“We need a second green revolution” Hybrid rice - Bayer ...

“We need a second green revolution” Hybrid rice - Bayer ...

“We need a second green revolution” Hybrid rice - Bayer ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

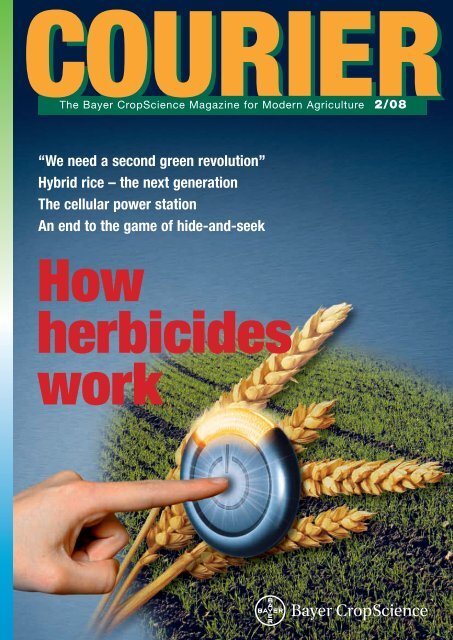

COURIER<br />

The <strong>Bayer</strong> CropScience Magazine for Modern Agriculture 2/08<br />

<strong>“We</strong> <strong>need</strong> a <strong>second</strong> <strong>green</strong> <strong>revolution”</strong><br />

<strong>Hybrid</strong> <strong>rice</strong> – the next generation<br />

The cellular power station<br />

An end to the game of hide-and-seek<br />

How<br />

herbicides<br />

work

Contents<br />

2 <strong>“We</strong> <strong>need</strong> a <strong>second</strong><br />

<strong>green</strong> <strong>revolution”</strong><br />

6 <strong>Hybrid</strong> <strong>rice</strong> –<br />

the next generation<br />

10 Less stress – higher yield<br />

14 How herbicides work<br />

18 The cellular power station<br />

22 An end to the game of<br />

hide-and-seek<br />

26 Atento ®, a new solution<br />

for managing Asian rust<br />

28 Gaining the advantage<br />

through innovation<br />

Published by: <strong>Bayer</strong> CropScience AG, Monheim / Editor:<br />

Bernhard Grupp / With contributions from: Agroconcept<br />

GmbH, K. Doughty, M. Wiedenau / Design and Layout:<br />

Xpertise, Langenfeld / Lithography: LSD GmbH & Co. KG,<br />

Düsseldorf / Printed by: Dynevo GmbH, Leverkusen / Reproduction<br />

of contents is permissible providing <strong>Bayer</strong> is<br />

acknowledged and advised by specimen copy / Editor’s<br />

address: <strong>Bayer</strong> CropScience AG, Corporate Communications,<br />

Alfred-Nobel-Str. 50, 40789 Monheim am Rhein,<br />

Germany, FAX: 0049-2173-383454 / Website:<br />

www.bayercropscience.com<br />

Forward-Looking Statements<br />

This publication may contain forward-looking statements<br />

based on current assumptions and forecasts made by<br />

<strong>Bayer</strong> Group or subgroup management. Various known and<br />

unknown risks, uncertainties and other factors could lead<br />

to material differences between the actual future results,<br />

financial situation, development or performance of the<br />

company and the estimates given here. These factors<br />

include those discussed in <strong>Bayer</strong>’s public reports which are<br />

available on the <strong>Bayer</strong> website at www.bayer.com. The<br />

company assumes no liability whatsoever to update these<br />

forward-looking statements or to conform them to future<br />

events or developments.<br />

2 COURIER 2/08<br />

<strong>“We</strong> <strong>need</strong> a<br />

<strong>green</strong><br />

Safeguarding food<br />

for a growing world<br />

population<br />

Modern agriculture: Combine<br />

harvester in a cereal field

<strong>second</strong><br />

<strong>revolution”</strong><br />

Arable land per capita<br />

2,000 sqm<br />

2,700 sqm<br />

5,100 sqm<br />

Our numbers are growing! By 2012,<br />

the world population is forecast to top<br />

the seven billion mark. In 2025, the<br />

number of people is even set to hit eight<br />

billion, with this rapid population<br />

growth taking place almost exclusively<br />

in developing countries, where over 80<br />

percent of all people already live. And it<br />

is precisely these countries that are<br />

already hit by food shortages. The World<br />

Bank estimates that the number of hungry<br />

people in the world could shoot up<br />

quite soon from 850 million at present<br />

to 950 million. United Nations forecasts,<br />

meanwhile, show that only 40 percent of<br />

the land that was available for growing<br />

food in 1950 will be available per capita<br />

for safeguarding the supply of food in<br />

2050.<br />

World population<br />

~ 9 Billion<br />

6.0 Billion<br />

2.8 Billion<br />

Source: FAO, Copyright <strong>Bayer</strong> CropScience<br />

2/08 COURIER 3

Securing food with less land<br />

Of the approximately 13 billion hectares of land covering the Earth’s surface,<br />

around 1.5 billion hectares are used for agriculture, with a further 3.5 billion<br />

hectares being used for meadowland and pasture. This area of land cannot be<br />

increased. Every year, around seven million hectares of agricultural land are<br />

lost as a result of building construction, erosion, desertification and other<br />

causes. Without modern crop protection measures and fertilization, we would<br />

already <strong>need</strong> significantly more arable land, namely around four billion hectares.<br />

As a result of population growth, agricultural production must increase by<br />

around two percent per year in order to be able to safeguard the amount of<br />

food required to supply all people.<br />

This figure does not yet take into account the increases in demand for meat.<br />

In China, for example, meat consumption has doubled in the last 15 years. For<br />

one kilogram of beef, it is necessary to produce well over seven kilograms of<br />

animal feed – this also drives up the demand for animal feed, which increases<br />

the competition for arable land for food production.<br />

On top of this, worldwide food reserves<br />

have now dropped to their lowest level for<br />

30 years. The main problem is that there is<br />

hardly any potential left for expanding the<br />

growing areas for wheat, <strong>rice</strong> or millet. In<br />

many parts of Asia, every last hill which<br />

can possibly be used has already been covered<br />

with fields and <strong>rice</strong> terraces. In many<br />

regions of Africa, it is likewise almost impossible<br />

to expand the amount of arable<br />

land. This is partly because the soils are<br />

simply not suitable, and partly because intensive<br />

farming would lead to desertification.<br />

<strong>Bayer</strong> CropScience research scientists assess enhanced stress tolerance characteristics in a new generation of<br />

hybrid <strong>rice</strong>.<br />

4 COURIER 2/08<br />

Extreme weather phenomena<br />

threaten harvests<br />

Another problem is that meteorologists<br />

worldwide are registering extreme weather<br />

events with increasing frequency – the absence<br />

or displacement of tropical rainfall<br />

as well as abnormal ocean current phenomena.<br />

One well known example is El<br />

Niño: every three to six years, torrential<br />

rains devastate whole tracts of land in<br />

South America, while at the same time extreme<br />

weather leads to droughts in South<br />

East Africa, Indonesia and Australia, and<br />

frost in Florida, causing enormous harvest<br />

losses for farmers.<br />

But it is not just natural catastrophes<br />

that cause billions of dollars’ worth of agricultural<br />

damage each year: persistently unfavorable<br />

farming conditions such as water<br />

shortages, increasing salination of arable<br />

soils and extreme heat and cold are prime<br />

causes of enormous harvest losses. Corn,<br />

<strong>rice</strong> and wheat are no longer able to withstand<br />

the extreme environmental effects.<br />

Climate change is adding to the stresses to<br />

which plants are subjected, with grave<br />

effects; even with the best of care for their<br />

fields, farmers regularly lose 30-70 percent<br />

of their harvests.<br />

Stop the self-destruction<br />

program in cereals<br />

“There is an urgent <strong>need</strong> for us not only to<br />

make agricultural production more efficient,<br />

but also to do it in a way which is<br />

sustainable,” says Professor Friedrich<br />

Berschauer, Chairman of the Board of<br />

<strong>Bayer</strong> CropScience. A key objective of the<br />

crop protection scientists is to increase<br />

corn, <strong>rice</strong> and wheat yields and make the<br />

plants more resistant to severe heat, cold,<br />

drought or intense sunlight. These factors<br />

put plants under enormous stress, triggering<br />

a process which can even lead to selfdestruction:<br />

the plant increases its energy<br />

consumption and can therefore no longer<br />

produce certain energy transport molecules,<br />

which are however <strong>need</strong>ed by the<br />

cells to survive. The supply gap has dra-<br />

Fruit and vegetables supermarket in India. The wide range of

matic consequences for the plant, which<br />

can no longer supply leaves, fruit or stems<br />

properly with energy. Individual cells<br />

gradually die, followed ultimately by the<br />

whole plant.<br />

Stress-tolerant plants are<br />

considerably better at coping<br />

with climate fluctuations<br />

Researchers at <strong>Bayer</strong> Crop Science are using<br />

a trick to protect <strong>rice</strong> plants, for example,<br />

against a number of stress factors.<br />

They have put the plants on a fitness program.<br />

“Our idea was to get crops into<br />

shape,” says Michael Metzlaff of the <strong>Bayer</strong><br />

CropScience Innovation Center for Plant<br />

Biotechnology in Ghent, Belgium. To<br />

achieve this, his team is pursuing two<br />

strategies: firstly, the scientists incorporate<br />

genes into the plants which should help<br />

them deal with excessive stress caused by<br />

dry and wet conditions. Secondly, they quite<br />

specifically deactivate individual genes<br />

which trigger excessive stress reactions in<br />

normal plants and lower the yield. “Our<br />

goal is to enable plants to produce high,<br />

stable yields over the longer term in spite<br />

of fluctuating environmental conditions,”<br />

Metzlaff says.<br />

fruits forms a good basis for a healthy nutrition.<br />

A “<strong>second</strong> <strong>green</strong> <strong>revolution”</strong><br />

is <strong>need</strong>ed<br />

For Berschauer, biotechnology is a vital<br />

tool to safeguard the supply of food for the<br />

world population in the future. <strong>“We</strong> <strong>need</strong> a<br />

<strong>second</strong> <strong>green</strong> revolution. If we use plant<br />

biotechnology in combination with crop<br />

protection solutions in a targeted manner,<br />

we can achieve significant advances in<br />

productivity,” comments <strong>Bayer</strong> Crop-<br />

Science’s CEO. Other experts share this<br />

view: according to the estimates of the<br />

Consultative Group on International Agricultural<br />

Research, only with biotechnology<br />

can harvests be increased by around 25<br />

percent.<br />

Antifungal agents help<br />

wheat plants to grow<br />

In Canada, <strong>Bayer</strong> CropScience researchers<br />

are already using advances in seed breeding<br />

to increase canola oil yields by up to 30<br />

percent compared with conventional varieties.<br />

In addition to plant biotechnology,<br />

new crop protection agents can also increase<br />

harvest yields. The latest example is<br />

the active ingredient trifloxystrobin. Farmers<br />

all over the world have been using this<br />

agent for years to protect cereal, vegetable<br />

and fruit crops against harmful fungal diseases.<br />

But trifloxystrobin, an antifungal<br />

agent belonging to the strobilurin group of<br />

active ingredients, can do more: it also<br />

increases the ability of plants to withstand<br />

stress. “Field trials show that crops in<br />

Stress causes dramatic harvest losses<br />

Yield (kg/hectare)<br />

20,000<br />

16,000<br />

12,000<br />

8,000<br />

4,000<br />

0<br />

which strobilurins are used produce better<br />

harvests than those protected with other<br />

types of antifungal agent,” says Dr. Dirk<br />

Ebbinghaus, a <strong>Bayer</strong> CropScience research<br />

scientist. Crops protected with trifloxystrobin<br />

also do much better than untreated<br />

plants under conditions of drought. “Our<br />

active ingredient clearly triggers a number<br />

of different positive effects in the plant<br />

which result in an above-average increase<br />

in yield,” says Ebbinghaus. The latest research<br />

results have also shown that certain<br />

active ingredients, i.e. the <strong>Bayer</strong> Crop-<br />

Science insecticide Gaucho ®, can even<br />

make <strong>rice</strong> plants more resistant to fluctuations<br />

in the salt content of water.<br />

Protecting biodiversity<br />

Because the demand for high-quality food<br />

in adequate quantities and at affordable<br />

p<strong>rice</strong>s must not be allowed to jeopardize<br />

nature, <strong>Bayer</strong> Crop Science has committed<br />

itself to an important principle: using stateof-the-art<br />

technologies, the company wants<br />

to help both small and large-scale farmers<br />

achieve higher productivity on land already<br />

used for agriculture. This protects natural<br />

habitats from being converted into arable<br />

land. ■<br />

Utz Klages<br />

Find more information at<br />

www.bayercropscience.com<br />

Corn Wheat Soy Millet Oats Barley<br />

Losses caused by<br />

abiotic factors<br />

(drought, heat,…)<br />

Losses caused by<br />

biotic factors<br />

(insects, fungi,…)<br />

Average yield<br />

Source: <strong>Bayer</strong> CropScience<br />

Stress reduces harvests dramatically: cereals appear to suffer particularly from<br />

abiotic stress caused by heat, cold, drought or the oxygen deficiency that results<br />

from stagnant water or compacted soil. The potential harvest (total column length)<br />

is partly compromised by insect pests, plant diseases and competition from weeds.<br />

However, abiotic factors are responsible for the lion’s share of harvest losses.<br />

2/08 COURIER 5

<strong>Hybrid</strong> <strong>rice</strong><br />

– the next generation<br />

<strong>Bayer</strong> CropScience’s hybrid <strong>rice</strong> is known for its especially<br />

high yield potential. A new variety from the Arize product<br />

range also has an important, additional characteristic:<br />

Arize Dhani is resistant to bacterial leaf blight.<br />

In 2008, Indian <strong>rice</strong> farmers were able to<br />

benefit for the first time from a new option<br />

for protecting their crops against attack<br />

by the bacterial pathogen Xanthomonas<br />

oryzae. Arize ® Dhani is the name of the<br />

new variety that <strong>Bayer</strong> CropScience<br />

has just brought onto the market in five<br />

Indian States. This is the world’s first<br />

hybrid <strong>rice</strong> with greater than 95 percent<br />

6 COURIER 2/08<br />

resistance against all known races of<br />

bacterial leaf blight.<br />

Bacterial leaf blight is a particular problem<br />

in the eastern Indian states, especially<br />

Chhattisgarh, West Bengal and Orissa. “A<br />

total area of about six to seven million<br />

hectares is affected here”, explains Arun<br />

Mittal, <strong>rice</strong>-product manager of Bioscience<br />

in India. BioScience is the <strong>Bayer</strong> Crop-<br />

Science Business Unit that specializes in<br />

the development and production of varietal<br />

seed.<br />

The <strong>rice</strong>-growing area affected by bacterial<br />

leaf blight corresponds to about 15<br />

percent of the total Indian crop. Depending<br />

on the severity and timing of infection,<br />

harvest losses of between 20 and 60 percent<br />

can occur, according to Mittal. In fact,

actericidal agents are available for use<br />

against bacterial leaf blight – but none of<br />

them has proven effective enough to date.<br />

In developing Arize Dhani, <strong>Bayer</strong> Crop-<br />

Science has taken advantage of the fact<br />

that nature already presents us with <strong>rice</strong><br />

varieties that are partially resistant to bacterial<br />

leaf blight. Breeders tested the resistance<br />

properties of such varieties against<br />

various isolates of Xanthomonas oryzae that<br />

had been collected for the purpose from locations<br />

throughout India. Their investigations<br />

showed that none of these varieties<br />

possessed resistance that was effective<br />

against the entire spectrum of bacterial leaf<br />

blight isolates occurring in India.<br />

In order to create a variety that achieved<br />

just this, the breeders brought the resist-<br />

A technician at the Bioscience site in Ghent, Belgium,<br />

removes seeds from a <strong>rice</strong> plant.<br />

ance genes from the naturally-occurring<br />

varieties together into the optimal combination.<br />

They did this through advanced<br />

breeding, using molecular markers. The<br />

comprehensive resistance thus achieved<br />

was then brought together with a strong<br />

yield potential using well-proven hybridization<br />

technology. Like <strong>Bayer</strong> CropScience’s<br />

other hybrid <strong>rice</strong> varieties, Arize Dhani has<br />

a yield potential that is 20 to 30 percent<br />

higher than that of conventional <strong>rice</strong> varieties.<br />

Its yield advantage over conventional<br />

varieties is even greater under conditions<br />

of infection by bacterial leaf blight. “When<br />

the disease hits, farmers who use Arize<br />

Dhani can produce up to 80 percent more<br />

yield than their neighbours using classical<br />

varieties”, says Arun Mittal. Arize Dhani<br />

will therefore help farmers operating in areas<br />

threatened by the disease to achieve<br />

greater income security. It’s no coincidence<br />

that the product is called “Dhani”: this<br />

Hindi word is used to describe a “rich person”.<br />

Market leader in hybrid <strong>rice</strong><br />

Arize Dhani is already the eighth hybrid<br />

<strong>rice</strong> variety that <strong>Bayer</strong> CropScience has introduced<br />

in India. All of these products are<br />

characterized by an especially high yield<br />

potential. The availability of such a large<br />

2/08 COURIER 7

number of different products can be explained<br />

in terms of differences in the properties<br />

they possess, such as the <strong>rice</strong>’s grain<br />

shape and size, and aroma; it also has to do<br />

with adaptability to local climatic conditions.<br />

Arize Dhani is the first hybrid <strong>rice</strong> that<br />

offers the additional benefit of broad resistance<br />

to bacterial leaf blight. As a global<br />

leader, <strong>Bayer</strong> CropScience plans to continue<br />

to bring further <strong>second</strong>-generation<br />

hybrid <strong>rice</strong> varieties of this type onto the<br />

market. These varieties deliver a double<br />

benefit: high yield potential combined<br />

with, for example, resistance to a particular<br />

pest or to other types of stress.<br />

<strong>Bayer</strong> CropScience is market leader in<br />

the hybrid <strong>rice</strong> market in India. However,<br />

hybrid <strong>rice</strong> currently accounts for only two<br />

percent of the Indian <strong>rice</strong> cultivated area.<br />

8 COURIER 2/08<br />

Increasing this proportion would be a way<br />

of increasing the productivity of Indian<br />

<strong>rice</strong> cultivation, which is clearly lower than<br />

in other countries “India is only in 16th<br />

place in terms of <strong>rice</strong> productivity”, says<br />

Frédéric Arboucalot, Global Manager of<br />

<strong>Bayer</strong> CropScience’s <strong>rice</strong> seed business.<br />

The comparison with the People’s Republic<br />

of China – the other country confronted<br />

with the <strong>need</strong> to feed a population of more<br />

than a billion – is telling. With 44 Million<br />

hectares, India’s area under cultivation is<br />

one and a half times bigger than that of<br />

China; nevertheless, Chinese farmers harvest<br />

considerably more <strong>rice</strong>. In 2006, the<br />

figure was 184.1 million tonnes for China,<br />

compared with only 136.5 million tonnes<br />

for India. Productivity in China equated to<br />

more than six tonnes of <strong>rice</strong> a hectare,<br />

compared with just over three tonnes a<br />

What is hybrid <strong>rice</strong>?<br />

<strong>Hybrid</strong>s are produced by crossing two<br />

different parental plant lines. Under this<br />

approach, one of the lines is deliberately<br />

sterilized to prevent the usual process of<br />

self-pollination. The plants, which are then<br />

purely female, receive pollen exclusively<br />

from plants of the <strong>second</strong> parental line<br />

growing in the immediate vicinity. In this<br />

way, the genetic material of the two lines<br />

is combined, and the female plants produce<br />

the hybrid seed.<br />

Targeted choice of the two parental<br />

lines allows to produce hybrids with<br />

specific, desirable properties: for example,<br />

a particularly high yield potential. In fact,<br />

finding suitable parental lines is an<br />

expensive and protracted process. <strong>Bayer</strong><br />

CropScience develops the lines it <strong>need</strong>s in<br />

India, Brazil, USA and soon in Thailand.<br />

Thanks to the modern molecular<br />

biology techniques used at its Rice<br />

Research Laboratory in Singapore, <strong>Bayer</strong><br />

CropScience is now able to accelerate the<br />

development of new hybrid varieties. The<br />

company is a world leader in hybrid technology;<br />

besides <strong>rice</strong>, <strong>Bayer</strong> CropScience<br />

also develops oilseed rape and cotton<br />

seed using the hybrid approach.<br />

hectare in India. <strong>Hybrid</strong> <strong>rice</strong> was introduced<br />

into China as early as the 1970s, and<br />

it is now grown on more than half of the<br />

area under <strong>rice</strong> cultivation.<br />

Increasing demand for <strong>rice</strong><br />

In an article for Rice Today – the house<br />

magazine of the International Rice Research<br />

Institute (IRRI) in the Philippines – at the<br />

beginning of 2008, the IRRI researcher Dr.<br />

Sushil Pandey predicted that the demand<br />

for <strong>rice</strong> will continue to rise in coming<br />

years. In fact, an additional 50 million<br />

tonnes will be <strong>need</strong>ed by 2015; Asia alone<br />

will account for 38 million tonnes of this.<br />

For comparison: the total global <strong>rice</strong> harvest<br />

in 2006 was around 635 million tones,<br />

according to FAO-figures.<br />

The main reason for the anticipated increase<br />

in demand is strong population<br />

growth. In India, the population has been<br />

increasing by 1.7 percent a year on average.<br />

The UN forecasts that it could climb<br />

from 1.10 billion (2005) to 1.26 billion by<br />

2015. A further increase is also expected in<br />

China – despite the “one child policy” – to<br />

1.39 billion people by 2015. According to<br />

the demographers’ forecasts, the whole of<br />

Asia could have a population of 4.35 billion<br />

inhabitants by then; in 2005, the figure<br />

lay at 3.91 billion. In other words, an<br />

eleven percent increase in ten years.<br />

The major part of the required increase<br />

in production must come from an improvement<br />

in the yield per hectare, points out Dr.<br />

Pandey in his Rice Today article, because<br />

there is no capacity for extending the area<br />

under cultivation. In China, the <strong>rice</strong>-growing<br />

area actually declined by three million<br />

hectares between 1997 and 2006. The reason:<br />

<strong>rice</strong> farming is increasingly in competition<br />

with other forms of land use.<br />

This increase in productivity will be<br />

achievable primarily through the development<br />

and distribution of improved technologies,<br />

according to Dr. Pandey. This is,<br />

at the same time, the only possibility of<br />

avoiding a further, rapid increase in the<br />

p<strong>rice</strong> of <strong>rice</strong>.<br />

New Rice Research Laboratory<br />

in Singapore<br />

Among these technical solutions will be<br />

new possibilities for crop protection, as<br />

well as seed with improved yield potential.<br />

In order to bring forward this type of development,<br />

<strong>Bayer</strong> CropScience is investing<br />

five million Euros in its new Rice Research<br />

Laboratory in Singapore. The Institute<br />

began its work in June 2008, and it

will contribute a significant extension in<br />

breeding capacity for hybrid <strong>rice</strong>, among<br />

other things. Here, the use of modern biochemical<br />

methodology will accelerate the<br />

otherwise prolonged process of developing<br />

new varieties.<br />

One example is DNA marker technology,<br />

through which certain genes can be detected<br />

in the genetic material – thus allowing<br />

scientists to determine to what extent<br />

the genes have been retained during crossing<br />

and appear in the progeny. Indeed, <strong>Bayer</strong><br />

CropScience’s researchers used DNA<br />

marker technology to follow the fate of individual<br />

resistance genes during the crossing<br />

process that led to the development of<br />

the bacterial leaf blight-resistant Arize<br />

Dhani. DNA marker analysis is an integral<br />

tool in molecular breeding, which in turn<br />

helps to accelerate the development of new<br />

varieties significantly.<br />

<strong>Bayer</strong> CropScience had good reason to<br />

choose Singapore as the location for its research<br />

laboratory. “This is the best place<br />

for the Institute, because 90 percent of<br />

global <strong>rice</strong> cultivation takes place in Asia”,<br />

explained Dr. Joachim Schneider, who<br />

leads <strong>Bayer</strong> CropScience’s BioScience<br />

Business Unit, at the laboratory’s inauguration<br />

ceremony in June. “With this laboratory,<br />

we want to be able to develop new,<br />

highly-efficient <strong>rice</strong> hybrids more rapidly,<br />

so that <strong>rice</strong> farmers throughout Asia can<br />

then benefit from them”, declared Dr.<br />

Schneider.<br />

<strong>Bayer</strong> CropScience’s hybrid <strong>rice</strong> is now<br />

on the market in six Asian countries. Besides<br />

India, these are Bangladesh, Indonesia,<br />

Pakistan, the Philippines and Vietnam.<br />

Arize-Products are also available in Brazil,<br />

and further market introductions are<br />

planned in several other countries, including<br />

Thailand and the USA.<br />

The product portfolio will also continue<br />

to expand. Just as Arize Dhani combines<br />

high yield potential with resistance to bacterial<br />

leaf blight, other products will bring<br />

different supplementary characteristics.<br />

“Examples of the characteristics we are<br />

currently working into hybrid <strong>rice</strong> varieties<br />

include resistance to Brown Plant Hopper,<br />

and significantly-increased tolerance to<br />

salinity or submergence”, explains Bio-<br />

Science’s Frédéric Arboucalot. In the<br />

meanwhile, plans for Arize Dhani in 2009<br />

include further expansion into the Indian<br />

market, and introduction in Bangladesh. ■<br />

Karl Hübner<br />

Bacterial leaf blight (Xanthomonas oryzae) lesions on the leaves and ear of <strong>rice</strong> plants.<br />

Bacterial leaf blight<br />

The most characteristic symptoms of bacterial leaf blight are light-coloured,<br />

longitudinal stripes on the leaf lamina. Badly-infected plants first wilt, then quickly<br />

dry out. Diagnosis of the disease can be confirmed by cutting off the leaf at the<br />

lower end of a lesion and dipping the cut end into water: masses of bacteria can<br />

be seen against the light, streaming into the water, which eventually becomes<br />

cloudy.<br />

Warm temperatures and high humidity favour the development of bacterial<br />

leaf blight. Damp areas, strong winds that damage the <strong>rice</strong> plants, and over-fertilising<br />

are further factors that encourage the disease. Moreover, the presence of<br />

weeds or infected <strong>rice</strong> stubble ensures the survival of the pathogen between<br />

crops, such that a new outbreak of the disease can occur as soon as the following<br />

crop is sown.<br />

The younger the plants are at the time of infection, the greater the resulting<br />

harvest loss. In some regions, local losses of up to 60 percent are recorded. Asian<br />

countries are particularly badly affected: besides threatening millions of hectares<br />

in India, the disease is also a problem in other Asian countries such as<br />

Bangladesh, Myanmar, Japan and Indonesia.<br />

Touring the new <strong>Bayer</strong> CropScience Rice Breeding Support Laboratory are Dr. Joachim Schneider, Head of<br />

BioScience (far left), Mr. Julian Ho of the Singapore Economic Development Board (<strong>second</strong> from right), and<br />

Mr. Marcus Yim of <strong>Bayer</strong> South East Asia (far right).<br />

2/08 COURIER 9

Less stress – hig<br />

Trifloxystrobin: a well-proven fungicide<br />

with additional benefits<br />

Heat makes the farmer sweat: but crop plants also become stressed<br />

under conditions of high temperature and water shortage – with yield<br />

losses as the result. Scientific studies have demonstrated that <strong>Bayer</strong><br />

CropScience fungicides containing the active substance trifloxystrobin<br />

can improve the stress tolerance of plants, thereby securing the harvest.

her yield<br />

Whether in fruit orchards in Baden,<br />

French vineyards, Brazilian soybean fields<br />

or the extensive areas of maize and wheat<br />

grown in the American Mid-West – farmers<br />

around the globe are using Flint ®, Nativo ®<br />

and Stratego ® to protect their crops against<br />

damaging fungal diseases. Flint, the wellproven<br />

product from <strong>Bayer</strong> CropScience,<br />

has built up a reputation over the years as a<br />

specialist against scab. Vintners also<br />

appreciate this user-friendly fungicide because<br />

of its excellent activity against powdery<br />

mildew and phomopsis, as well as for<br />

the fact that it does not endanger beneficial<br />

insects. In South American countries, Nativo<br />

is used to control a range of diseases in<br />

soybean, <strong>rice</strong> and vegetables; farmers in<br />

North America put their trust in the Stratego<br />

brand when it comes to protecting<br />

against cereal diseases.<br />

These brands, along with several others<br />

<strong>Bayer</strong> CropScience offers farmers in more<br />

than 90 countries, have one thing in common<br />

– they contain the active substance trifloxystrobin.<br />

This compound belongs to<br />

the chemical class of the strobilurins, and<br />

it obviously possesses characteristics that<br />

set it apart from other fungicides. Besides<br />

High temperatures and drought cause stress<br />

to crop plants, resulting in harvest losses.<br />

its efficacy against fungal diseases, it also<br />

appears to have a positive influence on<br />

plant growth and yield. Many farmers who<br />

treat their crops regularly with Flint, Stratego<br />

or Nativo have observed that the plants<br />

grow more robustly, and that their leaves<br />

are a more intense <strong>green</strong>. But there’s more<br />

to it than that: “Field trials confirm that the<br />

yield of many different crops increases<br />

much more when strobilurins are applied<br />

than when fungicides from other classes<br />

of active substance are applied.”, explains<br />

Dr. Dirk Ebbinghaus, Crop Protection<br />

Research Scientist at <strong>Bayer</strong> CropScience.<br />

Researchers around the world are seeking<br />

an explanation for this so-called <strong>green</strong>ingeffect.<br />

Dr. Ebbinghaus’ research group at<br />

<strong>Bayer</strong> CropScience is taking a close look at<br />

trifloxystrobin in order to investigate its<br />

full potential. The aim is to be able to show<br />

how the line of products from Flint to Nativo<br />

can be used in a more directed way to<br />

achieve the yield increases of which they<br />

are known to be capable.<br />

Biotic and abiotic stress<br />

“Strobilurins appear to trigger a whole<br />

range of positive effects in the plant, which<br />

then combine to produce higher-than-average<br />

yields”, explains the researcher. One of<br />

the most important factors: trifloxystrobin<br />

seems to increase the plant’s ability to tolerate<br />

stress. Ebbinghaus’ team has found<br />

that crop plants treated with the <strong>Bayer</strong><br />

product are better able to tolerate water<br />

shortage than untreated plants. “Against a<br />

background of impending climate change,<br />

this result is particularly interesting”, emphasizes<br />

the researcher. Farmers are already<br />

more worried today about prolonged<br />

periods of drought than about problems<br />

caused by pests, diseases and weeds. A<br />

large number of effective crop protection<br />

agents are available to control these socalled<br />

biotic stress-factors. In contrast,<br />

farmers are more-or-less helpless to compensate<br />

either for water shortage and the<br />

burning sun, or for the converse - unexpected<br />

cold periods or excessive rainfall.<br />

Ebbinghaus makes it clear how important<br />

this is: “Yield losses due to stress caused by<br />

climatic factors can be enormous. Experts<br />

estimate that up to 80 percent of harvest<br />

losses around the world are attributable to<br />

2/08 COURIER 11

Marketing expert Dr. Albert Witzenberger (right) und researcher Dr. Dirk Ebbinghaus are very satisfied with the<br />

results of studies. Trifloxystrobin-treated plants are looking good – and the measurements underline this.<br />

abiotic stress factors such as drought, heat,<br />

cold or flooding”. Agricultural scientists<br />

expect that the anticipated climate changes<br />

will make the situation even worse. The<br />

worrying implications: considerable economic<br />

penalties for farmers in some of the<br />

world’s regions, and a world-wide shortage<br />

of basic foodstuffs.<br />

If this situation is to be kept under control,<br />

crop protection agents that strengthen<br />

crop plants’ resistance to stress are among<br />

the tools that are <strong>need</strong>ed. The trifloxystrobin-containing<br />

<strong>Bayer</strong> fungicides Flint,<br />

Stratego and Nativo have the potential to<br />

do this. The work of the scientists in<br />

Ebbinghaus’ group has provided an insight<br />

as to why plants treated with trifloxystrobin<br />

are better able than untreated plants<br />

to withstand periods of drought. “Drought<br />

12 COURIER 2/08<br />

means stress for every crop plant, and they<br />

respond by releasing free radicals”, explains<br />

Ebbinghaus. These are actually poisonous<br />

to the plant, but they can nevertheless<br />

render them harmless through the activity<br />

of certain enzymes. “Our results indicate<br />

that trifloxystrobin increases the activity<br />

of these enzymes”, he adds.<br />

When it comes to lack of water, many<br />

crop plants switch to a sort of emergency<br />

programme. An example: lemon trees will<br />

respond to a period of drought during the<br />

fruit development period by dropping most<br />

of their fruit prematurely (in nature, the<br />

few remaining lemons would then ensure<br />

the continuation of the species). “Trifloxystrobin<br />

obviously has the potential to influence<br />

the plant’s water balance positively,<br />

such that this type of emergency response<br />

Investigating the distribution of the active<br />

substance on cereal leaves.<br />

is delayed”, suggests Dr. Albert Witzenberger,<br />

Fungicide Product Manager at <strong>Bayer</strong><br />

CropScience. This is another of the substance’s<br />

assets. Witzenberger himself saw<br />

how dramatic this effect can be in the summer<br />

of 2005, whilst visiting a citrus plantation<br />

in south-east Brazil. He describes<br />

the bleak situation: “It hadn’t rained in the<br />

region for weeks. Most of the trees had already<br />

shed the portion of their lemons that<br />

were still unripe”. But some of the lemon<br />

trees appeared to be resisting the heat and<br />

lack of water – they were still replete with<br />

fruit. “The reason was obvious: these were<br />

the trees that had been treated with our<br />

fungicide”, he explains.<br />

But that isn’t the end of the yield- and<br />

quality-increasing properties that make the<br />

<strong>Bayer</strong> active substance so interesting for<br />

farmers. It is obviously also capable of ensuring<br />

that the harvested commodity contains<br />

more of its most valuable constituents.<br />

Trifloxystrobin sets itself further<br />

apart from other substances in the same<br />

class through its effect on protein synthesis<br />

in cereals, as studies in the United Kingdom<br />

have shown: wheat plants that have<br />

been treated with trifloxystrobin are able to<br />

use the nitrogen that is available in the soil<br />

more effectively.<br />

And it’s not only the protein content of<br />

wheat grain that is increased: it also contains<br />

more starch. Ebbinghaus explains the<br />

reasons for both of these effects: “The stro-

If trees suffer stress – for example<br />

during a drought – they drop the<br />

majority of their fruit. The small<br />

remaining crop then ripens, but is<br />

nevertheless unable to compensate<br />

in terms of harvest.<br />

bilurins stimulate not only photosynthetic<br />

activity, and thus the production of starch,<br />

they also increase nitrogen assimilation –<br />

one of the basic foundations of protein<br />

synthesis”.<br />

The ability of strobilurins to improve<br />

yield also manifests itself in maize crops.<br />

The more than 600 field trials with Stratego<br />

that <strong>Bayer</strong> CropScience has conducted<br />

in North America demonstrate this conclusively.<br />

Product Manager Witzenberger<br />

summarizes the results as follows: “Trifloxystrobin-treated<br />

maize plants are generally<br />

<strong>green</strong>er and more stable. The corns<br />

in the cobs are larger, and have better quality,<br />

because they contain more sugar and<br />

starch.” This leads to measurably higher<br />

yields: the average corn yield increase in<br />

response to treatment was greater than 680<br />

liters per hectare. This has impressed many<br />

North American farmers. For example<br />

Tim Geiger, who cultivates maize on large<br />

holdings in Ottawa and Illinois: “It was unbelievable.<br />

My fields contained plants that<br />

had developed in a much healthier way.<br />

And the yields were higher than they’ve<br />

ever been.” ■<br />

Iris Freundorfer<br />

Strong retention – long duration of action<br />

Trifloxystrobin’s main job is to protect the plant from fungal infection.<br />

The active substance succeeds in doing this because it inhibits respiration<br />

in fungal cells, thus removing the pathogen’s ability to use energy. While<br />

other fungicides are also able to do this, trifloxystrobin stands out because<br />

of its so-called “mesostemic activity”: this term describes the active substance’s<br />

unique behavior during uptake and distribution on, and within,<br />

the plant.<br />

Put in concrete terms, this means that trifloxystrobin sticks particularly<br />

well to the leaf surface, building a depot of active substance molecules<br />

which even heavy rain fails to wash off to any extent. The depot provides<br />

for a steady redistribution of the active substance across the leaf, and<br />

small quantities also penetrate gradually into the leaf tissue. The result<br />

is a particularly long duration of action.<br />

At the same time, mesostemic behavior is a prerequisite for trifloxystrobin’s<br />

anti-stress bonus; the unfolding of this useful side-effect also<br />

depends on the steady release of the right “dose” of active substance<br />

into the plant.<br />

2/08 COURIER 13

How<br />

herbicides<br />

work<br />

The effects of crop protection agents are tested in the <strong>green</strong>house.<br />

Without the means to control weeds,<br />

neither the required yield nor the desired<br />

quality of the products deriving from a<br />

crop can be guaranteed. Under most<br />

circumstances, herbicides are the cheapest<br />

and most reliable form of weed control.<br />

However, they should be used only after<br />

other, cultural options for weed control<br />

have been considered and put into practice.<br />

In order to avoid the problems that arise<br />

if an active substance is over-used, it is<br />

necessary to select a rotation in which herbicides<br />

with different modes of action can<br />

be applied. Knowledge of the mode of action<br />

of herbicides can help towards developing<br />

a successful strategy for controlling<br />

weeds.<br />

How are herbicides<br />

taken up by the plant?<br />

In order to be effective, herbicides must be<br />

able to move from the spray deposit (foliar<br />

herbicides) or the soil solution (soil herbi-<br />

14 COURIER 2/08<br />

cides) into the plant. Products are classified<br />

as contact or systemically-active herbicides,<br />

depending on the extent and nature<br />

of uptake, redistribution and activity<br />

within the plant.<br />

1. Foliar herbicides<br />

The contact herbicides belong to this<br />

group. They penetrate into the plant exclusively<br />

or predominantly via the leaf, and<br />

are then redistributed only to a limited extent.<br />

They therefore cause damage to the<br />

weed plant at, or near, the point of penetration.<br />

This means that contact herbicides tend<br />

to be effective mainly against species that<br />

lack stored reserves, such as annual weeds.<br />

The uptake of systemic foliar herbicides<br />

occurs mainly via the leaf, and is followed<br />

by extensive redistribution within the<br />

plant. The best-known examples are the<br />

growth substances, which interfere with<br />

the balance of growth hormones in the<br />

plant. Most grass herbicides and bindweed<br />

products also work via the leaf.<br />

Foliar herbicides are redistributed in the<br />

plant mainly via the transpiration stream<br />

that flows through the plant’s vascular bundles.<br />

The assimilates produced by photosynthesis<br />

in a particular leaf are only exported<br />

if it is producing more than it <strong>need</strong>s<br />

for growth and respiration within its own<br />

tissues. The greatest export of assimilates<br />

occurs in fully developed, photosynthetically-active<br />

leaves when weather conditions<br />

are optimal. Young, still-developing<br />

leaves do not export sugars – and herbicides<br />

applied to them are not re-distributed<br />

to any extent. Temperature is important for<br />

herbicide efficacy: at temperatures below<br />

10°C, activity is usually low; whereas at<br />

temperatures greater than 25°C, there may<br />

be scorching of the crop plant, or reduced<br />

activity against the target species.

Special additives protect crop plants against the effects of herbicides. These are called „safeners“. <strong>Bayer</strong> CropScience is recognized as one of the world leaders in this technology.<br />

2. Soil herbicides<br />

The uptake of these active substances occurs<br />

via the roots, and is followed by re-distribution<br />

within the plant. The herbicides<br />

tend to be active in the leaves, or other<br />

above-ground parts of the plant, where<br />

they disrupt respiration processes and photosynthesis.<br />

The active substances reach<br />

the soil through the medium of water, and<br />

can remain there for some time. Soil herbicides<br />

should therefore only be applied to<br />

moist soils: under dry conditions, these<br />

products may lose their activity altogether.<br />

Soil herbicides play an important role in<br />

the control of weed grasses and dicotyledons<br />

during the pre-seeding and pre-emergence<br />

periods, or sometimes in the early<br />

post-emergence period. Examples include<br />

active substances such as metazachlor in<br />

oilseed rape and flufenacet (in Cadou ®) in<br />

cereals.<br />

3. Foliar and soil herbicides<br />

Some herbicides are active via both the<br />

leaf and the soil. Examples include the<br />

ALS-inhibitors, e.g. Atlantis ® and Husar ®.<br />

The relative degree of uptake via leaves<br />

and roots of products within this category<br />

of herbicides determines the timing of application<br />

– whether pre-emergence, early<br />

post-emergence or from the 3-leaf stage<br />

onwards. Combined foliar and root uptake<br />

can be achieved using a mixture of active<br />

substances: a typical example of this type<br />

of mixture is the sugar beet herbicide Betanal<br />

® Expert.<br />

4. Safeners<br />

Safeners are herbicide additives that accelerate<br />

the breakdown of the active substance<br />

within the crop plant. In contrast,<br />

they do not interfere with the intended action<br />

within target grass weeds, which apparently<br />

possess different variants of the<br />

relevant target enzymes. The product Atlantis,<br />

for example, has excellent activity<br />

against grasses. It would not be possible to<br />

use Atlantis in cereals – which, strictly<br />

speaking, are also grasses – if the product<br />

didn’t contain a safener. The safener activates<br />

an enzyme in cereals that accelerates<br />

the breakdown of the active substance, thus<br />

making the cereal plant insensitive to it.<br />

The secret is that the safener does not activate<br />

the corresponding enzyme in weed<br />

grasses – they remain sensitive and are<br />

killed off.<br />

Mode of action<br />

The mode of action describes the way in<br />

which physiological processes within the<br />

plant are influenced by the herbicide. In<br />

most cases, the active substance binds to a<br />

protein, thereby blocking one of the plant’s<br />

essential metabolic processes. The protein<br />

is usually an enzyme that regulates a particular<br />

biochemical reaction within the<br />

metabolic chain. However, the inhibition<br />

can also take place at structural and regu-<br />

2/08 COURIER 15

latory binding sites. Herbicides tend to<br />

possess a single main mode of action, but<br />

many also have <strong>second</strong>ary sites of action at<br />

which they can also disturb the plant’s metabolism.<br />

Herbicides are classified into different<br />

groups according to their main site of action<br />

within the plant’s metabolism. Here is<br />

a list of the various modes of action:<br />

• Photosynthesis inhibitors<br />

• Pigment synthesis inhibitors<br />

• Amino acid synthesis inhibitors<br />

• Fatty acid synthesis inhibitors<br />

• Cell division inhibitors<br />

Photosynthesis is among the plant’s<br />

most central metabolic processes, and is<br />

thus a particularly suitable target for herbicidal<br />

action. Photosynthesis inhibitors can<br />

disrupt the electron transport system of<br />

Photosystem II, or they can inhibit the formation<br />

of radicals in Photosystem I. Both<br />

have fatal consequences for the target<br />

weed, the cells of which are no longer able<br />

to store the energy derived from light.<br />

Herbicides can also disrupt photosynthesis<br />

indirectly, by inhibiting the synthesis<br />

of compounds that are important to it –<br />

pigments such as carotenoids, chlorophylls<br />

and cytochromes. The carotenoids, for example,<br />

have a protective function within<br />

photosynthesis, and it is this very function<br />

Modes of action of herbicides<br />

Inhibition of amino acid synthesis<br />

Product examples:<br />

Alister, Atlantis, Attribut, Basta, Husar, Maister<br />

Raw materials<br />

Site of action of the herbicide<br />

ALS<br />

(enzyme) Amino acid =<br />

building-block<br />

for proteins<br />

······· ·······<br />

16 COURIER 2/08<br />

Amino acid chain = protein<br />

that is shut off by herbicides. Products possessing<br />

this property include soil and foliar<br />

herbicides that can be used at an early development<br />

stage in autumn or spring<br />

against both mono- and dicotyledons (e.g.<br />

Mikado ®).<br />

Among the most well-known herbicides<br />

are those that inhibit the synthesis of<br />

amino acids and thus disrupt the production<br />

of proteins, including enzymes. Here,<br />

three important target enzymes can be affected:<br />

glutamine synthetases (target of<br />

glufosinate in Basta ®), 5-EPSPS-Synthase<br />

(target of glyphosate) and acetolactatesynthase<br />

(target of ALS-inhibitors). The<br />

latter enzyme is the target of action for sulfonylureas<br />

and the imidazolinones. With<br />

Husar, Atlantis und Maister ®, the <strong>Bayer</strong><br />

CropScience portfolio has some wellproven<br />

herbicides from this class.<br />

Fatty acid metabolism is important to<br />

the process of cell membrane formation.<br />

Disturbance of this process through the action<br />

of a herbicide leads to the development<br />

of a thinner cuticle, and thus to a disruption<br />

of water uptake: this type of action<br />

is characteristic of FOPs (e.g. Puma ®<br />

Super) and DIMs. But compounds from<br />

other groups can attack fatty acid metabolism<br />

too: another example is ethofumesate<br />

(Betanal ® Expert).<br />

Other herbicides act like plant hormones<br />

(auxin herbicides) and set off uncontrolled<br />

cell growth. This is why the<br />

term growth substances is also applied to<br />

representatives of this group. Examples include<br />

the phenoxyacetic acids such as the<br />

well-known MCPA-, MCPP-P- and 2,4-D<br />

compounds.<br />

The process of cell division is vitally<br />

important. Some herbicides inhibit the system<br />

that regulates cell division – the<br />

microtubule system – such that cells can<br />

develop with several nuclei or too many<br />

chloroplasts. The grass herbicide flufenacet<br />

belongs to the group of substances<br />

that prevent cell division in plant tissues.<br />

Decision criteria<br />

Inhibition of fatty acid synthesis<br />

Product examples:<br />

Betanal Expert, Puma Super<br />

Raw materials<br />

ACCase<br />

Cell membrane<br />

Herbicides should be applied according to<br />

the principles of Good Agricultural Practice<br />

and Integrated Crop Protection. This<br />

means that local conditions, rotation, and<br />

possible cultural methods should all be<br />

considered when developing a strategy for<br />

controlling weeds. Rotation is particularly<br />

important, and it has a direct influence on<br />

soil cultivation, the incidence of weeds and<br />

the ability of a crop to compete with them,<br />

and it determines the spectrum of herbicides<br />

that is available for weed control.<br />

Oils and<br />

fats<br />

Inhibition of cell di<br />

Product examples:<br />

Cadou, Husky<br />

Without herbicides<br />

Normal cell division

vision<br />

If herbicide use becomes necessary, the<br />

first step towards choosing the most suitable<br />

product is to determine which weed<br />

species are present – or are likely to appear<br />

– and the current and anticipated density of<br />

infestation. The prevalent weed flora and<br />

the known thresholds of action determine<br />

the choice of the best herbicide, based on<br />

its spectrum of activity.<br />

The efficacy of a product and the overall<br />

success of weed control are influenced<br />

by a number of factors, including the<br />

growth conditions, the timing and rate of<br />

application, the technology used to apply,<br />

and other, local circumstances. If all of<br />

these factors are considered together, then<br />

the product’s full potential can be realised.<br />

But economic factors also play a role in the<br />

decision-making process. Depending on<br />

the situation on the farm and the number<br />

and types of different crops grown, early<br />

treatment of cereals can help to avoid work<br />

peaks later in the season. The decision as<br />

to whether to treat pre-sowing, or pre- or<br />

post-emergence, influences both the<br />

choice of herbicide, and the work-regime<br />

throughout the season.<br />

Herbicide-treated<br />

No cell division<br />

Resistance<br />

Inhibition of photosynthesis<br />

Product examples:<br />

Betanal Expert, Betanal Quattro, Sencor<br />

Light energy<br />

Limiting the rotation to one or two crops,<br />

and intensive use of herbicides with identical<br />

or similar modes of action, favour the<br />

development of resistance in weeds. Shifts<br />

within the weed population always start<br />

with single, resistant individual plants –<br />

these are universally present in nature. The<br />

repeated use of herbicides with a common<br />

mode of action creates a selection pressure<br />

that promotes the spread within the population<br />

of plants possessing the resistance<br />

characteristics. Unless the control strategy<br />

is changed, these resistant weeds can<br />

Site of action of the herbicide<br />

Solar energy<br />

conversion<br />

enzymes<br />

Chloroplasts<br />

(in plant cells)<br />

Sugar +<br />

oxygen<br />

spread such that they eventually gain the<br />

upper hand, and can no longer be controlled<br />

effectively.<br />

Thus to be on the safe side, resistance<br />

management should be considered in advance,<br />

whilst planning which crop to grow.<br />

The key to active substance rotation is to<br />

design the rotation so that the same mode<br />

of action is not used twice in successive<br />

crops. ■<br />

Inhibition of pigment synthesis<br />

Product examples:<br />

Alister, Husky, Laudis, Mikado<br />

Without herbicides<br />

Carotenoids protect the<br />

<strong>green</strong> pigmentation<br />

Ultra-violet light (damaging)<br />

Visible light (productive)<br />

Herbicide-treated<br />

UV-light destroys <strong>green</strong><br />

pigmentation<br />

2/08 COURIER 17

The cellular powe<br />

Plant cells can capture light energy and store it ready<br />

for use in metabolism, so they’re just like miniature<br />

solar panels – only considerably more efficient.<br />

18 COURIER 2/08

station<br />

Macrocosmos, microcosmos – it’s always<br />

fascinating to see that something<br />

familiar to us that is very large can also be<br />

rediscovered in a corresponding form at<br />

the microscopic level. Take, for example,<br />

the comparison between a city and a cell:<br />

the cell’s equivalent to the city limits is the<br />

cell membrane, which delineates the cell<br />

from the external environment or from<br />

neighbouring cells; situated in the membrane<br />

are points of passage that allow for a<br />

controlled traffic of “goods”, such as one<br />

might find between neighbouring countries.<br />

Let’s continue with entities that are<br />

above the level of the State, such as the<br />

European Union (within which the borders<br />

have largely been raised). With a bit of<br />

imagination, you can also find their equivalents<br />

at the cellular level, for example in<br />

the skeletal muscles, where the individual<br />

cells are united together into associative<br />

units, the muscle fibres, in order to be able<br />

to work more effectively. So it’s not surprising<br />

that there are also correspondences<br />

in terms of energy-production and -transport<br />

at the cellular level, where terms such<br />

as “power station” and “energy transmitters”<br />

can equally be applied.<br />

Plant cells are characterised by the fact<br />

that they possess “solar panels”, the socalled<br />

chloroplasts. With the help of these<br />

cell organs (or “organelles”), they are able<br />

to capture light energy and convert it into<br />

other forms of energy that are useful to the<br />

plant, although not into electrical energy<br />

like our solar panels can, but rather into<br />

chemical energy, without which biomass<br />

could not be created. This ability makes<br />

plants the basis for all terrestrial life as we<br />

know it: all animals, including man, use<br />

the energy that plants fix and turn into biomass,<br />

either directly or indirectly, in order<br />

to maintain their own vital processes. This<br />

certainly applies to herbivores, which consume<br />

plants directly, but also to carnivores<br />

insofar as they survive by eating herbivores<br />

and even, in the end, to decomposers<br />

such as fungi, which gain the energy they<br />

<strong>need</strong> for their own metabolism through the<br />

degradation of organic matter.<br />

Natural solar panels<br />

Chloroplasts, the solar panels of the plant<br />

cell, are extremely complex units. Scientists<br />

speculate about their origin: like mitochondria,<br />

which we’ll talk about in more<br />

detail below, they possess their own ringformed<br />

DNA, similar to that of bacteria<br />

and blue-<strong>green</strong> algae. Chloroplasts are capable<br />

of multiplying independently within<br />

the plant cell. Thus the so-called endosymbiont<br />

theory suggests that chloroplasts<br />

were originally independent, blue alga-like<br />

organisms that were taken up by other single-celled<br />

organisms many aeons ago: but<br />

instead of being digested as food, they<br />

rather continued to live inside their new<br />

hosts in a symbiotic relationship.<br />

Within the chloroplasts can be found<br />

the thylakoids, rolled up membrane systems<br />

that look rather like a pile of coins. It<br />

is here that the light-absorbing agents are<br />

stored, particularly the <strong>green</strong> pigment<br />

chlorophyll. And it’s also here that the<br />

wonder of energy-capture and conversion<br />

occurs – photosynthesis.<br />

Sugar made from CO2<br />

The process of photosynthesis can be divided<br />

into three stages:<br />

• First, light (a form of electromagnetic<br />

energy) is absorbed;<br />

• The electromagnetic energy is converted<br />

directly into chemical energy;<br />

• Finally, the chemical energy is used in the<br />

production of organic matter and is thus<br />

made available for subsequent use within<br />

the cell.<br />

When light hits the thylakoid membranes<br />

in the chloroplast, it sets the electrons present<br />

in the absorbing pigments into a more<br />

excited, and thus more energy-rich, state.<br />

Excited electrons can be given up easily.<br />

Operating through several intermediate<br />

steps, electron transfer ensures that two<br />

molecules important to subsequent metabolic<br />

processes are formed – or to be more<br />

accurate, are regenerated – the energy-coupling<br />

agent ATP (adenosine triphosphate)<br />

and the reducing agent NADPH, a molecule<br />

with the rather challenging name of<br />

nicotinamide adenine dinucleotide phosphate<br />

hydrogen.<br />

With the help of ATP, the plant cell is<br />

able to synthesize the energy-rich substance<br />

glucose within its chloroplasts, using<br />

the energy-poor substances carbon<br />

dioxide (CO2) and water as building<br />

blocks. During this reaction, the water<br />

molecules are split into oxygen, electrons<br />

and hydrogen ions; NADPH is oxidized to<br />

NADP +, and energy-rich ATP returns to its<br />

low-energy form, ADP. The formula for the<br />

reaction is as follows:<br />

6 CO2 + 12 H2O ➞<br />

C6H12O6 + 6 H2O + 6 O2.<br />

From six molecules of carbon dioxide<br />

and twelve molecules of water, a molecule<br />

of glucose arises, as a sort of energy-store;<br />

the by-products of this reaction are six<br />

2/08 COURIER 19

molecules of water and six molecules of<br />

oxygen. This oxygen is released into the<br />

surrounding air. The fact that our atmosphere<br />

today comprises about 20 percent<br />

oxygen is largely the result of millions of<br />

years-worth of photosynthetic activity. So<br />

people and animals owe not only the basis<br />

for their nourishment to plants, but also the<br />

air they breathe.<br />

Plants can synthesize glucose from CO2<br />

in one of two ways. In most crop plants, the<br />

intermediate molecules in the reaction<br />

have three carbon atoms (the so-called C3plants).<br />

In other species such as maize, elephant<br />

grass and sugar cane, CO2-fixation<br />

proceeds via oxalacetate, a compound with<br />

four C-atoms (C4-plants). This latter reaction<br />

is quicker, more efficient, and requires<br />

less water. C4-plants are therefore often<br />

used for producing biomass (energy<br />

plants). The temperature optimum for C4plants<br />

is higher than that of C3-plants, so<br />

Specimen of a plant cell<br />

Cell wall<br />

20 COURIER 2/08<br />

the former tend to grow in warmer climates.<br />

The working efficiency of photosynthesis<br />

is estimated at around 20-35 percent,<br />

depending on the wavelength of the absorbed<br />

light. The synthesis of a mole of<br />

glucose requires 8,000 to 14,300 kJ of light<br />

energy.<br />

Energy production in the<br />

mitochondria<br />

Let’s return once more to the endo-symbiont<br />

theory: plant cells benefit from the<br />

presence of chloroplasts because of their<br />

ability to capture the energy of light<br />

through photosynthesis and channel it into<br />

energy-rich organic substances such as<br />

glucose and starch (macromolecules comprised<br />

of many glucose units). When the<br />

cell <strong>need</strong>s energy – as it always does, to<br />

run metabolic processes, growth and cell<br />

Vacuole<br />

Cell membrane<br />

Mitochondria<br />

Smooth endoplasmatic<br />

reticulum<br />

division – then the glucose energy safe<br />

must be cracked. Just as for photosynthesis,<br />

the cell does this with the help of certain<br />

organelles that possess their own<br />

DNA, reproduce themselves independently<br />

and also appear to have an ancestry going<br />

back to bacterium-like predecessors – the<br />

mitochondria. These organelles are found<br />

in the cells of all complex organisms, in<br />

plants as well as in animals and fungi.<br />

Mitochondria are particularly numerous in<br />

cells that use a lot of energy, such as muscle<br />

cells, nerve cells and egg cells.<br />

In the mitochondria, the chemical energy<br />

stored in glucose or other organic substances<br />

is made available through oxidative<br />

degradation. With the release of energy, the<br />

cell’s battery – the ADP/ATP-System – is<br />

recharged. The complete oxidation of one<br />

mole of glucose delivers 38 moles of ATP,<br />

meaning that the efficiency of oxidative<br />

glycolysis lies at almost 40 percent – mak-<br />

Chloroplast<br />

Nucleus membrane<br />

with pores<br />

Ribosomes<br />

Rough endoplasmatic<br />

reticulum<br />

Microtubuli<br />

Golgi apparatus<br />

Lysosomes

ing it a pretty effective system, on a par<br />

with the energy yield of modern steam turbines.<br />

Thus the mitochondria really do<br />

earn their reputation as the cell’s powerhouse.<br />

During the oxidation of organic<br />

compounds, hydrogen is split off and<br />

brought together with molecular oxygen to<br />

produce water (4 H + O2 ➞ 2 H2O). The<br />

formation of water is the main energyyielding<br />

reaction. You could consider this<br />

process (cell respiration, as it is called) as<br />

being the opposite of photosynthesis: in<br />

the chloroplasts, glucose and oxygen are<br />

produced from CO2 and water (with sunlight<br />

providing the energy); whereas in the<br />

mitochondria, glucose and oxygen are degraded<br />

again to CO2 and water in order to<br />

release energy.<br />

Consequences for the farmer<br />

The growth and yield of crop plants will<br />

increase as the factors that are important<br />

for photosynthesis approach their optimum<br />

levels. Factors such as sunlight and temperature<br />

are of course beyond the farmer’s<br />

control (the temperature optimum for photosynthesis<br />

in full sunlight lies at 35°C).<br />

Drought has a negative effect on photosynthetic<br />

productivity because the plant protects<br />

itself from drying out by closing<br />

its stomata, thereby limiting the exchange<br />

of the gases necessary for this process.<br />

Given the facts of climate change, it is interesting<br />

to note that photosynthesis functions<br />

most efficiently at an ambient CO2concentration<br />

range of 0.1 to 1 percent.<br />

However, the CO2-concentration in the atmosphere<br />

currently lies at around 0.037<br />

percent (370 ppm), meaning that plants are<br />

working at below capacity. The anticipated<br />

increase in the concentration of the <strong>green</strong>house<br />

gas CO2, which is expected to reach<br />

about 500 ppm in the course of the coming<br />

decades, is likely to boost the growth of<br />

plants to some extent.<br />

Laboratory studies have indeed shown<br />

that considerable yield increases (of 20-30<br />

percent) might be anticipated as the result<br />

of this so-called CO2-fertilising effect. But<br />

are these results really so easily translated<br />

from the laboratory to the field? On the<br />

other hand, would it really be possible to<br />

simulate an enhanced CO2-concentration<br />

in the field (for example over a cereal<br />

crop) in order to obtain a realistic picture<br />

in situ?<br />

The effort involved is considerable –<br />

but studies like this are indeed running at<br />

several sites around the world. One of<br />

these locations is the Johann Heinrich von<br />

Thünen-Institut (vTI), the former German<br />

Federal Agricultural Research Centre, in<br />

Brunswick, Germany. In the Brunswick<br />

carbon project, which is running over several<br />

cropping seasons, the CO2-concentration<br />

in the air above selected portions of a<br />

field is being maintained at a constant 450-<br />

550 ppm using controlled release of the<br />

gas. The scientists are measuring growth,<br />

but they are also monitoring other parameters<br />

such as the plants’ water balance. The<br />

results obtained so far are actually rather<br />

sobering: biomass production in wheat and<br />

sugar beet increased by a rather modest<br />

6-14 percent; at the same time, water use<br />

decreased. Moreover, protein content decreased<br />

by about 10 percent in the grain of<br />

winter barley, for example. Thus, the yield<br />

may increase, but the quality of the harvest<br />

also changes.<br />

This demonstrates once again how<br />

highly complex the metabolism of plant<br />

cells is; the capture, storage and use of<br />

energy are only three aspects among many.<br />

A glimpse into these biochemical processes<br />

is fascinating, but it quickly becomes obvious<br />

that it is not easy to intervene or indeed<br />

to steer them. And that’s another way in<br />

which a microscopically small cell is similar<br />

to a large municipality. ■

An end to the game<br />

Movento ® is the new innovative insecticide<br />

from <strong>Bayer</strong> CropScience. It moves<br />

easily within the plant, allowing it to reach<br />

insect pests that have burrowed deeply into<br />

the plant’s tissues. It is characterised by a<br />

broad and long-lasting efficacy, mainly<br />

against sucking insects. At the same time,<br />

Movento works hand-in-hand with beneficial<br />

arthropods and honey bees.<br />

Crop protection products must work.<br />

This is a rather obvious statement – but it<br />

encapsulates the challenge that keeps<br />

thousands of researchers around the world<br />

occupied for entire careers. It isn’t just a<br />

matter of rendering the pest harmless<br />

through contact with, or uptake of, the<br />

active substance: the active substance first<br />

22 COURIER 2/08<br />

has to reach the pest. If insects are lodged<br />

deep inside plant tissues (for example in a<br />

lettuce heart or at the ends of roots), the<br />

challenge may be a considerable one.<br />

With its new insecticide Movento, <strong>Bayer</strong><br />

CropScience now has a trump card in its<br />

hand. “There’s no escaping this product – it<br />

penetrates through to the remotest parts of<br />

the plant, providing reliable control of pests”,<br />

says Emmanuel Salmon, Product Manager<br />

for insecticides at <strong>Bayer</strong> CropScience. The<br />

active substance spirotetramat spreads<br />

throughout the entire plant – it simply<br />

reaches every part, from root tissues to<br />

young, developing shoots. Spirotetramat’s<br />

movement up and down the plant is continuous,<br />

so it eventually becomes distributed<br />

evenly throughout the plant’s tissues. This<br />

is what sets it apart from almost all the insecticides<br />

that have appeared on the market<br />

so far. As Emmanuel Salmon points out,<br />

“Movento is currently the only modern insecticide<br />

that is able to ride the plant’s bidirectional<br />

transport system.”<br />

Integrated Crop Protection<br />

with Movento<br />

<strong>Bayer</strong> CropScience’s scientists are especially<br />

proud of the fact that besides being extremely<br />

effective against insect pests,<br />

Movento also possesses remarkable environmental<br />

properties. Movento can be considered<br />

safe to populations of beneficial

of hide-and-seek<br />

arthropods. There were no long-lasting, adverse<br />

effects on beneficial bugs, lacewings,<br />

spiders, earwigs, ladybird beetles or trichogramma.<br />

Furthermore, there was no longer<br />

lasting effect on predatory mites. Moreover<br />

large scale, internal field tests also demonstrated<br />

safety to honey bees as long as the<br />

product is used correctly. This good selectivity<br />

discloses manifold options for the<br />

combined use of this product with beneficials.<br />

Movento can be highly recommended<br />

for the use in Integrated Pest Management.<br />

The active substance’s really innovative<br />

property is its ability to move within both<br />

the upward-bound water column, and the<br />

assimilate stream that moves mainly in the<br />

opposite direction. Systemic insecticides<br />

from older chemical classes have so far<br />