Manual and spare parts list aluminum slewing crane

Manual and spare parts list aluminum slewing crane

Manual and spare parts list aluminum slewing crane

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

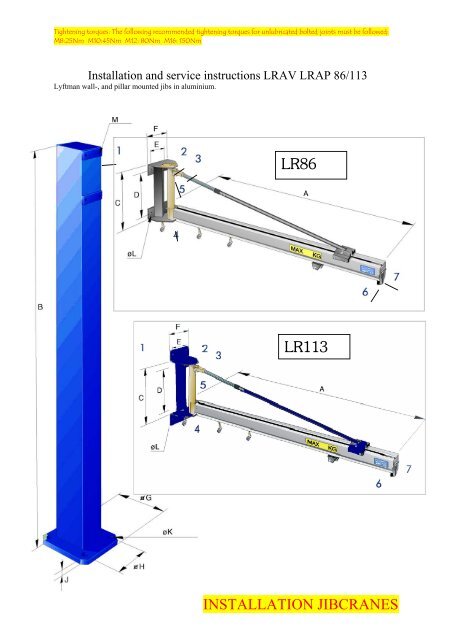

Tightening torques: The following recommended tightening torques for unlubricated bolted joints must be followed:<br />

M8:25Nm M10:45Nm M12: 80Nm M16: 150Nm<br />

Installation <strong>and</strong> service instructions LRAV LRAP 86/113<br />

Lyftman wall-, <strong>and</strong> pillar mounted jibs in aluminium.<br />

LR86<br />

LR113<br />

INSTALLATION JIBCRANES

Tightening torques: The following recommended tightening torques for unlubricated bolted joints must be followed:<br />

M8:25Nm M10:45Nm M12: 80Nm M16: 150Nm<br />

During design <strong>and</strong> installation it is vital to take into account relevant st<strong>and</strong>ards<br />

<strong>and</strong> regulations, the load bearing capacity of the floor/wall or other means of<br />

attachment <strong>and</strong> the relevant basic design information for the LR-System.<br />

Use only LR-System original <strong>parts</strong>.<br />

Follow recommended tightening torques.<br />

Installation preparations<br />

� Start by checking that all material is available in accordance with the order approval <strong>and</strong><br />

packing slips. It is advisable to do this when sorting the material in a suitable place where<br />

it will not be in the way of installation work.<br />

� Use only original LR-System components. When using supplementary bolts etc use only<br />

the specified grade.<br />

� Be accurate! Accuracy is a prerequisite for acheiving a reliable installation that works<br />

well. It is a must from personnel safety point of view. We have taken a great deal of care<br />

to ensure that the lifting device will be safe <strong>and</strong> you are the one to put the final touch to<br />

this work.<br />

� This <strong>crane</strong> is designed to be as light as possible, this facilitates the least possible rotation<br />

force. The <strong>crane</strong> is designed for SWL indicated on load capacity plate. Do not exceed the<br />

SWL. Choose a location where the <strong>crane</strong> can rotate through the complete working area.<br />

� Place the <strong>crane</strong> so that mainly the outer third of the jib is used, this will facilitate<br />

manoeuvering.<br />

� We recommend that, after completion of installation but before taking the unit into<br />

service, it be inspected by an accredited testing agency.<br />

� We are naturally at your service with hints <strong>and</strong> advice should you require them. It is better<br />

to ask once too much, nothing must be unclear!<br />

INSTALLATION JIBCRANES

Tightening torques: The following recommended tightening torques for unlubricated bolted joints must be followed:<br />

M8:25Nm M10:45Nm M12: 80Nm M16: 150Nm<br />

Installation of column<br />

Erect the column with the required foundation. It is vital that the column is chosen <strong>and</strong> installed<br />

according to the specifics of the floor in question. Contact your TAWI Lyftman representative if there<br />

are any uncertainties. Adjust the column until it is completely in a vertical position.<br />

Installation of bracket<br />

Bolt the wall bracket onto a wall or column. The choice of erecting method is dependant on existing<br />

conditions. Make sure that the wall bracket is in a vertical position, measure the angle of the axle tube<br />

with a spirit level.<br />

There are 4 pcs of bolt <strong>and</strong> 4 pcs locking nut included in the accessories box on delivery, which are to<br />

be inserted in the threaded hole of the column. Adjust the bracket <strong>and</strong> tighten the bolt. If the <strong>crane</strong> is<br />

of a low headroom model there are 4 pcs of bolt <strong>and</strong> 4 pcs of locking nuts in the accessories box<br />

which are to be inserted in the holes of the columns.<br />

Installation of jibarm<br />

Unscrew the bolt (2) that holds the shaft on the bracket. Assemble the shaft tube with the track <strong>and</strong><br />

fork (3) on the brace into the holder. It is important that the bolt (4) is tightened properly <strong>and</strong> that the<br />

forks split pin (5) is locked.<br />

Place the shaft tub into the bracket <strong>and</strong> assemble the shaft from the top, tighten the shaft to the bracket<br />

with the M6 bolt. The shaft should now be unable to rotate.<br />

The jib, which can be supplied with one or two braces depending on its length <strong>and</strong> load capacity,<br />

might need to be adjusted horizontally. The jib should rise towards its end with appr. 2 millimetres per<br />

meter.<br />

Adjust this by unloading the jib <strong>and</strong> loosening the split pin (5) <strong>and</strong> the fork from the holder. Rotate the<br />

fork in a suitable direction <strong>and</strong> reinsert the fork into the holder <strong>and</strong> insert the split pin. Check the angle<br />

again, carry out further adjustments if neccessary.<br />

Installation of tube holder <strong>and</strong> trolley<br />

Loosen the bolt (6) which holds the end piece (7) at the end of the jib <strong>and</strong> slide the tube holders <strong>and</strong><br />

the trolley into the track. Put the end piece back in place <strong>and</strong> retighten the bolt. The leatherstraps are<br />

designed to carry tubes for compressed air or vacuum. On the bracket the eyelet bolt with S-hook <strong>and</strong><br />

leather strap shall be attached to the tube.<br />

Make sure that the clip in the axle of the trolley is locked in place after installing the lifting equipment.<br />

Inspection<br />

Make sure that nothing blocks the jibs working area <strong>and</strong> that all bolts <strong>and</strong> nuts are sufficiently<br />

tightened. Please take extra care to inspect the rotation lock installation according to next page.<br />

The jib <strong>crane</strong> is supplied with selflubricating bearings for the rotation movement <strong>and</strong> in the trolley´s<br />

bearings. Lubrication is normally not needed. When the jib has been in operation for some time <strong>and</strong><br />

the cable trolleys tend to jam, the trolleys <strong>and</strong> track may be lubricated with teflon spray.<br />

To obtain maximum safety we recommend that all bolts are inspected <strong>and</strong> tightened regulary.<br />

Make sure that the rotation <strong>and</strong> trolley movements operate appropriately.<br />

The rotation lock <strong>and</strong> brace attachments must also be checked regularly. Action must be taken<br />

immediately at any sign of damage or wear: make sure the jib arm is not used until the worn <strong>parts</strong> have<br />

been replaced with original Lyftman <strong>spare</strong> <strong>parts</strong>.<br />

INSTALLATION JIBCRANES

Tightening torques: The following recommended tightening torques for unlubricated bolted joints must be followed:<br />

M8:25Nm M10:45Nm M12: 80Nm M16: 150Nm<br />

WARNING!<br />

Under no circumstances may any type of rotation obstacle be<br />

installed. Obstructing the range of movement results in stress <strong>and</strong><br />

strain to the material which can cause fractures to the jib arm <strong>and</strong><br />

brace causing the jib arm to fall down.<br />

Use manual force ONLY to stop the rotation of the jib arm at all<br />

times.<br />

INSTALLATION JIBCRANES

Arm:<br />

Jib <strong>crane</strong>s with arm in<br />

aluminium up to 125 kg<br />

LRAV/LRAP<br />

Type Load, A C D E F L Arm Weight,<br />

kg<br />

profile kg<br />

LRAV2/80 40-80 2000 577 507 110 150 14 LR86 12<br />

LRAV3/80 40-80 3000 577 507 110 150 14 LR86 15<br />

LRAV3-4/40 40 4000 577 507 110 150 14 LR86 18<br />

LRAV5/40 40 5000 577 507 110 150 14 LR86 19<br />

LRAV4/60 60 4000 577 507 110 150 14 LR86 19<br />

LRAV6/40 40 6000 860 800 150 200 18 LR113 65<br />

LRAV4/80 80 4000 860 800 150 200 18 LR113 55<br />

LRAV5/80 80 5000 860 800 150 200 18 LR113 60<br />

LRAV2/125 125 2000 860 800 150 200 18 LR113 45<br />

LRAV3/125 125 3000 860 800 150 200 18 LR113 50<br />

Column:<br />

Type For jib arm type** B G H J K M Weight,<br />

kg<br />

LPM15361 LRAV2/80 3610 250 200 20 18 M12 115<br />

LRAV3/80<br />

LRAV3-4/40<br />

LRAV5/40<br />

LRAV4/60<br />

LPM20386 LRAV6/40 3860 300 250 20 24 M16 170<br />

LRAV4/80<br />

LRAV5/80<br />

LRAV2/125<br />

LRAV3/125<br />

** Jib arm with 1 pce trolley, 3 pcs trolley for air tube with leather strap, end<br />

stop, load signs <strong>and</strong> 4 pcs M12-bolt.<br />

TAWI AB, Box 10205, Transportgatan 1, S-434 23 KUNGSBACKA, SWEDEN Tel 0046 300 185 00, Fax 0046 300 189 90<br />

Info@tawi.se<br />

www.TAWI.com<br />

COMPLETE SYSTEMS FOR SAFER LIFTING<br />

1

Arm:<br />

Lowbuilt jib <strong>crane</strong> with arm in<br />

aluminium up to 40 kg<br />

LRAV-L/LRAP-L<br />

Type Load, A C D E F L Arm<br />

kg<br />

profile<br />

LRAV2/40L 40 2000 300 232 110 150 Ø14 LR86<br />

LRAV3/40L 40 3000 300 232 110 150 Ø14 LR86<br />

LRAV3,5/40L 40 3500 300 232 110 150 Ø14 LR86<br />

Column:<br />

Type For jib arm<br />

type**<br />

B G H J K M<br />

LPM15361L LRAV2/40L<br />

LRAV3/40L<br />

LRAV3,5/40L<br />

Custom<br />

made<br />

300 250 20 Ø24 M16<br />

** Jib arm with 1 pce trolley, 3 pcs trolley for air tube with leather<br />

strap, end stop, load signs <strong>and</strong> 4 pcs M12-bolt.<br />

TAWI AB, Box 10205, Transportgatan 1, S-434 23 KUNGSBACKA, SWEDEN Tel 0046 300 185 00, Fax 0046 300 189 90<br />

Info@tawi.se<br />

www.TAWI.com<br />

COMPLETE SYSTEMS FOR SAFER LIFTING<br />

1

Underbraced jib <strong>crane</strong>s with arm in<br />

aluminium up to 25 kg<br />

Arm:<br />

LRAU<br />

Type Load, A C D E F L Arm<br />

kg<br />

profile<br />

LRAU2/25 25 2000 441 341 110 150 Ø14 LR113<br />

LRAU3/25 25 3000 441 341 110 150 Ø14 LR113<br />

Pelare:<br />

Type For jib arm<br />

type**<br />

B G H J K M<br />

LPM15361L LRAUPV2/25<br />

LRAUPV3/25<br />

Custom<br />

made<br />

250 200 20 Ø18 M12<br />

** Jib arm with 1 pce trolley, 3 pcs trolley for air tube with leather<br />

strap, end stop, load signs <strong>and</strong> 4 pcs M12-bolt.<br />

TAWI AB, Box 10205, Transportgatan 1, S-434 23 KUNGSBACKA, SWEDEN Tel 0046 300 185 00, Fax 0046 300 189 90<br />

Info@tawi.se<br />

www.TAWI.com<br />

COMPLETE SYSTEMS FOR SAFER LIFTING<br />

1

Spare <strong>parts</strong> jib <strong>crane</strong> type LRAV<br />

No. DESCRIPTION LRAVX/XXX Antal<br />

Art nr<br />

1. Aluminium profile L:XXXX mm 1 *<br />

2. End plate 1 83300<br />

3. Hexagonal screw M6x60 2 MC6S660<br />

4. Locking nut M6 2 M6MM6L<br />

5. Hexagonal screw M10x35 1 M6S1035<br />

6. Locking nut M10 1 M6MM10L<br />

7. Support brackets for staytube, lower 2 1R41821<br />

8. Assembling plate for staytube, lower 1 1R41934<br />

9. Staytube Al DIA25x2 1 1alrör25<br />

10. Hexagonal screw M6x35 4 MC6S635<br />

11. Locking nut M6 4 M6MM6L<br />

12. Assembling plate for staytube, upper 1 1R41758<br />

13. Threaded rod M12 L:200 mm 1 1M12200<br />

14. Toggle M12x48 with ES-bolt 1 1G1248<br />

15. Socket head cap screw M6x55 1 MC6S655<br />

16. Locking nut M6 1 M6MM6L<br />

17. Tubular shaft 1 1R41768<br />

18. Shaft 1 1R41774<br />

19. Screw M6x20 1 MC6S620<br />

20. Locking nut M6 1 M6MM6L<br />

21. Slide bearing 1 1BK1F20215<br />

22. Bracket 1 1R41679<br />

23. Column H:XXXX mm 1 *LPMXXXXXL<br />

24. Trolley 1 182100<br />

25. Cable trolley 1 184150<br />

26. Leather strap 1 144136<br />

27. S-hook 1 144135<br />

28. Eye-bolt 1 1ögla<br />

29. Hexagonal nut M5 1 M6MM5<br />

30. Tensilock screw M12x20 4 M6SF1220<br />

* Type of column <strong>and</strong> profile varies depending on capacity.<br />

See separate info.

Spare <strong>parts</strong> jib <strong>crane</strong> type LRAV-L<br />

No. DESCRIPTION LRAVX/XXXL (lowbuilt) Antal<br />

Art nr<br />

1. Aluminium profile L:XXXX mm 1 *<br />

2. End plate 1 83300<br />

3. Hexagonal screw M6x60 2 MC6S660<br />

4. Locking nut M6 2 M6MM6L<br />

5. Hexagonal screw M10x35 1 M6S1035<br />

6. Locking nut M10 1 M6MM10L<br />

7. Support brackets for staytube, lower 2 1R41821<br />

8. Assembling plate for staytube, lower 1 1R41934<br />

9. Staytube Al DIA25x2 1 1alrör25<br />

10. Hexagonal screw M6x35 4 MC6S635<br />

11. Locking nut M6 4 M6MM6L<br />

12. Assembling plate for staytube, upper 1 1R41758<br />

13. Threaded rod M12 L:200 mm 1 1M12200<br />

14. Toggle M12x48 with ES-bolt 1 1G1248<br />

15. Socket head cap screw M6x55 1 MC6S655<br />

16. Locking nut M6 1 M6MM6L<br />

17. Tubular shaft 1 1R41767<br />

18. Shaft 1 1R41773<br />

19. Screw M6x20 1 MC6S620<br />

20. Locking nut M6 1 M6MM6L<br />

21. Slide bearing 1 1BK1F20215<br />

22. Bracket 1 1R41759<br />

23. Column H:XXXX mm 1 *LPMXXXXXL<br />

24. Trolley 1 182100<br />

25. Cable trolley 1 184150<br />

26. Leather strap 1 144136<br />

27. S-hook 1 144135<br />

28. Eye-bolt 1 1ögla<br />

29. Hexagonal nut M5 1 M6MM5<br />

30. Tensilock screw M12x20 4 M6SF1220<br />

* Type of column <strong>and</strong> profile varies depending on capacity.<br />

See separate info.