JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DONATI SOLLEVAMENTI S.r.l. - Via Roma, 55 - 21020 Daverio (VA) - Tel. 0332 942611 - Fax. 0332 948597<br />

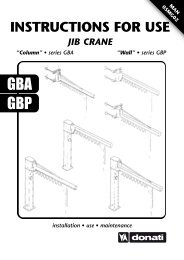

§ Column(CBB column-mounted version):<br />

Made of pressed steel bent in a tubular structure with a polygonal shape it allows a high rigidity and<br />

stability for the crane; it is fixed to the base using a base plate and a system of bolts or log bolts. In the<br />

upper part a couple of plates support the arm of the crane and allow it to rotate (fig.1).<br />

§ Support bracket ( MBB wall-mounted version):<br />

It is formed of a couple of plates made of pressed steel; fixed to the wall or anchored to a column using<br />

staybolts or screws, it acts as a support to the arm and allows it to rotate.(fig. 2).<br />

§ articulated jib:<br />

The jib cranes, both in the wall and column versions, are fitted with an “articulated arm”" composed by two<br />

segments ( semi-arms) fastened.<br />

The articulated arm is made using two cantilevered girders. The semi-arm on the “tie” side is generally<br />

made in boxes casing, while the “cantilever” side can be made using a T-beam or a tubular profile in<br />

which end is fixed the hoist.( fig. 3)<br />

The first segment, semi-arm on the tie side, rotates around the axis situated on the column or on the<br />

bracket where it is fastened. The second segment, semi-arm on the cantilever side, rotates on the ends of<br />

the first segment and is fitted with a planarity regulation system. The two semi-arms can be of different<br />

lengths and are able to rotate independently of each other. Reciprocal mobility, thanks to the “pantograph”<br />

effect, allows the lifting equipment to reach any point in the area to be served, avoiding any obstacles to<br />

the rotation as well as increasing the surface area served behind the column or fixing pillar of the bracket.<br />

The entire articulated arm is directly integral with, via suitable reinforcements, the rotation tube. The two<br />

semi-arms, rotating on their own rotation axes via bearings, allow the optimal use of the available space at<br />

a height due to the absence of staybolts.<br />

fig.1<br />

fig.3<br />

5<br />

fig.2