Much.More.Sustainability - Sustainability Report 2023

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

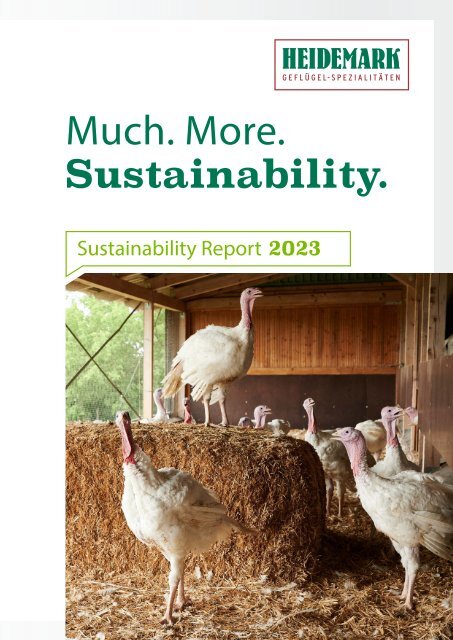

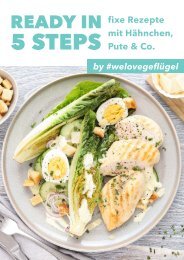

<strong>Much</strong>. <strong>More</strong>.<br />

<strong>Sustainability</strong>.<br />

<strong>Sustainability</strong> <strong>Report</strong> <strong>2023</strong>

01.<br />

1.1 Company 08<br />

1.2 Facts & figures 10<br />

1.3 Mission statement 12<br />

1.4 Stakeholder dialogue 14<br />

1.5 Materiality matrix 16<br />

Company<br />

02.<br />

Economy<br />

2.1 Value chain 20<br />

2.2 Quality 22<br />

2.3 Innovation & research 24<br />

A different, more expressive image –<br />

Jamie will upload some more for me<br />

here<br />

03.<br />

Animal welfare<br />

3.1 Husbandry systems 28<br />

3.2 Indicators 30<br />

3.3 Loading 31<br />

04.<br />

Ecology<br />

4.1 Climate & energy 34<br />

4.2 Water 36<br />

4.3 Packaging 38<br />

4.4 Waste 39<br />

4.5 Biodiversity 40<br />

05.<br />

Social responsibility<br />

5.1 Employees 44<br />

5.2 Personnel development 46<br />

5.3 Occupational health<br />

& safety 47<br />

5.4 Regional commitments 48

HEIDEMARK<br />

INTRODUCTION<br />

4 SUSTAINABILITY REPORT <strong>2023</strong><br />

FOREWORD 5<br />

Dear readers,<br />

As a third-generation family business, we can look<br />

back on over 50 years of commercial operations.<br />

The four dimensions of sustainability – economy,<br />

animal welfare, ecology and social responsibility –<br />

have a significant impact on our poultry farming,<br />

slaughtering, fabrication, processing and logistics<br />

business areas. To date, we have been able to<br />

ensure and create a sustainable future for turkey<br />

husbandry by always incorporating these four dimensions.<br />

We have a responsibility to use the resources available<br />

to us sparingly along our entire value chain.<br />

<strong>Sustainability</strong> affects us all, and in all areas of life.<br />

Our company’s strategy is to use renewable energy,<br />

digitalise entire areas of the business and thus<br />

become faster and less error-prone, while continuing<br />

to use sustainable packaging. These are just<br />

a few examples of a more conscious use of scarce<br />

resources.<br />

Being a family entrepreneur,<br />

a very approachable and direct<br />

corporate culture is important<br />

to me.<br />

Our doors are always open, so that all issues can<br />

be addressed directly. Close ties with our employees,<br />

a friendly and informal culture, and strong<br />

engagement with our customers, suppliers, and<br />

especially the farmers are extremely important to<br />

me. The transformation of the job market into an<br />

employee-centric market is also making it increasingly<br />

challenging for us to find new employees<br />

and retain them for long periods within the company.<br />

Therefore, we strive every day to become<br />

a little better in this area. These efforts make us<br />

more attractive as an employer and secure jobs in<br />

our region. We give people of all nationalities and<br />

ages good prospects and a secure job.<br />

In recent years, outbreaks of avian influenza (bird<br />

flu) have had a severe impact on our business activities.<br />

Unfortunately, this has almost become a<br />

major year-round issue. Once a seasonal occurrence<br />

in autumn and winter, it has now become<br />

endemic and shows little respite even during<br />

the summer months. We are therefore working<br />

hard to make vaccination programmes possible<br />

throughout the European Union. Last winter, the<br />

Federal Ministry of Agriculture presented a policy<br />

paper outlining the planned future of turkey<br />

husbandry in Germany. The requirements go far<br />

above the established husbandry practices. Turkey<br />

husbandry can only continue to exist in Germany<br />

if there is a general societal acceptance of<br />

the long-established husbandry methods that are<br />

subject to the QS control system and the animal<br />

welfare initiative "Initiative Tierwohl". In recent<br />

months, therefore, we have intensified our dialogue<br />

with diverse stakeholder groups and created<br />

transparency with regard to how our turkeys<br />

are kept.<br />

Despite the challenging market conditions,<br />

we maintain a very optimistic outlook: in 2022,<br />

we successfully established labelling scheme<br />

"Haltungsform 3" and ensured consistent availability<br />

of the required products on the market. We<br />

also launched a new processing facility for con-<br />

venience products and made investments in<br />

new machinery. We are currently engaged in<br />

projects involving the use of alternative energy<br />

sources – with the goal of chieving carbon<br />

neutrality at our production facility in Ahlhorn<br />

until 2045. This sense of optimism and our<br />

ongoing work on improvement processes are<br />

already paying off for our business. Our inclusion<br />

of the four sustainability dimensions –<br />

economy, animal welfare, ecology and social<br />

responsibility – is worthwhile in all respects.<br />

Not least because it enables us to look forward<br />

with a clear conscience and offer both secure<br />

jobs and high-quality products.<br />

The progress we have already made in recent<br />

years and our plans for the coming years are<br />

explained in detail on the following pages.<br />

Enjoy reading the report!<br />

To ensure sustainable<br />

corporate develoment,<br />

we focus on expertise,<br />

high quality and<br />

reliability.<br />

Christopher Kalvelage

01.<br />

Company

HEIDEMARK<br />

1.1<br />

8 SUSTAINABILITY REPORT <strong>2023</strong><br />

COMPANY<br />

9<br />

Company<br />

At HEIDEMARK, we employ around 1,800 people<br />

and pursue the goal of creating turkey products of<br />

the highest quality.<br />

In 1965, Reinhold Kalvelage founded a feed mill<br />

in Höltinghausen. HEIDEMARK has been a 100%<br />

owner-managed family business ever since, now<br />

under the leadership of Christopher Kalvelage,<br />

who took the reins in 2015 and represents the<br />

third generation of his family.<br />

At our headquarters in Ahlhorn, we operate<br />

the largest and most efficient turkey slaughterhouse<br />

in Europe. Its annual capacity is approximately<br />

200 m kg of turkey meat with an annual<br />

turnover of € 604 m (financial year: 2022). Our core<br />

business is the rearing and transport of turkeys as<br />

well as the processing and marketing of turkey<br />

products, which are sold to food retailers and<br />

industrial customers. We operate our own parent<br />

stock farms, hatcheries and fattening farms,<br />

where around 2.7 million turkeys are reared every<br />

year. Being fully aware of our responsibilities towards<br />

our industry, we want to play our part in the<br />

development of sustainable turkey husbandry.<br />

Refrigerated<br />

lorries<br />

Live animal<br />

transport lorries<br />

51 39<br />

€ 604 m Turnover in the<br />

financial year 2021/22<br />

German industry leader with a market share of<br />

approx. 50%<br />

The slaughter volume is approx. 250<br />

m kg per year. This corresponds to<br />

approx. 14.5 m toms and hens.<br />

Financial year 2021/22<br />

Chicks marketed in the 2022 financial year<br />

approx. 16 m

HEIDEMARK<br />

1.2<br />

10 SUSTAINABILITY REPORT <strong>2023</strong><br />

FACTS & FIGURES 11<br />

Facts & figures<br />

Over<br />

1,800<br />

people<br />

from<br />

38 countries<br />

work for us<br />

80%<br />

Trainee<br />

retention rate<br />

34%<br />

Women in management<br />

positions<br />

2%<br />

Reduction in fuel consumption<br />

compared to previous year<br />

Our turkey<br />

utilisation rate is<br />

97%<br />

Water<br />

recycling rate<br />

44%<br />

20<br />

newly installed<br />

charging points<br />

15 %<br />

Energy savings since 2012<br />

Since 2020,<br />

instead of<br />

Christmas<br />

presents, we<br />

have made<br />

donations to<br />

worthy causes

HEIDEMARK<br />

1.3<br />

12 SUSTAINABILITY REPORT <strong>2023</strong><br />

MISSION STATEMENT 13<br />

Mission statement<br />

<strong>Sustainability</strong> has been a major focus at<br />

HEIDEMARK for many years. In 2015, we established<br />

our first in-house workshops in order to<br />

elaborate and consolidate key topics and develop<br />

a mission statement.<br />

Our current initiatives are designed to meet both the way in which we structure these issues and<br />

the present and future needs of our society while our approach to sustainability management.<br />

also securing our long-term business operations. Since 2018, Dr. Hanna Strüve has been responsible<br />

for all sustainability activities as head of<br />

For us, sustainability means developing sustainable<br />

turkey husbandry by taking into account animal<br />

welfare as well as economic, ecological and aging Partner, Christopher Kalvelage. In addi-<br />

a dedicated department, reporting to the Man-<br />

social factors. We also aim to contribute to the implementation<br />

of the United Nations’ Sustainable ability team was established. The team regularly<br />

tion, an eight-member interdisciplinary sustain-<br />

Development Goals (SDGs)*.<br />

meets to discuss current projects and potential<br />

In 2017, we took the decision to further improve improvements, thereby ensuring progress on the<br />

respective issues.<br />

And this work has certainly paid off: since<br />

2019, HEIDEMARK has been certified under<br />

the ZNU Standard for Sustainable Business<br />

Practices (https://www.znu-standard.com/en/).<br />

Since then, our work has been reviewed each<br />

year via external audits, making our annual performance<br />

quantifiable. Our holistic approach to<br />

sustainability (based on four dimensions) in line<br />

with the ZNU standard, as well as the integration<br />

of additional sustainability guidelines, help us to<br />

work on incremental improvements in a structured<br />

manner. In this way, we aim to ensure that<br />

our company continually evolves in the spirit of<br />

sustainability.<br />

To this end, we make sure all employees get<br />

involved in these efforts by providing training<br />

for new staff and teaching our trainees to act as<br />

sustainability ambassadors. Only by working together<br />

systematically can we improve our structures,<br />

methods, and processes, and continue<br />

working towards our sustainability goals.<br />

We focus our support on the following SDGs*:<br />

2<br />

3<br />

4<br />

6<br />

7<br />

8<br />

12<br />

17<br />

Zero hunger<br />

Good health and well-being<br />

Quality education<br />

Clean water and sanitation<br />

Affordable and clean energy<br />

Decent work and economic growth<br />

Responsible consumption and production<br />

Partnerships for the goals<br />

*All 17 SDGs can be found at: https://sdgs.un.org/goals

14<br />

HEIDEMARK<br />

SUSTAINABILITY REPORT <strong>2023</strong><br />

1.4<br />

STAKEHOLDER DIALOGUE<br />

15<br />

Stakeholder dialogue<br />

Internal and external communication is a key element<br />

of our business – it is the only way we can increase the<br />

acceptance of our commercial activities and, at the<br />

same time, recognise emerging trends.<br />

We attach great importance to maintaining a view every step of the slaughter and fabrication<br />

constant dialogue with our stakeholders. Given<br />

that companies are required to interact with during ongoing operations. The separated aisle<br />

process from our transparent visitor walkway<br />

numerous and diverse internal and external allows production to continue unhindered and<br />

stakeholders, whereby each group has specific also enables us to safeguard our operational<br />

expectations and demands, our sustainability hygiene standards.<br />

team has identified the key stakeholder groups<br />

in relation to our company, along with their In collaboration with WING (Science and Innovation<br />

for Sustainable Poultry Production) in<br />

respective interests, risks, opportunities and<br />

potential solutions. We have incorporated the Vechta, a branch of TiHo Hannover (University<br />

results into our materiality matrix and derived of Veterinary Medicine Hannover Foundation),<br />

corresponding targets and measures.<br />

we focus on sharing knowledge, especially for<br />

the benefit of school pupils, by providing objective<br />

and scientifically-grounded insights into<br />

Over the last two years, we<br />

have worked hard to expand poultry farming. Barn visits allow us to directly<br />

our internal and external demonstrate how turkeys are kept. Furthermore,<br />

we consider regular discussions with an-<br />

communications.<br />

imal protection organisations to be important.<br />

To this end, we have not only expanded our Only through dialogue can we establish understanding<br />

and demonstrate what humane live-<br />

communications team, but also attend numerous<br />

job fairs and report internally on sustainability<br />

issues via newsletters. This year, we have To maintain an ongoing dialogue and further<br />

stock husbandry looks like.<br />

also improved communication with our production<br />

employees by introducing an employtively<br />

participate in 25 diverse working groups<br />

the development of turkey husbandry, we acee<br />

app, which is available in various languages. and are consistently prepared to engage in collaborative<br />

research in our test stables.<br />

To give visitors some insights into turkey husbandry<br />

and processing, they are welcome to<br />

Authorities<br />

Neighbours<br />

NGOs<br />

Trade<br />

Suppliers<br />

Employees<br />

Business<br />

owners<br />

Farmers<br />

Consumers<br />

We attach great<br />

importance to maintaining a constant<br />

dialogue with our stakeholders.

HEIDEMARK<br />

1.5<br />

16 SUSTAINABILITY REPORT <strong>2023</strong><br />

MATERIALITY MATRIX 17<br />

4<br />

Materiality<br />

matrix<br />

Reduce the economic risk for farmers<br />

Food safety<br />

High success rate & hygiene standards<br />

Employees’ sense of<br />

identity & belonging<br />

Waste<br />

Internal<br />

communication<br />

Packaging<br />

Innovation &<br />

product variety<br />

Proof of origin<br />

Professional leadership<br />

Purchase & sales price<br />

Product quality<br />

Climate<br />

Appreciating employees<br />

Fair payment<br />

Reconciliation of family & career<br />

Animal welfare & health<br />

Sustainable migration<br />

Shortage of skilled workers<br />

Respect for the animal<br />

Feed<br />

The purpose of our materiality matrix is to illustrate<br />

the impact of our business activities on sustainability<br />

issues (inside-out perspective) and, conversely,<br />

the significant impact of sustainability issues on<br />

our business activities (outside-in perspective).<br />

In this way, we aim to create transparency in our<br />

business activities vis-à-vis our internal and external<br />

stakeholders. We use retrospective information<br />

to identify issues affecting our operations, and<br />

predictive data to highlight future developments<br />

for which we have a growing need to prepare.<br />

By referring to the materiality matrix, we can identify<br />

genuinely important sustainability topics and<br />

queries, thereby engaging in relevant dialogue with<br />

our stakeholder groups. Only through an honest and<br />

fact-based discourse can we work together every day<br />

to gradually improve all aspects of turkey husbandry.<br />

3<br />

Appreciation for the farmers<br />

Addition of phosphorous / antibiotics<br />

Emissions: odour & noise<br />

Transport & slaughter<br />

Temporary<br />

delivery<br />

problems<br />

Price/performance<br />

ratio<br />

Water consumption & industrial<br />

water treatment<br />

Economic security<br />

The X axis shows the importance of our business<br />

activities for HEIDEMARK and the Y axis their importance<br />

for our stakeholders. Since each stakeholder<br />

group has specific needs, these were also taken into<br />

account. They are ranked in order of relevance. The<br />

top-right quadrant represents the issues that are most<br />

important to us. These sustainability issues are not only<br />

of special significance for us, but are also considered<br />

extremely important by our stakeholders. These key<br />

topics are underpinned by our sustainability goals. In<br />

concrete terms: we need to work on these issues<br />

every day.<br />

Relevance from a stakeholder perspective<br />

Discrepancy between animal welfare &<br />

BauGB (German federal building code)<br />

Respect for human rights<br />

Herbs & spices<br />

Traffic<br />

Company doctor<br />

Competitiveness<br />

Image/scandals/<br />

legal infringements<br />

Driver training / HGV safety technology<br />

The materiality matrix is updated annually by<br />

our sustainability team. It is also updated to<br />

reflect significant changes in the law.<br />

Relevance:<br />

1<br />

2<br />

3<br />

low<br />

Economic economy<br />

medium Animal welfare<br />

high<br />

Ecology<br />

1 2 3<br />

4<br />

4<br />

very high<br />

Social responsibility<br />

Operational relevance for HEIDEMARK

02.<br />

Economy<br />

Our<br />

sustainability goals<br />

• Changeover to mono-materials<br />

in our primary packaging<br />

by the end of <strong>2023</strong><br />

• 50% reduction in the number<br />

of printers in our administrative<br />

offices by the end of 2024

HEIDEMARK<br />

2.1<br />

20 SUSTAINABILITY REPORT <strong>2023</strong><br />

VALUE CHAIN 21<br />

Value chain<br />

9<br />

8<br />

Animal husbandry<br />

Alongside processing, turkey husbandry is our<br />

10<br />

7<br />

6<br />

core competence and forms the basis for our value<br />

5<br />

chain.<br />

4<br />

11<br />

Our main suppliers are farmers in Germany, Po-<br />

are removed from the barns and brought to<br />

land, France, Belgium, Denmark, the Netherlands<br />

Ahlhorn in a special live animal transport lorry.<br />

and the Czech Republic. We stay in close contact<br />

with all of them through our local field service.<br />

Animal husbandry is divided<br />

into parent stock farms,<br />

hatcheries, and rearing and<br />

fattening farms.<br />

In parent stock farms, the hens are inseminated<br />

by the toms so that they lay fertilised eggs. The<br />

eggs are then artificially incubated in the hatchery<br />

to ensure that the chicks hatch on the 28th<br />

day. From the hatchery, the animals are transferred<br />

to special rearing and fattening barns,<br />

where they are reared for 16 to 21 weeks. The<br />

farmers are obliged buy their feed from feed<br />

mills that meet our quality standards. The content<br />

of the mixed feed is adjusted according to<br />

the age of the animals. The main ingredients for<br />

all age groups are maize, wheat and soya, which<br />

are purchased on the world market. When the<br />

A large part of our workforce is based there. The<br />

turkeys are then slaughtered and processed<br />

into meat products. The finished products are<br />

delivered to customers on the same day using<br />

our refrigerated logistics fleet.<br />

Our turkey utilisation rate is 97%. The products<br />

that are not used for food production (such as<br />

feathers and blood) are converted into processed<br />

animal proteins or into pet food. Packaging<br />

waste and other waste materials are recycled<br />

as far as possible. Our entire value chain<br />

is certified under the QS standard. Neutral<br />

external inspections take place at all stages of<br />

production. These external inspections, as well<br />

as our own daily checks that form part of our<br />

quality management system, guarantee that<br />

we deliver safe products to our customers. We<br />

market our products primarily to national and<br />

international food retailers, and also to industrial<br />

customers, which process our products.<br />

20<br />

19<br />

17<br />

12<br />

18<br />

16<br />

Customers<br />

Production<br />

13<br />

15<br />

1<br />

14<br />

2<br />

3<br />

animals have reached their final weight, they<br />

Feed<br />

Animal husbandry<br />

Production<br />

1<br />

Maize<br />

5<br />

Parent stock<br />

11<br />

Anaesthesia<br />

16<br />

Water<br />

2<br />

Soya<br />

6<br />

Hatchery<br />

12<br />

Slaughter<br />

17<br />

Wastewater treatment plant<br />

3<br />

Wheat<br />

7<br />

Rearing<br />

13<br />

Processing + packaging<br />

18<br />

Packaging materials<br />

4<br />

Feed<br />

8<br />

Fattening<br />

14<br />

Loading<br />

19<br />

Other ingredients<br />

9<br />

Manure<br />

15<br />

Refrigerated transport<br />

20<br />

Slaughterhouse waste<br />

10<br />

Live animal transport

22<br />

HEIDEMARK<br />

SUSTAINABILITY REPORT <strong>2023</strong><br />

2.2<br />

QUALITY<br />

23<br />

Quality<br />

We safeguard our processes<br />

by means of internal checks,<br />

whose results are validated<br />

via neutral external<br />

inspections. Apart from<br />

meeting the legal standards,<br />

HEIDEMARK complies with<br />

the requirements specified<br />

by several external quality<br />

assurance systems and maintains<br />

the relevant national and<br />

international certifications.<br />

Standard for Sustainable<br />

Business Practices<br />

Since 2019, our Ahlhorn location has been certified under the ZNU<br />

Standard for Sustainable Business Practices, and undergoes annual<br />

inspections by an external certification body. The ZNU standard<br />

requires and promotes the development of an integrated<br />

management system for a more sustainable business.<br />

Through systematic and joint sustainability planning, we incrementally<br />

improve our internal structures, methods and processes.<br />

Because the ZNU standard advocates for more sustainable business<br />

practices, our sustainability team is continuously challenged<br />

to gradually enhance sustainability aspects within each of our<br />

specialist departments.<br />

www.znu-standard.com/en/<br />

www.heidemark-tierwohl.de<br />

HEIDEMARK PRO Tierwohl - our own animal welfare standard<br />

Since 2022, a number of farms have gone one step further by being certified to the HEIDEMARK PRO animal welfare standard.<br />

Accordingly, they now offer their animals an outdoor climate area, considerably more space and a wider range<br />

of enrichment materials. Naturally, these farms are also certified under the QS, ITW and VLOG standards.<br />

www.heidemark-tierwohl.de<br />

Verband Lebensmittel ohne Gentechnik e.V.<br />

The HEIDEMARK farms certified by the ITW also commit to feeding their turkeys with non-genetically modified feed.<br />

At these farms, an additional inspection of the feeding process is carried out in accordance with the standard published<br />

by the German Association Food without Genetic Engineering (Verband Lebensmittel Ohne Gentechnik (VLOG)).<br />

www.ohnegentechnik.org/en<br />

Our internal quality management<br />

system regulates all<br />

requirements for processes,<br />

marketable products and also<br />

the handling of non-conforming<br />

products. Thanks to our<br />

in-house laboratory analyses<br />

we can quickly provide relevant<br />

information and steer<br />

our production processes<br />

QS – the inspection system for<br />

foodstuffs<br />

The QS system guarantees strict quality assurance across all<br />

stages of food production. Each individual stage is inspected<br />

by external certification bodies – the parent stock farms, the<br />

hatchery, the rearing and fattening farms, the feed companies, the<br />

logistics facilities, the slaughterhouse and fabrication line, all the<br />

way to the food retail counter.<br />

www.q-s.de/en<br />

Halal<br />

The feeding and slaughtering of turkeys at HEIDEMARK complies with the regulations of the Halal standard and is<br />

considered permissible in accordance with Islamic principles.<br />

www.halal-certification.de<br />

DLG – German Agricultural Society (Deutsche Landwirtschaftsgesellschaft)<br />

In 2022, we were awarded the “Long-Term Product Quality Award” by the DLG for the 14th time. This award highlights<br />

our consistent pursuit of quality and is only presented to companies whose food products have been regularly and<br />

successfully tested by the DLG for at least five years.<br />

accordingly. Our complaint<br />

statistics are analysed by<br />

an interdisciplinary team to<br />

ensure consistent, collective<br />

improvements in this area.<br />

By adhering to strict internal<br />

and external rules, we guarantee<br />

consumer protection<br />

and maximise the safety of<br />

our processes and products.<br />

ITW – Initiative Tierwohl<br />

(animal welfare initiative)<br />

This cross-sector alliance of agriculture, the meat industry and<br />

food retailers has set itself the goal of promoting animal welfare<br />

in livestock husbandry. We have been a member since its<br />

inception in 2015. The participating farms are committed to reducing<br />

the stocking density in their barns by 10% and to providing<br />

additional enrichment materials for their animals. At the same<br />

time, the ITW-certified farms must undergo even more frequent<br />

inspections.<br />

www.initiative-tierwohl.de/en<br />

BRC Global Standard<br />

The “Global Standard for Food Safety” guarantees safety and quality requirements that food producers must meet.<br />

BRC is a recognised standard, particularly in English-speaking Europe and parts of Asia.<br />

www.brcgs.com<br />

International Featured Standards<br />

This seal of quality distinguishes processes that guarantee the highest levels of food safety, hygiene and a sound<br />

operational infrastructure. It also serves as a guarantee that our customers are buying products that conform to<br />

these standards.

HEIDEMARK<br />

2.3<br />

24 SUSTAINABILITY REPORT <strong>2023</strong><br />

INNOVATION & RESEARCH 25<br />

Innovation & research<br />

As a manufacturer and supplier to the trade and<br />

As industry, a manufacturer HEIDEMARK and supplier develops to the over trade, 400 HEIDE- new<br />

MARK products develops every over year, 400 which new are products presented each to year, our<br />

which customers are presented after a product to our development customers after phase. a product<br />

development phase.<br />

technology: using individual experimental<br />

compartments we can scientifically<br />

investigate how innovations<br />

could be implemented in practice.<br />

For example, we are currently investigating<br />

ways to optimise our feed recipes<br />

with the goal of reducing our use<br />

rate with the German Research Centre<br />

for Artificial Intelligence GmbH (DFKI)<br />

and various companies to develop a<br />

mobile visual quality detection system<br />

for food, with the goal of improving<br />

the screening process. Fruits, vegetables<br />

or cuts of meat with significant<br />

We create new variations and refine our cutting<br />

techniques, with the result that we can now process<br />

almost all of the turkey – except for 3%. This<br />

forms part of our concept of sustainability. At the<br />

same time, we don’t just take current food trends<br />

into account. We also draw fresh inspiration from<br />

store checks and professional tools such as the<br />

Mintel database, which gives us global access to<br />

trends, new products and ingredients. This is important<br />

for our business since it helps us to strike<br />

a chord with consumers and lets us identify which<br />

aspects we need to focus on moving forward. Ensuring<br />

careful handling of the allocated resources<br />

is always a prerequisite. Naturally, we also ask our<br />

suppliers to participate in this process; for example,<br />

by organising annual supplier days with our<br />

(mostly regional) partners.<br />

Research conducted<br />

in our own test<br />

stables<br />

In the area of animal husbandry, we conduct<br />

research in our two test stables and carry out<br />

application observations. Whether comparing<br />

feed rations, alternative protein sources, animal<br />

genetics, enrichment materials or new housing<br />

of – or completely replacing – soya as<br />

a protein source by switching to processed<br />

animal protein.<br />

In recent years, we have already<br />

gained numerous insights via a wide<br />

range of research projects and have<br />

also brought them to the market, ensuring<br />

that many of our findings are<br />

actually implemented in practice on<br />

turkey farms.<br />

Use of artificial<br />

intelligence<br />

(AI)<br />

signs of damage or spoilage must be<br />

identified and removed from the processing<br />

cycle. This involves a complex<br />

quality control process that poses an<br />

enormous challenge for the human<br />

eye. In order to optimise this process<br />

with the help of artificial intelligence,<br />

the Movi-Q project focused on developing<br />

a mobile system for automatic<br />

quality recognition.<br />

The goal is to develop a commercially<br />

viable prototype so that the new system<br />

can subsequently be used on an industrial<br />

scale.<br />

By using artificial intelligence it is possible<br />

to significantly increase the level<br />

Product development<br />

We are also embracing AI by support-<br />

of automation in the food industry, im-<br />

ing innovative projects in this field.<br />

HEIDEMARK is currently working on<br />

the Movi-Q project (Mobile visual<br />

quality recognition through artificial<br />

intelligence for the food indus-<br />

prove food processing through better<br />

quality control and achieve more sustainable<br />

production by reducing food<br />

waste. This can also have a positive economic<br />

impact. The project is being fund-<br />

try). The German Institute of Food<br />

ed by the Federal Ministry of Food and<br />

Technologies (DIL) intends to collabo-<br />

Agriculture.

03.<br />

Our<br />

sustainability goal<br />

Animal<br />

welfare<br />

• Increase the proportion of animals<br />

from labelling scheme "Haltungsform<br />

3" by 50% by the end of 2025

HEIDEMARK<br />

3.1<br />

28 SUSTAINABILITY REPORT <strong>2023</strong><br />

HUSBANDRY SYSTEMS 29<br />

m 2<br />

Max. 58 kg/m2 toms<br />

Max. 52 kg/m2 hens<br />

Husbandry systems<br />

The different husbandry systems in animal farming<br />

were established by the German retail sector to provide<br />

transparency for purchasing decisions. Accordingly,<br />

they make it easy to determine in which husbandry system<br />

the animal was kept.<br />

• Dry bedding suitable for pecking, scratching and dust bathing<br />

• Fundamentally robust and healthy breeding lines<br />

• QS-approved feed<br />

• Recording of diagnostic data at the slaughterhouse<br />

and qualified antibiotic monitoring<br />

• QS certification<br />

Housing system<br />

(in open barns)<br />

• Inspection of all farms by neutral external certification<br />

bodies in accordance with the QS inspection system<br />

The farms are classified according to<br />

the respective husbandry systems on<br />

that supply us are certified in accordance<br />

with husbandry system 1, which<br />

of husbandry and animal welfare programmes<br />

is very important to us, in 2022<br />

m 2<br />

At least 10% more space<br />

Max. 53 kg/m2 toms<br />

Max. 48 kg/m2 hens<br />

the basis of the QS and ITW guidelines.<br />

Depending on the husbandry<br />

level, the farms must present the<br />

corresponds to the QS standard. The<br />

majority of German farms are also<br />

certified in accordance with husband-<br />

we created a framework to ensure a continuous<br />

supply of goods from husbandry<br />

system 3 in close collaboration with our<br />

Housing system<br />

(in open barns)<br />

corresponding certificate, which is<br />

dependent on regular inspections by<br />

external auditors.<br />

We currently offer products originating<br />

from husbandry systems 1 to 3.<br />

As a minimum requirement, all farms<br />

ry system 2, which meets the criteria<br />

established by the ITW animal welfare<br />

initiative. These farms have reduced<br />

their stocking density by 10% and also<br />

use non-GMO animal feed.<br />

Since the ongoing development<br />

stakeholders. We are in the process of<br />

gradually expanding this segment with<br />

the goal of establishing it as part of our<br />

customers’ product ranges in the long<br />

term.<br />

Our farms that correspond to husbandry<br />

system 3 are certified under<br />

• Organic enrichment materials made of changeable and consumable<br />

materials, e.g. straw, pecking stones. At least one item for every 400 m2<br />

of barn area or part thereof<br />

• Fundamentally robust and healthy breeding lines<br />

• QS-approved non-GMO feed<br />

• Recording of diagnostic data at the slaughterhouse and qualified<br />

antibiotic monitoring<br />

• Inspection of all farms by neutral external certification bodies in<br />

accordance with the QS, ITW and VLOG inspection systems<br />

Facts and figures about<br />

outdoor climate areas<br />

The size of the outdoor climate<br />

area (OCA) constitutes a minimum<br />

of 20% and a maximum of<br />

25% of the usable barn area.<br />

The OCA has a minimum height of<br />

2 metres. Openings to the OCA<br />

are evenly distributed along the<br />

longitudinal side and must account<br />

for a minimum of 5% of the<br />

width of the outdoor climate area.<br />

the HEIDEMARK PRO Tierwohl welfare<br />

standard. In concrete terms, this means<br />

the farms are required to reduce their<br />

stocking density by 30% and provide<br />

more enrichment materials as well as an<br />

additional outdoor climate area for the<br />

animals. The other husbandry systems<br />

already include an outdoor climate stimulus<br />

in the form of open barns. However,<br />

this is enhanced by the addition of a second<br />

barn area and an additional opening<br />

in the barn.<br />

The specific requirements for the different<br />

husbandry systems are listed below.<br />

• Organic enrichment materials made of changeable and consumable<br />

materials, e.g. straw, pecking stones. For every 400 m2 of barn area or<br />

part thereof, at least one pecking stone and for every 200 m2 of barn<br />

area or part thereof, one filled hanging rack and one bale of straw<br />

• Fundamentally robust and healthy breeding lines<br />

• Slow-growing or fast-growing breeds in compliance<br />

with the minimum slaughtering age<br />

• QS-approved non-GMO feed<br />

m 2<br />

• Recording of diagnostic data at the slaughterhouse<br />

and qualified antibiotic monitoring<br />

At least 30% more space<br />

Max. 41 kg/m2 toms<br />

Max. 37 kg/m2 hens<br />

Housing system with<br />

permanent access to the<br />

outdoor climate area<br />

• Inspection of all farms by neutral external certification bodies in<br />

accordance with the QS, ITW, VLOG and HEIDEMARK PRO inspection<br />

systems

30<br />

HEIDEMARK<br />

SUSTAINABILITY REPORT <strong>2023</strong><br />

3.2<br />

3.3<br />

INDICATORS LOADING 31<br />

Indicators<br />

Loading<br />

Since 2010, we have been working with experts<br />

from research and agriculture to make animal welfare<br />

verifiable by means of indicators.<br />

Our goal is to load the animals for transport to the<br />

slaughterhouse as calmly and animal-friendly as<br />

possible.<br />

We have developed a bonus system on this basis.<br />

The more positive the animal welfare indi-<br />

health in turkeys can be influenced by the bedding<br />

quality. In addition to recording this data<br />

We use a loading technique that we helped to develop,<br />

whereby we try to ensure that the turkeys<br />

For these reasons, we use loading conveyors<br />

at HEIDEMARK.<br />

cators, the higher the bonus payment for the<br />

in the barns, other relevant animal welfare indi-<br />

are handled as little as possible. Were the loading<br />

Via conveyor belts, the turkeys are transported<br />

turkey farmer. These payments are independent<br />

of the current animal welfare programmes. In<br />

other words, we make sure the turkey farmer also<br />

has a financial incentive to promote the turkeys’<br />

well-being.<br />

By recording the animal welfare indicators we can<br />

cators are recorded at slaughter. The birds’ foot<br />

pad health and breast skin changes are evaluated<br />

with the aid of cameras. The results of this evaluation<br />

are reported back to the turkey farmers,<br />

enabling them to continuously improve their<br />

barn and bedding management in order to keep<br />

the animals in better condition. Through our field<br />

procedure to be carried out manually, the loading<br />

staff would need to touch each bird and place<br />

it into the boxes on the lorry. Given that these<br />

animals weigh between 15 and 21 kg each, this<br />

would place an enormous physical strain on the<br />

loading staff. This loading procedure would also<br />

subject the animals to additional stress.<br />

directly from the barn to the transport boxes on<br />

the lorries. As a result, they usually require little<br />

to no handling. This protected loading process<br />

improves animal welfare and reduces the workload<br />

for the loading personnel.<br />

generate data about the animals’ well-being and<br />

service staff and our team of veterinarians, we<br />

thus make a positive contribution to husbandry<br />

provide livestock owners with expert support to<br />

management on farms. For example, foot pad<br />

ensure optimal conditions for their animals.<br />

In order to fully guarantee animal<br />

welfare during loading and<br />

transport, both the loading personnel<br />

and the drivers are specially<br />

trained to ensure they have<br />

the necessary expertise to safely<br />

handle the animals. At their destination<br />

in Ahlhorn, the turkeys<br />

are inspected and evaluated by<br />

the district’s official veterinarians<br />

upon arrival.

04.<br />

Ecology<br />

Our<br />

sustainability goals<br />

• Conversion of all print jobs<br />

to FSC paper by the<br />

end of <strong>2023</strong><br />

• Plant 2 hectares of flowerbeds<br />

on our own turkey farms<br />

by the end of 2025<br />

• We plan to reduce our CO2e<br />

emissions by 40% by 2030<br />

and to achieve carbonneutral<br />

operations by 2045

HEIDEMARK<br />

4.1<br />

34 SUSTAINABILITY REPORT <strong>2023</strong><br />

CLIMATE & ENERGY 35<br />

Climate & energy<br />

Since 2012, we have maintained our certification under<br />

the DIN EN ISO 50001 energy management system for<br />

our Ahlhorn site by means of annual external audits. In<br />

2015, our own turkey farms were also included in our<br />

energy management system.<br />

In recent<br />

years, we<br />

have<br />

consistently<br />

met our goal<br />

of achieving<br />

1.3% energy<br />

savings<br />

per year.<br />

In recent years, we have consistently<br />

met our goal of achieving 1.3% energy<br />

savings per year. As a result, we have<br />

reduced our energy consumption<br />

by 15% since 2012. In 2022, for example,<br />

we reduced the temperature<br />

of our hot water system, including the<br />

water used for cleaning, resulting in<br />

savings of around 250 tonnes of CO2e<br />

with no reduction in quality.<br />

15%<br />

We also installed a new, state-of-theart,<br />

high-efficiency crate washing system<br />

in 2022. It has a 30% higher output,<br />

but uses one third less water than<br />

our old system. In order to achieve our<br />

climate targets, we began working<br />

on a transformation concept for our<br />

production site in <strong>2023</strong>. The site is currently<br />

being re-evaluated in terms of<br />

energy usage. Based on the results of<br />

energy savings over the<br />

last 10 years<br />

this analysis, we plan to develop a new heating<br />

and cooling concept to avoid the use of<br />

fossil fuels at our Ahlhorn site in the future. At<br />

the same time, we are currently analysing our<br />

electricity consumption. In the long term, we<br />

plan to use green electricity and green lorry/<br />

car fuel. The plan is to become as self-sufficient<br />

as possible by installing our own wind and solar<br />

farm.<br />

6,228 t CO2*<br />

6000<br />

4000<br />

2000<br />

2022<br />

Our goal:<br />

40%<br />

reduction in<br />

CO2e emissions<br />

2032<br />

2045<br />

*These are the Scope 1+2 emissions of HEIDEMARK Mästerkreis GmbH & Co. KG;<br />

the calculations were carried out using the market-based method.<br />

Our climate goal is<br />

carbon neutrality<br />

by 2045.

HEIDEMARK<br />

4.2<br />

36 SUSTAINABILITY REPORT <strong>2023</strong><br />

WATER<br />

37<br />

Water<br />

UV wastewater disinfection<br />

system<br />

Microbiological safety is a key aspect<br />

of wastewater disposal. We want to<br />

and must ensure this before we return<br />

the wastewater to the environment.<br />

So how do we prevent the release<br />

of multi-resistant bacteria into the<br />

immediate environment? We have<br />

installed a UV wastewater disinfection<br />

system. This is permanently monitored,<br />

just like our entire wastewater<br />

treatment plant. If a fault occurs<br />

unexpectedly, a push notification is<br />

immediately sent to the supervisor’s<br />

phone and the fault is rectified.<br />

The fact that we need to protect our environment and<br />

use the available resources with extreme care is undisputed.<br />

How do we do this at HEIDEMARK?<br />

We have installed an additional system<br />

next to our wastewater treat-<br />

the authorities. We are proud of our<br />

tion, we are regularly inspected by<br />

ment plant to recycle the pretreated water treatment plant.<br />

water that it produces – and thus We are also especially proud of our<br />

conserve one of the world’s most valuable<br />

resources. We have managed person responsible for our wastewa-<br />

energy management officer and the<br />

to increase our water recycling ter treatment plant, Rainer Lüken. He<br />

rate from 21% to 44% in recent was instrumental in developing the<br />

years. Our treated water has the plant from the outset and is always<br />

quality of ironing water. The quality coming up with new, profitable ideas<br />

of this water is confirmed via regular for further improvements in the area<br />

internal and external tests. In addi-<br />

of water usage.<br />

Water recycling<br />

rate<br />

21.58%<br />

24.98%<br />

44.12%<br />

44.80%<br />

44.20%<br />

2018 2019 2020 2021 2022<br />

We can control<br />

our wastewater<br />

treatment<br />

plant’s<br />

parameters<br />

remotely via<br />

smartphone.<br />

The water from the<br />

plant is sampled<br />

twelve times<br />

per year.<br />

Every day, additional samples are<br />

taken at various stages in the water<br />

recycling process. Specifically,<br />

these samples are collected upon<br />

the water’s arrival from the production<br />

facility, at the discharge point<br />

in the primary treatment plant, and<br />

before the water is discharged into<br />

the receiving water body.

38<br />

HEIDEMARK<br />

SUSTAINABILITY REPORT <strong>2023</strong><br />

4.3<br />

PACKAGING<br />

4.4<br />

WASTE<br />

39<br />

Packaging<br />

Waste<br />

Our top priority is to ensure that our products are<br />

always securely packaged and remain so until their<br />

expiration date.<br />

Consistent waste avoidance not only protects the environment,<br />

but also improves our economic performance at the<br />

same time.<br />

Nevertheless, we are constantly working on<br />

ways to further improve our packaging without<br />

jeopardising product safety. The focus here is<br />

on functionality, reducing the volume of packaging<br />

material and, of course, recyclability. To<br />

achieve this, we maintain a constant dialogue<br />

with our suppliers. To date, we have successfully<br />

worked on reducing the material thickness to<br />

the minimum required for machine handling.<br />

We also rely on mono-materials that greatly<br />

simplify the disposal process for the consumer.<br />

In other words, we want to make it as easy<br />

as possible to dispose of the packaging components<br />

after consuming the product. And<br />

wherever possible, we dispense with the use<br />

of packaging components altogether: some of<br />

our products no longer have an absorbent insert,<br />

which significantly reduces the amount of<br />

material used in the packaging.<br />

Of a total of 164 different materials in our<br />

primary and secondary packaging, at least<br />

90% are compatible with the recycling circuit<br />

in Germany.<br />

With this in mind, we are always trying to reduce<br />

the amount of material used in our product packaging,<br />

as well as the volume of waste we produce.<br />

As far as possible, we try to recycle unavoidable<br />

waste and thus contribute to a closed-loop economy.<br />

In 2022, 91% of our total waste volume<br />

was recycled. Almost 8% of this waste was converted<br />

into biogas in a biogas plant. On average,<br />

only 1% of our waste is incinerated as residual<br />

waste.<br />

In 2022, HEIDEMARK generated a total waste volume<br />

of around 86,000 tonnes – approximately<br />

13,000 tonnes less than in 2021. However, this figure<br />

must be evaluated in relation to the slaughter<br />

volume – naturally, if fewer turkeys are slaughtered,<br />

less waste is produced. Even when the reduced<br />

slaughter volume is considered, we were<br />

still able to reduce our total waste volume by 2%<br />

compared to the previous year. At HEIDEMARK<br />

we want to continue in this direction by eliminating<br />

waste wherever possible. We only produce<br />

hazardous waste (as defined in the European<br />

Commission’s waste regulation) in very small<br />

quantities. Indeed, hazardous waste accounts for<br />

just 0.004% of the total volume of waste that we<br />

generate.<br />

90%<br />

recyclable<br />

packaging<br />

HEIDEMARK<br />

reduced its<br />

waste volume<br />

by 2%<br />

compared to the<br />

previous year.

HEIDEMARK<br />

4.5<br />

ECOLOGY<br />

4.1<br />

40 SUSTAINABILITY REPORT <strong>2023</strong><br />

BIODIVERSITY 4.5 TOPIC<br />

BIODIVERSITY 41<br />

Biodiversity<br />

In 2022, we began sowing flowering meadows on some<br />

of our turkey farms.<br />

It hums and<br />

buzzes: our<br />

insect<br />

filling station<br />

for greater<br />

biodiversity.<br />

Flowering<br />

meadow<br />

To prevent pests from entering the<br />

barns, we keep the plants and flowers<br />

a safe distance from the animal<br />

housing.<br />

In Saxony-Anhalt we have planted a<br />

2000-sqm wildflower meadow in partnership<br />

with the landscape conservation<br />

association “Altmark-Elb-Havel-Winkel”.<br />

This meadow of poppies,<br />

sunflowers and thistles provides a<br />

habitat for insects and thus promotes<br />

species conservation. In 2025, we plan<br />

to expand these areas to two hectares,<br />

and then gradually expand them further<br />

over the following years.<br />

Feed<br />

Our feed rations contain 20% soya.<br />

The use of soya is frequently criticised<br />

because primary forests in some parts<br />

of Brazil are being converted into soya<br />

bean cultivation areas. For this reason,<br />

we rely on agricultural raw materials<br />

that are deforestation-free. Deforestation-free<br />

raw materials refers to crops,<br />

in this case soya, that can be cultivated<br />

without first having to clear land. For<br />

South American soya, we request sustainability<br />

certificates (RTRS and ProTerra)<br />

from our feed suppliers every year.<br />

The new EU regulation on deforestation-free<br />

supply chains means that, in<br />

future, products placed on the market<br />

in the European Union must originate<br />

solely from deforestation-free areas. In<br />

line with this, Qualität und Sicherheit<br />

GmbH (QS) has developed the Soja<br />

Plus standard (freedom from deforestation),<br />

according to which all QS-certified<br />

feed companies must be certified<br />

from 2024. Since our entire value chain<br />

is certified under the QS standard, this<br />

applies to all feed companies that supply<br />

us. The mandatory criteria to ensure<br />

freedom from deforestation are<br />

then verified via external audits.<br />

Despite this, we continue to research<br />

alternative protein sources with the<br />

goal of replacing soya with other raw<br />

materials. For this purpose, we conduct<br />

ongoing feeding trials in our own<br />

test stables.

Our<br />

sustainability goals<br />

• From 2024, every manager will<br />

be required to attend at least<br />

two management training<br />

courses per year<br />

05.<br />

• We plan to conduct a staff<br />

survey at least every<br />

three years<br />

• We aim to maintain our 80%<br />

trainee retention rate<br />

until 2025<br />

• By 2025, we plan to offer at<br />

least 15 training places<br />

per year<br />

Social<br />

responsibility<br />

• We intend to expand and<br />

improve our internal<br />

communications by means<br />

of our employee app

44<br />

HEIDEMARK<br />

5.1<br />

SUSTAINABILITY REPORT <strong>2023</strong> EMPLOYEES 45<br />

Employees<br />

At HEIDEMARK, we never judge people by their nationality,<br />

culture, religion or sexual orientation. Their<br />

professional skills with regard to the job in question<br />

are all that matter to us.<br />

The proportion of women in<br />

leadership positions at our company is 34%.<br />

We have anchored this in our Code of Conduct<br />

and live these values every day. In order to<br />

overcome language barriers, we have also appointed<br />

employees from our production and<br />

human resources departments to act as interpreters.<br />

These colleagues enable us to assist<br />

our non-German-speaking employees more<br />

to promote integration in general, our Human<br />

Resources department maintains a constant<br />

dialogue with our permanent contacts at the<br />

Federal Employment Agency and with other cooperation<br />

partners (e.g. educational institutions<br />

and schools).<br />

49.17%<br />

from Romania<br />

29.96%<br />

from Germany<br />

effectively. They also provide support on issues<br />

outside the workplace.<br />

For example, we work with the local authorities<br />

to facilitate the arrival of new workers and find<br />

solutions as required. We also help new employees<br />

to find accommodation and provide a limited<br />

number of modern living spaces. In order<br />

In recent years, we have implemented a flexible<br />

working time model to improve the work-life<br />

balance for our staff. Based on the results of our<br />

employee satisfaction survey, we evaluate our<br />

working conditions at least every three years<br />

and adapt them to the needs of our workforce.<br />

<strong>Much</strong>.<br />

<strong>More</strong>.<br />

Us.<br />

3.52%<br />

from Vietnam<br />

3.52%<br />

from Bulgaria<br />

2.09%<br />

from Lithuania<br />

63%<br />

male*<br />

11.74%<br />

other countries<br />

37%<br />

female*<br />

We are a member of the Verband der<br />

Ernährungswirtschaft e.V. (VdEW), which<br />

concludes collective agreements with the<br />

Nahrung-Genuss-Gaststätten (NGG) trade union.<br />

This means that we are a collectively bound employer.<br />

To guarantee fair pay regardless of factors<br />

such as gender or religion, our management<br />

team receives regular reports on this topic. To<br />

ensure that we can offer our staff long-term prospects<br />

within our company, around 65% of our<br />

employees have permanent contracts.<br />

*of all employees at HEIDEMARK

46<br />

HEIDEMARK<br />

5.2<br />

5.3<br />

SUSTAINABILITY REPORT <strong>2023</strong> PERSONNEL DEVELOPMENT<br />

OCCUPATIONAL HEALTH & SAFETY 47<br />

Personnel development<br />

Occupational health & safety<br />

At HEIDEMARK we endeavour to counteract the shortage<br />

of skilled workers through various training and further<br />

education opportunities. Accordingly, we provide<br />

training in five different professions every year.<br />

A healthy working environment is essential for our employees<br />

and for the company as a whole. To guarantee this, we<br />

have a company doctor who carries out all the necessary<br />

occupational health check-ups.<br />

In 2022<br />

we had a<br />

total of 22<br />

trainees.<br />

In 2022 we had a total of 22 trainees<br />

and a retention rate of 80%. It is<br />

gratifying to note that several of our<br />

past trainees have excelled to such<br />

an extent within our company that<br />

they currently occupy managerial<br />

roles.<br />

Feedback and employee discussions<br />

take place at regular intervals. This<br />

enables us to work with individual<br />

employees to identify their specific<br />

development and support needs as<br />

well as suitable training measures.<br />

HEIDEMARK invests in its employees<br />

and thus in the future of the company.<br />

And this starts with our onboarding<br />

process, which is based on a<br />

structured and personalised induction<br />

plan. We also offer a mentoring<br />

scheme to aid new employees during<br />

their transition into the company.<br />

Our managers are required to<br />

attend annual leadership seminars,<br />

thereby ensuring continuous improvements<br />

in this area. In <strong>2023</strong>, we<br />

will launch a new management<br />

programme called “Leading at<br />

HEIDEMARK”. This will enable our<br />

managers to participate in the creation<br />

of seminar topics aligned with<br />

their current challenges, thereby<br />

fostering a contemporary leadership<br />

culture at HEIDEMARK.<br />

Via these measures we can ensure<br />

continuous personnel development<br />

and contribute towards SDG 4: “Ensure<br />

inclusive, equitable and quality<br />

education and promote lifelong<br />

learning opportunities for all”.<br />

This also includes, among other things, flu vaccinations<br />

and suitability assessments for workplaces.<br />

Since 2022, we have offered our employees<br />

easier access to occupational disability insurance<br />

as well as a bicycle leasing scheme with the goal<br />

of encouraging them to cycle more often and<br />

thus take preventive steps towards protecting<br />

their health. At the same time, we encourage our<br />

staff to take part in various sporting events in order<br />

to promote team cohesion and increase their<br />

motivation to participate in group exercise.<br />

To prevent accidents, we have appointed occupational<br />

safety specialists and safety officers who<br />

sit on our occupational safety committee, which<br />

meets regularly to discuss improvements, perform<br />

evaluations and carry out workplace inspections<br />

with our company doctor. In this way, risk<br />

assessments can be created for every workplace.<br />

In addition, we have commissioned an external<br />

company to carry out audits at regular intervals,<br />

highlight any deficiencies and systematically help<br />

us to improve occupational safety.<br />

During the coronavirus pandemic, we tested all<br />

our employees on a regular basis over a period of<br />

several months. In total, more than 300,000 tests<br />

were carried out. We also installed air purification<br />

systems in our production building to prevent<br />

infections. When the vaccines became available<br />

in 2021, we were able to quickly achieve a high<br />

vaccination quota among our employees by organising<br />

vaccination appointments with the local<br />

GP surgeries.<br />

<strong>Report</strong>able accidents<br />

5.9 5.6<br />

4.5<br />

2020 2021 2022<br />

per 100 employees<br />

With regard to accidents, we have<br />

set ourselves a target of keeping<br />

the number of reportable<br />

accidents per 100 employees to<br />

fewer than five per year.

HEIDEMARK<br />

5.4<br />

48 SUSTAINABILITY REPORT <strong>2023</strong><br />

REGIONAL COMMITMENTS 49<br />

Regional commitments<br />

Each year, HEIDEMARK donates money to a number of worthy<br />

causes. We favour local donations due to our strong<br />

ties to the Oldenburg Münsterland region since 1965.<br />

Instead of<br />

buying gifts for<br />

our business<br />

customers, we<br />

donate<br />

money to<br />

good causes at<br />

Christmas time.<br />

volunteer fire department in Ahlhorn,<br />

the language support school<br />

in Ahlhorn, or the hospice in Cloppenburg,<br />

HEIDEMARK donates to<br />

these organisations. We provide fast,<br />

of both financial donations and food.<br />

Weekly donations to food banks are<br />

more important than ever as these<br />

vital services have seen a significant<br />

increase in demand.<br />

77 .380 €<br />

donated to food<br />

We also provide support outside<br />

our region; for example, by donating<br />

food and money to the flood<br />

victims in the Ahr Valley and sending<br />

food to the people of Ukraine.<br />

In the latter case, we donated<br />

around € 70,000 worth of food<br />

to the Ukrainians – it was distributed<br />

in the towns of Bucha, Irpin<br />

and Hostomel in the Kiev region.<br />

We are always happy to see firsthand<br />

how our donations have been<br />

used. This was the reason for our visit<br />

banks in 2022<br />

penburg in 2022. The hospice helps<br />

people during their most difficult<br />

journey and makes their remaining<br />

time as rich and fulfilling as possible.<br />

For this purpose, a professional<br />

team of full-time and voluntary staff<br />

is available around the clock at the<br />

wanderlicht inpatient hospice. During<br />

our conversations on site we<br />

learned which activities – partially<br />

financed by donations – took place<br />

in 2022 as well as those planned for<br />

<strong>2023</strong>.<br />

*<br />

100 k €<br />

in 2022<br />

for other causes<br />

HEIDEMARK not only provides financial<br />

support, but also donates food<br />

and other products.<br />

Support<br />

in the form of<br />

donations<br />

is a part of the<br />

HEIDEMARK<br />

culture.<br />

Whether it's for amateur sports, the<br />

uncomplicated support in the form<br />

to the wanderlicht hospice in Clop-<br />

*Value of goods for products

50<br />

HEIDEMARK<br />

SUSTAINABILITY REPORT <strong>2023</strong><br />

Imprint<br />

Publisher<br />

HEIDEMARK GmbH<br />

Lether Gewerbestrasse 2<br />

26197 Alhorn, Germany<br />

Dr. Hanna Strüve<br />

<strong>Sustainability</strong> Officer<br />

Design<br />

Extra & Bold Design GmbH<br />

Europa-Allee 20<br />

49685 Emstek, Germany<br />

Picture credits<br />

Photographs:<br />

Sigrun Strangmann Photography<br />

Images from film footage:<br />

BOCKFILM Film- und Fernsehproduktion GmbH<br />

Illustrations:<br />

Mauco Sosa<br />

Translation agency<br />

Schmieder Übersetzungen GmbH<br />

Schussenstraße 16<br />

88273 Fronreute-Staig, Germany