drinkworld Technology + Marketing 2/2023

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ZKZ 62006<br />

ISSN 1433-1594 Vol. 27 No. 2 June <strong>2023</strong> US $ 12 · € 12<br />

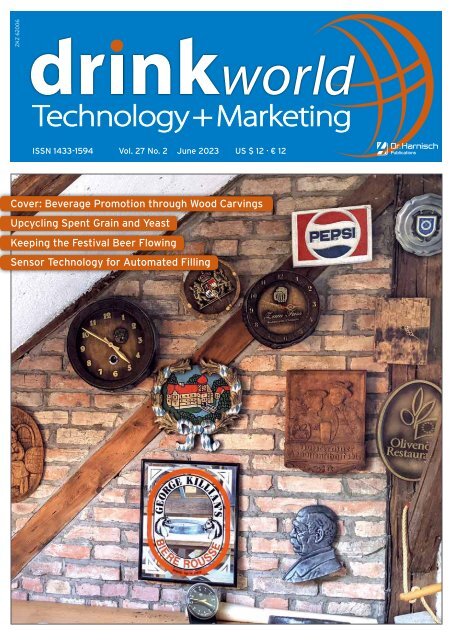

Cover: Beverage Promotion through Wood Carvings<br />

Upcycling Spent Grain and Yeast<br />

Keeping the Festival Beer Flowing<br />

Sensor <strong>Technology</strong> for Automated Filling

We understand how you strive for constant<br />

product quality and optimized costs.<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality<br />

requirements while optimizing resources and<br />

securing process repeatability.<br />

Endress+Hauser helps you to improve your processes:<br />

• With a hygienic, robust product portfolio that meets international<br />

standards<br />

• With access to traceable, reliable and real-time data<br />

• With a network of industry application experts that help you<br />

ensure greater plant availability throughout the product life cycle<br />

Do you want to learn more?<br />

www.eh.digital/3YWu4iG

Editorial<br />

Getting older, gracefully<br />

It’s no secret that the beverage<br />

industry targets consumers according<br />

to age groups. Probably more research<br />

dollars are invested into Generation Z<br />

than any other at the moment. This is<br />

because they are new and different to<br />

those before and less understood.<br />

Another fascinating age group is the<br />

older population, the baby boomers,<br />

now becoming silver agers. They,<br />

excuse me, we, are actually very easy<br />

to read and our needs are simple.<br />

Firstly there are a lot of us and we are<br />

staying around longer than before.<br />

This means this market is growing<br />

with some studies expecting around 2<br />

billion by 2050. This group has a big<br />

interest in staying healthy and mostly<br />

enjoys a disposable income to help<br />

it happen, especially in developed<br />

countries where independent living is<br />

more common.<br />

Manufacturers can look at this<br />

situation from two sides. Firstly, a lot<br />

more products are coming to market<br />

with active ingredients to address<br />

health and vitality issues, and secondly,<br />

on the practical side, package size<br />

and design is being revisited for those<br />

growing older and weaker, or with<br />

smaller appetites or family size.<br />

Anti-ageing beverages are very<br />

prolific and more of them are coming<br />

all the time. They are often made up<br />

of superfruits, lots of vitamins and<br />

minerals, various assorted botanical<br />

ingredients and with a dash of scientific<br />

research, all mixed together, lightly<br />

carbonated and then bottled in glass.<br />

Much of the sale may be the sizzle,<br />

but older people are notorious for not<br />

drinking enough, so there are certainly<br />

a lot of positive results. There is also<br />

a lot of variety, since combinations of<br />

the above are almost infinite and new<br />

ingredients are being trialled all the<br />

time.<br />

Transporting beverages is sometimes<br />

a big challenge for older people. This<br />

was leading to a growth in home<br />

delivery services even before Covid.<br />

Smaller bottles or cartons are practical<br />

for many reasons and it‘s good to see<br />

sensible coming back into fashion.<br />

Another trend which silver agers<br />

are embracing is the Home Brewing<br />

Ian D. Healey<br />

Editor-in-Chief<br />

concept. Of course, this is not restricted by<br />

age group and indeed recent figures from<br />

the German Federation of Brewers (DBB)<br />

show that the number of registered home<br />

brewers has tripled in the past eight years.<br />

That‘s good news for sure.<br />

As we said above, it is important for people<br />

of my age to drink enough fluids. Whether<br />

this comes as a functional drink with fruits<br />

and vitamins or a unique self-made brew of<br />

hops, malt and yeast, the water is the key<br />

to staying fit and healthy for longer.<br />

Cheers<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong> 3

12.09.22 15:54<br />

Contents<br />

hnology<br />

d food<br />

ZKZ 62006<br />

ISSN 1433-1594 Vol. 27 No. 2 June <strong>2023</strong> US $ 12 · € 12<br />

Cover: Beverage Promotion through Wood Carvings<br />

Upcycling Spent Grain and Yeastand<br />

Keeping the Festival Beer Flowing<br />

Sensor <strong>Technology</strong> for Automated Filling<br />

Issue 2 · June <strong>2023</strong><br />

For more than 60 years, promotional items for beer and beverages have<br />

been produced in the "Atelier Zillich", an old four-storey farmhouse near<br />

Tutzing, Germany. These are barrel bottoms, clocks, coats of arms and tap<br />

plates. <strong>drinkworld</strong> talked with Peter Zillich, Craftsman and Collector about<br />

his life's work.<br />

Our cover story starts on page 6.<br />

Cover: Atelier Zillich<br />

Ingredients<br />

10 Premiumization of Water<br />

16 Case Study: Upcycling BSG Waste to<br />

Produce Value-Added By-Products<br />

Processing<br />

20 How one OEM is Engineering with Sustainability in<br />

Mind<br />

23 For Efficient Applications in the Lab: Scale Up<br />

Your Automation<br />

24 Supplying Beverages at Large Events<br />

About 39 million tons of brewer’s spent grain (BSG)<br />

is produced annually worldwide. That is the same as<br />

approximately 3 900 000 waste removal trucks which,<br />

end-to-end will wrap around Earth’s equator 6.8 times.<br />

BSG is the residual waste stream that remains after<br />

the brewing of beer. BSG is remarkably high in protein<br />

and fibre, has some residual energy, and is a healthy<br />

food intake for human, animal, and earth - if prepared<br />

correctly. See page 16 for the full story<br />

The Paulaner Brewery Group has been using underground<br />

ring-based piping since 2010 to supply its Oktoberfest<br />

tents with beer. This year the brewery installed a world<br />

premier: the first above-ground vacuum isolated piping<br />

for the central beer supply system. The entire system has<br />

a modular design that offers the following advantages:<br />

weather conditions have no negative impacts and<br />

installation/deinstallation times are significantly reduced.<br />

The full details are on page 24<br />

4

Contents<br />

Departments<br />

3 Editorial<br />

33 Fax<br />

42 Supplier's Guide<br />

Events<br />

41 Calendar of Events<br />

<strong>Marketing</strong><br />

6 Wood Craftsmanship in Drinks Promotion<br />

Atelier Zillich: Museum now For Sale<br />

38 Nearing the finish line: Vetropack Starts up<br />

Furnaces in New Plant in Northern Italy<br />

GROW<br />

YOUR<br />

BUSINESS<br />

fairtrade<br />

agrofood<br />

food + bev tec<br />

process & packaging<br />

ingredients<br />

bakery & confectionery<br />

Packaging<br />

28 Sensor <strong>Technology</strong> for Automated Filling<br />

34 First 5-liter party keg made of CO 2<br />

reduced tinplate<br />

36 Markem-Imaje’s Brand New Coding Innovations<br />

Impress Industry at interpack <strong>2023</strong><br />

<strong>2023</strong><br />

Iran<br />

Tehran<br />

Iraq<br />

Erbil<br />

16 - 19<br />

June<br />

19 - 21<br />

September<br />

30th edition<br />

www.iran-agrofood.com<br />

6th edition<br />

www.iraq-agrofood.com<br />

Ghana<br />

Accra<br />

21 - 23<br />

November<br />

7th edition<br />

www.agrofood-westafrica.com<br />

2024<br />

Nigeria<br />

Lagos<br />

28 - 30<br />

March<br />

9th edition<br />

www.agrofood-nigeria.com<br />

Ethiopia<br />

Addis Ababa<br />

06 - 08<br />

June<br />

6th edition<br />

www.agrofood-ethiopia.com<br />

Sensors installed in a filling installation often look<br />

inconspicuous. But they are indispensable for efficient<br />

processes. Dinkelacker uses sensor technology at nearly<br />

every station. The technical requirements are very high Only<br />

selected sensor solutions can rise to the challenge. This is<br />

why Dinkelacker relies on technology provided by a specific<br />

partner. This series is particularly well suited for applications<br />

in the beverage industry. Take a look at page 28 for the<br />

complete story<br />

Show contacts at fairtrade Messe GmbH & Co. KG<br />

Ethiopia, Ghana, Ivory Coast, Nigeria<br />

Ms Freyja Detjen Tel. +49-6221-4565-19 • f.detjen@fairtrade-messe.de<br />

Ms Nele Winter Tel. +49-6221-4565-31 • n.winter@fairtrade-messe.de<br />

Iran, Iraq<br />

Ms Clarissa Nusch Tel. +49-6221-4565-11 • c.nusch@fairtrade-messe.de<br />

www.fairtrade-messe.de<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong> 5

Cover Story<br />

Wood Craftsmanship in Drinks Promotion<br />

Atelier Zillich: Museum now For Sale<br />

For more than 60 years, promotional<br />

items for beer and beverages have been<br />

produced in the "Atelier Zillich", an old<br />

four-storey farmhouse in Monatshausen<br />

3 near Tutzing, Germany. These are<br />

barrel bottoms, clocks, coats of arms<br />

and tap plates. <strong>drinkworld</strong> talked with<br />

Peter Zillich, Craftsman and Collector<br />

about his life's work.<br />

It all began in the early 60s with a wood<br />

carving factory in Söcking. At that time<br />

there was a great demand for figures of<br />

saints, angels, cherubs and crosses. In<br />

Germany after the war, people wanted<br />

to renew what had been destroyed or<br />

decorate their rebuilt houses. - Initial<br />

experiments with plastic yielded<br />

6

Cover Story<br />

foamed cherubs. A gifted animal carver<br />

remembered his Westphalian brewing<br />

acquaintances and series production<br />

could begin.<br />

they had to equip their guest rooms - for<br />

example with decorative coats of arms<br />

or barrel bottoms. This quickly changed<br />

when German breweries began to export<br />

beer, especially Löwenbräu, which<br />

had a particularly capable importer in<br />

This resulted in an independent studio in<br />

Starnberg's rented premises. However,<br />

the prerequisite was still a wood-carved<br />

model, which initially had to be molded<br />

with caoutchouc, later with the much<br />

more suitable silicone to enable threedimensional<br />

copies.<br />

Soon they had to move to a 500-yearold<br />

farmhouse in Monatshausen, which<br />

initially offered plenty of space for<br />

production and magazines. Even today,<br />

models from that time wrapped in<br />

yellowed paper lie under a sloping roof.<br />

Cutting the glass mat, cleaning<br />

equipment, mixing gelcoat, laminating<br />

polyester, accelerator and hardener<br />

mixed by themselves are together a lot of<br />

preparatory work. Lamination of a slug,<br />

demolding, hardening, deburring and<br />

dedusting takes a day.<br />

Then there was the painting. The beige<br />

blank gradually turned into old lager<br />

oak, the slightly silvery "iron ring" was<br />

finished and at the climax the actual<br />

trademarks or advertising slogans were<br />

hand-painted. Each piece is unique.<br />

Peter Zillich calls this handicraft and<br />

thus justifies the term "atelier" or<br />

"studio".<br />

Peter Zillich took over the business in<br />

1969. In Germany many breweries had<br />

contractually bound restaurants, in return<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

7

Cover Story<br />

the USA. Zillich graduated from the<br />

FU and worked several times on the<br />

French beverage market, seized the<br />

opportunity. "We were globalizing when<br />

the word didn't even exist."<br />

This photo portrait shows the legacy of<br />

a company that seems to be still alive<br />

yesterday. It also includes drawings,<br />

files, ancient brewery templates, correspondence,<br />

reference and address books,<br />

etc. - Atelier Zillich was a member of the<br />

Luxembourg Gambrinus Brotherhood.<br />

With a nostalgic wink, Zillich would<br />

like his "museum" to be sold in its<br />

entirety. Visits are possible at any time.<br />

Interested parties can contact atelierzillich@t-online.de<br />

by e-mail for more<br />

details or to make an appointment.<br />

Peter Zillich talked with Sabine Straka,<br />

Editor-at-large with Dr. Harnisch<br />

Publications.<br />

8

Cover Story<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

9

Ingredients<br />

Premiumization of Water<br />

by DONNA BERRY<br />

More than one million bottles of water<br />

are sold every minute around the<br />

world and the industry shows no sign<br />

of slowing down, according to a <strong>2023</strong><br />

report by the United Nations University<br />

Institute for Water, Environment and<br />

Health. This equates to about US$270<br />

billion and 350 billion liters a year, and is<br />

expected to nearly double by 2030.<br />

Most bottled water is consumed at<br />

home by those who say that their tap<br />

water is unfit for consumption, blaming<br />

it on contamination, chlorination or off<br />

flavors. These purchases are a necessity.<br />

For others, bottled water is purchased<br />

as a convenience for on-the-go<br />

consumption. Many also find appeal in<br />

the promises brands make.<br />

One of those promises comes from<br />

PATH, which has a mission statement<br />

of “Forging the PATH to end single-use<br />

plastic bottles.” PATH is a refillable,<br />

recyclable bottled water in a sleek,<br />

durable aluminum bottle that comes in<br />

three varieties. PATH Still is filled with<br />

ultra-purified water through a sevenstep<br />

reverse-osmosis process and<br />

enhanced with electrolytes for a pHbalanced<br />

beverage. PATH Sparkling is<br />

delicately carbonated, offering a slight<br />

effervescence. PATH Alkaline includes<br />

specialty electrolytes with a final pH of<br />

9.5 or higher. To kick off summer <strong>2023</strong>,<br />

the company launched a limited-edition<br />

summer bottle of PATH Still that is<br />

perfect for on-the-go summer activities.<br />

Promises, Promises<br />

Through savvy marketing and valueadded<br />

formulations, bottled water<br />

companies tout the health and wellness<br />

benefits of proper hydration. Adding<br />

flavor without any calories is a common<br />

tactic. Carbonation is another, with<br />

the two often offered together. Other<br />

approaches to premiumize water include<br />

adding caffeine, vitamins, minerals,<br />

protein, fiber or other functional<br />

micronutrients.<br />

A growing brand in this space is Bubly<br />

from PepsiCo. Introduced to the U.S.<br />

market in 2018 in eight flavors—apple,<br />

cherry, grapefruit, lemon, lime, orange,<br />

mango and strawberry—the brand has<br />

grown with new flavors and caffeinated<br />

formulations, as well as distribution in<br />

select global markets.<br />

The brand is as much about being a<br />

flavored sparkling water with no calories<br />

and free of artificial colors, flavors and<br />

sweeteners, as it is about being fun.<br />

Cans and bottles feature bright, bold<br />

packaging, and unique smiles for every<br />

flavor. Can tabs include a witty greeting,<br />

such as “Hey u,” “hiii” and “yo,” and<br />

personal messages, such as “I feel like I<br />

can be open around u,” “hold cans with<br />

me” and “love at first phssst.”<br />

The brand’s first-ever limited-edition<br />

flavor—bellini bliss bubbly—was<br />

introduced late last year. It speaks to<br />

the growing ready-to-drink mocktail<br />

trend and features the tropical flavors<br />

of peach, pineapple and mango.<br />

“Bubly sparkling water has always been<br />

committed to creating fun, refreshing<br />

and unique flavors that truly resonate<br />

with our consumers, so we’re incredibly<br />

excited to unveil bellini bliss as our firstever<br />

mocktail,” said Zach Harris, vice<br />

president-water portfolio at PepsiCo<br />

Beverages North America. “We’re all<br />

about getting folks to see the bubly side<br />

of life. And bellini bliss helps people do<br />

just that.”<br />

The brand also now has a line extension:<br />

bubly bounce. The sparkling water<br />

provides hydration with a little (35<br />

milligrams) caffeine. The new line is<br />

packaged in the signature bright colors<br />

of the bubly brand but also sports new<br />

effervescent and energetic graphics.<br />

It comes in five combination flavors:<br />

blood orange grapefruit, blueberry<br />

pomegranate, citrus cherry, mango<br />

passion fruit and triple berry.<br />

“Bubly sparkling water was created to<br />

bring more smiles into the sparkling<br />

water category, and new bubly bounce<br />

takes it to the next level with caffeine,”<br />

said Harris. “As more individuals seek<br />

out sparkling waters with added benefits,<br />

bubly bounce delivers all of the delicious<br />

flavor and hydration of the original, now<br />

with just a kick of caffeine.”<br />

Bubly bounce is one of many<br />

carbonated waters with added<br />

functionality. Another is Bubbl’r,<br />

a flavored energy water line from<br />

Klarbrunn, an independent distributor<br />

and manufacturer of Pepsi products.<br />

It is loaded with antioxidants from<br />

vitamins and caffeine from natural<br />

sources (guarana seed extract), and<br />

10

Ingredients<br />

THE HIGHEST QUALITY CO2 AND AIR TESTING INSTRUMENTATION<br />

Gauge Tester Carbonation Stones Purity Tester<br />

Air & CO2 Tester Piercing Device Volume Meter Pilot Plant<br />

MADE IN THE USA SINCE 1908<br />

...Zahm & Nagel is a trusted name in the industry built on quality and service for over 100 years.<br />

For all your testing requirements from air testing and CO2 volume metering to carbonation<br />

equipment and gauge testing...Zahm & Nagel produces the highest quality testing and<br />

carbonation equipment in the brewing industry.<br />

WWW.ZAHMNAGEL.COM<br />

e-mail: sales@zahmnagel.com / phone: 716.537.2110<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

11

Ingredients<br />

touted as being a healthy alternative<br />

to traditional energy drinks.<br />

The five-calorie-per-can waters contain<br />

a little bit of fruit juice, mainly for color,<br />

and are sweetened with erythritol and<br />

stevia extract. Some of the more exotic<br />

varieties are blood orange mango,<br />

cherry guava and pitaya berry. The<br />

brand’s most recent addition is Triple<br />

Berry Breez’r, which is made from a<br />

combination of blueberries, raspberries<br />

and blackberries. It was developed in<br />

response to research showing that berry<br />

flavors are some of the fastest-growing<br />

flavors in the sparkling water category.<br />

“More than ever, people are looking<br />

for healthier beverages with functional<br />

benefits,” said Tyler Hartmann, director<br />

of marketing and brand development for<br />

Bubbl’r.<br />

Not to be left out of the flavored sparkling<br />

water trend, Perrier Carbonated Mineral<br />

Water, a brand that started in 1863<br />

in Vergèze, South France, and is now<br />

enjoyed in more than 140 countries, has<br />

entered this space with a canned line<br />

that depicts its iconic green bottle. Now<br />

owned by Nestlé Waters, the premium<br />

mineral water line comes in lemon,<br />

lime, L'orange, peach, pineapple, pink<br />

grapefruit and strawberry flavors.<br />

To educate consumers about the line<br />

extension, the company is running<br />

a “Feel the Flavor” global marketing<br />

campaign through <strong>2023</strong>. The campaign<br />

is running across digital, social, shopper<br />

and experiential channels.<br />

Talking Rain Beverage Company, the<br />

maker of Sparkling Ice beverages, has<br />

also stepped up its game with marketing.<br />

At the beginning of the year, the<br />

company launched the Flavorful Giving<br />

program, an initiative that celebrates<br />

the people, places and communities<br />

that inspire consumers to “Live in Full<br />

Flavor.” Throughout <strong>2023</strong>, Sparkling Ice<br />

is partnering with a different charitable<br />

organization every month—each with its<br />

own unique flavor—focusing on a range<br />

of topics including youth development,<br />

veteran care, wellness, education and<br />

more.<br />

The company is also growing its Sparkling<br />

Ice +Caffeine lineup. Just in time for the<br />

summer season, watermelon lemonade<br />

joined black raspberry, blue raspberry,<br />

cherry vanilla, citrus twist, orange<br />

passion fruit and strawberry citrus. Each<br />

can of the zero-sugar beverage contains<br />

70 milligrams of caffeine and only five<br />

calories along with antioxidants and<br />

vitamin A.<br />

On the “Still” Side of<br />

Innovation<br />

While bubbles are an attractive feature<br />

to many adult consumers, some prefer<br />

still water. But they, too, want to be<br />

12

made to feel special by their water<br />

selection.<br />

Acqua Panna, an Italian brand of natural<br />

spring bottled water owned by Nestlé,<br />

has been making inroads outside of its<br />

borders. “The water is sourced from<br />

the sun-drenched hills of Tuscany with<br />

each drop of Acqua Panna naturally<br />

filtered by the earth and perfected by<br />

time on a 14-year journey to the spring,<br />

giving it a special mineral balance for<br />

the smoothest taste,” according to the<br />

company. The water was first bottled in<br />

1880, and was the first still water to be<br />

produced in plastic bottles within the<br />

boundaries of Italy.<br />

Acqua Panna is an alkaline water with a<br />

pH of 8.0 or higher at the time of bottling.<br />

This contributes to its smooth taste<br />

appreciated by chefs and sommeliers<br />

around the world. This adult-centric<br />

still water is best consumed between<br />

53°F/12°C and 64°F/18°C, without ice<br />

cubes or lemon.<br />

Wood Craftsmanship<br />

in Drinks Promotion<br />

Atelier Zillich:<br />

Museum now For Sale<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

atelier-zillich@t-online.de<br />

13

Ingredients<br />

For adults who want to flavor their<br />

still waters, Twinings offers a premium<br />

flavor enhancer called Cold Infuse.<br />

Each infuser includes fruits and herbs,<br />

specially blended to brew in cold water.<br />

Varieties include blueberry apple, lemon<br />

ginger, mango passion fruit, peach<br />

passion fruit, strawberry lemon and<br />

watermelon mint. There’s also varieties<br />

with additional benefits, such as<br />

immune support raspberry hibiscus and<br />

probiotics pineapple coconut.<br />

Adults aren’t the only ones with their<br />

own premium bottled still water. After<br />

all, most children don’t like bubbles<br />

either.<br />

Hapi Water was developed by a dentist<br />

who saw the damage sugar was doing to<br />

kids’ teeth. The drink was created as a<br />

healthy alternative to fruity beverages<br />

many kids tend to drink. It has also<br />

become a go-to for adults who are drawn<br />

to the taste and healthy ingredients.<br />

With zero grams of sugar, a good source<br />

of vitamin C and zero calories in every<br />

shelf-stable pouch, Hapi Water comes in<br />

apple, grape, punch and strawberry kiwi<br />

flavors.<br />

For even younger consumers, Gerber<br />

Products Company, a part of Nestlé,<br />

offers organic fruit-infused water<br />

to provide toddlers with on-the-go<br />

hydration in natural flavors little ones<br />

will love. Made with real organic fruit<br />

puree without any added sugars,<br />

artificial sweeteners or artificial<br />

flavors. The waters come in spill-proof<br />

pouches with a resealable spout,<br />

as well as multi-serve shelf-stable<br />

bottles.<br />

for Gerber Organic Fruit Infused Water<br />

could help to improve your little one’s<br />

diet and keep them hydrated throughout<br />

the day.”<br />

Healthy beverage choices are important<br />

for growing toddlers, and nutrition<br />

experts recommend water, milk and no<br />

more than four ounces of fruit juice per<br />

day for children one to three years of<br />

age. The Gerber toddler beverages are<br />

94% water with a splash of organic fruit<br />

puree and natural flavors.<br />

The Author<br />

Donna Berry is a food and beverage industry<br />

consultant and editor with over 25 years experience<br />

in tracking trends and advancements in<br />

product development.<br />

“Beverage habits are an important part<br />

of the nutrition discussion between<br />

parents and their little ones. While<br />

we often think about what foods a<br />

child is fed, beverages contribute 27%<br />

of a toddler’s daily calorie intake,”<br />

said Erin Quann, head of medical<br />

affairs at Gerber/Nestlé Nutrition.<br />

“According to Nestlé’s latest Feeding<br />

Infants and Toddlers Study, more than<br />

20% of toddlers drink fruit-flavored<br />

drinks, which contribute calories and<br />

added sugar to their diet but very few<br />

nutrients. Swapping fruit flavored drinks<br />

14

Ingredients<br />

Time is Running Out<br />

to Secure Your Spot<br />

You’ll have access to:<br />

More than<br />

100 Science FIRST sessions<br />

Nearly 500 posters focused<br />

on cutting-edge science<br />

Multiple opportunities<br />

for high-value networking<br />

and connection<br />

An immersive,<br />

experiential experience<br />

at the Innovation Lab<br />

100 food and food<br />

tech startups<br />

plus a multi-day<br />

pitch competition<br />

Register Now at<br />

iftevent.org<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

15

Ingredients<br />

Case Study: Upcycling BSG Waste to<br />

Produce Value-Added By-Products<br />

Valorising through disruptive technology that’s faster than the speed of sound to create<br />

new income streams for manufacturers<br />

Green Cell Technologies® (GCT®) and<br />

RWH Holdings® (RWH®) have worked<br />

with several global brewers over a period<br />

of 8 years to understand the challenges<br />

around what to do with their leftovers –<br />

Brewers Spent Grain (BSG) and Brewers<br />

Spent Yeast (BSY) – and the answer, as it<br />

would happen, is Disrupt it.<br />

Preamble<br />

About 39 million tons of brewer’s<br />

spent grain (BSG) is produced annually<br />

worldwide. That is the same as<br />

approximately 3 900 000 waste removal<br />

trucks which, end-to-end will wrap around<br />

Earth’s equator 6.8 times. BSG is the<br />

residual waste stream that remains after<br />

the brewing of beer. BSG is remarkably<br />

high in protein and fibre, has some residual<br />

energy, and is a healthy food intake for<br />

human, animal, and earth - if prepared<br />

correctly.<br />

Unfortunately, BSG usually spoils within<br />

a day due to its high water, sugar, and<br />

protein content.<br />

This brief period makes BSG difficult to<br />

transport, and process further into food or<br />

other human-grade products. Therefore, it<br />

is predominantly used in the feed sector<br />

as it is not readily available for human<br />

consumption, (Food Valley, 2022).<br />

Molecules found in the cellular structures<br />

of meat, fruit, vegetables, berries, nuts,<br />

grain, seeds etc. provide sustaining<br />

nutrition to achieve good health and<br />

wellbeing. Those molecules represent a<br />

comprehensive - across the spectrum -<br />

variety of all the macro and micronutrients<br />

necessary for human beings (including<br />

animals and earth) to flourish.<br />

However, current food and beverage<br />

processing methods damage many of<br />

these ‘molecules of interest’ and nullify<br />

their efficacy. With reduced nutrition in<br />

processing and a loss of fibre, there is only<br />

a sense of satiety but not much nutritional<br />

or health benefit. Existing processing<br />

methods cannot easily and effectively<br />

process skins, seeds, and grains (which<br />

contain significant nutritional or valuable<br />

properties), or radically reduce the fibre<br />

particle size to a level that will not upset<br />

16

Ingredients<br />

the organoleptic sensibilities of the<br />

consumer.<br />

Therefore, a conventional processor ends<br />

each day with not only a large pile of waste,<br />

which impacts the environment, but also<br />

an end-product that is sold to consumers<br />

with a vastly reduced nutritional profile as<br />

compared to what it could be. Ironically,<br />

the ‘waste’ represents the majority of the<br />

raw material molecules that are required<br />

for optimal nutrition. The ‘waste’ also<br />

represents most of the fibre, which if<br />

ingested, would aid other nutritional and<br />

health benefits. Instead, consumers are<br />

mostly left fibre deficient.<br />

Disrupting BSG<br />

Disruptor® technology was used in<br />

several trials, to deploy a non-chemical<br />

process (Dynamic Cellular Disruption® -<br />

DCD®) to open greater than 99% of all<br />

cell structures of the BSG ‘waste’ mass.<br />

Important to note that DCD and Disruptor<br />

technology can be applied to any organic<br />

and some inorganic materials.<br />

During the DCD process, other than pipe<br />

loss, which is the same volume irrespective<br />

of the production size, there is zero waste<br />

generated as the plant material can be<br />

used in its entirety.<br />

DCD also renders bio-available, all the<br />

molecules for the body to utilise, and<br />

ensures digestibility of the insoluble<br />

material(s). DCD does not manufacture<br />

molecules but instead, extracts what is<br />

available within the cell structure - more<br />

efficiently. This is from the source material<br />

and therefore, outcomes are wholly reliant<br />

on the source material itself.<br />

DCD also reduces the microbiological<br />

contaminants, yeasts and moulds found in<br />

source materials – product that is passed<br />

through the Disruptor will show improved<br />

microbiological cleanliness.<br />

In short, the DCD process and Disruptor<br />

technology increases available nutrition<br />

per serving and reduces particle size and<br />

waste, which has a positive impact in the<br />

consumer as well as the environment. The<br />

increased extraction of molecules signifies<br />

an increase in yield and nutrition, and with<br />

the utilisation of what would normally be<br />

considered waste, has a positive economic<br />

Roy Henderson - CEO<br />

impact on the processing value chain as<br />

well as environmental impact – circular<br />

economy.<br />

Conventional Vs DCD/Disruptor<br />

<strong>Technology</strong> Processing – BSG<br />

Conventional manufacturing of BSG<br />

typically involves drying and milling<br />

into a powder. Analysis of the powder<br />

will show that the particle size remains<br />

big which influences the taste of end<br />

products (comments of “cardboard” and<br />

“grittiness” are common).<br />

Conventional drying and milling methods<br />

do not guarantee any increase in yield<br />

or nutrition, digestibility, or microbial<br />

cleanliness.<br />

DCD and Disruptor extract processing<br />

allows for particles to be reduced to sub-<br />

100 micron, microbially clean, increased<br />

available nutrition and bio-available – all<br />

in one step.<br />

The resultant emulsion can be dried, then<br />

milled into a very fine powder, complete<br />

with health benefits ready for further use<br />

in manufacturing if required.<br />

This then opens possibilities of extended<br />

product lines and additional revenue<br />

generation for brewers.<br />

BSG Testing Methodology<br />

Demonstrating that DCD and Disruptor<br />

technology adds value to BSG<br />

Jan Vlok - Head of R&D<br />

manufacture, 200kg of BSG were<br />

processed. Material samples were taken<br />

for analysis pre and post DCD and sent for<br />

independent laboratory analysis.<br />

1. University of Stellenbosch – pre and post<br />

DCD amino acid profile measurement.<br />

2. SGS (SANAS accredited commercial<br />

lab) – pre and post DCD microbiological<br />

and heavy metal measurement.<br />

3. Hearshaw and Kinnes (H&K) for<br />

pre and post DCD pesticide residue<br />

measurement.<br />

Results<br />

Phyto-Chemistry: Amino Acids (protein)<br />

The report shows an average protein<br />

increase of 29%. This is clinically very<br />

significant if one considers that the<br />

barley or starch source used for beer<br />

manufacture before it became BSG, was<br />

subjected to substantial boiling to conduct<br />

extraction for the beer manufacturing<br />

process of which, much of the protein<br />

will have already been solubilised into<br />

the beer liquid. This is proven by the step<br />

that is required to minimise it to prevent<br />

cloudy beer.<br />

Microbiological<br />

The report found that there was a<br />

1600000-fold decrease (99.999%<br />

improvement) in total plate count<br />

from 16000000cfu/g to 10cfu/g<br />

between the pre-DCD and post-DCD<br />

samples. The DCD process also reduced<br />

yeasts and moulds to “not detected”<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

17

Ingredients<br />

from 16800cfu/g and 28000cfu/g,<br />

respectively.<br />

Heavy metals<br />

The test measured for heavy metals<br />

typically examined for food and beverage<br />

production safety, those being mercury,<br />

cadmium, lead, and arsenic. All results<br />

are

Ingredients<br />

Advanced Synthetic<br />

Lubricants<br />

For The Beverage and Bottling Industry.<br />

Engineered from the ground up to provide unsurpassed performance in beverage processing plants. These high<br />

performance, 100% synthetic lubricants provide extended lube intervals, multiple application capability, lubricant<br />

inventory consolidation and improved performance. All while maintaining strict H1 safety requirements.<br />

SFGO Ultra Series:<br />

Food Machinery Grade Fluid Lubricants<br />

• High-Performance, 100% Synthetic H1 Fluids.<br />

• Extremely Versatile, Recommended for Air Compressors,<br />

Hydraulic Systems, Bearings, Gearboxes and Chains.<br />

• Available in 13 ISO viscosity grades.<br />

SynXtreme FG Series:<br />

Food Machinery Grade Synthetic Greases<br />

• Advanced, 100% Synthetic, Calcium Sulfonate Complex Type Greases.<br />

• Super Multi-Purpose, Ideal for a Variety of Applications.<br />

• Provides Excellent Anti-Wear and Extreme Pressure Protection.<br />

SSO-FG 100 and SSO-FG 150<br />

• These high-quality, fully synthetic lubricants are designed for use in<br />

can seaming/closing equipment with oil recirculating systems<br />

and related applications.<br />

Lubriplate® Lubricants<br />

Authorized Master Distributor Europe:<br />

Finke Mineralölwerk GmbH<br />

Rudolf-Diesel-Straße 1 / 27374 Visselhövede Deutschland<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June<br />

www.lubriplate.de<br />

<strong>2023</strong><br />

/ E-mail: info@lubriplate.de / Tel: +49 (0) 4262 79 95 23<br />

Registered ISO 9001<br />

and ISO 50001<br />

19

Processing<br />

How one OEM is Engineering with<br />

Sustainability in Mind<br />

SPX FLOW, a B2B process solutions<br />

provider, conserved 6,150,000 liters<br />

in water use across its global sites<br />

in 2022. For B2C customers, water<br />

conservation shows up in the solutions<br />

B2B companies design, manufacture,<br />

and service for their production sites.<br />

A few revolutionary water reduction<br />

breakthroughs from SPX FLOW include:<br />

APV Homogenizer Water Recycling<br />

System (HWRS)<br />

Imagine you’re at Niagara Falls watching<br />

millions of gallons of water plunge over<br />

the steep cliff. Out of curiosity, you<br />

start counting.<br />

One thousand one … one<br />

thousand two … one thousand<br />

…<br />

All told, that’s enough time for about<br />

2 million gallons to cascade over<br />

Horseshoe Falls, one of the three marine<br />

marvels that make up Niagara Falls.<br />

That’s also how much water this new<br />

homogenizer technology is helping B2C<br />

customers save each year. And that’s<br />

just the savings for one homogenizer<br />

over one year.<br />

Traditional homogenization requires<br />

the use of copious amounts of water.<br />

The more homogenizers that are in<br />

use, the more water is consumed and<br />

wasted. Now imagine a plug-and-play<br />

system that can fit or retrofit to any<br />

homogenizer and reduce water usage<br />

by up to 97% [2]. You read that right<br />

- a homogenizer that uses just 3% of<br />

its current water consumption to run<br />

the same processes it currently runs.<br />

Featuring a closed-loop water treatment<br />

system, SPX FLOW has engineered the<br />

HWRS to virtually eliminate all water<br />

use and be easily installed or retrofitted<br />

to both new and existing homogenizers<br />

by any manufacturer.<br />

How it works: Where normally a<br />

continual flow of water gets supplied to<br />

homogenizers to cool the transmission<br />

oil and lubricate the plungers, the HWRS<br />

recaptures that water, cleans and chills<br />

it, then returns it into the homogenizer.<br />

It’s a crucial technology that comes just<br />

in time as the cost of water rises, and<br />

supply shrinks, making sustainability<br />

increasingly important.<br />

APV/WCB D4 Double Seat<br />

Mixproof Food and Beverage<br />

Valves<br />

Another B2C design SPX FLOW<br />

engineers cultivated to help reach<br />

water goals is the D4 valve series that<br />

optimizes the flow of fluid through the<br />

valve manifold. The series consumes<br />

up to five times less cleaning fluid<br />

than most marketplace valves during<br />

clean-in-place (CIP). This improvement<br />

leads to less chemical and water use<br />

which limits the amount of waste-water<br />

treatment, and the related energy<br />

consumption needed for this additional<br />

process.<br />

20

One B2C U.S. beer producer experienced the impact<br />

of these valves firsthand. It needed help optimizing its<br />

processing lines by introducing a valve that could meet<br />

rigorous production demands, but also minimize the effects<br />

of water hammering. There was ease of maintenance and<br />

safety concerns while providing production efficiency to<br />

balance too.<br />

It was such a tall ask that a range of competitor valves were<br />

kept on-site to test over time, and all failed to meet every<br />

requirement. The D4 Series Double Seat Mixproof valve was<br />

offered up as a contender.<br />

QUALITY<br />

GUARDS.<br />

Processing<br />

Naturally<br />

protected with<br />

Nagardo ®<br />

glycolipids!<br />

What they saw:<br />

The mixproof valve design resisted the hydraulic shock<br />

created by pressure spikes and high flow velocities and<br />

created more freedom within the process, a benefit given<br />

long-term plans for process expansion. Competitor’s valves<br />

led to false and nuisance alarms due to the external switches<br />

and cabling that were susceptible to snags and natural<br />

vibrations during operation. The D4 valve’s protected<br />

design was found to reduce potential false alarms. Enhanced<br />

sanitary measures like the D4 leakage chamber eliminated<br />

buildup / blockage that can compromise the process fluid’s<br />

integrity. The leakage chamber flush option also kept the<br />

vent area clean.<br />

While this brewery is a case study example, the D4 series is<br />

used across other dairy, processed food and personal care<br />

applications with wins of their own.<br />

APV Pigging <strong>Technology</strong> (ARRS)<br />

Ambient dairy and plant-based products are becoming<br />

increasingly popular across fresh product categories and<br />

introduced in regions with select taste preferences. Keeping<br />

dairy and plant-based products at ambient temperature<br />

while also maintaining their long shelf-life qualities requires<br />

special processing throughout and before packing, leaving<br />

no room for post-contamination. Given the amount of<br />

time and attention given to a process like this, none of<br />

the product should be wasted during water flush after the<br />

production cycle is over. Every drop counts and adds to the<br />

top and bottom line of B2C businesses.<br />

Safety enabled by nature<br />

Innovative natural<br />

preservative with EU<br />

approval<br />

Excellent performance<br />

Patented technology<br />

developed in Germany<br />

First preservation technology<br />

for non alcoholic<br />

beverages entering the<br />

European market since<br />

40 years<br />

nagardo.com<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

21

Processing<br />

With this technology, one B2C<br />

custom<br />

er, when calculating the benefits of the<br />

ARRS, found it recovered a million dollars’<br />

worth of residual product by year end.<br />

How did they arrive at this number? The<br />

extreme product recovery by the ARRS.<br />

Once a production cycle is over, the<br />

process line is typically cleaned-in-place<br />

(CIP) and/or sterilized-in-place (SIP) using<br />

cleaning fluids. This process is imperative<br />

for products such as ambient products and<br />

yogurts or dessert creams and cosmetics<br />

because cross-contamination can lead to<br />

product recalls and harm B2C consumers.<br />

After CIP/SIP is complete, a rubber, tightfitting<br />

projectile, is forced through the<br />

process pipeline, that cleanly scrapes and<br />

recovers residual product to limit waste. It<br />

leaves less than 0.5% in the line and offers<br />

87% in product savings in the product<br />

pipes between valve manifolds [3].<br />

After scraping, the pig is returned to<br />

the launch station by compressed air,<br />

maintaining aseptic conditions, and<br />

keeping the line clear for the next cycle.<br />

The new APV innovation also yields up to<br />

50% more uptime since the minimization<br />

of repeated clean-in-place cycles<br />

translates to a reduction of chemical and<br />

water usage by 60-70%.<br />

In Honor of April 22nd<br />

Earth Day is celebrated each April to<br />

acknowledge the role we all play in<br />

the health of our air, waterways, and<br />

communities. You may see companies,<br />

brands and nations release statements<br />

and pledge commitments to the Earth<br />

around this time of year. But what’s<br />

more important are the steps we take to<br />

address our planet’s pressing needs not<br />

just on Earth Day but every day. In food<br />

and beverage manufacturing, energy,<br />

emissions, water and waste are used daily.<br />

These are natural byproducts of feeding<br />

and building the world, but how we do<br />

so, can be curbed to benefit ecosystems<br />

everywhere.<br />

B2B Companies like SPX FLOW are<br />

committed to leading by example to<br />

make our world safer, healthier, and more<br />

sustainable by innovating how things<br />

are made, conserving residual product,<br />

and aligning with the green goals of B2C<br />

producers to support a sustainable value<br />

chain from beginning to end.<br />

[1] As referenced by the United States Environmental<br />

Protection Agency; https://www.epa.gov/<br />

sustainability/lean-water-toolkit-chapter-2<br />

[2] Figures contingent on actual running conditions<br />

within a plant.<br />

[3] Figures are indicative and dependent on actual<br />

running conditions.<br />

SPX FLOW, a B2B Process Solutions<br />

Provider, Engineers Sustainable<br />

<strong>Technology</strong> for B2C Production How one<br />

OEM is Designing <strong>Technology</strong> to Help B2C<br />

Customers Reach Sustainability Goals<br />

SPX FLOW Prioritizes Water Savings<br />

<strong>Technology</strong> Design for Customers B2B<br />

Process Solutions Provider SPX FLOW<br />

Sustainably Innovates for Food and<br />

Beverage Producers Food and Beverage<br />

Producers Reach Sustainability Goals<br />

with Help of SPX FLOW B2B <strong>Technology</strong><br />

On the eve of Earth Day, we’re reminded<br />

of our planet’s beauty and rarity of<br />

natural resources essential to daily life.<br />

Water is one of these precious natural<br />

resources. The manufacturing industry<br />

generally uses more than its fair share<br />

of freshwater withdrawals, as much as<br />

18.2 billion gallons per day [1]. Given<br />

these numbers, food and beverage<br />

manufacturers design with sustainability<br />

in mind, particularly attune to reducing<br />

water consumption.<br />

Business-to-business (B2B) manufacturers<br />

must prioritize sustainability<br />

goals to help business-to-consumer<br />

(B2C) companies reach theirs. This<br />

symbiotic relationship cultivates an<br />

internal supply chain of water, waste,<br />

emissions, and energy savings that not<br />

only helps save the planet but increases<br />

B2C companies’ bottom line. The less<br />

consumed in the process line, the less<br />

invested in replacing material further<br />

down the line, particularly in processes<br />

like clean-in-place between batch cycles<br />

22

Processing<br />

For Efficient Applications in the Lab:<br />

Scale Up Your Automation<br />

METTLER TOLEDO makes working with<br />

its UV/Vis spectrophotometers more<br />

effective: The "InMotion" autosampler<br />

independently and reliably feeds samples<br />

for analysis. In addition to the standardized<br />

25 to 100-milliliter sample volumes,<br />

customized sample racks developed for<br />

individual customer needs are unique.<br />

This advances laboratory automation,<br />

for which the company offers further<br />

instruments and sound advice.<br />

Unrivaled in individual sample<br />

racks<br />

With standard sample volumes of 25<br />

to 100 milliliters available in a modular<br />

system, the "InMotion" autosampler<br />

scores particularly well with extensive<br />

analysis material from the chemical and<br />

beverage industries.<br />

The UV/Vis spectrophotometer<br />

can be<br />

easily connected to<br />

the InMotion via an<br />

immersion probe or<br />

flow cell, making it<br />

an effective tool in a<br />

range of instruments<br />

the manufacturer<br />

has developed for<br />

efficient and safe<br />

automation of<br />

analytical processes.<br />

Start smart<br />

METTLER TOLEDO advises that<br />

spectrophotometric automation brings<br />

the most significant efficiency gains<br />

when customized. This is why the<br />

company focuses on information and<br />

advice right from the start. For the<br />

very first step towards automation,<br />

METTLER TOLEDO provides informative<br />

documentation in the form of a guide<br />

and webinar.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

23

Processing<br />

Tapping the first keg in the Bräurosl festival tent on opening day of the 187th Oktoberfest on the Theresienwiese in Munich, 9 September 2022. Image:<br />

Hannes Magerstaedt<br />

Supplying Beverages at Large Events<br />

World premier – first in-tent vacuum insulated piping (VIP) system for festival beer at the<br />

Munich Oktoberfest 2022<br />

In 2022, millions of visitors once again<br />

visited the Oktoberfest in Munich<br />

after a two-year hiatus forced by the<br />

corona pandemic. And none of them<br />

died of thirst! The Paulaner Brewery<br />

Group introduced a world premier<br />

this year in the Pschorr Bräurosl beer<br />

tent: the first vacuum insulated piping<br />

system (VIP) for beer installed directly<br />

in the tent at a height of 3.5 meters.<br />

The measurement technology for the<br />

smooth operation of the beverage<br />

The Picomag instruments from Endress+Hauser (nominal diameter DN 15) measure the flow, temperature<br />

and conductivity values of the non-alcoholic beverages.<br />

Image: Endress+Hauser<br />

supply system, including the nonalcoholic<br />

keg dispensers, is from<br />

Endress+Hauser.<br />

Paulaner has been using underground<br />

ring-based piping since 2010 to supply<br />

its Oktoberfest tents with beer. This year<br />

the brewery installed a world premier<br />

in the Bräurosl tent: the first aboveground<br />

vacuum isolated piping for the<br />

central beer supply system. The entire<br />

system has a modular design that offers<br />

the following advantages: weather<br />

conditions have no negative impacts<br />

and installation/deinstallation times are<br />

significantly reduced. The temperature<br />

difference is a mere +0.3° C within 24<br />

hours, at an ambient temperature of 30°<br />

C and a beer temperature of 0° C. This<br />

represents a considerable improvement<br />

over the underground piping system.<br />

Another centerpiece is the measurement<br />

technology from Endress+Hauser. As<br />

summed up by brewing engineer Uwe<br />

Daebel: “Our recipe for success: we<br />

have the innovative ideas and work<br />

24

Processing<br />

together with reliable partners like<br />

Endress+Hauser to implement them.”<br />

The measurement technology can<br />

be found at many points within the<br />

Oktoberfest tent:<br />

Bierant for the Oktoberfest<br />

beer in the tent*<br />

(*Works according to the artesian<br />

principle. Any air or gas present in the<br />

VIP system is removed and the beer is<br />

distributed to the taps via “pythons”).<br />

An ingenious idea by Uwe Daebel,<br />

brewing engineer at the Paulaner<br />

Brewing Group! Everyone knows what<br />

the word hydrant means and how it<br />

functions. According to Wikipedia, a<br />

hydrant is an outlet from which water<br />

can be tapped. Accordingly, a socalled<br />

Bierant © (a portmanteau of the<br />

German Bier and hydrant) retrieves the<br />

beer from the transfer piping and sends<br />

it to the taps. The Bräurosl Oktoberfest<br />

tent contains four Bieranten©, each<br />

of which is furnished with innovative<br />

measurement technology. The Liquicap<br />

M FMI51 capacitive level sensor<br />

monitors the level and the Picomag<br />

electromagnetic flowmeter monitors not<br />

only the flow, but also the temperature<br />

and conductivity. The combination of<br />

these three measurement parameters<br />

plays an important role in efficient CIP<br />

cleaning of the dispenser technology.<br />

The full potential comes to bear first<br />

and foremost with the gastronomy<br />

Jack-of-all-trades. Pocket-sized Picomag for simultaneously measuring flow, temperature and conductivity.<br />

Image: Endress+Hauser<br />

technology however, since it has to<br />

be cleaned every 14 days at the latest,<br />

and then documented with the help of<br />

the conductivity measurement value.<br />

Where several instruments might be<br />

needed for monitoring the parameters,<br />

now a single device – the Picomag from<br />

Endress+Hauser – takes over this task.<br />

The instrument’s compact dimensions<br />

are advantageous in tight installation<br />

spaces. The Picomag furthermore<br />

comes with an integrated IO-Link<br />

interface as a standard feature and can<br />

be easily integrated into common field<br />

bus systems. Cloud connectivity is also<br />

simple to establish.<br />

Delivery of the beer via the<br />

technology container – the<br />

control center of the central<br />

beer supply system for the<br />

festival tent<br />

Beer transfer takes place via the<br />

technology container. The tanker truck<br />

is connected to the central supply<br />

system on the beer and gas side via<br />

hoses. The beer volume is determined<br />

with a custody transfer system.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

25

Processing<br />

Since the tanker trucks and beer tanks<br />

are connected on the gas side (gas<br />

pendulum process = equal pressure), a<br />

pump is needed to transfer the beer to<br />

the tanks (capacity, 3 x 28,000 liters),<br />

which are installed on a stainless steel<br />

frame approximately 4 meters above<br />

the technology container. When the<br />

system is in the “festival tent” operating<br />

mode, the three tanks simultaneously<br />

and continuously feed the transfer<br />

piping. From there the beer is fed to the<br />

dispenser taps via the four Bieranten©.<br />

To compensate for the reduced pressure<br />

in the system caused by the falling levels<br />

in the tanks, the pressure is regulated<br />

and kept constant with CO2 gas, which<br />

is monitored by the Deltapilot FMB50<br />

hydrostatic level instrument. The three<br />

beer lines to the tanks are equipped<br />

with Liquiphant M FTL50H vibration<br />

point level switches, which trigger<br />

the empty tank notification when the<br />

beer is removed from the tanks at the<br />

conclusion of the Oktoberfest.<br />

Monitoring the keg beverages<br />

Apart from the festival beer, the tent<br />

offers other beverages delivered in<br />

kegs. Whether non-alcoholic beer, soft<br />

drinks, mineral water, Paulaner Spezi<br />

(a mixture of cola and orange soft<br />

drink) or Shorle (apple juice mixed with<br />

carbonated water), an Endress+Hauser<br />

instrument is responsible for monitoring<br />

the flow at each tap. The Bräurosl tent<br />

thus has 30 Picomag flowmeters with<br />

integrated IO-Link interfaces for the keg<br />

beverages. The instruments monitor<br />

three parameters in this environment as<br />

well: flow, temperature and conductivity.<br />

The Bierant© is equipped with innovative instrumentation: the Liquicap M FMI51 for continuous<br />

level monitoring and the Picomag (nominal diameter DN 20) for monitoring flow, temperature and<br />

conductivity.<br />

Image: Endress+Hauser<br />

the next day using the data captured<br />

by the instruments – relaxed and<br />

worry-free. This ensures no beverage<br />

shortages and no thirsty visitors.<br />

But that’s not all. At the end of a largescale<br />

event such as the two-week<br />

Oktoberfest, the captured data can be<br />

used to carry out a detailed analysis.<br />

Optimizing beverage consumption and<br />

personnel resources at future events<br />

thus becomes child’s play.<br />

Brewing engineer Uwe Daebel next to the Bierant©, the centerpiece of the beverage supply system.<br />

Image: Endress+Hauser<br />

All important information at a<br />

glance<br />

How do you reliably maintain a focus on<br />

the beverage supply system? It’s easy:<br />

either by viewing the display monitor<br />

(Maß-o-Meter) in the technology<br />

container located on site, or via the<br />

comfort of a cloud connection from any<br />

location. All Endress+Hauser Picomag<br />

instruments are furnished with an IO-<br />

Link interface as a standard feature.<br />

The current value is continuously<br />

transmitted to the IO-Link master and<br />

then passed to the cloud. That means at<br />

the end of an Oktoberfest day, Paulaner<br />

can order the volume of beverages for<br />

26

ZKZ 62006<br />

12.09.22 15:54<br />

Processing<br />

chnology<br />

and food<br />

ISSN 1433-1594 Vol. 27 No. 2 June <strong>2023</strong> US $ 12 · € 12<br />

Cover: Beverage Promotion through Wood Carvings<br />

Upcycling Spent Grain and Yeastand<br />

Keeping the Festival Beer Flowing<br />

Sensor <strong>Technology</strong> for Automated Filling<br />

Come and see for yourself:<br />

www.harnisch.com<br />

Perfectly positioned.<br />

The international specialist magazines from Dr. Harnisch Publications<br />

You can now explore our newly designed website, with a<br />

clear focus on responsive design and easily usable applications.<br />

Alongside the free-to-use digital magazine editions, you will<br />

find bonus news coverage, events, subscription and<br />

general information on all our magazines. Take a look at<br />

www.harnisch.com for all relevant content.<br />

Our publications include:<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

- <strong>Technology</strong> & <strong>Marketing</strong> -<br />

27

Packaging<br />

Sensor <strong>Technology</strong> for Automated Filling<br />

by MARTINA SCHILI<br />

Traditional beer specialties<br />

Beer lovers in South West Germany are<br />

familiar with these traditional brands:<br />

Dinkelacker, Wulle Biere, Schwaben<br />

Bräu, Sanwald, Cluss or Haigerlocher.<br />

They are all regional beer specialties,<br />

each with its own character, and are<br />

brewed by Dinkelacker. The family<br />

The independent Dinkelacker brewery is family-owned and still brews beer in the same location in<br />

Stuttgart where Carl Dinkelacker founded the company in 1888.<br />

brewery has been in existence since<br />

1888. It was founded by Carl Dinkelacker<br />

in the Tübinger Straße in the heart of<br />

Stuttgart. And it is still headquartered<br />

there today. The company has always<br />

placed great importance on the best<br />

raw materials. They form the basis<br />

for the quality of the beers - whether<br />

Kellerbier in a swing top bottle, topfermented<br />

wheat beer or non-alcoholic<br />

Pilsner. This quality standard is also<br />

reflected in the technical components<br />

used in production. For this reason,<br />

Dinkelacker has long been relying on<br />

Leuze application know-how, as well as<br />

sensor technology that meets the most<br />

stringent requirements for reliability,<br />

robustness and hygiene.<br />

Strictly in accordance with<br />

the German purity law<br />

Processes in a brewery follow a<br />

precisely defined sequence. Thousands<br />

of visitors on guided Dinkelacker<br />

brewery tours are impressed by this<br />

every year. If you take a look behind<br />

28

Packaging<br />

the scenes, you can experience the<br />

brewing process from start to finish:<br />

first, 40,000 liters of brewing water<br />

and 8.5 tons of malt from local<br />

farmland are mixed to create beer<br />

mash. For its malt, which consists of<br />

barley and wheat, Dinkelacker uses<br />

summer barley from the Strohgäu and<br />

the Swabian Alp. Dinkelacker is one of<br />

the few breweries in the world who still<br />

use a strain master. When it is ready,<br />

the mash is pumped there and filtered.<br />

Experts call this the "lautering" of the<br />

wort. The spent brewer grains remain,<br />

which are then used as supplementary<br />

animal feed. The mash turns into wort.<br />

The wort is then boiled and the hops<br />

is added. The brewery procures this<br />

from Tettnang near Lake Constance.<br />

This is followed by the brewery's own<br />

selected yeast, the last ingredient of<br />

the beer. The beer wort runs through a<br />

cooler into the beer storage cellar into<br />

one of 39 huge storage tanks. Each<br />

tank contains between 300,000 and<br />

500,000 liters and is up to 25 m high.<br />

It is filled from the bottom until it is<br />

approx. three-quarters full, as the beer<br />

needs space to ferment in the tank. In<br />

order to deliver the finished product<br />

to the consumer, it is pumped to the<br />

filling installation.<br />

Indispensable sensor<br />

technology<br />

The sensors installed in the filling<br />

installation often look inconspicuous.<br />

But they are indispensable for<br />

efficient processes. Dinkelacker uses<br />

Leuze sensor technology at nearly<br />

every station. "To ensure fault-free<br />

operation, we depend on particularly<br />

robust and reliable sensors", explains<br />

Florian Fahr, Head of <strong>Technology</strong><br />

at Dinkelacker. "The requirements<br />

for the technical components in the<br />

filling installation are very high. Here,<br />

there are strong vibrations and the<br />

sensors must be able to withstand<br />

frequent cleaning processes." Only<br />

selected sensor solutions can rise to<br />

the challenge. This is why Dinkelacker<br />

The beer ferments in the 39 huge storage tanks before it is pumped to the filling installation.<br />

Leuze multiple light beam safety devices of type MLD 500 secure the working range of the robots<br />

against access from outside.<br />

relies on the technology provided<br />

by the Sensor People from Leuze.<br />

Andreas Eberle, Local Industry<br />

Manager Packaging at Leuze, explains<br />

the advantages: "Primarily, retroreflective<br />

photoelectric sensors of<br />

the Leuze PRK series were installed<br />

here." This series is particularly well<br />

suited for applications in the beverage<br />

industry. The metal housing of the<br />

optical sensors is resistant. As a result,<br />

the devices can also function optimally<br />

in harsh environments." Furthermore,<br />

the optically switching devices even<br />

detect highly transparent objects<br />

such as bottles, due to the reflection<br />

principle. High-gloss plastic crates with<br />

different imprints are also detected. At<br />

Dinkelacker, the technology provided<br />

by Leuze has proven its high reliability<br />

in practice, as Andreas Eberle knows:<br />

"Many of the sensors have already<br />

been working in the family-owned<br />

brewery with great precision for<br />

decades. Some were installed at the<br />

end of the 1990s, some at the start<br />

of the 2000s." Another advantage:<br />

by focusing on one sensor series, the<br />

brewery has to stock fewer different<br />

spare parts and in the rare event of<br />

a defect, they can react quickly and<br />

exchange sensors easily. And if there<br />

should be an urgent problem, they<br />

appreciate the close proximity to the<br />

headquarters of the Sensor People,<br />

who will promptly offer support.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · June <strong>2023</strong><br />

29

Packaging<br />

Material flow without jamming<br />

or collisions<br />

The Leuze sensors are used at different<br />

points in the filling installation and<br />

they have specific tasks. The process<br />

starts in the filling installation with the<br />

cleaning of bottles, beer crates and<br />

barrels. Cleanliness and hygiene play<br />

an important role. "The PRK optical<br />

sensors are installed on the individual<br />

conveyor sections and detect<br />

pallets, barrels, beer crates or even<br />

bottles", explains Frank Karle, Head<br />

of Electrical Workshop at Dinkelacker.<br />

"Thus the speed of the conveyor<br />

belts is automatically regulated to<br />

prevent jamming and collisions." In<br />

the barrel filling section, Dinkelacker<br />

has installed approx. 100 sensors on<br />

the conveyor belts. Up to 240 barrels<br />

an hour are cleaned and filled there.<br />

Two new robots which look like a full<br />

beer glass support the employees:<br />

they lift the empty or full barrels and<br />

place them on the conveyor belt or<br />

on pallets. Dinkelacker newly installed<br />

the robots while the hospitality sector<br />

was shut down during the Corona<br />

pandemic. Leuze safety technology<br />

also has a part to play at the robots:<br />

multiple light beam safety devices of<br />

type MLD secure the working range<br />

against unauthorized access from<br />

outside. Two PRK sensors which are<br />

switched crosswise in front of each of<br />

Filled beer bottles on their way to labelling.<br />

the robots reliably detect an incoming<br />

pallet. They then start the muting<br />

function, which briefly bridges the<br />

safety light barriers so that the pallet<br />

can pass through.<br />

72,000 bottles cleaned hourly<br />

Empty beer crates are cleaned by<br />

running them through a special<br />

cleaning machine. The bottles, which<br />

were removed previously, end up in a<br />

large bottle cleaning machine. There,<br />

they are cleaned with water heated<br />

to 80°C - the machine can handle up<br />

No need for heavy lifting: in the barrel filling installation, two modern robots grip the beer barrels and<br />

place them on conveyor belts or pallets.<br />

to 72,000 bottles in one hour. Here<br />

too, Leuze sensors are indispensable<br />

for safe operation: sensors of the<br />

PRK series detect immediately when<br />

a bottle is not in line on the bottle<br />

cleaning machine. Then they stop the<br />

machine. Again, access is monitored<br />

by safety light curtains. After cleaning,<br />

each bottle is checked for residues. If<br />

there are any residues in the bottle<br />

after the first pass, or remnants of<br />

labels are still adhering to the outside,<br />

the bottle is put through the bottle<br />

cleaning machine for a second time.<br />

If this is still the case afterwards,<br />

the bottle is rejected. This means: "If<br />

beer lovers want to do breweries a<br />

favor, they should not put anything<br />

in the bottles and open empty swingtop<br />

bottles before placing them in the<br />

crate", says Frank Karle.<br />

Freshly filled<br />

If the bottles are undamaged and<br />

completely clean, they are filled. Leuze<br />

sensors make it possible to regulate<br />

the conveyor belt speed. The system<br />

calculates the optimal speed based on<br />

the spacing between two bottles. The<br />

reusable bottle installation then fills<br />

the bottles with beer. It can manage<br />

up to 66,000 bottles per hour. This<br />

corresponds to 3,300 crates. The<br />

swing-top bottle installation works<br />

on a separate production line. It fills<br />

30,000 bottles an hour. That means<br />

30

Packaging<br />

1,500 crates per hour. As the filling<br />

process continues, checks are carried<br />

out to see if the level of the bottle<br />

contents is correct. After closing, PRK<br />

sensors detect if each reusable bottle<br />

has been correctly fitted with crown<br />

caps or if the swing-top bottle has<br />

been closed correctly. This is followed<br />

by labeling: the bottle is aligned and<br />

labels are applied to the neck, front<br />

and back. Here too, nothing is left to<br />

chance: every label is checked for its<br />

correct position on the bottle while it is<br />

still in the machine.<br />

Every crate in view<br />

Then the crater starts its work. The<br />

machine fills several crates at once<br />

with 20 beer bottles each. Leuze sensor<br />

technology is also employed at this<br />

station: "During full-crate monitoring,<br />

sensors detect in a fraction of a second<br />

Here, the swing-top bottles are aligned as the beer crates are filled. For this purpose, one Leuze sensor<br />

per bottle detects the position of the label.<br />

if a crate is completely filled", explains Andreas Eberle. "If a bottle is missing or in a horizontal position, the crate is rejected<br />

and the error is corrected manually by an employee." When crates are filled with swing-top bottles, they are also aligned so<br />

their labels face outwards, for a pleasing look. Leuze sensors detect the labels on the bottles and support the machine with<br />

the correct positioning. This is followed by the last step:<br />

the crates are placed on pallets and delivered. Here too,<br />

sensors are used for presence detection of the pallets and<br />

optimize the material flow.<br />

Continued tradition<br />

Six widely known brands, beers for every taste and<br />

production which is virtually fully automated and fills<br />

many thousands of bottles and quite a number of barrels<br />

per hour: the Dinkelacker family-owned brewery from<br />

Stuttgart has successfully transitioned into the modern<br />

age. The Sensor People from Leuze make an important<br />

contribution to efficient production in all process steps,<br />

with their reliable and robust sensors. These are things<br />

Retro-reflective photoelectric sensors from the Leuze PRK series can<br />