The Softwood Forest Products Buyer - March/April 2024

Get the latest softwood industry news in the Softwood Forest Products Buyer! This issue features stories on the FenceTech 2024 convention, the NAHB International Builders' Show and the NKBA Kitchen & Bath Show, Prime Lumber Products, lumber shipping trends and much more.

Get the latest softwood industry news in the Softwood Forest Products Buyer! This issue features stories on the FenceTech 2024 convention, the NAHB International Builders' Show and the NKBA Kitchen & Bath Show, Prime Lumber Products, lumber shipping trends and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MILLER LUMBER —Continued from page 53<br />

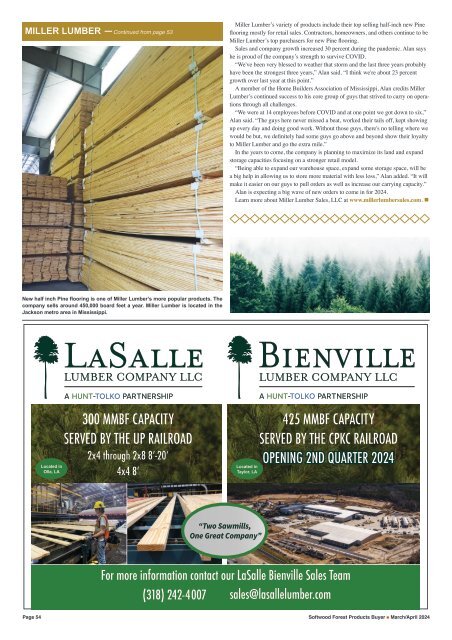

New half inch Pine flooring is one of Miller Lumber’s more popular products. <strong>The</strong><br />

company sells around 450,000 board feet a year. Miller Lumber is located in the<br />

Jackson metro area in Mississippi.<br />

Miller Lumber’s variety of products include their top selling half-inch new Pine<br />

flooring mostly for retail sales. Contractors, homeowners, and others continue to be<br />

Miller Lumber’s top purchasers for new Pine flooring.<br />

Sales and company growth increased 30 percent during the pandemic. Alan says<br />

he is proud of the company’s strength to survive COVID.<br />

“We've been very blessed to weather that storm and the last three years probably<br />

have been the strongest three years,” Alan said. “I think we're about 23 percent<br />

growth over last year at this point.”<br />

A member of the Home Builders Association of Mississippi, Alan credits Miller<br />

Lumber’s continued success to his core group of guys that strived to carry on operations<br />

through all challenges.<br />

“We were at 14 employees before COVID and at one point we got down to six,”<br />

Alan said. “<strong>The</strong> guys here never missed a beat, worked their tails off, kept showing<br />

up every day and doing good work. Without those guys, there's no telling where we<br />

would be but, we definitely had some guys go above and beyond show their loyalty<br />

to Miller Lumber and go the extra mile.”<br />

In the years to come, the company is planning to maximize its land and expand<br />

storage capacities focusing on a stronger retail model.<br />

“Being able to expand our warehouse space, expand some storage space, will be<br />

a big help in allowing us to store more material with less loss,” Alan added. “It will<br />

make it easier on our guys to pull orders as well as increase our carrying capacity.”<br />

Alan is expecting a big wave of new orders to come in for <strong>2024</strong>.<br />

Learn more about Miller Lumber Sales, LLC at www.millerlumbersales.com. •<br />

NORTHEAST TRENDS - Continued from page 22<br />

door all at once and the market is going to move. It’s called ‘eat what you kill.’<br />

What do you do when the market is flat? It is very hard to trade. <strong>The</strong>y start shorting<br />

the market. That creates the rush through the door.”<br />

<strong>The</strong> distributor primarily handles pressure European and Spruce-Pine-Fir,<br />

treated wood and said now that interest rates have stopped going up the market is<br />

due for a boost.<br />

“Interest rates are trickling down now,” he said. “That plays into the overall<br />

market conditions. People who didn’t qualify for first time home buyers may be<br />

qualified now on the second go-around.”<br />

Regarding claims that inventory is heavy, the source said that he was skeptical.<br />

“It is like a gas tank,” he noted, “You don’t need a full tank to drive around<br />

on right now. In terms of inventory, you don’t want to have a quarter of a tank.<br />

So, we really have half a tank and if you need to fuel up a little bit then put some<br />

more fuel in.<br />

“I don’t see anyone moving around on full tanks in inventory and having a lot,”<br />

he added. “<strong>The</strong>y used to do ‘just in time’ buying. Everyone was fishing behind the<br />

net. ‘We need this now.’ <strong>The</strong>se days, you never know what you can get.”<br />

A New Hampshire source agreed that January’s weather conditions “slowed<br />

things down” throughout the country.<br />

“Business is still fairly steady,” he added, “although not spectacular.”<br />

He noted that the “prognosis for spring is pretty good.”<br />

“<strong>The</strong>re is hope on the horizon,” he said. “If the winter weather hadn’t been as<br />

bad, I think there would have been some more orders for the mills.”<br />

<strong>The</strong> distributor, who works primarily with Western and Eastern Spruce, European<br />

imports, Southern Yellow Pine and Douglas Fir, said he runs the full “gamut<br />

of commodity framing lumber and structural panels.”<br />

He further noted that the decline of Western Spruce Pine Fir (WSPF), which is<br />

logged in Canada, has put Southern Yellow Pine (SYP) “under pressure.”<br />

He offers SYP “stress grade dimensional lumber, boards and timbers.”<br />

“We’ve already heard some shutdown announcements from some majors,” he<br />

said regarding the decade long decrease in WSPF. “That has led to an increase in<br />

Southern Yellow Pine production. It is the cheapest fiber on the planet from a raw<br />

material standpoint.”<br />

<strong>The</strong> WSPF decline can be traced to an infestation of bark beetles, wildfires and<br />

policy factors.<br />

On the other hand, the demand for SYP, which is grown from TX to NC, has<br />

taken off since 2009.<br />

A Connecticut lumber distributor and manufacturer said that weather has not<br />

influenced business yet this year.<br />

“We are at the end of the business where weather isn’t really going to affect us<br />

unless we get a deep snow,” he said. “Most of the materials that come to us are<br />

rough sawn and S4S,” he said. “So, we are always processing.”<br />

He said that oftentimes wet ground conditions pose a bigger threat than the<br />

snow itself.<br />

“Machinery tends to sink,” he said. “No one goes in the forest in the spring unless<br />

the ground is frozen solid.”<br />

<strong>The</strong> source said that he services the retail sector in Connecticut, Rhode Island,<br />

New York and New Jersey.<br />

Noting that 2023 was an “off year,” he noticed that January of <strong>2024</strong> was “very<br />

busy.”<br />

“I think 2023 was the year after COVID,” he said. “<strong>The</strong>re was a little bit of<br />

recovery there. A lot of people had overpriced product that they had bought during<br />

COVID. Everyone has whittled through the majority of that now.” •<br />

INLAND WEST TRENDS - Continued from page 22<br />

that will spring some buyers back into the market,” he said.<br />

According to the source, October through December of 2023 was “tough.”<br />

“That was an anomaly though for the activity level and sales overall,” he said.<br />

“It was good to see a slight rebound in January.”<br />

An Idaho lumberman said that business has been “fair” so far this year.<br />

He noted that the fourth quarter of 2023 was “the hardest and toughest we’ve<br />

ever been through.”<br />

“<strong>The</strong> weather and the fact that we do a lot with the agricultural business made it<br />

hard for pricing,” he said.<br />

Specializing in industrial application, low grade materials, he expects a “gradual<br />

increase” this year.<br />

Continued on page 56<br />

Free &<br />

Clear<br />

Located in<br />

Olla, LA<br />

300 MMBF CAPACITY<br />

SERVED BY THE UP RAILROAD<br />

2x4 through 2x8 8’-20’<br />

4x4 8’<br />

Located in<br />

Taylor, LA<br />

425 MMBF CAPACITY<br />

SERVED BY THE CPKC RAILROAD<br />

OPENING 2ND QUARTER <strong>2024</strong><br />

Timber <strong>Products</strong>’ KodiakPly Shasta<br />

Series siding is the same KodiakPly panel<br />

you know and trust, but with a patchfree,<br />

Okoume face. <strong>The</strong> answer to your<br />

exterior needs, KodiakPly Shasta Series<br />

is made with a Douglas fir core and holds<br />

a timeless look with durable properties to<br />

meet the demands of the environment.<br />

Contact us today to learn more!<br />

For more information contact our LaSalle Bienville Sales Team<br />

(318) 242-4007 sales@lasallelumber.com<br />

1-800-547-9520 | timberproducts.com<br />

KodiakPly Shasta Series Siding Panels<br />

Sizes: 4' x 8', 4' x 9', 4' x 10'<br />

Thickness: 11/32", 15/32", 19/32"<br />

Groove patterns: Plain, 4", 8", RBB 12"<br />

Patch-free face<br />

Cedar-like appearance<br />

Page 54 <strong>Softwood</strong> <strong>Forest</strong> <strong>Products</strong> <strong>Buyer</strong> • <strong>March</strong>/<strong>April</strong> <strong>2024</strong> <strong>Softwood</strong> <strong>Forest</strong> <strong>Products</strong> <strong>Buyer</strong> • <strong>March</strong>/<strong>April</strong> <strong>2024</strong> Page 55