Mastering ozonolysis: production from laboratory to ton scale in ...

Mastering ozonolysis: production from laboratory to ton scale in ... Mastering ozonolysis: production from laboratory to ton scale in ...

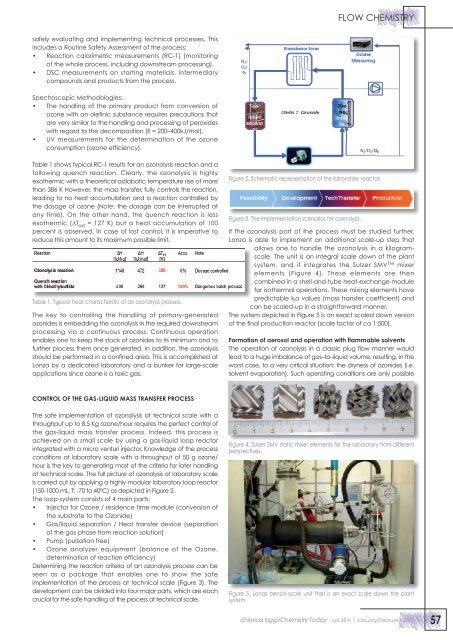

safely evaluating and implementing technical processes. This includes a Routine Safety Assessment of the process: • Reaction calorimetric measurements (RC-1) (monitoring of the whole process, including downstream processing). • DSC measurements on starting materials, intermediary compounds and products from the process. Spectroscopic Methodologies: • The handling of the primary product from conversion of ozone with an olefinic substance requires precautions that are very similar to the handling and processing of peroxides with regard to the decomposition (E = 200–400kJ/mol). • UV measurements for the determination of the ozone consumption (ozone efficiency). Table 1 shows typical RC-1 results for an ozonolysis reaction and a following quench reaction. Clearly, the ozonolysis is highly exothermic with a theoretical adiabatic temperature rise of more than 386 K However, the mass transfer, fully controls the reaction, leading to no heat accumulation and a reaction controlled by the dosage of ozone (Note: the dosage can be interrupted at any time). On the other hand, the quench reaction is less exothermic (ΔT ad = 127 K) but a heat accumulation of 100 percent is observed. In case of lost control, it is imperative to reduce this amount to its maximum possible limit. Table 1. Typical heat characteristic of an ozonolysis process. The key to controlling the handling of primary-generated ozonides is embedding the ozonolysis in the required downstream processing via a continuous process. Continuous operation enables one to keep the stock of ozonides to its minimum and to further process them once generated. In addition, the ozonolysis should be performed in a confined area. This is accomplished at Lonza by a dedicated laboratory and a bunker for large-scale applications since ozone is a toxic gas. CONTROL OF THE GAS-LIQUID MASS TRANSFER PROCESS The safe implementation of ozonolysis at technical scale with a throughput up to 8.5 Kg ozone/hour requires the perfect control of the gas-liquid mass transfer process. Indeed, this process is achieved on a small scale by using a gas-liquid loop reactor integrated with a micro venturi injector. Knowledge of the process conditions at laboratory scale with a throughput of 50 g ozone/ hour is the key to generating most of the criteria for later handling at technical scale. The full picture of ozonolysis at laboratory scale is carried out by applying a highly modular laboratory loop reactor (150-1000 mL, T: -70 to 40°C) as depicted in Figure 2. The loop-system consists of 4 main parts: • Injector for Ozone / residence time module (conversion of the substrate to the Ozonide) • Gas/liquid separation / Heat transfer device (separation of the gas phase from reaction solution) • Pump (pulsation free) • Ozone analyzer equipment (balance of the Ozone, determination of reaction efficiency) Determining the reaction criteria of an ozonolysis process can be seen as a package that enables one to show the safe implementation of the process at technical scale (Figure 3). The development can be divided into four major parts, which are each crucial for the safe handling of the process at technical scale. FLOW CHEMISTRY Figure 2. Schematic representation of the laboratory reactor. Figure 3. The implementation scenarios for ozonolysis. If the ozonolysis part of the process must be studied further, Lonza is able to implement an additional scale-up step that allows one to handle the ozonolysis in a kilogramscale. The unit is an integral scale down of the plant system, and it integrates the Sulzer SMV TM mixer elements (Figure 4). These elements are then combined in a shell-and-tube heat-exchange module for isothermal operations. These mixing elements have predictable k l a values (mass transfer coefficient) and can be scaled-up in a straightforward manner. The system depicted in Figure 5 is an exact scaled down version of the final production reactor (scale factor of ca 1:500). Formation of aerosol and operation with flammable solvents The operation of ozonolysis in a classic plug flow manner would lead to a huge imbalance of gas–to–liquid volume, resulting, in the worst case, to a very critical situation: the dryness of ozonides (i.e. solvent evaporation). Such operating conditions are only possible Figure 4. Sulzer SMV static mixer elements for the laboratory from different perspectives. Figure 5. Lonza bench-scale unit that is an exact scale down the plant system. chimica oggi/Chemistry Today - vol 29 n 1 January/February 2011 57

58 C M Y CM MY CY CMY K FLOW CHEMISTRY with highly diluted reactant feeds that are not economical viable. To increase the liquid volume ratio a re-circulation loop is required. A proper engineered loop reactor enables excellent interphase mass transfer via proper mixing elements under controlled pressure drop (vide supra). By feeding substrate in and pulling product out, the loop reactor can be operated continuously with the principle of a mixed flow reactor. Surprisingly, under depleted substrate and elevated product conditions the ozonolysis often remains very selective and overoxidation is not observed; full continuous operations can be achieved. If this is not the case, the reactor can also be operated semi-batch-wise with an appropriate dosage of ozone to control the reaction. The reaction temperature has to be kept below the flash point of the solvent. This is a pre-requisite that must be enforced via technical measures. The gas-liquid reaction zone must be very efficient to ensure the nearly complete consumption of ozone because that could influence the flash point of solvents. Lonza has performed extensive studies with an external safety institute to understand ozone flash-point variations. This understanding, coupled with experience and technical knowhow, is critical to the successful and safe operation of ozonolysis reactions, which has only been mastered by a few companies. CONCLUSION The above-mentioned aspects are essential for the safe development and scale up of ozonolysis processes. Lonza has repeatedly proven its ability to meet all these requirements for successful implementation at technical scale. Moreover, Lonza provides flexibility and time-savings by starting with pre-developed processes (also at large scale) based on our experience in scaling up processes from grams to tons. Lonza has undertaken each step outlined above for the development of production processes that have ozonolysis as a core step. For example, below is an ozonolysis reaction developed for a chrysanthemum acid ester and its corresponding aldehyde: A continuous process was developed for the production of an insecticide key intermediate. It uses a 450 L loop reactor ChimicaOggiAd_5.pdf for the conversion 12/16/2010 10:14:21 of AMthe chrysanthemic acid with chimica oggi/Chemistry Today - vol 29 n 1 January/February 2011 Figure 6. Ton-scale example of ozonolysis for the conversion of chrysanthemic acid. ACKNOWLEDGEMENT ozone. During development, scale up and implementation, the process was optimized to produce 0.5 t of product per day in continuous mode. Using on the newly developed process, Lonza has been able to manufacture commercial quantities of the intermediate. The industrial application of ozonolysis at Lonza was made possible thanks to a team of talented persons: Tiziano Zaupa, Anton Zenklusen, Detlef Roederer, and Eberhard Irle. REFERENCES AND NOTES 1. Hollemann, Wiberg, 101.Aufl., Lehrbuch der anorganischen Chemie, de Gruyter, Berlin, New York, 514ff (1995). 2. CRC handbook of Chemistry and Physics, pp. 8-23, 87Ed. CRC press, Boca Raton (2006). 3. Abwasserreinigung durch Ozon. Verfahrensberichte zur physikalischchemischen Behandlung von Abwässern. 8. Bericht. Frankfurt: Verband der Chemischen Industrie (1978). 4. Ozon in der Wasseraufbereitung; Begriffe Reaktionen, Anwendungsmöglichkeiten. Technische Mitteilung. Merkblatt W 225. DVGW Regelwerk. 5. R.T. Morrison, R.N. Boyd, Lehrbuch der organischen Chemie. 3. Aufl. Weinheim u.a.: Verl. Chemie, S. 436 ff (1986). 6. Organikum, Verlag VEB, 16. Aufl., 346f (1986). 7. D.M. Roberge, M. Gottsponer et al., Chem. Today, 27, pp. 8-11 (2009). 8. L. Bailey, Ozonation in Organic Chemisty, Academic Press, New York (1978). 9. B. Souza, J.Org. Chem., 25, p. 108 (1960). 10. M. Diaper, Can. J. Chem., 38, p. 1976 (1960). 11. L. Bailey, J. Am. Chem. Soc., 89, p. 4473 (1967). 12. S.L. Regen, C. Koteel, J. Am. Chem. Soc., 99, pp. 3837-3838 (1977). 13. E.v. Rudloff, Can. J. Chem., 43, pp. 1784-1791 (1965). 14. Fieser & Fieser, Reagents for Organic Syntheses, 1, John Wiley & Sons, pp. 809-819 (1967). 15. W. Petersen, J. Jaenichen et al., Verfahren zur Herstellung von 4--Methoxybenzoesäure aus pflanzlichem Anethol und dessen Verwendung in kosmetischen oder dermatologischen Produkten sowie Lebensmitteln, EP 2 060 556 A1 (2007). Center for Process Analytical Chemistry Rome Workshop March 21-24, 2011 www.cpac.washington.edu The Center for Process Analytical Chemistry (CPAC) Rome Workshop is an annual forum to present and discuss advances in continuous unit operations and measurement sciences linked to improved process control incorporating Quality by Design (QbD) approaches. The workshop will be held in Rome, Italy to bring together a group of international scientists and engineers of similar expertise for presentations and discussions in the areas of Micro-Instrumentation, Process Intensi�cation and new technical advances in Chemical and Biological Processes, including emerging applications for NeSSI (New Sampling/Sensor Initiative).

safely evaluat<strong>in</strong>g and implement<strong>in</strong>g technical processes. This<br />

<strong>in</strong>cludes a Rout<strong>in</strong>e Safety Assessment of the process:<br />

• Reaction calorimetric measurements (RC-1) (moni<strong>to</strong>r<strong>in</strong>g<br />

of the whole process, <strong>in</strong>clud<strong>in</strong>g downstream process<strong>in</strong>g).<br />

• DSC measurements on start<strong>in</strong>g materials, <strong>in</strong>termediary<br />

compounds and products <strong>from</strong> the process.<br />

Spectroscopic Methodologies:<br />

• The handl<strong>in</strong>g of the primary product <strong>from</strong> conversion of<br />

ozone with an olef<strong>in</strong>ic substance requires precautions that<br />

are very similar <strong>to</strong> the handl<strong>in</strong>g and process<strong>in</strong>g of peroxides<br />

with regard <strong>to</strong> the decomposition (E = 200–400kJ/mol).<br />

• UV measurements for the determ<strong>in</strong>ation of the ozone<br />

consumption (ozone efficiency).<br />

Table 1 shows typical RC-1 results for an <strong>ozonolysis</strong> reaction and a<br />

follow<strong>in</strong>g quench reaction. Clearly, the <strong>ozonolysis</strong> is highly<br />

exothermic with a theoretical adiabatic temperature rise of more<br />

than 386 K However, the mass transfer, fully controls the reaction,<br />

lead<strong>in</strong>g <strong>to</strong> no heat accumulation and a reaction controlled by<br />

the dosage of ozone (Note: the dosage can be <strong>in</strong>terrupted at<br />

any time). On the other hand, the quench reaction is less<br />

exothermic (ΔT ad = 127 K) but a heat accumulation of 100<br />

percent is observed. In case of lost control, it is imperative <strong>to</strong><br />

reduce this amount <strong>to</strong> its maximum possible limit.<br />

Table 1. Typical heat characteristic of an <strong>ozonolysis</strong> process.<br />

The key <strong>to</strong> controll<strong>in</strong>g the handl<strong>in</strong>g of primary-generated<br />

ozonides is embedd<strong>in</strong>g the <strong>ozonolysis</strong> <strong>in</strong> the required downstream<br />

process<strong>in</strong>g via a cont<strong>in</strong>uous process. Cont<strong>in</strong>uous operation<br />

enables one <strong>to</strong> keep the s<strong>to</strong>ck of ozonides <strong>to</strong> its m<strong>in</strong>imum and <strong>to</strong><br />

further process them once generated. In addition, the <strong>ozonolysis</strong><br />

should be performed <strong>in</strong> a conf<strong>in</strong>ed area. This is accomplished at<br />

Lonza by a dedicated <strong>labora<strong>to</strong>ry</strong> and a bunker for large-<strong>scale</strong><br />

applications s<strong>in</strong>ce ozone is a <strong>to</strong>xic gas.<br />

CONTROL OF THE GAS-LIQUID MASS TRANSFER PROCESS<br />

The safe implementation of <strong>ozonolysis</strong> at technical <strong>scale</strong> with a<br />

throughput up <strong>to</strong> 8.5 Kg ozone/hour requires the perfect control of<br />

the gas-liquid mass transfer process. Indeed, this process is<br />

achieved on a small <strong>scale</strong> by us<strong>in</strong>g a gas-liquid loop reac<strong>to</strong>r<br />

<strong>in</strong>tegrated with a micro venturi <strong>in</strong>jec<strong>to</strong>r. Knowledge of the process<br />

conditions at <strong>labora<strong>to</strong>ry</strong> <strong>scale</strong> with a throughput of 50 g ozone/<br />

hour is the key <strong>to</strong> generat<strong>in</strong>g most of the criteria for later handl<strong>in</strong>g<br />

at technical <strong>scale</strong>. The full picture of <strong>ozonolysis</strong> at <strong>labora<strong>to</strong>ry</strong> <strong>scale</strong><br />

is carried out by apply<strong>in</strong>g a highly modular <strong>labora<strong>to</strong>ry</strong> loop reac<strong>to</strong>r<br />

(150-1000 mL, T: -70 <strong>to</strong> 40°C) as depicted <strong>in</strong> Figure 2.<br />

The loop-system consists of 4 ma<strong>in</strong> parts:<br />

• Injec<strong>to</strong>r for Ozone / residence time module (conversion of<br />

the substrate <strong>to</strong> the Ozonide)<br />

• Gas/liquid separation / Heat transfer device (separation<br />

of the gas phase <strong>from</strong> reaction solution)<br />

• Pump (pulsation free)<br />

• Ozone analyzer equipment (balance of the Ozone,<br />

determ<strong>in</strong>ation of reaction efficiency)<br />

Determ<strong>in</strong><strong>in</strong>g the reaction criteria of an <strong>ozonolysis</strong> process can be<br />

seen as a package that enables one <strong>to</strong> show the safe<br />

implementation of the process at technical <strong>scale</strong> (Figure 3). The<br />

development can be divided <strong>in</strong><strong>to</strong> four major parts, which are each<br />

crucial for the safe handl<strong>in</strong>g of the process at technical <strong>scale</strong>.<br />

FLOW CHEMISTRY<br />

Figure 2. Schematic representation of the <strong>labora<strong>to</strong>ry</strong> reac<strong>to</strong>r.<br />

Figure 3. The implementation scenarios for <strong>ozonolysis</strong>.<br />

If the <strong>ozonolysis</strong> part of the process must be studied further,<br />

Lonza is able <strong>to</strong> implement an additional <strong>scale</strong>-up step that<br />

allows one <strong>to</strong> handle the <strong>ozonolysis</strong> <strong>in</strong> a kilogram<strong>scale</strong>.<br />

The unit is an <strong>in</strong>tegral <strong>scale</strong> down of the plant<br />

system, and it <strong>in</strong>tegrates the Sulzer SMV TM mixer<br />

elements (Figure 4). These elements are then<br />

comb<strong>in</strong>ed <strong>in</strong> a shell-and-tube heat-exchange module<br />

for isothermal operations. These mix<strong>in</strong>g elements have<br />

predictable k l a values (mass transfer coefficient) and<br />

can be <strong>scale</strong>d-up <strong>in</strong> a straightforward manner.<br />

The system depicted <strong>in</strong> Figure 5 is an exact <strong>scale</strong>d down version<br />

of the f<strong>in</strong>al <strong>production</strong> reac<strong>to</strong>r (<strong>scale</strong> fac<strong>to</strong>r of ca 1:500).<br />

Formation of aerosol and operation with flammable solvents<br />

The operation of <strong>ozonolysis</strong> <strong>in</strong> a classic plug flow manner would<br />

lead <strong>to</strong> a huge imbalance of gas–<strong>to</strong>–liquid volume, result<strong>in</strong>g, <strong>in</strong> the<br />

worst case, <strong>to</strong> a very critical situation: the dryness of ozonides (i.e.<br />

solvent evaporation). Such operat<strong>in</strong>g conditions are only possible<br />

Figure 4. Sulzer SMV static mixer elements for the <strong>labora<strong>to</strong>ry</strong> <strong>from</strong> different<br />

perspectives.<br />

Figure 5. Lonza bench-<strong>scale</strong> unit that is an exact <strong>scale</strong> down the plant<br />

system.<br />

chimica oggi/Chemistry Today - vol 29 n 1 January/February 2011<br />

57