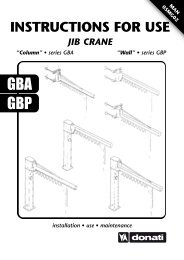

JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

JIB CRANES WITH AN ARTICULATED ARM MANUALLY ROTATED

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DONATI SOLLEVAMENTI S.r.l. - Via Roma, 55 - 21020 Daverio (VA) - Tel. 0332 942611 - Fax. 0332 948597<br />

6.2 The qualifications of maintenance staff.<br />

§ To be capable to adequately carry out maintenance work of jib cranes maintenance staff must:<br />

• know the laws in force related to accident prevention during work carried out on machines with motor<br />

transmissions and be able to apply them.<br />

• have read and understood chapter 3 “Safety and Accident Prevention”.<br />

• be able to use and consult this document.<br />

• know the functioning of the machine.<br />

• recognise irregularities regarding functioning and when necessary take necessary measures to rectify<br />

them.<br />

§ Professional figures appointed and authorised to carry out maintenance on the crane are:<br />

Operator of the jib crane.<br />

• Typical maintenance activities:<br />

• Verification of proper functioning of the jib crane. Cooperation with staff appointed to periodical<br />

and/or extra maintenance work, after having informed them of any anomalies found in the<br />

functioning.<br />

• Cleaning and lubrication of the parts of the crane (hoist) which the operator is normally in contact<br />

with (push-button panel, hook) and simple maintenance work which does not require intervention<br />

at a height (e.g. lubrication of the thrust bearing of the hook).<br />

• Technical knowledge required:<br />

• knowledge of the functions and use of the jib crane<br />

• knowledge of the lubricants utilised in the crane and in the hoist and of the dangers associated with<br />

their use.<br />

• Qualification required:<br />

• suitability to the work in relation to the specific operative and environmental characteristics.<br />

Mechanical maintenance officer<br />

• Typical maintenance activities:<br />

• mechanical regulation of the clearance of brakes and mechanisms<br />

• test movements and mechanical regulation of the safety devices<br />

• check mechanical clearance and wear of the components (chain, hook, etc.)<br />

• replacement of components which can wear out (chain, hook, chain guide, pulleys) according to<br />

this publication<br />

• ordinary maintenance of mechanical units after substitution of parts with original spare parts<br />

• Technical knowledge required:<br />

• good knowledge of mechanical lifting systems and handling with a manual and motor driven<br />

system<br />

• good knowledge of safety devices used on the hoist (limit switches, brakes, overload switch,<br />

etc.)<br />

• basic knowledge of the moderately difficult techniques for electric checking and adjustment<br />

(limit switch adjustment, replacement of fuses, motor connection, etc.)<br />

• knowledge of the methods of measurement and testing to determine the actual state of the<br />

conditions of the crane and of the hoist (tests of: brakes, chain and hook wear, anomalous<br />

noise, etc.)<br />

• logical trouble-shooting methods of non complex breakdowns and evaluation of the results<br />

• ability to arrange the necessary measures to put the hoist back into working order<br />

• ability to write a maintenance intervention report<br />

• Qualification required:<br />

•• • • Complete<br />

training of an industrial mechanic having a specialisation in and experience of liftingsystem<br />

maintenance or of industrial handling<br />

47