Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The company VISSON in co-operation with Philips Research Laboratories utilizes conductive wires,<br />

which are coated with light-emitting layer. This layer is very thin and made out of electroluminescent<br />

material. The woven structure forms an x-matrix out of wires. At each crossing point, the light-emitting<br />

layer starts to illuminate when applying electricity and therefore a pixel is generated.<br />

The Italian-made fabric Luminex ® contains coloured light emitting diodes and is commercialised by the<br />

Luminex SpA. A tiny light source distributes light throughout the fabric of the whole<br />

polymethylmethacrylate fabric, which has a light conductive fibre woven in. Out of this fabric, tailored<br />

made clothes are produced, for example sparkling cocktail dresses or costumes for opera singers.<br />

The fibres are powered by tiny rechargeable batteries that can be turned on and off by the wearer via<br />

a hidden switch [158].<br />

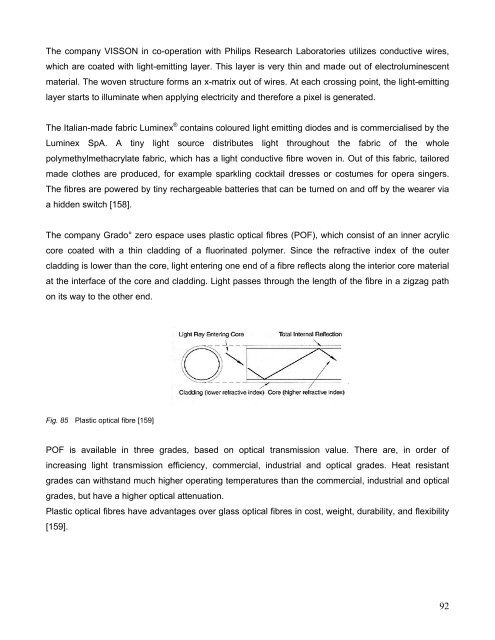

The company <strong>Grado</strong>° zero espace uses plastic optical fibres (POF), which consist of an inner acrylic<br />

core coated with a thin cladding of a fluorinated polymer. Since the refractive index of the outer<br />

cladding is lower than the core, light entering one end of a fibre reflects along the interior core material<br />

at the interface of the core and cladding. Light passes through the length of the fibre in a zigzag path<br />

on its way to the other end.<br />

Fig. 85 Plastic optical fibre [159]<br />

POF is available in three grades, based on optical transmission value. There are, in order of<br />

increasing light transmission efficiency, commercial, industrial and optical grades. Heat resistant<br />

grades can withstand much higher operating temperatures than the commercial, industrial and optical<br />

grades, but have a higher optical attenuation.<br />

Plastic optical fibres have advantages over glass optical fibres in cost, weight, durability, and flexibility<br />

[159].<br />

92