3<br />

Our Approach to Sustainability ......................... 4<br />

Our Sustainability Principles .............................. 5<br />

Stakeholder Engagement .................................... 6<br />

Key Issues ............................................................ 7<br />

Environment .................................................... 10<br />

Climate Change ................................................ 12<br />

Driving Efficiency in<br />

Our Clients’ Operations ................................... 14<br />

Operational Excellence in<br />

Our Operations ................................................. 16<br />

Society .............................................................. 18<br />

Localization ......................................................20<br />

People ................................................................22<br />

Health & Safety ................................................24<br />

Community ......................................................26<br />

Suppliers ............................................................ 29<br />

Using Technology to Improve Lives .................30<br />

Governance ...................................................... 32<br />

Our Approach to Governance ..........................34<br />

Global Reporting Initiative (GRI) Index .........38<br />

DRESSER-RAND<br />

SUSTAINABILITY COUNCIL<br />

Asier Alea<br />

Business Development Manager—<br />

Environmental Solutions<br />

Blaise Derrico<br />

Vice President, Investor Relations<br />

Brad Dickson<br />

Vice President, Chief Marketing Officer<br />

Mark Mai<br />

Vice President, General Counsel & Secretary<br />

Ken Marcia<br />

Vice President, Worldwide Supply Chain<br />

& Process Innovation<br />

Jim Methven<br />

Director, Global Singular Processes<br />

Gustavo Nechar<br />

Vice President, Human Resources<br />

Jesus Pacheco<br />

Executive Vice President, New Equipment<br />

Worldwide<br />

Peter Salvatore<br />

Vice President, Chief Safety Officer<br />

Greg Stubbs<br />

Senior Manager, Sustainability &<br />

HSE Process Innovation<br />

The <strong>Dresser</strong>-<strong>Rand</strong> Sustainability Council represents a<br />

cross-functional team of senior managers and executive<br />

leaders chartered by our CEO with board oversight. The<br />

council is charged with developing a sustainability strategy<br />

of competitive advantage that engages opportunities of<br />

shared value for <strong>Dresser</strong>-<strong>Rand</strong> and its stakeholders. We wish<br />

to thank Jim Methven, Ken Marcia and Jesus Pacheco for<br />

their valuable input over the last three years, and welcome<br />

Ann Ackerson, vice president, Supply Chain, and Scott Wisler,<br />

director, Centers of Technical Excellence, to the Council.<br />

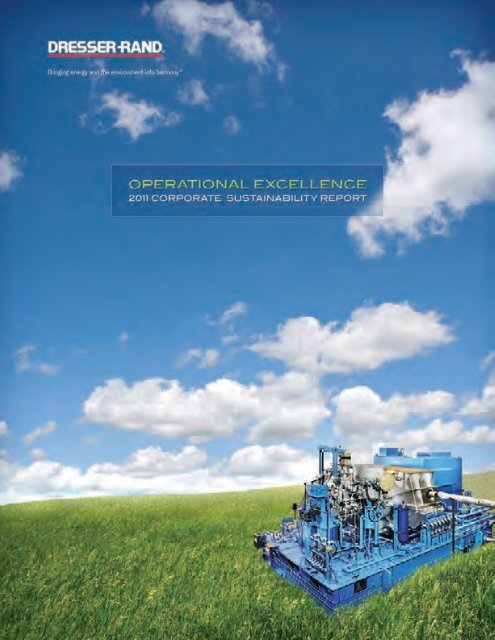

On the cover: <strong>Dresser</strong>-<strong>Rand</strong> supplied this<br />

turbine generator set to Portugal in 2007.<br />

The plant burns 13 tonnes/hr of a forestry<br />

residue/cork dust biomass mixture,<br />

producing power for the grid.<br />

ECONOMIC IMPACT<br />

($ in millions, except EPS) 2011 2010 2009 2008<br />

Revenue $2,311.6 $1,953.6 $2,289.6 $2,194.7<br />

Cash flow from operating activities 108.1 375.6 129.8 234.8<br />

Net income 119.7 146.7 210.8 197.7<br />

Diluted earnings per share 1.53 1.80 2.57 2.36<br />

Annual shareholder return:<br />

DRC 17.1% 34.7% 83.0% -55.5%<br />

S&P 500 0.0% 12.8% 15.2% -36.8%<br />

PHLX Oil Service Sector Index -11.5% 25.8% 61.6% -59.9%<br />

Wages and benefits $657.4 $574.2 $562.6 $534.5<br />

Taxes paid $47.4 $111.5 $129.1 $109.1<br />

EC1 & EC3 GRI METRICS<br />

Revenue $2,311.6 $1,953.6 $2,289.6 $2,194.7<br />

Operating costs 1,397.1 1,116.9 1,377.1 1,328.1<br />

Selling & administrative expenses 364.6 300.5 287.3 273.8<br />

Employee compensation (wages<br />

& benefits)<br />

657.4 574.2 562.6 534.5<br />

Donations & other community<br />

investments<br />

698.9 293.0 392.0 411.0<br />

Retained earnings (end of period) 904.5 784.8 638.1 427.3<br />

Payments to capital providers<br />

(cash paid for interest)<br />

62.2 31.7 31.1 33.9<br />

Payments to governments (gross taxes) 47.4 111.5 129.1 109.1<br />

Coverage of defined benefit plan obligations Refer to 2011 10-K notes 11 & 12<br />

OPERATING COSTS:<br />

Cost of sales $1,662.3 $1,366.7 $1,632.1 $1,576.1<br />

Selling & administrative expenses 364.6 300.5 287.3 273.8<br />

Research and development expenses 27.6 23.9 20.3 12.7<br />

Employee compensation<br />

(wages & benefits)<br />

(657.4) (574.2) (562.6) (534.5)<br />

Total operating costs $1,397.1 $1,116.9 $1,377.1 $1,328.1<br />

ENDING HEADCOUNT<br />

Asia Pacific 524 500 414<br />

Europe 2,099 1,472 1,498<br />

Latin America 726 145 191<br />

Middle East/Africa 104 91 29<br />

North America 4,053 3,944 3,977<br />

Grand total 7,506 6,152 6,109<br />

HEADCOUNT PERCENT BY REGION<br />

Asia Pacific 7.0% 8.1% 6.8%<br />

Europe 27.9% 23.9% 24.5%<br />

Latin America 9.7% 2.4% 3.1%<br />

Middle East/Africa 1.4% 1.5% 0.5%<br />

North America 54.0% 64.1% 65.1%<br />

Total 100.0% 100.0% 100.0%

REVENUE BY BUSINESS SEGMENT<br />

47% New Units<br />

REVENUE BY END MARKET<br />

17% Environmental<br />

4% Other<br />

36% Refining<br />

and Chemical<br />

53% Aftermarket<br />

Parts & Services<br />

WORLDWIDE OPERATIONS AS OF 12/31/11<br />

■ 49 Service and Support Centers<br />

● 13 Manufacturing Facilities<br />

32% Oil &<br />

Gas Production<br />

11% Gas<br />

Transmission<br />

REVENUE BY DESTINATION<br />

14% Middle<br />

East & Africa<br />

15% Asia Pacific<br />

22% Europe<br />

18% Latin America<br />

EMPLOYEE BREAKDOWN<br />

BY REGION (TOTAL 7,506)<br />

54.0% North America<br />

9.7% Latin<br />

America<br />

7.0% Asia<br />

Pacific<br />

31%<br />

North America<br />

27.9% Europe<br />

1.4% Middle East/<br />

Africa

The future success of DRESSER-RAND relies upon continuing our<br />

legacy of supplying long-lasting, custom-engineered, energy-efficient<br />

product and service solutions. A significant factor in our success<br />

is our ability to operate efficiently, which is why we are focusing<br />

company-wide on OPERATIONAL EXCELLENCE. We intend to<br />

build on our strengths by implementing global singular processes<br />

(GSP) so that we are maximizing our successes. When we operate<br />

more efficiently, we reduce cost, cycle time and—importantly—waste.<br />

Through our expertise and innovative technologies, we are creating<br />

a more sustainable tomorrow—for our clients, employees, suppliers,<br />

stockholders, and the communities where we work. We are using data,<br />

processes, people, and technology to define a common way of doing<br />

business with less repetition across operations. <strong>Dresser</strong>-<strong>Rand</strong> is truly<br />

focused on bringing energy and the environment into harmony.<br />

OVERVIEW<br />

CORPORATE SUSTAINABILITY REPORT 1

TO OUR<br />

STAKEHOLDERS<br />

<strong>Dresser</strong>-<strong>Rand</strong> is proud of the progress we have been making on bringing energy and the environment into harmony. At <strong>Dresser</strong>-<strong>Rand</strong>,<br />

our approach to sustainability covers issues relating to the environment, society and governance.<br />

Our mission for 2012 and beyond is to grow value for our stockholders in a way that is sustainable. 2012 will be a year in which we<br />

focus on our number one priority—safety—and strengthen the contributors to our long-term performance, with continuing emphasis<br />

on Operational Excellence.<br />

The <strong>Dresser</strong>-<strong>Rand</strong> sustainability platform includes activities to address climate change and expand our products and services for the<br />

growing environmental solutions markets. We are reducing our environmental footprint through, among other things, our Operational<br />

Excellence initiatives, and are contributing to our clients’ sustainability goals through our products and technologies. We continue to<br />

invest in local communities and continuously work to create a safe and healthy workplace for our employees.<br />

Over the past two years we redefined our markets from simply oil and gas to energy infrastructure. We are now squarely engaged in a<br />

growth strategy in the environmental solutions markets, expansion of our footprint to meet localization requirements and a step-up in<br />

technology investments to maintain our leadership position in the industry. Consistent with this strategy, this past year we invested more<br />

than $700 million in businesses that enhance our ability to serve the growing environmental solutions markets, including the acquisition<br />

of Grupo Guascor and our investment in Echogen Power Systems. More recently, on January 4, 2012, we acquired Synchrony, Inc.<br />

Guascor is a leading supplier of diesel and gas engines and provides customized energy solutions across worldwide energy infrastructure<br />

markets. Guascor has substantial experience in the design, construction and development of power generation and cogeneration plants<br />

and mini-hydroelectric plants, and the development and exploitation of wind farms and biomass, used oil and landfill energy recovery,<br />

photovoltaic solar energy, and aerobic processing.<br />

Echogen is a technology development company focused on developing innovative heat-to-electricity power generation systems that use<br />

supercritical working fluids to transform heat into power without creating new emissions. This technology drives value for the client<br />

through its unique combination of a lower cost per unit of electricity produced, compact footprint, higher energy recovery from the<br />

waste heat stream, and ability to generate power from a wider range of heat sources when compared to competing technologies available in<br />

the marketplace today. Echogen technology may be applied in many of our oil & gas markets to reduce the adverse environmental impacts<br />

such as in refining and petrochemical facilities. In addition, this technology will provide enhanced power generation in environmentally<br />

friendly combined heat and power (CHP) applications and compressed air energy storage (CAES) systems.<br />

Synchrony is a technology development company with a portfolio of world-class technologies and products including active magnetic<br />

bearings (AMB), high-speed motors and generators, and power electronics for clean, efficient and reliable rotating machinery.<br />

OPERATIONAL EXCELLENCE AND SUSTAINABILITY<br />

Over the past 10 years we have made excellent progress in improving productivity and cycle times, while reducing waste and costs<br />

through our focus on Operational Excellence. We are committed to further improvement.<br />

It’s our belief that sustainability and Operational Excellence are inextricably linked. Operational Excellence is our commitment to<br />

invest in people, processes, facilities, and supplier relationships that enable us to compete and excel in quality, cost and cycle time.<br />

With ever-increasing pressure on resources, as well as the impacts of our operations and products on the environment and society,<br />

sustainability must be at the very core of our efforts to achieve the greatest success. As we enter 2012, our initiatives will embrace<br />

Operational Excellence as we strive to embed sustainability into our operations, our supply chain, our culture, and our workforce.<br />

Our focus will be on making sure continuous improvement is effected through process improvement programs. By identifying<br />

concrete opportunities for these gains, we will strive for measurable improvement and clear accountability. These strategies are<br />

aligned with achieving Operational Excellence and ultimately contribute to the overall value and sustainability of the business.<br />

Our corporate sustainability report gives you the details behind our 2011 accomplishments and our commitments for 2012 in<br />

each of three areas—society, environment and governance. We hope you read the entire report and that you sense our enthusiasm<br />

and commitment to sustainability. We want to engage our stakeholders as a responsible corporate citizen that contributes positively<br />

to the environment and society. We welcome your feedback.<br />

We feel very good about the progress we’ve made, and we are confident about where we are going as we continue “bringing energy<br />

and the environment into harmony.”<br />

Vincent R. Volpe Jr.<br />

President and Chief Executive Officer<br />

2 DRESSER-RAND

VISION<br />

Our vision is to earn client loyalty for life.<br />

MISSION<br />

OVERVIEW<br />

Our mission is to provide the most reliable<br />

and efficient rotating equipment technology<br />

and service solutions and lead in safety,<br />

environmental stewardship, quality, and<br />

cycle time.<br />

GUIDING PRINCIPLES AND VALUES<br />

Safety and Environmental Stewardship<br />

are our priorities and critical considerations<br />

in everything we do.<br />

Integrity and Ethics guide our conduct<br />

and create the foundation for a sound<br />

business reputation.<br />

Employee Expertise and Responsibility<br />

result from recruiting, training and developing<br />

individuals, and encouraging cultural diversity<br />

in an environment of integrity, teamwork<br />

and empowerment.<br />

Operational Excellence is our commitment<br />

to invest in people, processes, facilities,<br />

and supplier relationships that enable us<br />

to compete and excel in quality, cost and<br />

cycle time.<br />

Innovation enables us to deliver unparalleled<br />

value through leading-edge technology and<br />

creative solutions.<br />

Lifelong Support focused on servicing<br />

a global installed base is essential for our<br />

long-term growth and client satisfaction.<br />

Lifelong Loyalty acknowledged by all<br />

employees as the ultimate driver of our<br />

success. Achieved through disciplined<br />

processes and reflects a supportive<br />

attitude that delivers long-term relationships<br />

with clients.<br />

Increased Stockholder Value through<br />

superior financial performance and growth.<br />

CORPORATE SUSTAINABILITY REPORT 3

OUR APPROACH TO<br />

SUSTAINABILITY<br />

4 DRESSER-RAND<br />

Sustainability provides a framework for understanding emerging trends, viewing<br />

the world holistically and understanding how these emerging trends in society,<br />

technology and energy resources should influence our business decisions.<br />

By 2050, the world’s population is expected to grow from nearly seven billion<br />

to more than nine billion people. Most of this population growth will occur in<br />

developing countries. As the world’s population grows, the demand on all<br />

energy resources will increase. Even as the United States establishes global<br />

goals to achieve 20% of its energy coming from renewables by 2030, fossil<br />

fuels will remain the prime source in its energy basket through 2050. And<br />

with 75 years of oil and 130 years of natural gas available to us, these natural<br />

resources will be sufficient to meet the energy demand and growth of the<br />

developing countries into the future.<br />

<strong>Dresser</strong>-<strong>Rand</strong> supports the prudent development of our oil, gas and coal<br />

natural resources. Investment in technologies that enhance the efficiencies<br />

of our clients’ operations and lower carbon intensity are aligned with our<br />

sustainability principles.<br />

Therefore, we believe we can support sustainability by investing in advanced<br />

technologies and improving our core products and services. Also, we continue<br />

to position <strong>Dresser</strong>-<strong>Rand</strong> in expanding our support of environmental solutions,<br />

emerging renewables technologies and alternative energy markets. We<br />

do this by using a diligent approach to innovation and investing in new and<br />

emerging technologies.<br />

We continue to build upon our sustainability principles and values by following<br />

a business approach that deals with sustainability issues that intersect with our<br />

value chain. This presents opportunities for shared value with our clients that are<br />

also important to our stakeholders and the greater societies where we operate.<br />

OUR SUSTAINABILITY PRINCIPLES<br />

• Maintaining the highest standards of business ethics, governance, integrity,<br />

and safety<br />

• Embracing opportunities and managing risks deriving from economic,<br />

environmental and social developments<br />

• Responsibly using material and energy resources<br />

• Providing environmental solutions with economic value for our clients<br />

• Addressing issues of consequence to our stakeholders with sustainable<br />

business practices<br />

• Developing technologies, products, and services that bring energy and the<br />

environment into harmony<br />

• Investing in the development of our employees and the communities where<br />

we operate<br />

• Creating long-term stockholder value through sustainable processes,<br />

products and services<br />

By including our suppliers and clients across our value chain, and engaging<br />

our employees and the communities in which we operate, we can identify and<br />

provide solutions that create long-term stockholder value through sustainable<br />

products and services that benefit society.<br />

The future of energy demand presents an array of challenges, and we look<br />

forward to the opportunities that come with it.<br />

Brad Dickson<br />

Vice President, Chief Marketing Officer

OUR SUSTAINABILITY PRINCIPLES EMBRACE ISSUES<br />

RELATING TO ENVIRONMENT, SOCIETY AND GOVERNANCE<br />

SOCIETY<br />

People<br />

Localization<br />

Health and Safety<br />

Community<br />

Suppliers<br />

Diversity<br />

Labor Relations<br />

Philanthropy<br />

ENVIRONMENT<br />

Climate Change<br />

Facility Efficiency<br />

Technology<br />

Product Efficiency<br />

Material Conservation<br />

Waste and Recycling<br />

Water Conservation<br />

SUSTAINABILITY<br />

AT<br />

DRESSER-RAND<br />

GOVERNANCE<br />

Policies<br />

Board Oversight<br />

Compliance<br />

Guiding Principles<br />

Internal Committees<br />

ECONOMIC IMPACT: By operating responsibly,<br />

we improve our economic standing by decreasing risks<br />

and enhancing our attractiveness to stakeholders<br />

OVERVIEW<br />

CORPORATE SUSTAINABILITY REPORT 5

STAKEHOLDER<br />

ENGAGEMENT<br />

• ANNUAL MEETING OF<br />

STOCKHOLDERS<br />

• ANNUAL REPORT<br />

• COMMUNICATIONS WITH<br />

STOCKHOLDERS, INVESTORS<br />

AND ANALYSTS<br />

• FACILITY TOURS<br />

• INVESTMENT CONFERENCES<br />

AND QUARTERLY CONFERENCE<br />

CALLS<br />

6 DRESSER-RAND<br />

<strong>Dresser</strong>-<strong>Rand</strong> recognizes the importance of engaging its stakeholders to<br />

understand their concerns and issues. The dialogue developed between<br />

<strong>Dresser</strong>-<strong>Rand</strong> and its stakeholders allows us to appreciate different viewpoints<br />

and better understand how our business value propositions can be aligned<br />

with the goals of our stakeholders and larger societal goals. We engage<br />

our employees, clients, stockholders, communities, regulatory authorities,<br />

and other stakeholders through various avenues of communication. Our<br />

stakeholders and our engagement with them have evolved over our long<br />

history, rather than as a result of a formal, defined process.<br />

The stakeholders we conscientiously engage include clients, employees,<br />

communities, suppliers, and stockholders. We strive to gain our clients’<br />

loyalty for life through localization efforts and by delivering a superior value<br />

proposition. We engage our employees by offering training and development<br />

opportunities to help them advance in their careers and strive to reach balance<br />

by creating a culture of teamwork, dedication and passion that encourages<br />

their creative contributions. As a technology leader in our industry, we support<br />

our communities by helping to develop educated and skilled citizens. We<br />

view our Supply Chain as an extension of our manufacturing network, and<br />

our business model requires strong, enduring supplier relations with globally<br />

competitive companies. We keep our stockholders informed through regular<br />

and timely communications and events.<br />

We believe stakeholder engagement is important, because our understanding<br />

of their priorities often leads to shaping our business strategy, technology<br />

and geographical focus for investment and solutions. Over the past few years,<br />

we invited industry analysts to address our leadership team at our worldwide<br />

management meeting. The analysts shared their views on the industry and<br />

on <strong>Dresser</strong>-<strong>Rand</strong>. We also have senior management participate in industrywide<br />

forums that provide thought leadership on pressing issues relating to<br />

energy and the environment. These include EU Turbine (European Association<br />

of Gas and Steam Turbine Manufacturers) and the Construction Industry<br />

Institute (includes addressing sustainability for capital projects).<br />

As we progress, we will continue to engage our stakeholders.<br />

Blaise Derrico<br />

Vice President, Investor Relations

KEY ISSUES<br />

“OUR MISSION FOR 2012 AND<br />

BEYOND IS TO GROW VALUE FOR<br />

OUR STOCKHOLDERS IN A WAY<br />

THAT IS SUSTAINABLE.<br />

”<br />

ECONOMIC IMPACT: By operating our company with a consistent<br />

strategy and the highest standards of integrity and transparency, we are<br />

creating value for our stockholders<br />

OVERVIEW<br />

At <strong>Dresser</strong>-<strong>Rand</strong>, we are providing premier-quality products and services for our<br />

clients to address the needs of the worldwide energy infrastructure. We are driving<br />

Operational Excellence through our global operations to reduce our environmental<br />

impacts. Recognizing that our strength is in our employees, suppliers and service<br />

providers, we are providing them growth opportunities with critical consideration<br />

to their health and safety. We are supporting the communities where we work and<br />

live through local sourcing and educational partnerships. By operating our company<br />

with a consistent strategy and the highest standards of integrity and transparency,<br />

we are creating value for our stockholders.<br />

Our approach to sustainability is to integrate our sustainability principles into our<br />

business processes. We require annual training on ethical business practices and<br />

integrate safety into our daily work lives. We remind ourselves that the only way is<br />

the safe, ethical way. We have a robust risk management system that<br />

quantifies risk and helps us determine how to reach our goals in<br />

the way that will reap the most benefit.<br />

One of the major goals of our drive for<br />

Operational Excellence is to reduce waste—a<br />

major step towards a sustainable business. By<br />

requiring the same of our suppliers, we reduce<br />

waste up and down our entire supply chain,<br />

passing increasingly sustainable products<br />

on to our clients.<br />

Another of our major initiatives on our<br />

journey to Operational Excellence<br />

is to singularize global processes,<br />

ensuring that streamlining<br />

efforts are replicated quickly and<br />

efficiently and that we’re not<br />

expending valuable time and<br />

cost to reinvent processes at<br />

each location. Our goals are<br />

to reduce cost and cycle time<br />

while increasing value—and<br />

developing sustainable processes<br />

and a sustainable business is<br />

the smartest way to achieve<br />

those goals.<br />

Sustainability is becoming<br />

a way of thinking and<br />

a part of our culture as<br />

we continue our journey<br />

toward bringing energy and<br />

the environment into harmony.<br />

CORPORATE SUSTAINABILITY REPORT 7

8 DRESSER-RAND<br />

❮ CLIMATE<br />

Innovate to create technology<br />

solutions to mitigate greenhouse<br />

gas (GHG) emissions and to<br />

develop technologies for alternative<br />

energy sources for the future.<br />

❮ LOCALIZATION<br />

Expand our reach to extend the<br />

benefits of job creation, local<br />

sourcing and partnerships in<br />

research and development and<br />

education in the communities<br />

where we operate.<br />

❮ COMMUNITIES<br />

Maintain and develop educational<br />

partnerships that support science<br />

and technology education to<br />

enable tomorrow’s workforce.

❮ DRIVING EFFICIENCY IN<br />

OUR CLIENTS’ OPERATIONS<br />

Increase energy efficiency<br />

and reduce the footprint of our<br />

products while providing superior<br />

service to extend their usefulness.<br />

❮ PEOPLE<br />

Provide training and development<br />

opportunities in a collaborative<br />

culture to attract and retain superior<br />

and creative talent.<br />

❮ SUPPLIERS<br />

Drive operational excellence and<br />

energy efficiency into our supply<br />

chain through the deployment<br />

of lean principles and supplier<br />

partnerships.<br />

OVERVIEW<br />

❮ DRIVING OPERATIONAL<br />

EXCELLENCE IN OUR<br />

OPERATIONS<br />

Reduce the environmental<br />

footprint of our operations through<br />

operational excellence, which<br />

embodies systematic measurement,<br />

monitoring and continuous<br />

improvement.<br />

❮ HEALTH AND SAFETY<br />

Institute disciplined, consistent<br />

operational processes to ensure<br />

the health and safety of every<br />

employee while striving to drive<br />

our injury rate to zero.<br />

❮ GOVERNANCE<br />

Operate with strict adherence<br />

to the highest standards of ethical<br />

behaviors while considering<br />

sustainability issues in our<br />

decision-making.<br />

CORPORATE SUSTAINABILITY REPORT 9

SECTION 1<br />

ENVIRONMENT<br />

Bringing energy and the environment into harmony. We are focused on reducing the negative<br />

impacts that our products, services, operations, and the energy industry we serve have on the<br />

environment. Clients who use our technologies want to be responsible stewards of the world’s<br />

limited resources while reducing their own environmental footprint. With regard to DRESSER-RAND<br />

and its facilities, we realize that greater efficiency through OPERATIONAL EXCELLENCE results in<br />

both cost reductions and conservation.<br />

10 DRESSER-RAND<br />

2011 COMMITMENTS 2011 ACCOMPLISHMENTS<br />

Continue to focus on our internal<br />

sustainability initiatives<br />

Continue development and implementation<br />

of an eco-design process<br />

Develop a company-wide waste management<br />

program<br />

Improve and expand processes for<br />

collecting and documenting data for<br />

sustainability indicators<br />

Continue development of innovative<br />

technologies that promote sustainability<br />

Improved our workplace environment<br />

across the company using Lean Six<br />

Sigma processes<br />

Continued “Lean to Green” training<br />

which incorporates health and safety<br />

aspects and eco-efficiency into our<br />

Lean Six Sigma tools and processes<br />

across the company<br />

Continued Environmental and<br />

Sustainability Awareness training<br />

across the company<br />

Discussions with Process Innovation resulted<br />

in a tactical plan to incorporate eco-design<br />

criteria into our Value Engineering Initiative<br />

and leverage existing engineering processes<br />

Developed strategy and corporate waste<br />

management standards<br />

Formulated a process to collect critical<br />

information and purchased software<br />

New test facility for Rampressor with<br />

application in carbon capture and<br />

sequestration<br />

Acquired Grupo Guascor and added<br />

a broad range of sustainable energy<br />

technologies to our portfolio<br />

Invested in Echogen Power Systems for<br />

supercritical CO2 waste-energy solutions<br />

The Ebro river valley in Catalonia, Spain, where <strong>Dresser</strong>-<strong>Rand</strong><br />

has six facilities and approximately 700 employees.

2012 GOALS<br />

Develop new standards and procedures<br />

for company-wide waste management<br />

Advance design for oil-free compressors<br />

with active magnetic bearing (AMB)<br />

technology<br />

Incorporate HSE & “Lean to Green” into<br />

key process Value Stream Maps<br />

Develop the eco-design process with the<br />

engineering community of practice (CoP) to<br />

incorporate basic eco-design considerations<br />

into our R&D engineering process<br />

Initiate “green supply chain” discussion<br />

and advance through the strategy and<br />

planning stage<br />

ENVIRONMENT<br />

CORPORATE SUSTAINABILITY REPORT 11

ADDRESSING<br />

CLIMATE CHANGE<br />

Innovate to create technology<br />

12 DRESSER-RAND<br />

solutions to mitigate<br />

greenhouse gas emissions and<br />

to develop technologies for<br />

alternative energy sources<br />

for the future.<br />

Increasing global population and per capita income, centered primarily<br />

in developing countries, will drive demand for energy and the products<br />

and natural resources necessary to produce them.<br />

A widely believed consequence of global economic growth and<br />

increased population is a rise in greenhouse gas emissions and global<br />

average temperatures.<br />

We believe that <strong>Dresser</strong>-<strong>Rand</strong> is in a unique position regarding climate<br />

change. Regardless of the source of energy, whether from traditional<br />

sources (such as fossil fuels) or from emerging clean energy applications<br />

(such as wind and wave energy), our products can lessen overall<br />

environmental impacts.<br />

Our focus on Operational Excellence allows us to provide competitive<br />

solutions and equipment that increase energy efficiency and reduce<br />

emissions for oil production, refining, petrochemical and liquefied natural<br />

gas (LNG) facilities, pipelines, and a multitude of other applications. In<br />

addition, applying Operational Excellence to our own operations improves<br />

productivity, reducing resource consumption and the carbon footprint<br />

of our operations.<br />

We believe we can add value to our clients’ operations by increasing<br />

the efficiency of our products and by providing solutions that lower<br />

carbon emissions.<br />

We are aggressively pursuing innovations and technologies that<br />

help address our clients’ environmental concerns and reduce their<br />

carbon footprints.<br />

Greg Stubbs<br />

Senior Manager, Sustainability & HSE Process Innovation

CARBON CAPTURE UTILIZATION<br />

AND STORAGE—RAMGEN®<br />

SUPERSONIC COMPRESSION<br />

TECHNOLOGY<br />

Interest in carbon capture and storage<br />

(CCS) has been slow to attract investment<br />

around the world as economic recovery has<br />

taken center stage. However, the dialogue<br />

on global warming continues unabated.<br />

Currently, the investment is predominantly<br />

directed towards enhanced oil recovery<br />

(EOR), a form of carbon capture utilization<br />

and storage (CCUS) that can provide<br />

economic benefit without subsidies such as<br />

a carbon pricing mechanism. <strong>Dresser</strong>-<strong>Rand</strong><br />

is a leader in the EOR compression market.<br />

The cost of large-scale implementation of<br />

CCS technologies is challenging, and the<br />

ongoing issues of storing large quantities<br />

of CO2 must be addressed. We expect that<br />

the technologies associated with CCUS<br />

will become economically feasible in the<br />

near- to mid-term.<br />

In 2008, <strong>Dresser</strong>-<strong>Rand</strong> made an investment<br />

in Ramgen Power Systems LLC and began<br />

supporting the development of technology<br />

that is expected to reduce the cost of<br />

compression by 50% when compared to<br />

the current cost of existing compression<br />

technologies. The Ramgen technology<br />

also offers significant footprint savings<br />

and high-grade heat for energy recovery.<br />

In 2011, Ramgen completed a dedicated<br />

CO2 closed-loop compressor test facility<br />

at the <strong>Dresser</strong>-<strong>Rand</strong> Olean, N.Y., campus.<br />

This one-of-a-kind test facility supports<br />

Ramgen Power System’s demonstration<br />

World’s first supersonic CO 2 compression<br />

test facility, located in Olean, N.Y., USA.<br />

of a 10 MW Ramgen supersonic CO2<br />

compressor. It is designed to validate a<br />

10:1 compression ratio technology in a<br />

single stage—which on an equivalent basis<br />

takes eight to 10 stages using conventional<br />

technology. This full-scale demonstration<br />

testing is expected to begin in 2012.<br />

OCEAN WAVE ENERGY—<br />

HYDROAIR TURBINE<br />

We are working to provide solutions for<br />

harnessing renewable ocean wave energy<br />

and efficiently converting it to electricity<br />

for use on land. <strong>Dresser</strong>-<strong>Rand</strong> engineered<br />

and developed the patent-pending<br />

HydroAir turbine (shown at right)—<br />

a variable-radius turbine (VRT) that<br />

has substantially higher efficiency<br />

than comparable devices. An initial<br />

prototype was installed in Australia in<br />

2010. <strong>Dresser</strong>-<strong>Rand</strong> and Ireland-based<br />

Ocean Energy Limited, a market leader<br />

in developing oscillating water column<br />

(OWC) plants, signed a memorandum<br />

of understanding in 2010 to develop a<br />

complete range of full-scale devices to<br />

produce electricity. This partnership could<br />

lead to an Irish industry generating 600<br />

MW of electricity by 2020, enough to<br />

supply the needs of 450,000 households.<br />

In addition, it was announced in January<br />

2012 that the Cornwall, U.K.–based<br />

Wave Hub selected Ocean Energy and<br />

<strong>Dresser</strong>-<strong>Rand</strong> to deploy its technologies<br />

at its flagship testing site in 2012.<br />

ENVIRONMENT<br />

CORPORATE SUSTAINABILITY REPORT 13

DRIVING EFFICIENCY IN OUR<br />

CLIENTS’ OPERATIONS<br />

14 DRESSER-RAND<br />

We engage our clients at all levels of their organizations on a day-to-day<br />

basis as well as in executive dialogue regarding their most pressing issues.<br />

Through our alliance agreements with key clients, we have developed<br />

performance metrics. We have also established semiannual or annual<br />

executive-to-executive communications (executive sponsor meetings)<br />

where collaborative exchange is held on issues such as safety, reliability,<br />

operational performance, technology needs, future business projections,<br />

and supply chain.<br />

As with our 2009 report, we again chose to obtain an in-depth view of our<br />

2010 Sustainability Report from one of our largest clients to obtain critical<br />

“voice of client” feedback on our activities and the report itself. Some of that<br />

feedback is incorporated into this report.<br />

We maintain an intense client focus through:<br />

• Our New Equipment and Services client-facing organization, whose mission<br />

is to earn client loyalty for life<br />

• 49 service and support centers and 76 sales offices in 32 countries,<br />

with plans to add more to provide responsive support and service<br />

to our clients’ installed base<br />

• A global network of approximately 180 independent representatives,<br />

all of whom promote our brand, sell our products and provide service<br />

and aftermarket support to our installed base locally in more than<br />

150 countries<br />

• Enhanced relationships and alliance agreements with key clients;<br />

we have more of these relationships in place than any other original<br />

equipment manufacturer in the markets we serve<br />

• Configuration sessions or tools that minimize cycle time and help<br />

our clients optimize their equipment solutions<br />

• Technology updates<br />

• Our Client Interface Response System (CIRS)—an interactive, Web-based<br />

tool that allows clients to communicate with <strong>Dresser</strong>-<strong>Rand</strong> technical<br />

experts about an issue, technical query or problem on a specific piece<br />

of existing equipment<br />

• On-line, on-site or off-site product training<br />

We are hard at work providing the most reliable and efficient rotating<br />

equipment technology and service solutions with a view towards earning<br />

client loyalty for life.<br />

Jesus Pacheco<br />

Executive Vice President, New Equipment Worldwide

PROVIDING OUR CLIENTS WITH<br />

SUSTAINABLE SOLUTIONS<br />

With a team dedicated solely to<br />

environmental solutions, <strong>Dresser</strong>-<strong>Rand</strong><br />

is well positioned to serve the emerging<br />

environmental solutions markets. We<br />

support our clients in their efforts to<br />

reduce the environmental footprint<br />

associated with their day-to-day operations<br />

through improving the efficiency of their<br />

power generation activities, supporting<br />

their renewable energy initiatives and<br />

reducing the greenhouse gas (GHG)<br />

emissions from their operations.<br />

With its acquisition of Guascor,<br />

<strong>Dresser</strong>-<strong>Rand</strong> now has capabilities in the<br />

design, construction and development of<br />

power generation and cogeneration plants<br />

and mini-hydroelectric plants, as well as<br />

the development and exploitation of wind<br />

farms and biomass, used oil and landfill<br />

energy recovery, photovoltaic solar energy,<br />

and aerobic processing.<br />

Our technologies support our clients’<br />

competitiveness by improving process<br />

efficiencies and reducing emissions,<br />

enabling them to meet increasingly<br />

stringent environmental regulations.<br />

INNOVATION NORWAY<br />

GRANTS AWARD FOR GREEN<br />

TECHNOLOGY<br />

In 2011, <strong>Dresser</strong>-<strong>Rand</strong> was awarded<br />

$684,000 USD (4 million NOK) in<br />

public grant funding by Innovation<br />

Norway (IN). The grant will be used to<br />

support testing a new, environmentallyfriendly<br />

turbine-generator set, known as<br />

the <strong>Dresser</strong>-<strong>Rand</strong> KG2-3G unit.<br />

IN, a development funding arm of the<br />

Norwegian government that supports<br />

environmental initiatives, awarded<br />

<strong>Dresser</strong>-<strong>Rand</strong> the funding because the<br />

KG2-3G turbine is expected to drastically<br />

reduce fuel consumption, decrease CO2<br />

emissions 35 percent, and decrease NOx<br />

and CO emissions 80 percent when<br />

compared to the rating of the existing<br />

KG 2-3E turbine. The KG2-3G turbine<br />

also comes with an acoustic enclosure for<br />

onshore installation and is suitable for a<br />

variety of applications, including biofuel<br />

systems.<br />

The unit will be installed at the WINGAS<br />

Transport GmbH site in Greifswald,<br />

Germany, where the North Stream<br />

pipeline comes into Europe from Russia.<br />

WINGAS will provide natural gas for<br />

the field test in exchange for the heat and<br />

power produced by the KG2-3G turbine.<br />

The electric power will be exported and<br />

the exhaust heat used to heat pipeline gas<br />

coming out of the Baltic Sea.<br />

More than 900 KG2 gas turbines have<br />

been delivered for standby, industrial and<br />

oil and gas applications worldwide.<br />

GAME-CHANGING<br />

TECHNOLOGY: THE DATUM® ICS<br />

The DATUM® ICS is an advanced<br />

technology platform that uses<br />

high-efficiency DATUM centrifugal<br />

compressor technology driven by a<br />

high-speed, close-coupled, oil-free, electric<br />

motor. The DATUM ICS is the first<br />

technology to incorporate a proprietary,<br />

integrated gas-liquid separation unit,<br />

avoiding the use of a large static inlet<br />

scrubber to protect the compressor. The<br />

compression system is complete with<br />

process gas coolers, process piping, valves<br />

and instrumentation, all packaged into a<br />

single lift module.<br />

The DATUM ICS provides a complete<br />

compression system for applications in<br />

upstream, midstream and downstream<br />

markets, and features the industry’s<br />

smallest footprint with up to a 50% space<br />

and weight reduction—all of which<br />

translates into significantly less steel being<br />

used offshore and delivering real value<br />

through the lowest total installed cost.<br />

Our first unit was built and shipped in<br />

September 2010 and is expected to start<br />

operation in 2012.<br />

Working with subsea integrators, we plan<br />

to take this proven DATUM ICS design<br />

and fit it for service on the sea floor. In<br />

June 2011 we partnered with Statoil in a<br />

joint research and development project.<br />

Initially, the companies will focus on<br />

configuring the DATUM ICS package for<br />

high-power applications in a nominal eight<br />

to 12 MW range. Once the equipment<br />

operating conditions and package<br />

requirements have been clearly defined,<br />

<strong>Dresser</strong>-<strong>Rand</strong> will build a high-power<br />

ICS and test it in a unique liquid-gas<br />

hydrocarbon test facility in Olean, N.Y.,<br />

USA. In addition, <strong>Dresser</strong>-<strong>Rand</strong> plans to<br />

conduct testing on a sub-sea test stand<br />

to be constructed alongside the ICS test<br />

facility.<br />

CASE STUDY<br />

ENVIRONMENT<br />

DRESSER-RAND TEAMS UP WITH<br />

KING FAHD UNIVERSITY FACULTY<br />

AND STUDENTS FOR NOISE<br />

REDUCTION RESEARCH<br />

<strong>Dresser</strong>-<strong>Rand</strong> finalized a collaborative<br />

research agreement with King Fahd<br />

University of Petroleum and Minerals<br />

(KFUPM), and last May we participated<br />

in the first annual KFUPM Research Day<br />

to highlight activity taking place under<br />

the research agreement.<br />

KFUPM organized the event, with lectures,<br />

technical presentations and an exhibition<br />

held on the KFUPM campus to enable<br />

faculty, researchers, graduate students,<br />

and guests to learn about research<br />

activities at the university and build an<br />

environment of innovation.<br />

We exhibited the <strong>Dresser</strong>-<strong>Rand</strong> Duct<br />

Resonator (DR) Array demonstration<br />

rig and performed an interactive<br />

demonstration of the DR Array noise<br />

reduction technology. The KFUPM<br />

students from the mechanical engineering<br />

department presented findings under a<br />

<strong>Dresser</strong>-<strong>Rand</strong>–funded research project<br />

focused on improving the DR Array<br />

technology.<br />

The research team from KFUPM included<br />

Dr. Samir Mekid and three students.<br />

Two undergraduate students worked<br />

on reducing the manufacturing cost of<br />

DR Array technology, collaborating with<br />

another team of students from Lehigh<br />

University on the same topic. A graduate<br />

student studied resonator arrays in<br />

general to further improve the acoustic<br />

performance of <strong>Dresser</strong>-<strong>Rand</strong> DR Array<br />

technology.<br />

<strong>Dresser</strong>-<strong>Rand</strong> and Saudi Aramco are<br />

evaluating opportunities to apply noise<br />

reduction technology to compressor<br />

installations at production facilities within<br />

the Kingdom.<br />

CORPORATE SUSTAINABILITY REPORT 15

OPERATIONAL EXCELLENCE IN<br />

OUR OPERATIONS<br />

16 DRESSER-RAND<br />

Our primary environmental impact is derived from manufacturing our<br />

products. We use a specialized software application to track our direct and<br />

indirect energy usage for our Scope 1 and Scope 2 greenhouse gas (GHG)<br />

emissions. We report under the Global Reporting Initiative (GRI) direct energy<br />

consumption (EN3), indirect energy consumption (EN4), and total direct and<br />

indirect GHG emissions (EN16). Our software uses the globally accepted<br />

World Resources Institute GHG Protocol and the ISO 14064 standard to<br />

collect our GHG emissions data. A third-party firm provides integrated<br />

advisory, financial and implementation services for the energy value chain.<br />

We continue to apply our lean manufacturing and lean office processes<br />

to reduce waste in manufacturing and transactional processes. In 2011,<br />

our Global Process Innovation group coordinated lean initiatives and<br />

environmental stewardship through the Lean Sigma Certificate workshop<br />

for the third year running. The workshop was expanded to encompass<br />

more of our worldwide locations in 2011. A total of 189 participants graduated<br />

in 2011 from the Lean Sigma Certificate workshops, and 54 Lean Sigma<br />

improvement projects resulted from these workshops. The majority of these<br />

lean improvement projects yielded increased capacity and reduced cycle<br />

time via the elimination of wasteful, non-value-added activities.<br />

We continue to expand the implementation of a client-focused, continuous<br />

improvement toolkit to improve quality, on-time delivery, health and safety,<br />

and profitability. Six Sigma workplace process implementation continues<br />

within our manufacturing sites. Each site has established a scoring matrix to<br />

determine sustainability improvement. A process is in place for self-audits on<br />

the requirements of the scoring matrix, with follow-up audits by the respective<br />

site leadership teams.<br />

We are making significant progress introducing Standard Work Processes<br />

in our service centers. Through 2011, more than 35,000 work instructions<br />

have been standardized, written and translated into the respective service<br />

center location’s local language. Results of this activity indicate significant<br />

improvement in efficiency of such complex tasks as teardown and rebuild of<br />

steam turbines.<br />

In 2011, <strong>Dresser</strong>-<strong>Rand</strong> worked with its transportation and logistics providers<br />

to continue to identify opportunities for decreasing its carbon footprint.<br />

Actions taken included the consolidation of shipments where possible and<br />

slow steaming of ocean-going vessels to reduce the carrier company’s<br />

carbon footprint.<br />

We also continue to evaluate our fork truck fleet for opportunities to reduce<br />

the number of combustion engine emission–style trucks and replace them<br />

with electric trucks. In March 2012, we entered into an operational lease to<br />

replace 25 combustion engine–emission trucks with electric-style fork trucks.<br />

Jim Methven<br />

Director, Global Singular Processes

OPERATIONAL EXCELLENCE—<br />

QUALITY, COST AND<br />

CYCLE TIME<br />

<strong>Dresser</strong>-<strong>Rand</strong> implemented an ongoing<br />

evaluation of Quality Assurance programs<br />

for its operations and those of its suppliers.<br />

The intent of this initiative is to continue<br />

to maintain a proactive productivitybased<br />

quality metric to link costs of<br />

poor quality to volume; maintain a<br />

high-level, productivity-based quality<br />

improvement plan; and to focus on<br />

preventing quality defects and defect<br />

escapes to downstream processes.<br />

<strong>Dresser</strong>-<strong>Rand</strong> aggressively pursues<br />

quality in its developing country sourcing<br />

program, which incents our legacy supply<br />

companies to improve quality in order<br />

to stay competitive. Our continued<br />

focus is intended to improve our quality<br />

year-over-year, but we still have much to<br />

do in order to further improve cycle time<br />

and delivery to our clients.<br />

All of our Process Innovation and Supply<br />

Chain management initiatives are focused<br />

on improving quality, reducing cost,<br />

reducing cycle time, and improving<br />

on-time delivery—or in other words,<br />

achieving Operational Excellence. We<br />

have the right people in place to improve<br />

cycle time and implement cost reduction;<br />

now we need to focus on data and systems<br />

in order to maximize and sustain these<br />

improvements.<br />

Our project prioritization process will<br />

ensure that resources are efficiently<br />

deployed with maximum impact on<br />

the performance of the company. This<br />

includes determining which operations<br />

and suppliers need more support in order<br />

to improve quality and reduce cycle time.<br />

Actively pursuing supplier alternatives and<br />

working with suppliers to reduce scrap and<br />

rework help reduce costs.<br />

Our strategy is to develop a supplier-toclient<br />

on-time delivery culture across<br />

execution teams and to improve on-time<br />

delivery performance against agreed-to<br />

dates defined in the project master<br />

schedule.<br />

RESPONSIBLY USING MATERIALS<br />

AND ENERGY RESOURCES<br />

We have initiatives underway throughout<br />

the company to use material and energy<br />

resources more responsibly, including<br />

through the reduction of waste and<br />

increased recycling. A few examples of<br />

this are mentioned below.<br />

Our plant in Naroda, India, operates a<br />

solar water heating system. The system<br />

provides heated water to the plant<br />

and office buildings at a savings of<br />

approximately 44,000 kWh of energy<br />

per year. In addition, the plant conserves<br />

energy by using variable-frequency drives<br />

in its compressor test facility and on its<br />

compressor cooling water tower.<br />

ENVIRONMENT<br />

During 2011, our Burlington, Iowa, plant<br />

expanded its recycling effort, adding new<br />

types of materials for recycling. For the<br />

year, the volume of material going to local<br />

landfill was more than 90% less than<br />

2009 levels and consistent with 2010.<br />

The Burlington facility received the Des<br />

Moines County Landfill Sustainability<br />

Award for recycling.<br />

In 2011, our Naroda, India, plant installed<br />

an electrostatic oil filtration system and<br />

recycled 4,741 liters of oil for reuse. The<br />

plant’s wood recycling program resulted<br />

in the reuse of 582 cubic feet of wood,<br />

and the plant reduced its paper usage by<br />

implementing a two-sided printing policy<br />

and recycled 264 kg of scrap paper. In<br />

addition, each employee was provided a<br />

water bottle and a mug for tea, eliminating<br />

the use of paper cups.<br />

WATER USE<br />

Our Naroda plant installed a water<br />

harvesting system in 2010. In 2011 they<br />

installed an oil skimmer and 5-micron<br />

filter system to continuously filter the<br />

coolant solution, increasing coolant life<br />

and reducing coolant and water usage.<br />

PLANT BUILDING SOLAR<br />

WATER HEATING SYSTEM<br />

Use:<br />

Component cleaning<br />

Energy saved per year:<br />

44,000 kWh<br />

System:<br />

40 collectors<br />

Indirect heating capacity:<br />

6,000 liters per day @<br />

70 °C (158 °F)<br />

CORPORATE SUSTAINABILITY REPORT 17

SECTION 2<br />

SOCIETY<br />

Our business success is supported by our relationships with our employees and the communities<br />

where we operate. In the factory and in our global service operations, our priority is HEALTH<br />

AND SAFETY. In communities where we have a presence, we are focused on achieving long-term<br />

economic, social and environmental benefits through SUSTAINABLE INITIATIVES, job creation,<br />

supplier engagement, research and development activities, and educational support. Our<br />

commitment is to broaden these benefits by expanding our local presence in the places where<br />

we operate.<br />

18 DRESSER-RAND<br />

2011 COMMITMENTS 2011 ACCOMPLISHMENTS<br />

Enhance our progress and oversight<br />

for privacy issues<br />

Continue our training and development<br />

investment in our employees<br />

Create jobs and opportunities through<br />

our localization initiatives<br />

Strive to extend the reach of our corporate<br />

charitable initiatives<br />

Established a Data Protection<br />

Committee, consisting of the vice<br />

presidents of human resources, law<br />

and information technology, with<br />

responsibility for overseeing our<br />

compliance with international data<br />

protection and privacy regulations.<br />

Confirmed our compliance with<br />

French and Spanish data privacy<br />

regulations, and achieved safe harbor<br />

status for certain data transfers from<br />

France and Spain to the U.S.<br />

See “Training and Development”<br />

on page 23<br />

Progressed Saudi Arabia service<br />

and repair center; increased local<br />

employment at recently established<br />

Pune India Engineering Center;<br />

initiated localization plans in support<br />

of the Petrobras 8 “replicant” FPSOs<br />

award; increased local employment<br />

opportunities through our gas turbine<br />

repair and service center expansions<br />

See “Community” on pages 26-28<br />

Pune, India, where our global engineering<br />

support center employs approximately 200 people.

2012 GOALS<br />

Enhance our progress and oversight<br />

for privacy issues<br />

Continue our efforts to expand the reach<br />

of our corporate charitable initiatives with a<br />

focus on education, civic and social programs<br />

and encourage participation of our employees<br />

in these areas<br />

Develop globally effective programs/<br />

resources/policies and procedures<br />

for implementing a world-class HSE<br />

Management System with singular processes<br />

Engage schools in communities in which we<br />

work to foster education<br />

SOCIETY<br />

CORPORATE SUSTAINABILITY REPORT 19

LOCALIZATION<br />

<strong>Dresser</strong>-<strong>Rand</strong> is committed<br />

20 DRESSER-RAND<br />

to building long-term<br />

relationships with its clients<br />

around the world by delivering<br />

high-quality products and<br />

services. To meet that<br />

commitment, we are executing<br />

a localization strategy. By<br />

addressing local needs, we will<br />

enhance our competitiveness<br />

and improve response times.<br />

We strive to employ local<br />

resources.<br />

The first unit packaged and shipped<br />

from the Saudi Arabia service center.<br />

This steam turbine-gear package is<br />

destined for the Yanbu Export Refinery<br />

Project in Yanbu, Saudi Arabia.<br />

SAUDI ARABIA SERVICE AND<br />

REPAIR CENTER<br />

The Saudi Arabia facility is under<br />

construction and is expected to be<br />

completed in 2013. The organization<br />

is operational with a branch operation<br />

located in Jubail.<br />

<strong>Dresser</strong>-<strong>Rand</strong> is building an approximately<br />

10,000-square-meter manufacturing<br />

and repair facility in Dammam Second<br />

Industrial City in the Kingdom of<br />

Saudi Arabia. The facility’s capabilities<br />

will include single-stage steam turbine<br />

manufacturing, packaging and repairs<br />

(including industrial gas turbines), field<br />

support services, technical support<br />

services, and training. The technology<br />

center has been designed and facility<br />

construction will begin in May 2012.<br />

It will include offices, a training center,<br />

cafeteria, and mosque.<br />

The localization plan for Saudi Arabia<br />

is focused on hiring locally and will<br />

create employment opportunities at all<br />

levels of the organization from the shop<br />

floor to leadership positions. We have<br />

10 Saudi engineers on staff and two<br />

Saudi business managers.<br />

An agreement was recently signed with<br />

Saudi Petroleum Services Polytechnic<br />

(SPSP), which is a vocational school<br />

in Saudi Arabia. <strong>Dresser</strong>-<strong>Rand</strong> Arabia<br />

is sponsoring 37 students of various<br />

disciplines (welding, pipefitting,<br />

machinists, and electricians) to participate<br />

in a three-year training program. They<br />

will complete their second year in<br />

December 2012 and will then begin a<br />

one-year, on-the-job training assignment<br />

with <strong>Dresser</strong>-<strong>Rand</strong> Arabia.<br />

We have established a supply chain<br />

management (SCM) team that is in the<br />

process of identifying, qualifying and<br />

developing local suppliers for our activities<br />

in the Kingdom of Saudi Arabia. We also<br />

have a services organization in place for<br />

installation, commissioning, and technical<br />

support of our products in Saudi Arabia.<br />

GLOBAL ENGINEERING SUPPORT<br />

CENTER IN PUNE, INDIA<br />

<strong>Dresser</strong>-<strong>Rand</strong> inaugurated a global<br />

engineering support center (ESC) in India<br />

in November 2010. During 2011, we<br />

added 36 engineers, two project control<br />

specialists and two SCM employees.<br />

Located in SEZ, Cybercity, Magarpatta,<br />

Pune, this ESC is currently home to<br />

107 engineers and other employees<br />

supporting <strong>Dresser</strong>-<strong>Rand</strong> worldwide<br />

operations. With drafters, designers,<br />

engineers, and other personnel, the ESC<br />

will help meet demand for engineering,<br />

designing, buying, expediting, and project<br />

managing, and also provide support<br />

EMPLOYEE AND TEMPORARY WORKERS AS OF 12/31/11<br />

Full-Time Part-Time Full-Time Part-Time<br />

% of employees<br />

Region<br />

Non-Union Non-Union Union Union Temp. Total covered by CBA*<br />

Asia Pacific 355 3 166 0 81 605 32%<br />

Europe 416 7 1,608 68 104 2,203 80%<br />

Middle East/Africa 74 0 30 0 0 104 29%<br />

North America 2,688 5 1,359 1 613 4,666 34%<br />

Latin America 684 15 27 0 30 756 4%<br />

Total 4,217 30 3,190 69 828 8,334 43%<br />

*Collective bargaining agreements

to other back office needs of IT, SCM,<br />

finance, and HR on a worldwide basis for<br />

<strong>Dresser</strong>-<strong>Rand</strong> products and services.<br />

Magarpatta City practices various<br />

sustainable practices like rainwater<br />

harvesting, garbage segregation at source,<br />

vermiculture, use of fly-ash bricks in<br />

construction and has a solar water heating<br />

system and biogas plant.<br />

The <strong>Dresser</strong>-<strong>Rand</strong> localization strategy<br />

focuses on hiring locally. Starting in 2012,<br />

we also intend to visit local engineering<br />

colleges to recruit the best in-country<br />

resources. The long-range plan for the<br />

ESC includes hiring approximately 250 to<br />

300 employees over the next five years.<br />

The ESC in India complies with all<br />

statutory guidelines.<br />

GAS TURBINE REPAIR<br />

The <strong>Dresser</strong>-<strong>Rand</strong> Cilegon, Indonesia,<br />

service center was established in 1999 to<br />

serve Indonesia, Southeast Asia and the<br />

Australian markets. We are in the process<br />

of expanding Cilegon’s service capabilities<br />

to repair gas turbines. This is part of the<br />

strategy to roll out <strong>Dresser</strong>-<strong>Rand</strong> Turbine<br />

Technology Services repair expertise to a<br />

number of our strategically located service<br />

centers. In this regard, our service center<br />

in Campinas, Brazil, now has inspection<br />

capability for gas turbines, and our service<br />

Chevron’s Agbami FPSO located<br />

offshore Nigeria. <strong>Dresser</strong>-<strong>Rand</strong><br />

supplied six 26 MW gas turbine<br />

packages for main power<br />

generation and compression.<br />

<strong>Dresser</strong>-<strong>Rand</strong> is expanding<br />

its local shop capability to<br />

increase local content, which<br />

is an important aspect of the<br />

country’s investment plan.<br />

center in Peterborough, UK, has full strip<br />

and inspection capability, weld repair,<br />

machining, heat treatment, and coatings<br />

for component repair.<br />

BRAZIL LOCALIZATION<br />

<strong>Dresser</strong>-<strong>Rand</strong> Brazil locations are working<br />

on executing awards to supply more than<br />

$700 million of compression systems<br />

and related maintenance services for<br />

eight “replicant” FPSO vessels for Brazil’s<br />

pre-salt fields. The awards were announced<br />

in 2011. Engineering is on schedule and<br />

we are in the process of arranging for<br />

critical material deliveries. Construction<br />

of the new facility is scheduled to begin in<br />

the first half of 2012. The <strong>Dresser</strong>-<strong>Rand</strong><br />

Information Technology team is working<br />

on the global singular processes (GSP)<br />

requirements. Everything is on schedule<br />

with regard to local hiring and training.<br />

Standard work practices and safety<br />

procedures are being translated into<br />

Portuguese, and supply chain personnel<br />

are evaluating local suppliers.<br />

We are pursuing LEED certification.<br />

According to the Green Building Council,<br />

Leadership in Energy and Environmental<br />

Design (LEED) provides building<br />

owners and operators with a framework<br />

for identifying and implementing practical<br />

and measurable green building design,<br />

construction, operations and maintenance<br />

solutions.<br />

LEED certification provides independent,<br />

third-party verification that a building<br />

was designed and built using strategies<br />

aimed at achieving high performance in<br />

SOCIETY<br />

key areas of human and environmental<br />

health: sustainable site development,<br />

water savings, energy efficiency, materials<br />

selection and indoor environmental<br />

quality.<br />

SERVICE CENTER EXPANSION<br />

<strong>Dresser</strong>-<strong>Rand</strong> is enhancing its Services<br />

footprint to optimize its service to clients,<br />

including establishing new locations,<br />

expanding existing locations and<br />

relocating facilities as necessary. Standards<br />

are being developed to create consistency<br />

in size, appearance, layout, tools, systems,<br />

processes, and procedures of service<br />

centers worldwide. Efforts are underway<br />

to integrate new facilities acquired by<br />

<strong>Dresser</strong>-<strong>Rand</strong> in 2011, including Grupo<br />

Guascor. We continue to audit the<br />

operation, efficiency, quality, skill sets, and<br />

safety of our worldwide service network.<br />

CORPORATE SUSTAINABILITY REPORT 21

PEOPLE<br />

22 DRESSER-RAND<br />

We achieve client satisfaction, stockholder value and employee engagement<br />

through our initiatives in safety, compliance, technology, and Operational<br />

Excellence. We recognize the value of <strong>Dresser</strong>-<strong>Rand</strong> employees and their<br />

ongoing contributions and engagement to the success of the company.<br />

We have good practices in place, the right people in the right locations<br />

and the stage is set for enhancing employee engagement. The idea is to<br />

engage our employees in Operational Excellence initiatives. We believe<br />

one of the best ways to do this is to use Process Innovation and Lean Six<br />

Sigma principles. To that end, we are developing initiatives that will involve<br />

employees in problem solving using Kaizen workshops.<br />

Our employees have a passion for what they do. This is driven by their desire<br />

to earn client loyalty for life. We are committed to streamlining our processes,<br />

providing worldwide client support and product leadership in our industry.<br />

We are implementing a mechanism through which we can use employees’<br />

suggestions to contribute to reducing cycle times, increasing productivity,<br />

improving on-time deliveries, and reducing the cost of quality. We recognize<br />

the best way to make improvements is to ask employees for their input in<br />

areas they work in every day.<br />

We don’t want to reinvent the wheel. The <strong>Dresser</strong>-<strong>Rand</strong> STAR model,<br />

introduced in the Americas and Asia Pacific operations in 2010, embodies<br />

our work toward sustainable improvements in safety, quality, delivery,<br />

cost, and people. We want to achieve and sustain a recognized leadership<br />

position in health, safety and the environment by enhancing existing<br />

programs and implementing new programs that protect the health<br />

and safety of our employees, clients and suppliers, as well as protect<br />

and improve the environment in the locations where we and our clients<br />

conduct business.<br />

A commitment to safety—our number one priority—involves considerable<br />

focus and effort around work environment improvement, combined<br />

with a culture of discipline and responsible behaviors.<br />

We believe we have world-class Field Operations, which we have<br />

enhanced through the application of lean tools and processes. The<br />

speed, visual excellence, efficiency, safety, quality, and commitment<br />

of our Field Operations creates value for our clients and fosters<br />

employee engagement.<br />

Employee engagement involves a commitment to continuous improvement.<br />

We want to empower our employees at all levels of the organization and<br />

encourage teamwork and leadership in their daily lives. We will continue<br />

to remain focused on employee engagement because of its significant<br />

importance and long-term benefits.<br />

Gustavo Nechar<br />

Vice President, Human Resources

EMPLOYEE TRAINING<br />

<strong>Dresser</strong>-<strong>Rand</strong> is committed to educating<br />

our employees as well as our business<br />

partners. We offer training and<br />

development opportunities to help<br />

them advance in their careers and strive<br />

to reach balance by promoting a culture<br />

of teamwork, dedication and passion.<br />

<strong>Dresser</strong>-<strong>Rand</strong> views employee training<br />

and development as a strategic investment that<br />

significantly contributes to the success of our<br />

company, our employees and our clients. We<br />

have safety and compliance training and other<br />

flagship programs that provide the leadership,<br />

business acumen and technical skills needed<br />

to support our corporate mission. We are<br />

expanding our programs. As we acquire new<br />

businesses, our training programs are vital to<br />

their successful integration.<br />

In this ever-changing marketplace, our<br />

employees are provided with a variety of<br />

educational platforms including on-line<br />