- Page 1 and 2:

Joint Inte

- Page 3 and 4:

CONTENTS INFLUENCE OF CHEMICAL FERT

- Page 5 and 6:

THE EFFECT OF NITROGEN SUPPLY, LIMI

- Page 7 and 8:

THE INFLUENCE OF CHEMICAL AND BIOFE

- Page 9 and 10:

STUDIES REGARDING THE INFLUENCE OF

- Page 11 and 12:

PREFACE With the general aims to co

- Page 13 and 14:

For a better knowledge of applicati

- Page 15 and 16:

pH values pH values 8 6 pH values 6

- Page 17 and 18:

In the preluvosoil conditions the m

- Page 19 and 20:

REFERENCES Bedo, Z.- Lang, L. (1977

- Page 21 and 22:

mean (fixed, i.e. systematic effect

- Page 23 and 24:

29% in the first 15 years of the ex

- Page 25 and 26:

Table 2. Variance and regression pa

- Page 27 and 28:

The b = 1.7 value recorded for Trea

- Page 29 and 30:

THE IMPACT OF PLANT BREEDING ON SEE

- Page 31 and 32:

modified pedigree breeding method,

- Page 33 and 34:

“Rigel” seed multiplication com

- Page 35 and 36:

The benefits of the cultivars bred

- Page 37 and 38:

ABSTRACT SOME LESSONS LEARNED FROM

- Page 39 and 40:

about 100 m above sea-level with ye

- Page 41 and 42:

Table 3: Effect of treatments on so

- Page 43 and 44:

ammoniumlactate-soluble P2O5 and K2

- Page 45 and 46:

MODIS NDVI data from the Terra and

- Page 47 and 48:

NDVI 0,8 0,75 0,7 0,65 0,6 0,55 0,5

- Page 49 and 50:

The a*cos(2π*i/12) periodic compon

- Page 51 and 52:

RAINFALL, FERTILIZATION AND LIMING

- Page 53 and 54:

1999 to 2006. The main experiment

- Page 55 and 56:

Jolánkai M. (2005): Effect of clim

- Page 57 and 58:

classified according to the soil te

- Page 59 and 60:

Relatív termés (100 NP/NPK), % 3.

- Page 61 and 62:

ACKNOWLEDGEMENT This study was fina

- Page 63 and 64:

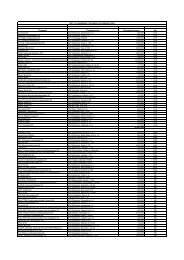

Table 2. The oldest and most import

- Page 65 and 66:

plan of the uniform countrywide fie

- Page 67 and 68:

• The effect of climate change ca

- Page 69 and 70:

MATERIALS AND METHODS An organic an

- Page 71 and 72:

TOC % 1,2 1 0,8 0,6 0,4 0,2 0 bc b

- Page 73 and 74:

The much better performance of the

- Page 75 and 76:

GREENHOUSE GAS EMISSION IN LONG-TER

- Page 77 and 78:

Carbon-dioxide and nitrous-oxide sa

- Page 79 and 80:

Nitrous-oxide emission Nitrous-oxid

- Page 81 and 82:

CH BC N2O = - 8,839 + 0,6904 * Mois

- Page 83 and 84:

INFLUENCES OF AMELIORATIVE FERTILIZ

- Page 85 and 86:

samples were measured by the ICP-AE

- Page 87 and 88:

Table 3. Influences of ameliorative

- Page 89 and 90:

Egner, H., Riehm, H., Domingo, W.R.

- Page 91 and 92:

To resolve genetics of grain qualit

- Page 93 and 94:

Table 2. Average values of analyzed

- Page 95 and 96:

CROP ROTATION AND GREEN MANURE INFL

- Page 97 and 98:

Organic Chemical Chemical fertiliza

- Page 99 and 100:

Influence of the crop rotation and

- Page 101 and 102:

REFERENCES 1. Budoi Gh., Penescu A.

- Page 103 and 104:

MATERIALS AND METHODS The experimen

- Page 105 and 106:

average of watered treatments resul

- Page 107 and 108:

Table 4: Changes in soil properties

- Page 109 and 110:

epetitions, where the main treatmen

- Page 111 and 112:

that usually conventional tillage h

- Page 113 and 114:

RESEARCHES REGARDING THE INFLUENCE

- Page 115 and 116:

Crop rotation Water regime Water re

- Page 117 and 118:

conditions. The values, registered

- Page 119 and 120:

CRISANA -THE FIRST ROMANIAN WHEAT V

- Page 121 and 122:

In addition, we used recurent selec

- Page 123 and 124:

Table 2: The root length of some wh

- Page 125 and 126:

Table 5: Productions and quality re

- Page 127 and 128:

EXPERIMENTS WITH PERENNIAL RYE (SEC

- Page 129 and 130:

green mass (6,8-7 t/ha/year dry mas

- Page 131 and 132:

REFERENCES Kotvics G. (1963): A Sec

- Page 133 and 134:

een shown to cause leucoencephaloma

- Page 135 and 136:

Marasas, W.F.O., Kellerman, W.C.A,

- Page 137 and 138:

minerals (Čuvanová et al. 2006).

- Page 139 and 140:

01/2). For the latest periods (fatt

- Page 141 and 142:

1. GENERAL APPROACH TO EUROREGIONAL

- Page 143 and 144:

Association - fig. 2), on the other

- Page 145 and 146:

communication between the two assoc

- Page 147 and 148:

The juridical settlement of the Bih

- Page 149 and 150:

EFFECT OF BORON FERTILIZATION ON AN

- Page 151 and 152:

3. Examinations of fruit quality Fo

- Page 153 and 154:

Fruit density was increased applyin

- Page 155 and 156:

Wills, R. B. H. - Lim, J. S. K. - G

- Page 157 and 158:

Nosticzius, 1992). Among these, soi

- Page 159 and 160:

RESULTS AND DISCUSSIONS The dry mat

- Page 161 and 162:

The amount of nitrogen uptake by th

- Page 163 and 164:

ABSTRACT THE EFFECT OF NITROGEN SUP

- Page 165 and 166:

exactly known due to the size of th

- Page 167 and 168:

Table 3: Dry matter production of p

- Page 169 and 170:

more definite in the non limed trea

- Page 171 and 172:

compare these levels with the Europ

- Page 173 and 174:

Table 3. Natural occurrence of myco

- Page 175 and 176:

CORRELATIONS OF SOCIAL AND ECONOMIC

- Page 177 and 178:

1600 1400 1200 1000 800 600 400 200

- Page 179 and 180:

Table 3: Land use/ha 1960 1970 1980

- Page 181 and 182:

RIDING TOURISM IN THE NORTHERN GREA

- Page 183 and 184:

visitors belonging to all types of

- Page 185 and 186:

Concerning the weather long autumn

- Page 187 and 188:

2000 1800 1600 1400 1200 1000 800 6

- Page 189 and 190:

technical supervision of the Debrec

- Page 191 and 192:

TISSUE CULTURE METHODS FOR SCREENIN

- Page 193 and 194:

symptoms could be observable in the

- Page 195 and 196:

experiments the other clones and we

- Page 197 and 198:

MATERIALS AND METHODS Shoot culture

- Page 199 and 200:

that callus induction and developme

- Page 201 and 202:

COMBINING ABILITY STUDIES IN A SEVE

- Page 203 and 204:

Table 1: Mean squares of GCA and SC

- Page 205 and 206:

combination. We could not obtained

- Page 207 and 208:

SUSTAINABLE LAND-USE BASED ON WESTS

- Page 209 and 210:

green manure treatment, where lupin

- Page 211 and 212:

In Westsik's crop rotation experime

- Page 213 and 214:

Crop rotation breaks the weed and i

- Page 215 and 216:

The reliability of the method was c

- Page 217 and 218:

The increased phosphorus rates incr

- Page 219 and 220:

REFERENCES Basha S.M, Roberts R.M (

- Page 221 and 222:

MATERIALS AND METHODS Sandy soils w

- Page 223 and 224:

AL soluble Ca (mg/kg) 350 300 250 2

- Page 225 and 226:

gradually from soils containing 100

- Page 227 and 228:

agriculture in Hungary, especially

- Page 229 and 230:

according to the treatments. Obtain

- Page 231 and 232:

Table 4: Results of regression anal

- Page 233 and 234:

From obtained data, it can be estab

- Page 235 and 236:

Tops soil (0-30 cm) samples were ta

- Page 237 and 238:

Table 5: Impact fertilizing and lim

- Page 239 and 240:

COMPOSTED SLAUGHTERHOUSE BY-PRODUCT

- Page 241 and 242:

The mature compost became friable,

- Page 243 and 244:

maximal yield could be reached at 5

- Page 245 and 246:

unfavourable years. 100-200 t/ha do

- Page 247 and 248:

THE EFFECT OF BENTONITE ON SPECIFIC

- Page 249 and 250:

RESULTS The effect of treatments on

- Page 251 and 252:

dosages significantly reduced the a

- Page 253 and 254:

DISCUSSION In our experiments, we f

- Page 255 and 256:

INVESTIGATION OF MINERAL CONTENT IN

- Page 257 and 258:

Element Ammonium-nitrate Superphosp

- Page 259 and 260:

According to our results, the effec

- Page 261 and 262:

REFERENCES Debreczeni, B., Debrecze

- Page 263 and 264:

micronutrient soil tests for many y

- Page 265 and 266:

LE and KCl-EDTA extracted similar a

- Page 267 and 268:

Table 4. Correlation coefficient be

- Page 269 and 270:

YIELD OF RYE AS AFFECTED BY THE CRO

- Page 271 and 272:

Table 2: Mean temperature at Nyíre

- Page 273 and 274:

It was found that either way of app

- Page 275 and 276:

2 The main modification properties

- Page 277 and 278:

4 Table 2: Percent of alfalfa and-

- Page 279 and 280:

THE IMPORTANCE OF LONG-TERM FIELD E

- Page 281 and 282:

essential to the determination of t

- Page 283 and 284:

The comparison of the nutrient cont

- Page 285 and 286:

environment for three years, then t

- Page 287 and 288:

PC 2 5 4 3 2 1 0 -1 -2 -3 -4 V2 V5

- Page 289 and 290:

Figure 2: Genetic similarity among

- Page 291 and 292:

Frenot, Y., Aubry, M., Misset, M. T

- Page 293 and 294:

Three foliar fertilizations were do

- Page 295 and 296:

CONCLUSIONS The rigorous experiment

- Page 297 and 298:

some pathogen agents, a chemical an

- Page 299 and 300:

� The pH decrease in the greenhou

- Page 301 and 302:

RESULTS AND DISSCUSSIONS 1. The pro

- Page 303 and 304:

may employ (wheat) flour produced f

- Page 305 and 306:

For the conditions in from Western

- Page 307 and 308:

Yield losses millet hay (%) 80 70 6

- Page 309 and 310:

- 0,6093) and extremely significant

- Page 311 and 312:

CONCLUSIONS The experimental field

- Page 313 and 314:

Evaluation of effect of fertilizati

- Page 315 and 316:

Table 3: Dry matter content of pars

- Page 317 and 318:

On sandy soil, the total N content

- Page 319 and 320:

THE INFLUENCE OF CHEMICAL AND BIOFE

- Page 321 and 322:

Bacillus megatherium soil bacteria,

- Page 323 and 324:

N content of plant: Studying the ni

- Page 325 and 326:

chernozem soil in all pots either.

- Page 327 and 328:

THE INFLUENCE OF USING BIOLOGICAL A

- Page 329 and 330:

2. The influence of using inoculant

- Page 331 and 332:

Table 3: The evolution of weight ga

- Page 333 and 334:

REFERENCES 4. Anon D.L. (1997): - S

- Page 335 and 336:

chernozem represents the dominant s

- Page 337 and 338:

AD% AD% 4 3,5 3 2,5 2 1,5 1 0,5 0 T

- Page 339 and 340:

Negative reaction was recorded in t

- Page 341 and 342:

The Tentant variety positively reac

- Page 343 and 344:

Table 1. The density of harmful pes

- Page 345 and 346:

vegetation period, without affectin

- Page 347 and 348:

THE IMPORTANCE OF CONTROLLING FORMA

- Page 349 and 350:

3:1 to 5:3 . In the following exper

- Page 351 and 352:

REFERENCES 1. Bartzokas, C. A., K.

- Page 353 and 354:

For micro-elements, EDTA+KCl 15 tim

- Page 355 and 356:

Ca CO3(%) = AL − Cax2,5 10000 EDT

- Page 357 and 358:

ABSTRACT BIOLOGICAL INVESTIGATION O

- Page 359 and 360:

profiles were typical for catena po

- Page 361 and 362:

Table 2: Collembola species composi

- Page 363 and 364:

Larsen, T., P. Schjonning, J. Axels

- Page 365 and 366:

The alimentary problem has constitu

- Page 367 and 368:

Table 3. The average annual consump

- Page 369 and 370:

FROM FARM TO FORK - EVALUATION OF C

- Page 371 and 372:

we made a deeper vertical sampling

- Page 373 and 374:

Although the toxic element content

- Page 375 and 376:

ACKNOWLEDGEMENTS This work was supp

- Page 377 and 378:

l/mp 120 100 80 60 40 20 0 Fig. 3 M

- Page 379 and 380:

during this period, though not so s

- Page 381 and 382:

• the pluviometric regime was als

- Page 383 and 384:

1. Specific weight was study accord

- Page 385 and 386:

Table 4. Absolut weight MA g result

- Page 387 and 388:

Very significant decrease are in V4

- Page 389 and 390:

OCEAN DYNAMICS: AIR-SEA INTERFACE G

- Page 391 and 392:

∂ C Φ = - ε (3) ∂z where Φ i

- Page 393 and 394:

n = - 1 ⁄ 2 [1]-[4]. The later mo

- Page 395 and 396:

elucidated yet. We must also imply

- Page 397 and 398:

RESEARCHES ON THE QUICK METHOD OF S

- Page 399 and 400:

SU8 = (Za/QB) - 100; C8 = (Z8/P8) -

- Page 401 and 402:

There are the following calculation

- Page 403 and 404:

- preheaters - towards condensation

- Page 405 and 406:

Circulation speed of the concentrat

- Page 407 and 408:

RESEARCH ON SEEDING AGENTS TO EFFEC

- Page 409 and 410:

• about 160 porcelain balls havin

- Page 411 and 412:

For the crystal mass the following

- Page 413 and 414:

WATER DIFFUSION IN BREAD DURING BAK

- Page 415 and 416:

RESULTS Temperature distribution: W

- Page 417 and 418:

During the chemical changes the por

- Page 419 and 420:

CONCLUSIONS The water content in th

- Page 421 and 422:

those portions that are not, are no

- Page 423 and 424:

Tension: For bread prepared under l

- Page 425 and 426:

obscured. It has been stated that r

- Page 427 and 428:

THE MATHEMATICAL MODELLING OF THE P

- Page 429 and 430:

It was marked with AI the area of t

- Page 431 and 432:

mcb [g] mcb [g] mcb [g] 0,040 0,030

- Page 433 and 434:

The calculation of engines with spa

- Page 435 and 436:

THE VARIATION OF EFFECTIVE POWER AN

- Page 437 and 438:

437

- Page 439 and 440:

ce [g/kW h] 400.019 350.019 300.019

- Page 441 and 442:

THE EFFECT OF THE GENOTYPE AND EXPL

- Page 443 and 444:

) The cultures were incubated at cc

- Page 445 and 446:

% embryogenic inductio 60 50 40 30

- Page 447 and 448:

Table 1 The three way Anova type 3x

- Page 449 and 450:

Table 4 The effect of developmental

- Page 451 and 452:

was the explant type (the developme

- Page 453 and 454:

ABSTRACT COMPARATIVE TESTS FOR SEPA

- Page 455 and 456:

Column extraction (Beck, H. and Mat

- Page 457 and 458:

Fat Percentage Fat percentage 4.4 4

- Page 459 and 460:

HIGHLIGHTING THE STATE OF FRESHNESS

- Page 461 and 462:

REFERENCES 1. Eftimie V.M. Particul

- Page 463 and 464:

In table 1 the results obtained as

- Page 465 and 466:

FORENSIC ASPECTS REGARDING DISASTER

- Page 467 and 468:

• depositing the bodies and the e

- Page 469 and 470:

FORM NO. 3 ITEM IDENTIFICATION Pers

- Page 471 and 472:

- utilised in a biogas processing p

- Page 473 and 474:

Viscosity [◦E] 14 12 10 8 6 4 2 0

- Page 475 and 476:

As in any other cyclic, infectious,

- Page 477 and 478:

usually incompatible with life or c

- Page 479 and 480:

The family doctors must be informed

- Page 481 and 482:

2. botulism of inoculation-through

- Page 483 and 484:

The repartition of the provenience

- Page 485 and 486:

3. The patients hospitalizations mo

- Page 487 and 488:

possibility that, due to the chelat

- Page 489 and 490:

difference of extinction % 120 100

- Page 491 and 492:

Horváth E., Szalai G., Pál m., P

- Page 493 and 494:

chlorophyll contents and the values

- Page 495 and 496:

Table 1.Estimative mean values for

- Page 497 and 498:

TREE GROWTH EQUATIONS IN DIFFERENT

- Page 499 and 500:

Image no.1 ImageTool programme was

- Page 501 and 502:

Following the results obtained, the

- Page 503 and 504:

ms. The placement of the areas was

- Page 505 and 506:

Another possible simulated break in

- Page 507 and 508:

- distribution after break case 2 y

- Page 509 and 510:

THE FREQUENCY OF DAYS WITH DIFFEREN

- Page 511 and 512:

200 190 180 170 160 150 140 130 120

- Page 513 and 514:

October, and at higher altitudes (0

- Page 515 and 516:

5. The frequency of tropical days r

- Page 517 and 518:

At the same time, the genesis of fl

- Page 519 and 520:

winter the floods frequency has sma

- Page 521 and 522:

% 14 12 10 8 6 4 2 0 I II III IV V

- Page 523 and 524:

RESEARCH REGARDING MAIN CHEMICAL RE

- Page 525 and 526:

• Ensuring the juice’ thermal s

- Page 527 and 528:

mud which is evacuated out of the p

- Page 529 and 530:

MATERIALS AND METHOD Apparatus Clea

- Page 531 and 532:

THE IMPORTANCE OF VOLATILE N-NITROS

- Page 533 and 534:

The fat cooked out of some of the b

- Page 535 and 536:

A problem concerning the formation

- Page 537 and 538:

Sample 3, found to contain 343 ppb

- Page 539 and 540:

LUNG CANCER CAUSED BY SMOKING AND C

- Page 541 and 542:

µg/g dry weight). The pulmonary Cd

- Page 543 and 544:

MATERIALS AND METHOD Apparatus and

- Page 545 and 546: for either TLC or reverse-phase LC

- Page 547 and 548: trigger still other responses. In t

- Page 549 and 550: these general patterns appear to be

- Page 551 and 552: The question of determining a “sa

- Page 553 and 554: CLINICAL AND EPIDEMIOLOGICAL ASPECT

- Page 555 and 556: Figure 3.-Life Cycle of Echinococcu

- Page 557 and 558: that the values are 1 case at 600.0

- Page 559 and 560: Paraclinical data From the laborato

- Page 561 and 562: THIN LAYER CHROMATOGRAPHY OF STERIG

- Page 563 and 564: Column Chromatography Loosely place

- Page 565 and 566: that spot intensity could be regene

- Page 567 and 568: its metabolism by oxidative pathway

- Page 569 and 570: Exposure time weeks 1 2 3 Table 2.

- Page 571 and 572: attempted accommodation to the diet

- Page 573 and 574: series, a dose of 0.5 ppm NDMA was

- Page 575 and 576: At 500 ppb and at all higher doses,

- Page 577 and 578: supernatants by a modified cadmium

- Page 579 and 580: adioimmunoassay and by cadmium satu

- Page 581 and 582: • The intermediary form appears b

- Page 583 and 584: sex. In fact, there are no data in

- Page 585 and 586: SOME ASPECTS OF SHELTER REGENERATIO

- Page 587 and 588: In the following lines it is presen

- Page 589 and 590: Număr de arbori 160 140 120 100 80

- Page 591 and 592: Analysing the data presented in the

- Page 593 and 594: WASTEWATER TREATMENT TEHNOLOGIES OF

- Page 595: As a result of the comparisons betw

- Page 599 and 600: REGIONAL DEVELOPMENT USING CONSTRUC

- Page 601 and 602: characterized by marshy plants like

- Page 603 and 604: watersurface, but their roots are t

- Page 605 and 606: • Which of the heavy metals that

- Page 607 and 608: Figure 2 shows that Cd also is conc