drinkworld Technology + Marketing 4/2023

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ZKZ 62006<br />

ISSN 1433-1594 Vol. 27 No. 4 November <strong>2023</strong> US $ 12 · € 12<br />

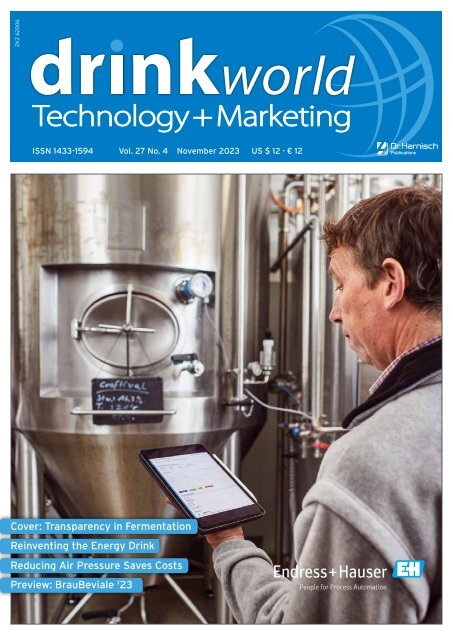

Cover: Transparency in Fermentation<br />

Reinventing the Energy Drink<br />

Reducing Air Pressure Saves Costs<br />

Preview: BrauBeviale '23

Leading process technology<br />

for the beverage and food<br />

industry<br />

Visit us in<br />

Hall 9, Stand 322<br />

BrauBeviale<br />

28—30 Nov. <strong>2023</strong><br />

Nuremberg<br />

bucherunipektin.com

Editorial<br />

Cleansing the Natural & Healthy Way<br />

Every so often our bodies say “Stop!“<br />

This is often because we have taken up<br />

too much of something and our system<br />

needs to filter it out. I had a colleague<br />

who regularly used to detox his body<br />

for a few weeks each year. This is more<br />

common than I thought and involves a<br />

range of beverages, which are easier<br />

for the body to consume.<br />

Essentially, fasting cleanses our<br />

body of toxins and forces cells<br />

into processes that are not usually<br />

stimulated when a steady stream<br />

of fuel from food is always present.<br />

When we fast, the body does not have<br />

its usual access to glucose, forcing<br />

the cells to resort to other means and<br />

materials to produce energy. Fasting<br />

can purify our body and our mind and<br />

can last from several hours to several<br />

days.<br />

Looking at the various teas and<br />

other products in the pharmacies<br />

and drugstores, the market seems<br />

to be huge and growing. In Germany<br />

‘Juice Cleansing‘ is very popular at<br />

the moment. Favourite juice and<br />

must products are beetroot, carrots,<br />

sauerkraut as well as some vegetable,<br />

fruit and herb mixes and cocktails,<br />

which naturally detoxify the body from<br />

within and aid in weight loss. A wide<br />

range of detox drinks are available on<br />

the market, including juices, smoothies,<br />

water, tea, and coffee, all of which<br />

provide numerous nutrients and boost<br />

the body's metabolism.<br />

Globally the detox drinks market is<br />

expected to hit a valuation of US$ 10<br />

billion by the end of 2033, increasing<br />

at 7.1% CAGR from <strong>2023</strong> to 2033.<br />

Currently it stands at US$ 5 billion in<br />

<strong>2023</strong>.<br />

Some reasons for this growth include<br />

an increasing number of people<br />

choosing a healthy lifestyle. People's<br />

growing emphasis on detox and<br />

healthy living, in general, has resulted<br />

in the increasing consumption of<br />

detox beverages. A comprehensive<br />

detox drink aids the body's cleansing<br />

and regeneration processes and<br />

replenishes it with new nutrients.<br />

Popular detox drinks include beet<br />

ginger detox juices, freshly squeezed<br />

lemonade, fruit-infused turmeric tea,<br />

and ginger shots.<br />

Rising incidence of chronic diseases<br />

such as cardiovascular disease, cancer,<br />

diabetes, and others is also propelling<br />

the global detox drinks market<br />

growth. Detox drinks are becoming<br />

increasingly popular around the world<br />

due to their potential to enhance the<br />

body's metabolism and provide other<br />

nutritional benefits. Moreover, detox<br />

beverages are gaining acceptance<br />

Ian D. Healey<br />

Editor-in-Chief<br />

among fitness enthusiasts since they<br />

are high in fresh vitamins, minerals, and<br />

antioxidants. Additionally, the rising<br />

expense of healthcare operations and<br />

an increase in the senior population are<br />

important factors pushing the global<br />

expansion of the detox drinks market.<br />

There is certainly a growing awareness<br />

about the advantages of detox drinks, which<br />

has brought about an increased demand<br />

for healthy & organic food products. The<br />

rising incidence of chronic diseases is<br />

also a significant factor propelling the<br />

consumption of detox drinks. We should<br />

not underestimate this market – and it is<br />

clear that the tasty and healthy range of<br />

new products will keep growth and health<br />

improving for a while to come.<br />

Photo: Bill Kaprelian<br />

Cheers<br />

www.drink-tm.com<br />

If you like it – subscribe!<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong> 3

Contents<br />

ZKZ 62006<br />

ISSN 1433-1594 Vol. 27 No. 4 November <strong>2023</strong> US $ 12 · € 12<br />

Issue 4 · November <strong>2023</strong><br />

Anyone who opens a bottle of their favorite beer knows what kind of<br />

taste experience to expect. For consumers, that’s a given. But behind<br />

this experience is a complex process, in which fermentation in particular<br />

must be precisely controlled. The multisensor fermentation monitor from<br />

Endress+Hauser enables live tracking of the fermentation process by combining<br />

various measurement methods with digital technologies.<br />

Our cover story starts on page 6.<br />

Cover: Transparency in Fermentation<br />

Reinventing the Energy Drink<br />

Cover: Endress+Hauser<br />

Reducing Air Pressure Saves Costs<br />

Preview: BrauBeviale '23<br />

Ingredients<br />

10 “Caffeine Alone is Not Enough”: Reinventing<br />

the ‘Energy Drink’ for a Modern Lens<br />

13 Synergy Flavors Celebrates 140 Years of<br />

Flavor Extraction Expertise in Italy with New Hop<br />

Essences Range in Europe<br />

16 Drinking for your Health<br />

19 Processed Dates: Natural Sweetening Alternatives<br />

Processing<br />

6 Complete Transparency During the Beer<br />

Fermentation Process<br />

24 How Reduced System Air Pressure Saves 16%<br />

Compressor Energy<br />

26 Steinecker Gets things Moving in the Tank<br />

Modern life is demanding as we try and balance work,<br />

education, family, commuting, exercise and even –<br />

occasionally – simply having fun. Energy drink sales<br />

are again on the rise and producers have adapted their<br />

offerings. A negative reputation has played a major role<br />

in shifting attitudes in recent years, and has brought the<br />

subsequent rise of a more natural, healthy approach to<br />

energy enhancement. See the story on page 10<br />

Air itself may be free, but compressed air is more expensive<br />

than many food and beverage plant operators realize. In<br />

the ever-evolving landscape of food processing, optimizing<br />

costs and reducing the carbon footprint have become key<br />

priorities. Reducing the system pressure of compressed air<br />

systems is one way to achieve this. However, all connected<br />

applications need to be configured for the lower pressure,<br />

especially the automated process valves that move thicker<br />

products through the process. The full story is on page 24<br />

4

Contents<br />

Departments<br />

3 Editorial<br />

40 Supplier's Guide<br />

Events<br />

20 FiEurope<br />

23 International Brewing Awards<br />

30 BrauBeviale<br />

42 Calendar of Events<br />

Packaging<br />

37 New Automatic Splicing Method for all Types of Roll<br />

Labels and Labelling Systems<br />

38 Sustainable Freshness Protection for Natural<br />

Mineral Water<br />

BrauBeviale is back! Visitors to BrauBeviale will discover<br />

many fascinating new technologies and applications to<br />

improve their daily business. These include: optimizing<br />

parts of their brewing or beverage operations, energy and<br />

resource conservation, an effective market presentation<br />

of their products and functional improvements to existing<br />

equipment. Any list of new options may include standalone<br />

machines that can easily be integrated into existing<br />

operations. Our preview starts on page 30<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong> 5

Cover Story<br />

Complete Transparency During the Beer<br />

Fermentation Process<br />

Anyone who opens a bottle of their favorite beer knows what kind of taste experience to<br />

expect. For consumers, that’s a given. But behind this experience is a complex process,<br />

in which fermentation in particular must be precisely controlled. The QWX43 multisensor<br />

fermentation monitor from Endress+Hauser enables live tracking of the fermentation<br />

process by combining various measurement methods with digital technologies.<br />

by JULIA ROSENHEIM& TIM SCHRODT<br />

Water, malt, hops and yeast. These basic<br />

ingredients are common to all types<br />

of beer. During the brewing process<br />

however, a wide range of parameters<br />

must be observed. Beginning with the<br />

preparation of the wort, fermentation<br />

plays an especially central role here. The<br />

prerequisite for optimal fermentation of<br />

the wort is a high-quality and repeatable<br />

process control system.<br />

In order to monitor and control the<br />

fermentation process, samples are often<br />

drawn manually once or twice a day.<br />

This normally occurs at the brewery<br />

using a handheld density measurement<br />

instrument. The samples are also<br />

sent to a lab on a frequent basis. The<br />

disadvantages are apparent. The brewer<br />

or its on-site employees need 15 to 30<br />

minutes per tank for the sampling. Even<br />

then, it only offers a snapshot of the<br />

fermentation process. Another issue<br />

is that in most cases the spindle or lab<br />

measurements are based on a single<br />

parameter, such as density, which is<br />

not sufficient to measure the extract<br />

content and the actual ethanol content<br />

that forms during fermentation.<br />

The result is that these parameters,<br />

as well as the degree of fermentation,<br />

must be determined with approximate<br />

equations. This makes it more difficult for<br />

the brewmaster to carry out sustained<br />

and comprehensible process control. In<br />

addition, the lab instruments often have<br />

to be recalibrated and adjusted, which<br />

involves more effort.<br />

How technology reduces the<br />

effort for the brewer<br />

With the QWMX43 fermentation<br />

monitor, instrumentation specialist<br />

Endress+Hauser developed a solution that<br />

reduces the effort for the brew master<br />

and provides a reliable analysis of the<br />

fermentation process at the same time.<br />

The multisensor instrument is mounted<br />

directly on the fermentation tank and<br />

immersed in the beer. It continuously<br />

measures the density, ultrasound runtime,<br />

viscosity, and process temperature during<br />

fermentation. Algorithms calculate in<br />

real-time the relevant parameters such as<br />

original wort, extract, alcohol content and<br />

degree of fermentation.<br />

“The QWX43 fermentation monitor<br />

simplifies our daily activities. Thanks to<br />

this innovation, we can learn about the<br />

current status of our beer much easier<br />

and faster,” says Joachim Rogg, the<br />

sixth generation to run the Rogg private<br />

brewery, which has been producing<br />

Barbara Lohmeier manages the Bräu z’Loh brewery. She relies on the QWX43 fermentation monitor to carry out her activities.<br />

6

Cover Story<br />

quality beer in Lenzkirch in the Black<br />

Forest region since 1846.<br />

The measurement data can be retrieved<br />

from the QWX43 fermentation monitor<br />

with any internet-capable device, either<br />

directly via the control system or by<br />

using the Value app in the Netilion IIoT<br />

ecosystem from Endress+Hauser. That<br />

means the brewer can monitor and<br />

control the fermentation process at<br />

any time, without having to be on-site.<br />

“Taking manual samples twice a day<br />

with the spindle, which only provides<br />

a snapshot of the highly-dynamic<br />

fermentation process, does not allow us<br />

to achieve such accuracy, not even in<br />

combination with a laboratory analysis,”<br />

says Rogg in describing the precise<br />

measurement values provided by the<br />

QWX43 fermentation monitor.<br />

The calibration and adjustment effort<br />

is eliminated as well. Using data saved<br />

in the Netilion platform, it’s also<br />

possible to compare a specific batch<br />

of beer to a reference batch during<br />

the process and directly react to<br />

The QWX43 fermentation monitor is mounted directly on the fermentation tank and immersed in the beer.<br />

deviations. Other advantages can be<br />

gained, such as maximizing the capacity<br />

of the fermentation tank through<br />

precise cooling or automatic in-tank<br />

carbonization, all without extensive effort<br />

and with the reliability of measurements<br />

running in the background.<br />

Barbara Lohmeier also relies on the<br />

QWX43 fermentation monitor at her<br />

brewery. “Thanks to this technology, I<br />

reduced the production effort by around<br />

10 percent,” said the head of Bräu z’Loh,<br />

which brews its beer in accordance with<br />

the Bavaria purity law of 1516. “I can use<br />

Barbara Lohmeier explains the fermentation process to one of her apprentices using the QWX43 fermentation monitor.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

7

Cover Story<br />

the time gained to devote more effort<br />

to our sales activities.” The QWX43<br />

fermentation monitor also helps her<br />

offer the three apprentices the best<br />

possible training. Using the detailed<br />

graphics and curves, Lohmeier can<br />

provide the trainees insights into the<br />

fermentation process and visually<br />

explain the workflows.<br />

Time to replace the yeast?<br />

The instrument provides the<br />

answer.<br />

Another example of potential process<br />

improvements through the QWX43<br />

fermentation monitor is the optimized<br />

utilization of the brewing yeast.<br />

Observing the pitching yeast is an<br />

important aspect here. The pitching<br />

yeast makes a crucial contribution to<br />

the productivity of the fermentation,<br />

the behavior during maturation and<br />

preservation of the desired quality. The<br />

risk of degeneration of the pitching<br />

yeast therefore must be detected<br />

at an early stage. Furthermore, it’s<br />

known from literature that yeast can<br />

be stressed particularly when using<br />

cylindrical conical fermentation tanks,<br />

which are considered efficient. The<br />

convection caused by the formation of<br />

CO 2<br />

leads to delayed settlement, so that<br />

the fermentation activity of the yeast<br />

decreases from batch to batch and must<br />

be changed more often compared to<br />

traditional fermentation processes.<br />

With the QWX43 fermentation monitor, we can learn about the current status of our beer much easier<br />

and faster,” says Joachim Rogg.<br />

Using the Netilion app, Brewer Joachim Rogg can retrieve the measurement values from the QWX43<br />

fermentation monitor at anywhere and from anywhere.<br />

Today, the quality of the pitching<br />

yeast can be characterized thanks to<br />

hygienically and technically mature<br />

process control steps, such as<br />

evaluating the ethanol formation rate,<br />

fermentation speed, the formation<br />

of common metabolic byproducts or<br />

the consumption of nutrients during<br />

fermentation. How these indicators<br />

run their course, both before and after<br />

the main fermentation process, is<br />

highly interesting. “With the QWX43<br />

fermentation monitor you immediately<br />

see when something is not right with the<br />

degree of fermentation, such as when<br />

adding dry yeast,” says Joachim Rogg.<br />

“You can then stop the process at an<br />

early stage and replace the yeast.”<br />

How can the process data from the<br />

QWX43 fermentation monitor be utilized<br />

to characterize the pitching yeast? The<br />

detailed and repeatable measurement<br />

values are reliable indicators of the<br />

ethanol formation and nutrients<br />

depletions. In addition, the increase<br />

in the number of yeast cells at the<br />

beginning of the process can be inferred<br />

by observing the increase in viscosity<br />

of the medium. By comparing current<br />

process data with data from previous<br />

fermentation processes, thresholds<br />

can be defined to manage reutilization<br />

of the yeast. Rather than replacing<br />

the brewers’ know-how, the QWX43<br />

fermentation monitor supports their<br />

activities - just like with Joachim Rogg<br />

and Barbara Lohmeier. “I can now track<br />

the fermentation process with pinpoint<br />

accuracy, even if I’m sitting in my office<br />

or at home,” says Lohmeier. “I save<br />

time but can still be sure that the entire<br />

process is running as it should.”<br />

The Authors<br />

Julia Rosenheim is Product Owner GIL Innovation<br />

Lab at Endress+Hauser Level+Pressure<br />

Tim Schrodt is Industry Manager, Food &<br />

Beverage, at Endress+Hauser Germany in Weil<br />

am Rhein<br />

8

made in the usa<br />

ZAHM&NAGEL<br />

producing the finest CO2 and air testing instrumentation since 1908<br />

. . . currently used in the industry<br />

in over 125 countries worldwide,<br />

Zahm & Nagel is a trusted name in<br />

the industry built on quality and<br />

service for over 100years.<br />

9 0 0 0 - R<br />

C O2<br />

P I L O T P L A N T<br />

the fast, effective<br />

and economical way<br />

to carbonate, filter<br />

and bottle beverages<br />

■<br />

■<br />

■<br />

Ideal for producing small quantities for<br />

test, marketing and feasibility analysis<br />

±1% accuracy in extremely rugged, all<br />

stainless steel construction<br />

Easy to clean and maintain, with several<br />

filter and fittings options for ultimate<br />

versatility<br />

Zahm & Nagel 9000-R Pilot Plant is designed for<br />

excellent and easy use in a laboratory setting with full<br />

stainless steel construction and gauges and filter<br />

cartridges that are easily disassembled for removal<br />

and cleaning of the filter stone. Optional woven filter<br />

cartridges are also available for easy disposal as well<br />

as optional quick-connect fittings.<br />

please visit our<br />

website for product<br />

demonstration videos<br />

For over 100 years Zahm & Nagel has been a world<br />

leader in the engineering, manufacture and service of<br />

quality control, testing and carbonating equipment for<br />

the beverage and brewing industries.<br />

www.zahmnagel.com<br />

e-mail: sales@zahmnagel.com / phone: 716.537.2110

Ingredients<br />

“Caffeine Alone is Not Enough”:<br />

Reinventing the ‘Energy Drink’ for a<br />

Modern Lens<br />

by FREDRIK HJELMQVIST<br />

Modern life is demanding as many know.<br />

Work, education, childcare, commuting,<br />

exercise and even – occasionally – just<br />

having fun, for consumers today it can<br />

feel like they need an endless reservoir<br />

of energy, just to make it through the<br />

day. It’s unsurprising then, that energy<br />

drink sales are on the rise. The global<br />

energy drinks market is projected to<br />

grow at a CAGR of 8% over the next<br />

decade, reaching a value of $108 billion<br />

by 2031. Energy boosting beverages are<br />

as popular as ever, but is caffeine content<br />

alone enough to excite consumers? The<br />

holistic wellness trend sweeping the<br />

food and beverage sector has made an<br />

indelible impact on shoppers’ priorities,<br />

blurring the lines between health,<br />

indulgence and functional nutrition. The<br />

consequence of this attitude shift for the<br />

beverage segment is that shoppers don’t<br />

just want ‘energy’ drinks, but solutions<br />

to give them an all-round boost with<br />

cognitive and mood support, as well as<br />

improved alertness and endurance.<br />

Read on as we discuss the latest<br />

nutraceutical trends and ingredients<br />

designed to promote a healthy mood and<br />

energize the body, and how producers<br />

can level up their energy drink offering<br />

for the modern market.<br />

A new view on ‘energy’<br />

Despite their enduring popularity,<br />

energy drinks have had somewhat<br />

of a bad reputation in the popular<br />

consciousness – thought of as ‘quick<br />

fixes’ full of sugar, excessive amounts of<br />

caffeine and artificial ingredients. Even<br />

among university-aged young adults -<br />

the demographic group most likely to<br />

consume energy drinks – the potential<br />

side effects of these beverages are well<br />

known. According to one study, after<br />

consuming a traditional energy drink,<br />

42% of students reported experiencing<br />

an increased heartbeat, 36% cited<br />

jitteriness and 29% spoke of anxiety<br />

or irritability. Results like this have<br />

played a major role in shifting attitudes<br />

towards energy drinks in recent years,<br />

and the subsequent rise of a more<br />

natural, healthy approach to energy<br />

enhancement.<br />

Perhaps the biggest change here<br />

relates to sugar content. Excessively<br />

sweet foods and beverages are an<br />

increasing concern for consumers, and<br />

regulators alike, with the European<br />

Soft Drinks association, UNESDA,<br />

extending its 2025 sugar reduction<br />

targets by a further 10%, mirroring<br />

similar initiatives from food standards<br />

agencies around the world. In tandem<br />

with increased regulatory scrutiny,<br />

consumers are driving progress<br />

through their purchasing decisions.<br />

Close to a quarter of recent energy<br />

drink launches featured a ‘sugar free’<br />

positioning, while 15% combined the<br />

claims ‘no added sugar’ and ‘natural<br />

energy drink’. This second point<br />

brings up the equally crucial factor<br />

of ‘naturalness’. Research from dsmfirmenich<br />

found that around 80%<br />

of beverage consumers wanted to<br />

know whether a product contained<br />

natural or artificial colorants, with<br />

the former achieving a significantly<br />

higher purchase intent. When it comes<br />

to the look, feel and taste of energy<br />

drinks designed for a contemporary<br />

audience, brands clearly need to focus<br />

on blending naturalness with that all<br />

important low-sugar positioning.<br />

Attitudes are also in flux regarding<br />

the functional side of energy drinks.<br />

Consumers still want their caffeine<br />

fix, but a simple, short-term energy<br />

boost is no longer enough for some.<br />

Digestive health and immune support,<br />

for example, were cited as the most<br />

appealing functional beverage benefits<br />

by more than 70% of consumers in a<br />

recent Global Data survey, while Mintel<br />

found that almost a third of energy<br />

drink consumers would be motivated<br />

to buy a product proven to promote<br />

brain health. Vitamin and mineral<br />

content too is a central purchase<br />

driver in the energy drink segment,<br />

both in terms of classic inclusions<br />

like fatigue-fighting B vitamins, and<br />

familiar favorites like vitamin C. The<br />

10

Ingredients<br />

energy drink market is entering a<br />

whole new era of dynamism, creating<br />

exciting opportunities for beverage<br />

manufacturers. What brands need now<br />

is the right, high-quality ingredients to<br />

address evolving consumer priorities<br />

around taste, color, sugar content and<br />

functionality.<br />

The fundamentals: Taste,<br />

texture and color<br />

It’s been said a thousand times; taste<br />

is king. No matter how revolutionary<br />

a beverage’s proclaimed benefits are,<br />

if it cannot deliver a delicious flavor<br />

and attractive sensory experience,<br />

consumers simply won’t come back for<br />

more. The challenge for today’s energy<br />

drink formulators is balancing taste<br />

against consumer expectations for<br />

a natural and low-sugar positioning.<br />

Here we’ve seen plant-based prebiotic<br />

fibers and, more recently, fermented<br />

sweetening options come to the fore as<br />

a natural solution to creating a great<br />

taste, without excess added sugar.<br />

Nature is similarly a key inspiration<br />

in the realm of colorants. Ingredients<br />

like β-Carotene – a family of carotenoid<br />

pigments – for instance, have been<br />

used to great success to bring vibrant<br />

red, orange and yellow hues to<br />

beverages, the natural way.<br />

There are even plant-derived solutions<br />

for improving product texture – an<br />

aspect too often overlooked in energy<br />

drink formulation. Hydrocolloids<br />

such as pectin are an invaluable tool<br />

for enhancing the appearance and<br />

mouthfeel of ready-to-drink beverages,<br />

imbuing drinks with a smooth texture<br />

that lets star flavors shine and ensures<br />

all active ingredients are thoroughly<br />

suspended.<br />

The main event: Energy<br />

boosting ingredients<br />

The clue is in the name – ‘energy’<br />

drinks, even naturally positioned,<br />

multifunctional ones, still need to<br />

provide consumers with a much-needed<br />

boost. Caffeine and, to a lesser extent,<br />

B vitamins remain the front runners in<br />

this space, but producers have begun<br />

exploring the potential of alternative<br />

energy enhancers. Proteins (including<br />

collagen peptides) and amino-acids<br />

have been shown to contribute to<br />

increased satiety, as well as sports<br />

recovery benefits like reduced muscle<br />

soreness, while vitamin-like substances<br />

like Coenzyme Q-10 help support a<br />

healthy cardiovascular system.<br />

Building out the nutrition<br />

profile: Additional functional<br />

ingredients<br />

As mentioned above, consumers<br />

are looking for more than ‘empty<br />

energy’ from their beverage choices.<br />

From CBD to yerba mate extract,<br />

adaptogens to vitamins, the wide<br />

array of functional ingredients we’ve<br />

seen added to energy drinks has<br />

gone a long way towards shifting the<br />

segment’s ‘unhealthy’ reputation. The<br />

crucial point to remember here for<br />

drinks manufacturers is not just what<br />

ingredients to include, but how they<br />

are incorporated. Not all trending<br />

ingredients are easy to blend into a<br />

beverage format, requiring careful<br />

management of sweetening solutions,<br />

texturizers, energy-boosting inclusions<br />

and functional extras to create the<br />

ideal end product. It’s here where the<br />

help of an experienced ingredients<br />

partner can add real value.<br />

Single supplier, multiple<br />

benefits<br />

To stand out in the increasingly<br />

competitive energy drinks space,<br />

brands need more than just a supplier<br />

– they need a strategic partner. The<br />

most experienced players operating<br />

in food and beverage ingredients<br />

today offer concept development<br />

support, formulation expertise,<br />

regulatory and marketing advice and<br />

efficiency improvements, as well as a<br />

comprehensive portfolio of sciencebacked<br />

solutions. Just as caffeine alone<br />

isn’t enough for today’s consumers,<br />

single-ingredient suppliers should not<br />

be the first choice for beverage brands<br />

looking to cement their position in<br />

the energy drink market. At dsmfirmenich,<br />

we strive to be this ‘onestop-shop’<br />

for our customers, helping<br />

them work smarter at speed to create<br />

the next energy drink sensation.<br />

The Author<br />

Fredrik Hjelmqvist is Senior Vice President<br />

Beverages & More at dsm-firmenich<br />

1) Global Opportunity Analysis and Industry<br />

Forecast, 2020-2031, Allied Market Research<br />

2) Ghozayel M, Ghaddar A, Farhat G, Nasreddine<br />

L, Kara J, Jomaa L. Energy drinks consumption<br />

and perceptions among University<br />

Students in Beirut, Lebanon: A mixed<br />

methods approach. PLoS One. 2020 Apr<br />

30;15(4):e0232199. doi: 10.1371/journal.<br />

pone.0232199. PMID: 32353017; PMCID:<br />

PMC7192412.3)<br />

3)Ibid, Ghozayel et al, Energy drinks consumption<br />

and perceptions among University<br />

Students in Beirut, Lebanon<br />

4) UNESDA, Soft drinks industry’s sugar<br />

reduction commitments across Europe,<br />

https://www.unesda.eu/sugar-and-caloriereduction/#:~:text=UNESDA%20has%20<br />

committed%20to%20reduce,milk%20<br />

based%20and%20hot%20beverages<br />

5) Mintel GNDP database, accessed March<br />

20226)<br />

6) Future Market Insights, Soft drinks industry’s<br />

sugar reduction commitments across<br />

Europe, September 2022, https://www.<br />

futuremarketinsights.com/reports/energydrinks-market?utm_source=adwords&utm_<br />

medium=ppc&utm_source=adwords&utm_<br />

medium=ppc&id=5&gclid=CjwKCAjw38SoBh-<br />

B6EiwA8EQVLtCoM9MUCAY62vk0dM8OqDc<br />

BzECHy7n9Ks5SeLddNCs0fZgGigbr5BoCKDwQAvD_BwE<br />

7) Global coloration study, dsm-firmenich<br />

2021<br />

8) GlobalData, 2021 Q2 global consumer survey<br />

9) A year of innovation in sports and energy<br />

drinks, Mintel 202010)<br />

10) Moon J, Koh G. Clinical Evidence and<br />

Mechanisms of High-Protein Diet-Induced<br />

Weight Loss. J Obes Metab Syndr. 2020 Sep<br />

30;29(3):166-173. doi: 10.7570/jomes20028.<br />

PMID: 32699189; PMCID: PMC7539343<br />

11) Kuwaba K, Kusubata M, Taga Y, Igarashi H,<br />

Nakazato K, Mizuno K. Dietary collagen peptides<br />

alleviate exercise-induced muscle soreness<br />

in healthy middle-aged males: a randomized<br />

double-blinded crossover clinical trial. J<br />

Int Soc Sports Nutr. <strong>2023</strong> Dec;20(1):2206392.<br />

doi: 10.1080/15502783.<strong>2023</strong>.2206392. PMID:<br />

37133292; PMCID: PMC10158542.<br />

12) Saini R. Coenzyme Q10: The essential nutrient.<br />

J Pharm Bioallied Sci. 2011 Jul;3(3):466-<br />

7. doi: 10.4103/0975-7406.84471. PMID:<br />

21966175; PMCID: PMC3178961.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

11

Join the<br />

Ingredients<br />

biggest EU<br />

ingredient event<br />

this November<br />

IN-PERSON 28-30 November, Frankfurt, Germany<br />

fi-europe.eu/harnisch23<br />

12

Ingredients<br />

Synergy Flavors Celebrates 140 Years of<br />

Flavor Extraction Expertise in Italy with<br />

New Hop Essences Range in Europe<br />

Synergy Flavors is introducing a new<br />

range of hop essences to celebrate 140<br />

years of flavor extraction at its site in<br />

Trieste, Italy. Synergy acquired the site,<br />

formerly named Janoušek, in 2018, to<br />

expand its European footprint and to<br />

maintain and build on the organisation’s<br />

reputation for high quality extracts and<br />

natural flavorings.<br />

The hop essences have been developed<br />

at the site in Trieste, a result of the Italian<br />

team’s heritage in flavors and extraction<br />

of natural ingredients combined with<br />

the expertise of Synergy’s colleagues in<br />

the US. The essences, which are suitable<br />

for both alcoholic and non-alcoholic<br />

beers, are the newest addition to the<br />

Synergy Pure range, and are currently<br />

available in three varieties: Chinook, an<br />

earthy sweet hop which is well suited<br />

to ales and stouts; Centennial, which<br />

possesses floral and tropical notes,<br />

suited to pale ales, IPAs and bitters; and<br />

a hop variety from Slovenia (SL) that is<br />

best paired with pilsners and lagers due<br />

to its earthy notes and floral and fruity<br />

aromas.<br />

The hop essences comprise only hops<br />

and water to ensure a clean taste<br />

delivery without any added bitterness,<br />

and can also be used to mitigate the<br />

overly-sweet notes which can sometimes<br />

be present in non-alcoholic beers.<br />

The steam-distillation process used to<br />

extract the hop essences can help save<br />

time, reduce costs, and improve yield<br />

compared to traditional dry-hopping<br />

processes. The essences are declarable<br />

on-pack as natural hop extract.<br />

Janoušek opened its doors in October<br />

1883, as one of the world’s first suppliers<br />

of herbal extracts and natural flavorings.<br />

After 135 years of serving customers<br />

across Italy and continental Europe,<br />

Janoušek was acquired by Synergy<br />

Flavors, part of the Carbery Group, in<br />

2018. Synergy Italy has a firmly rooted<br />

connection to the community of Trieste,<br />

where it continues to deliver sustainable<br />

initiatives and provide employment<br />

opportunities. The Mayor of Muggia,<br />

Paolo Polidori, is attending the local<br />

140-year anniversary celebrations at<br />

the Synergy site to thank the company<br />

for its long-standing contribution to the<br />

area.<br />

As well as enhancing Synergy’s global<br />

portfolio of flavorings and essences, the<br />

Trieste operation also supports Carbery<br />

Group in its dairy and nutrition market<br />

offering, enabling Synergy to provide<br />

local support in Continental Europe,<br />

while improving access to the Middle<br />

East and North Africa.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

13

Ingredients<br />

Since the acquisition, Synergy Italy has<br />

achieved strong growth, with an 82%<br />

increase in sales revenue between April<br />

2018 and June <strong>2023</strong>. The team has also<br />

grown by 64% in the same period, with<br />

minimal staff turnover following the<br />

acquisition.<br />

Eric Zabiolle, Managing Director and<br />

Head of Sales Europe, Synergy Italy,<br />

comments: “We are very excited to<br />

be celebrating such an important<br />

anniversary in our company’s history.<br />

From the traditional extraction<br />

techniques employed by Janoušek<br />

that are still in operation today, to the<br />

modern steam distillation extraction<br />

process which we used to develop<br />

our hop essences, Synergy is proud<br />

to showcase its Italian heritage and<br />

craftsmanship. We look forward to<br />

continuing to serve food and beverage<br />

customers around the region and<br />

supporting Synergy’s global operation<br />

with Italian-made essences and<br />

flavors.”<br />

Sebastiano Pagano, CEO, Synergy<br />

Flavors Europe, comments: “140<br />

years is an impressive milestone in<br />

any company’s history, and to still be<br />

helping customers internationally with<br />

their flavor requirements is testament<br />

to the passionate and skilled people<br />

who have been part of the company’s<br />

journey over the years. We continue to<br />

invest in Synergy Italy and look forward<br />

to another 140 years of innovative taste<br />

solutions.”<br />

PROCESS TECHNOLOGY&COMPONENTS<br />

The cross-sectoral media platform for suppliers and<br />

users in two languages: German and English<br />

© AERZEN<br />

Exclusive information around the pump and compressor<br />

industry as well as systems and components<br />

14<br />

Developments and trends<br />

First-hand future technology<br />

Targeted at international trade shows for 2024<br />

New since 2022: „Green Efficient Technologies“<br />

is published 4 times a year<br />

Dr. Harnisch Verlags GmbH · Eschenstr. 25 · 90441 Nuremberg · Tel.: +49 (0) 911 - 2018 0 · info@harnisch.com · www.harnisch.com

Ingredients<br />

The International Brewing<br />

& Cider Awards<br />

The Oscars of the international brewing<br />

and cider world since 1886.<br />

The world’s most historic international beer and cider<br />

competition, the International Brewing & Cider Awards<br />

is expanding. For the first time in its 137-year history,<br />

the Awards will take place in Manchester, UK in March<br />

2024, which will see industry professionals gather to<br />

celebrate the extraordinary and well-crafted beers<br />

and ciders from all corners of the world.<br />

The Awards will be accompanied by a public festival –<br />

The International Brewing & Cider Festival – a two-day<br />

ticketed event for the public, showcasing the range of<br />

beers and ciders entered into the competition from<br />

around the globe.<br />

Founded in 1886, The International Brewing &<br />

Cider Awards takes place every two years and has<br />

been the gold standard in rewarding the passion<br />

and craftsmanship of breweries and<br />

cidermakers worldwide.<br />

Brewers and cidermakers are encouraged to<br />

submit their finest beers and ciders for evaluation by<br />

a panel of global judges, who are all practicing<br />

brewers and cidermakers.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

15

Ingredients<br />

Drinking for your Health<br />

by DONNA BERRY<br />

“Food as medicine” is gaining<br />

momentum as consumers take health<br />

into their own hands. In response,<br />

beverage formulators are exploring the<br />

use of functional ingredients. Some<br />

have scientifically proven benefits, while<br />

others have a healthful halo that has<br />

been in place since the dawn of time.<br />

And with some functional ingredients,<br />

real benefits are yet to be determined.<br />

Regardless, today’s consumers wants<br />

in. They are raising their glass, can, cup<br />

or bottle and making a toast to their<br />

wellness journey.<br />

Beverages as delivery vehicle<br />

Functional foods come in varied formats;<br />

however, the number-one delivery<br />

vehicle for functional ingredients is<br />

beverage. Providing that the functional<br />

ingredients dissolve, beverages allow for<br />

a homogenous solution with a specified<br />

amount of the functional ingredient.<br />

Juices and smoothies packed with<br />

vitamins and antioxidants fueled this<br />

trend, which is now led by energy, with<br />

immunity gaining momentum.<br />

The top-tier functional ingredients are<br />

fairly mainstream. The most common<br />

is caffeine, followed by superfoods<br />

such as blueberries and spinach, then<br />

electrolytes, antioxidants, probiotics<br />

and added protein, according to a survey<br />

of 2,000 internet users aged 18 or older<br />

conducted by Kantar Profiles/Mintel in<br />

December 2022.<br />

“While their functionality may be a<br />

known added benefit, they may not<br />

always be the intentional catalyst to<br />

consumption,” according to said Doug<br />

Resh, director-commercial marketing,<br />

T. Hasegawa USA, Cerritos, California.<br />

“Conversely, nascent functional<br />

ingredients, like prebiotics, melatonin or<br />

adaptogens, may be sought out for their<br />

benefits among their niche audiences.”<br />

Consumer preferences for “added<br />

functional benefits” vary by gender.<br />

Skin support was important to 58% of<br />

women vs. 44% of men, while muscle<br />

recovery was important to 44% of<br />

men vs. 35% of women, according<br />

to Kerry’s “Functional Forecasting:<br />

The Role and Relevance of Health-<br />

Enhancing Ingredients in Beverages<br />

and Supplements” report. Immune<br />

support, however, was universal, with<br />

53% saying they would drink beverages<br />

that contained ingredients specific to<br />

immune support.<br />

Some of the micronutrients gaining<br />

traction in new beverages are botanicals,<br />

some of which are described as<br />

adaptogens, as well as nootropics. The<br />

latter is a term with the Greek translation<br />

of “towards the mind” and refers to<br />

compounds that directly or indirectly<br />

influence cognitive brain function.<br />

Examples include ashwagandha,<br />

citicoline and green tea extract.<br />

Adaptogens, on the other hand, are a<br />

class of non-toxic herbs, mushrooms<br />

and minerals known to boost the<br />

immune system and help the body fight<br />

off the effects of stress. These plantbased<br />

compounds have been used for<br />

centuries in Chinese and Ayurvedic<br />

healing traditions. Ginseng, for example,<br />

is said to regulate the body’s response<br />

to physical or mental stress.<br />

Ashwagandha is one of the fastestgrowing<br />

nootropics in the market. It<br />

is an evergreen shrub found in India,<br />

Africa and parts of the Middle East<br />

that has long been used in Ayurvedic<br />

medicine to increase energy, improve<br />

overall health and reduce inflammation,<br />

pain and anxiety.<br />

With all of these ingredients, proper<br />

dosing is necessary for the consumer<br />

to reap any purported benefits. This<br />

is why most applications are sold as<br />

individual servings in order to guarantee<br />

a specified amount of the compound.<br />

Recent innovations<br />

Ashwagandha is one of five key<br />

ingredients in Juni, a new sparkling tea<br />

brand. Each can of Juni is infused with<br />

what the company calls its “super-5”<br />

16

Ingredients<br />

blend, which consists of green tea, lion’s<br />

mane, acerola cherry, reishi mushroom<br />

and ashwagandha. Juni has zero<br />

sugar and contains only five calories.<br />

The product was designed to provide<br />

calmness to the mind, a refreshing<br />

vitality to the body and a burst of<br />

brightness to the day, according to<br />

Radhi Devlukia, co-founder.<br />

San Diego, California-based Geno<br />

develops and scales sustainable<br />

materials derived from plant-based<br />

feedstocks instead of fossil fuels. The<br />

company has entered the functional<br />

foods space with a natural (R)-1,3<br />

butanediol that is a palatable, affordable<br />

and effective ketogenic ingredient,<br />

according to Terry Kitagawa, nutrition<br />

product development manager. It<br />

offers a fast and easy way to raise betahydroxybutyrate<br />

(BHB) ketone levels,<br />

the primary energy source made in the<br />

body during ketosis.<br />

Studies have shown that ketone<br />

supplementation elevates BHB levels,<br />

providing a readily available energy<br />

source that can help boost mental clarity<br />

and athletic performance. Beverages<br />

are a popular application. The ingredient<br />

is made from plant sugars using Geno’s<br />

sustainable, proprietary fermentation<br />

process. It is vegan and also free of<br />

caffeine, gluten, salt and sugar.<br />

Vitanav Inc., Washington, D.C., for<br />

example, uses natural (R)-1,3 butanediol<br />

in Kenetik, a ketone energy drink that<br />

has been shown to increase brain activity<br />

associated with focus and creativity by<br />

17%. Kenetik contains no sugar and no<br />

caffeine and is flavored with fruit and<br />

sweetened with allulose and stevia.<br />

Mainstream juices and smoothies are<br />

now adding functional ingredients that<br />

support immunity. Uncle Matt’s Organic,<br />

Clermont, Florida, for example, is<br />

rolling out Superfruit Punch. It’s made<br />

with dark sweet cherries, blueberries<br />

and black elderberry. The antioxidantboosted<br />

beverage is just 45 calories per<br />

8-ounce serving and has no cane sugar,<br />

preservatives or added flavors.<br />

Earlier in the year, the company debuted<br />

Ultimate Wellness Juice Shots in two<br />

varieties, both containing live probiotics,<br />

vitamins C and D, and zinc. The<br />

“Defense” variety combines orange and<br />

pineapple juices with 500 milligrams of<br />

anti-inflammatory whole root organic<br />

turmeric, along with black pepper, which<br />

has been shown to assist with turmeric<br />

absorption. “Immune” is orange juice<br />

packed with black elderberries.<br />

“Today’s consumer is looking to<br />

beverages as a convenient and tasty way<br />

to supplement key nutrients,” said Matt<br />

McLean, founder and chief executive<br />

officer of Uncle Matt’s Organic.<br />

Natalie’s Orchid Island Juice Co.,<br />

Fort Pierce, Florida, has added freshsqueezed<br />

tomato juice enhanced with<br />

reishi mushrooms to its lineup. The reishi<br />

mushroom is associated with a variety<br />

of potential health benefits, including<br />

boosting the immune system, reducing<br />

risk of certain cancers, reducing<br />

depression and fatigue, among others.<br />

This functional, perishable juice joins<br />

others from the company. Resilient<br />

Juice, for example, is an immuneboosting<br />

blend of vitamin C-packed<br />

blood oranges, elderberry, turmeric and<br />

ginger. Aura Juice is a blend of blood<br />

orange juice and strawberry puree<br />

enhanced with ashwagandha.<br />

Chicago, Illinois-based 120/Life, has<br />

developed a functional juice marketed<br />

under the same name. It is made with<br />

only six natural ingredients, each shown<br />

in clinical studies to improve blood<br />

pressure numbers. They have properties<br />

similar to many of the same medications<br />

prescribed by doctors, according to the<br />

company.<br />

For example, many doctors will prescribe<br />

a diuretic as a first medication against<br />

high blood pressure. 120/Life contains<br />

hibiscus, which is a natural diuretic<br />

that retains potassium. Doctors<br />

also often prescribe an angiotensinconverting-enzyme<br />

(ACE) inhibitor. The<br />

pomegranate in 120/Life is a natural<br />

ACE inhibitor.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

17

Ingredients<br />

“This is a beverage with a purpose,” said<br />

Ira Antelis, founder. “It allows individuals<br />

to easily and conveniently consume in<br />

the name of their health.”<br />

The other ingredients include tart<br />

cherry, which has a deep, rich flavor,<br />

and serves as a potent source of<br />

anthocyanins, which are known for<br />

their anti-inflammatory and antioxidant<br />

properties. This helps alleviate muscle<br />

soreness and support joint health.<br />

Cranberry contains an abundance<br />

of phytochemicals and supports<br />

urinary tract health. Beetroot is an<br />

earthy vegetable that is a nutritional<br />

powerhouse. It is packed with nitrates<br />

that promote healthy blood flow and aid<br />

in maintaining optimal blood pressure<br />

levels. And lastly, magnesium, which<br />

is known as nature’s calming mineral,<br />

plays a vital role in more than 300<br />

enzymatic reactions within the body.<br />

Magnesium supports muscle and nerve<br />

function, reduces fatigue and promotes<br />

relaxation. Together, these ingredients<br />

work synergistically to provide a natural<br />

and effective solution for individuals<br />

seeking to manage their blood pressure<br />

without compromising taste or<br />

convenience, according to Antelis.<br />

Sports enthusiasts and athletes have<br />

their own specific dietary desires in the<br />

beverages they consume before, during<br />

and after activity. While refuel, replenish<br />

and rehydrate are the basis of most<br />

products, the category continues to<br />

evolve as science advances.<br />

“The sports nutrition category is huge,<br />

yet there is a major void in plant-based<br />

proteins that can effectively meet an<br />

elite athlete’s needs to build muscle<br />

and fuel recovery,” said James Wilks,<br />

founder of FȲTA (pronounced as “fightah”),<br />

a portfolio of high-performance<br />

sports nutrition powders made from<br />

upcycled barley protein.<br />

The protein comes from St. Louis, Missouribased<br />

EverGrain, AB InBev’s sustainable<br />

ingredient business. EverGrain’s team<br />

of scientists spent nearly a decade<br />

developing proprietary technologies,<br />

production processes and techniques to<br />

transform spent barley grain, a nutritious<br />

byproduct of the brewing process, into<br />

a high-quality protein ingredient that<br />

is soluble and viscous without being<br />

gritty or bitter. Research shows that its<br />

bioavailability, digestibility and speed<br />

of absorption makes it appropriate for<br />

sports and nutrition beverages, according<br />

to the company.<br />

Wilks said that upcycled barley protein<br />

enabled him to finally realize his vision<br />

for creating a line of plant-based<br />

performance products. A serving<br />

contains 30 grams of protein, along with<br />

3 grams of fiber and only 1 gram added<br />

sugar with zero artificial ingredients,<br />

flavors or preservatives. It was designed<br />

to contain all of the essential amino acid<br />

amounts needed for optimal muscle<br />

build, growth and recovery and has one<br />

of the highest, fastest protein absorption<br />

levels.<br />

Another recent sports nutrition<br />

innovation comes from Nuritas, Dublin,<br />

Ireland, a company using artificial<br />

intelligence to identify, unlock, clinically<br />

test and patent peptides. The technology<br />

turns peptides into powerful and precise<br />

ingredients that elevate natural efficacy<br />

of proteins.<br />

Nuritas teamed up with GNC, Pittsburgh,<br />

Pennsylvania, to launch Beyond Raw<br />

Dynamic Whey High-Tech Protein<br />

enhanced with PeptiStrong. PeptiStrong<br />

is Nuritas’ advanced plant-based solution<br />

for muscle recovery. These patented<br />

plant peptides augment the functions of<br />

whey proteins. They have three proven<br />

actions: boost muscle protein synthesis,<br />

reduce markers associated with muscle<br />

breakdown and decrease exerciseinduced<br />

inflammation. As a result, users<br />

experience more effective workout<br />

benefits, shorter recovery times and<br />

reduced muscle fatigue, according to<br />

Nora Khaldi, founder and chief executive<br />

officer of Nuritas.<br />

“Consumers can expect to experience<br />

a reduction in fatigue in the days after<br />

training,” said Khaldi. “This enables<br />

gym-goers to train better, and to train<br />

more often; helping them to reach<br />

their personal best. Whey provides the<br />

building blocks while peptides provide<br />

the cell-signal to help the body make the<br />

best use of nutrition and superpower<br />

the results.”<br />

Resh concludes, “Consumers are thirsty<br />

for even more. They are seeking easy and<br />

versatile ways to achieve health goals<br />

through meals, snacks and anything in<br />

between.”<br />

The Author<br />

Donna Berry is a food and beverage industry<br />

consultant and editor with over 25 years experience<br />

in tracking trends and advancements in<br />

product development.<br />

18

Processed Dates: Natural Sweetening<br />

Alternatives<br />

Ingredients<br />

Tunisia is one of the largest date<br />

exporters in the world. More than 200<br />

different date varieties grow in Tunisia,<br />

the most widespread being the Deglet<br />

Nour variety. Although the focus of<br />

Tunisian agriculture is on the export of<br />

fresh dates, the offer of processed dates<br />

is also growing. Dates can be processed<br />

into a variety of products: Syrup,<br />

powder, paste, juice from the fruits. The<br />

kernels can also be used to produce<br />

oil and coffee substitutes. The sugar<br />

alternatives such as date paste, powder<br />

and syrup impress with their taste<br />

and nutritional profile. The PAMPAT<br />

Tunisia project, implemented by the UN<br />

Industrial Development Organization<br />

(UNIDO) and financed by the Swiss State<br />

Secretariat for Economic Affairs (SECO),<br />

supports the marketing of date products<br />

on the national and international market<br />

together with other partners from the<br />

private and public sector. At this year's<br />

Anuga in Cologne, PAMPAT Tunisia<br />

organised a cooking show together with<br />

the Tunisian export promotion agency<br />

CEPEX to demonstrate the taste and<br />

uses of processed dates.<br />

2nd choice dates that cannot be sold as a<br />

fresh product are processed into natural<br />

sweeteners. Date syrup, for example, also<br />

contains minerals and vitamins from the<br />

date fruit compared to ordinary sugar<br />

(sucrose). Deglet Nour dates are rich<br />

in potassium, but also contain calcium,<br />

magnesium and B vitamins. Another<br />

advantage: date syrup has significantly<br />

fewer calories than sucrose. The date<br />

products consist mainly of fructose and<br />

retain the typical date flavor. Date syrup<br />

tastes less sweet than sugar and is good<br />

for sweetening mueslis and desserts,<br />

for example, but also as an ingredient in<br />

smoothies and mixed drinks.<br />

"We like to use alternative sweeteners<br />

in our recipes," says star chef Julia<br />

Komp from Cologne ("Sahila") at<br />

Anuga. "Especially if they contain<br />

valuable nutritional values in addition<br />

to the sweetness. Date syrup is<br />

also vegan and thus a good honey<br />

alternative. We appreciate date<br />

sweetness, also because it gives<br />

dishes an oriental touch." Date syrup<br />

is a good alternative to honey, maple<br />

syrup, agave syrup, sugar beet syrup<br />

etc. In the production process, dates<br />

are cooked and the date juice is<br />

extracted. The juice is then boiled<br />

down to syrup.<br />

Date products are still little known,<br />

but there is great potential because<br />

alternative natural, healthy and vegan<br />

sweeteners are in demand. "Almost<br />

one in three dates is not suitable for<br />

marketing as fresh dates”, explains<br />

Nuria Ackermann, Chief Technical<br />

Advisor of the PAMPAT Project (UNIDO).<br />

"And this proportion of 2nd choice dates<br />

will increase as global warming will<br />

reduce date quality. But with processed<br />

dates and the wide range of products,<br />

Tunisia has an opportunity to develop<br />

a new segment and add value. Through<br />

processing, 2nd choice dates can<br />

increase in value by five times."<br />

Examples of date products - their use and production:<br />

• Date paste: Alternative to conventional sugar. Rich in dietary fibre. Currently the main<br />

product with a production volume of around 10,000 tons<br />

• Date puree: Mainly consumed as an end product or used in fruit juices, cocktails and jams.<br />

Dates are blanched and kneaded in hot water, then cooked at low heat and crushed<br />

• Date powder: Substitute for refined sugar, especially in baking. Production steps are<br />

cleaning, pitting, drying at 70° C, grinding and sieving the dates<br />

• Liquid sugar: Alternative to sugar with a neutral taste, sweetener with high sweetening<br />

power, about 1.7 times as strong as normal sugar and low glycaemic index (11.9 g).<br />

To make it, dates are ground in water to obtain a kind of juice. The juice is purified,<br />

decolorised and concentrated by evaporation at 70° C.<br />

• Date syrup: Alternative to honey, maple syrup, etc. Juice is extracted from cooked dates,<br />

which is boiled down to syrup<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

19

Fi Europe<br />

Step into a World of Ingredients at Fi<br />

Europe <strong>2023</strong><br />

The tastemakers of the world will come together when Fi Europe returns to Frankfurt from<br />

28-30 November.<br />

Food & beverage professionals are<br />

invited to step inside a microcosm of<br />

the ingredients world at this year’s Fi<br />

Europe. With 135 countries represented,<br />

over 25,000 visitors and 1,200 exhibitors<br />

are expected to come together under<br />

one roof, resulting in a rich, immersive<br />

opportunity to experience the energy of<br />

invention and profitable connection.<br />

This year’s event blends real-world<br />

and digital interactions through the<br />

Fi Europe Event Platform, which will<br />

be open online pre- and post-show,<br />

extending the possibilities for exhibitors<br />

and visitors to discover new business<br />

opportunities, connect with the right<br />

people and be inspired by the latest<br />

industry trends and innovations. It also<br />

allows attendees to maximize their time<br />

in Frankfurt and prepare for the onsite<br />

event by planning a personalized<br />

agenda, bookmarking sessions they<br />

want to attend and reaching out to<br />

suppliers to set up meetings.<br />

Fi Europe’s winning formula combines<br />

a bustling show floor with an insightful<br />

conference line-up. In the exhibition<br />

hall, attendees can access an unrivalled<br />

breadth of products spanning the entire<br />

food & beverage supply chain. The<br />

global exhibitor base includes many<br />

high-profile names, from all parts of the<br />

food and beverage industry.<br />

The Future of Nutrition Summit (27<br />

November) and Fi Europe Conference<br />

(28-29 November) will provide<br />

exclusive, paid-for content that cannot<br />

be accessed elsewhere. It is focused<br />

on addressing current challenges and<br />

identifying immediate opportunities<br />

in the F&B industry. Its stellar speaker<br />

line-up includes Kalina Doykova, Senior<br />

Research Analyst at Euromonitor<br />

International, and Cyrille Filott, Global<br />

Strategist at Rabobank.<br />

The Future of Nutrition Summit offers a<br />

deep dive into disruptive technologies<br />

and solutions that have the potential to<br />

reshape the industry. Delegates will hear<br />

from presenters such as Floor Buitelaar,<br />

Managing Partner at Bright Green<br />

Partners; Mario Ubiali, Founder & CEO of<br />

Thimus; and Christine Gould, Founder &<br />

CEO of Thought For Food. Free-to-attend<br />

content will be offered at the Innovation<br />

Hub and Sustainability Hub.<br />

Yannick Verry, Brand Manager, Food Ingredients<br />

Europe and Americas<br />

The growing importance of sustainability<br />

as an industry challenge will be reflected<br />

in the event highlighting issues such<br />

as sustainable sourcing, labels and<br />

transparency, regulatory compliance,<br />

ESG, gender equity, and more. As<br />

part of its ongoing commitment to<br />

sustainability, Informa has recently<br />

partnered with the international civil<br />

society organisation Solidaridad.<br />

Through the Sustainability Hub, visitors<br />

can find out how Solidaridad’s work<br />

in creating sustainable supply chains<br />

globally can help with ethical and<br />

sustainable ingredient sourcing.<br />

In addition to the numerous informal and<br />

impromptu interactions that an industry<br />

gathering on this scale provides, there<br />

will be several organized networking<br />

opportunities. Data-driven matchmaking<br />

offers a scientific approach to making<br />

connections, and female professionals<br />

can look forward to inspiring others and<br />

being inspired at the popular Women’s<br />

Networking Breakfast.<br />

As well as encouraging diversity<br />

in all forms, Fi Europe champions<br />

20

Fi Europe<br />

innovation and excellence through its<br />

award programmes. The Fi Innovation<br />

Awards celebrate individuals and<br />

businesses breaking new ground and<br />

making a difference in the industry.<br />

They culminate in an evening awards<br />

ceremony held on Tuesday, 28<br />

November. The Startup Innovation<br />

Challenge offers a springboard for<br />

young companies with disruptive<br />

potential. Attendees can watch these<br />

startups pitch their concepts to a panel<br />

of investors, accelerators and influential<br />

industry players at the Innovation Hub<br />

on 28 November.<br />

Yannick Verry, Brand Manager, Food<br />

Ingredients Europe and Americas, says:<br />

“This year’s Fi Europe includes all the<br />

ingredients that food and beverage<br />

tastemakers need to innovate and grow<br />

their businesses, from expert content<br />

sessions to targeted networking<br />

opportunities and a show floor<br />

brimming with ideas. I am very excited<br />

about the collective transformational<br />

power of all of these elements and<br />

cannot wait to see what creativity and<br />

connections ensue from this melting<br />

pot of talent.”<br />

A Leap Forward in Beverage Carbonation<br />

<strong>Technology</strong><br />

The cutting-edge Armfield FT102XA<br />

miniature scale carbonator and filling<br />

system will be shown at Fi Europe at<br />

Booth 3.1 B140 and is ready to amaze<br />

the industry. With a remarkable 25 years<br />

of expertise in carbonation, Armfield<br />

proudly stands at the forefront of<br />

this game-changing technology. The<br />

precision and consistency it brings to<br />

carbonation experiments in the lab<br />

promises to accelerate new product<br />

development in unprecedented ways.<br />

Tailored for carbonating and filling a<br />

wide spectrum of beverages, including<br />

soft drinks, beer, milk, and juices,<br />

this versatile system effortlessly<br />

accommodates most cans, PET, and<br />

glass bottles. Whether you're into<br />

pre-mix or post-mix operations, this<br />

remarkable machine offers it all, with<br />

the added convenience of an optional<br />

automated syrup addition for post-mix<br />

concoctions. With a new CO 2<br />

scavenging<br />

system, Carbon Dioxide can be recycled<br />

back into the product to reduce CO 2<br />

consumption.<br />

The FT102XA Carbonator boasts a userfriendly<br />

installation, setup, and operation,<br />

thanks to its intuitive touchscreen control<br />

featuring a brand-new graphical interface.<br />

This HMI empowers you to configure<br />

and store various carbonation and filling<br />

parameters with ease. The semi-automatic<br />

cleaning program has also received<br />

enhancements, ensuring swift readiness<br />

for your next product or formulation.<br />

What's even more exciting is that<br />

combining the FT102XA with the FT104X<br />

opens doors to invaluable insights for<br />

scaling up to pilot or production plant<br />

levels, revolutionizing the pace of new<br />

product development. In the realm<br />

of carbonation and filling, Armfield is<br />

leading the way with the FT102XA, an<br />

innovation that promises to redefine<br />

your beverage creation process.<br />

Armfield Ltd make a range of<br />

miniature-scale research equipment<br />

for the food and beverage industry<br />

including UHT/HTST processors, ice<br />

cream and margarine makers, spray<br />

dryer/chillers, rapid extractors, edible<br />

oils processors, aseptic fillers, and<br />

homogenisers.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2023</strong><br />

21

Fi Europe<br />

Sustainable Production of High-Quality<br />

Extracts with Carbon Dioxide<br />

Natural extracts are widely used in food production. They are valued for their aroma, used<br />

as a natural colouring ingredient and in food supplements, for example, for their healthpromoting<br />

properties. The range of extracts from developing and emerging countries is<br />

huge and therefore enriches the offer on the EU market. The Import Promotion Desk (IPD),<br />

a project of the German Federal Ministry for Economic Cooperation and Development<br />

(BMZ), works with small and medium-sized companies in 16 partner countries which<br />

specialise in the production of high-quality extracts. They utilise indigenous plants and<br />

regional agricultural products, such as ginger, turmeric, black cumin, coriander, cardamom<br />

and coffee. Among them are companies which use the CO 2<br />

extraction method to obtain<br />

extracts from the raw plant material. “Apotec Bay Botanical Solutions” from Egypt and<br />

“Actifs Préciuex” from Tunis are two companies that use the CO 2<br />

extraction, which will<br />

be represented at this year’s Food Ingredients Europe (FiE) from 28 to 30 November in<br />

Frankfurt at Booth 4.0 F202.<br />

Extraction under pressure<br />

CO 2<br />

extraction uses carbon dioxide as<br />

a natural and environmentally friendly<br />

solvent. In the extraction process, CO 2<br />

is used in the so-called “supercritical”<br />

state of aggregation. In this state, CO 2<br />

has the characteristics of both a gas and<br />

a liquid. Heated and compressed under<br />

very high pressure, the CO 2<br />

penetrates<br />

the smallest pores of the raw material<br />

and dissolves out the desired substance.<br />

By lowering the pressure and heating,<br />

the CO 2<br />

becomes gaseous again and<br />

volatilises completely. This is how the<br />

pure extract is released. The advantage<br />

of CO 2<br />

is that it is very versatile as a<br />

solvent. By controlling temperature and<br />

pressure, CO 2<br />

can be used for various<br />

extraction processes and produce very<br />

different extracts.<br />

Further development of this technology<br />

has made it possible to increase the<br />

pressure significantly, thus reducing the<br />

duration of the process. Hence, the use<br />

of CO 2<br />

is not only sustainable, but also<br />

very efficient.<br />

Gentle oil extraction through<br />

C0 2<br />

extraction<br />

CO 2<br />

extraction enables the production<br />

of a pure oil that requires little to<br />

no post-processing. The Tunisian<br />

company "Actifs Précieux" relies on this<br />

sustainable and energy-efficient method<br />

for extracting high-quality natural<br />

ingredients. “This environmentally<br />

friendly approach offers numerous<br />

benefits, including preservation of<br />

heat-sensitive components, no solvent<br />

residues and a longer shelf life, which<br />

ultimately leads to cleaner and safer<br />

products”, summarises Hajer Derouiche<br />

from “Actifs Préciuex”. The Tunisian<br />

company has specialised in extraction<br />

based on natural raw materials from<br />

the Mediterranean region and Africa.<br />

They make products out of ginger, black<br />

cumin, mint, coriander seed and fruits,<br />

and Aleppo pine seeds, among others.<br />

Effective separation: pure<br />

extracts<br />

“Apotec Bay Botanical Solutions” from<br />

Egypt uses the CO 2<br />

method for its<br />

natural extracts, such as extracts of<br />

coffee, capsicum pepper, black pepper,<br />

cardamom, cinnamon and many more.<br />

“The process is not only considered to<br />

be the cleanest and gentlest method of<br />

extracting. It also increases the quality<br />

of the final product as it provides<br />

effective separation of the desired<br />

substance from the other components<br />

of the plant”, says Yousra Hafez from<br />

“Apotec Bay”.<br />

Wide range of extracts with<br />

multiple uses<br />

The use of extracts in the food industry<br />

is manifold: They are used as natural<br />

flavorings, colorings and aromas.<br />

In addition, extracts are used for<br />

their nutrient profile and associated<br />

additional benefits.<br />

For example, gingerol and shogaol are<br />

extracted from the ginger root. Gingerol<br />

and shogaol are responsible for the<br />

pungent ginger flavour and have an antiinflammatory<br />

effect at the same time.<br />

This extract has strong, warm and spicy<br />

ginger aroma, with a sharp and slightly<br />

bitter taste. It is used in functional foods<br />

and beverages, among others.<br />

Black cumin extract is rich in bioactive<br />

compounds such as thymoquinone and<br />

essential fatty acids, including linoleic<br />

and oleic acids. It is used as an ingredient<br />

in functional foods.<br />

An extract with a refreshing mint aroma<br />

is obtained from mint of the Mentha<br />

Spicata plant by CO 2<br />

extraction. It is<br />

often used in the food and beverage<br />

industry as a natural flavouring.<br />

22

<strong>Marketing</strong><br />

Registration Opens for the 2024<br />

International Brewing & Cider Awards<br />

Entries are now open for the 2024<br />

International Brewing & Cider Awards.<br />

Brewers and cidermakers from all<br />

around the globe are encouraged to<br />

submit their finest beers and ciders into<br />

the world’s most historic international<br />

competition of its kind.<br />

The International Brewing & Cider<br />

Awards is an unparalleled competition<br />

for brewers and cidermakers to have<br />

their products evaluated by a panel of<br />

commercially practicing brewers and<br />

cidermakers. Winners gain recognition<br />

on an international stage, showcasing<br />

their product as an outstanding example<br />

of its style.<br />

Founded in 1886, the event has become<br />