ELCO Case Study Booklet Condensing Gas Boilers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

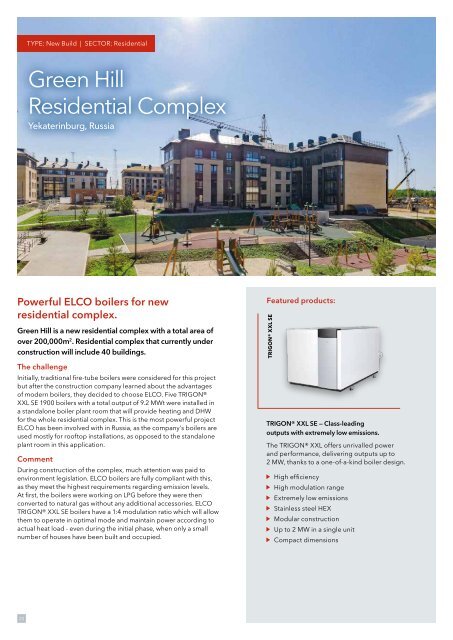

TYPE: New Build | SECTOR: Residential<br />

Green Hill<br />

Residential Complex<br />

Yekaterinburg, Russia<br />

RESIDENTIAL<br />

OFFICES<br />

Boiler house<br />

Powerful <strong>ELCO</strong> boilers for new<br />

residential complex.<br />

Green Hill is a new residential complex with a total area of<br />

over 200,000m 2 . Residential complex that currently under<br />

construction will include 40 buildings.<br />

Featured products:<br />

TRIGON® XXL SE<br />

System schematic<br />

HOTELS / MALLS<br />

The challenge<br />

Initially, traditional fire-tube boilers were considered for this project<br />

but after the construction company learned about the advantages<br />

of modern boilers, they decided to choose <strong>ELCO</strong>. Five TRIGON®<br />

XXL SE 1900 boilers with a total output of 9.2 MWt were installed in<br />

a standalone boiler plant room that will provide heating and DHW<br />

for the whole residential complex. This is the most powerful project<br />

<strong>ELCO</strong> has been involved with in Russia, as the company's boilers are<br />

used mostly for rooftop installations, as opposed to the standalone<br />

plant room in this application.<br />

Comment<br />

During construction of the complex, much attention was paid to<br />

environment legislation. <strong>ELCO</strong> boilers are fully compliant with this,<br />

as they meet the highest requirements regarding emission levels.<br />

At first, the boilers were working on LPG before they were then<br />

converted to natural gas without any additional accessories. <strong>ELCO</strong><br />

TRIGON® XXL SE boilers have a 1:4 modulation ratio which will allow<br />

them to operate in optimal mode and maintain power according to<br />

actual heat load - even during the initial phase, when only a small<br />

number of houses have been built and occupied.<br />

TRIGON® XXL SE — Class-leading<br />

outputs with extremely low emissions.<br />

The TRIGON® XXL offers unrivalled power<br />

and performance, delivering outputs up to<br />

2 MW, thanks to a one-of-a-kind boiler design.<br />

High efficiency<br />

High modulation range<br />

Extremely low emissions<br />

Stainless steel HEX<br />

Modular construction<br />

Up to 2 MW in a single unit<br />

Compact dimensions<br />

The plant scheme<br />

5 x TRIGON® XXL SE 1900<br />

(installed in cascade)<br />

Plate heat exhcangers are used<br />

for primary/secondary separation<br />

The <strong>ELCO</strong> solution<br />

Powerful boiler plant room with cascade of five<br />

TRIGON® XXL SE 1900 boilers. As the boilers will be<br />

part of a large system, it was decided to use plate<br />

heat exchangers to protect them. Thanks to the<br />

<strong>ELCO</strong> boilers' low emission levels, it was possible to<br />

use short flue chimneys.<br />

Benefits<br />

TRIGON® XXL SE 1900<br />

EDUCATION / SPORTS<br />

123<br />

litres<br />

For single boiler<br />

heat exchanger<br />

23<br />

mg/kWh<br />

NOx level<br />

(annual emission<br />

EN15502)<br />

103.3%<br />

Annual efficiency<br />

(NNG 40/30ºC)<br />

INDUSTRY<br />

20<br />

21