Ancorsteel® Phosphorus Alloys - GKN

Ancorsteel® Phosphorus Alloys - GKN

Ancorsteel® Phosphorus Alloys - GKN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

0810-ASPA-D-2<br />

Ancorsteel phosphorus alloys are ferrous base<br />

powders for P/M parts requiring superior<br />

electromagnetic performance. Compared with<br />

parts made from pure, high compressibility iron<br />

powders, those made from the phosphorus alloys<br />

have higher resistivity, permeability and<br />

induction, and reduced coercive force. The<br />

presence of phosphorus also decreases the<br />

susceptibility of a P/M component to nitrogen<br />

aging. Ancorsteel phosphorus alloys are produced<br />

by making ferrophosphorus additions to the highly<br />

compressible iron powders Ancorsteel 1000B or<br />

Ancorsteel 1000C.<br />

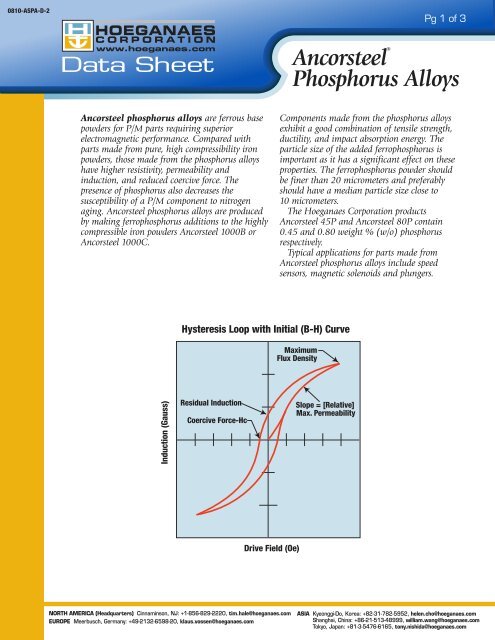

Induction (Gauss)<br />

Hysteresis Loop with Initial (B-H) Curve<br />

Residual Induction<br />

Coercive Force-Hc<br />

Drive Field (Oe)<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

Pg 1 of 3<br />

Ancorsteel ®<br />

<strong>Phosphorus</strong> <strong>Alloys</strong><br />

Components made from the phosphorus alloys<br />

exhibit a good combination of tensile strength,<br />

ductility, and impact absorption energy. The<br />

particle size of the added ferrophosphorus is<br />

important as it has a significant effect on these<br />

properties. The ferrophosphorus powder should<br />

be finer than 20 micrometers and preferably<br />

should have a median particle size close to<br />

10 micrometers.<br />

The Hoeganaes Corporation products<br />

Ancorsteel 45P and Ancorsteel 80P contain<br />

0.45 and 0.80 weight % (w/o) phosphorus<br />

respectively.<br />

Typical applications for parts made from<br />

Ancorsteel phosphorus alloys include speed<br />

sensors, magnetic solenoids and plungers.<br />

Maximum<br />

Flux Density<br />

Slope = [Relative]<br />

Max. Permeability<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com

0810-ASPA-D-2<br />

Data Sheet<br />

Ancorsteel ®<br />

<strong>Phosphorus</strong> <strong>Alloys</strong><br />

Typical Magnetic Properties<br />

Pg 2 3 of 34<br />

Grade Ancorsteel 1000B<br />

Compaction pressure, MPa (tsi) 415 (30) 550 (40) 690 (50)<br />

Sintering temperature, ˚C (˚F) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300)<br />

Sintered density, g/cm 3 6.79 6.80 7.09 7.12 7.26 7.28<br />

[Relative] maximum<br />

permeability, G/Oe<br />

2100 2300 2600 2800 3000 3200<br />

Maximum flux density, [T] 1.03 1.07 1.12 1.20 1.26 1.30<br />

Maximum flux density, G 10300 10700 11200 12000 12600 13000<br />

Residual induction, [T] 0.90 0.95 1.10 1.12 1.14 1.18<br />

Residual induction, G 9000 9500 11000 11200 11400 11800<br />

Coercive force, [A/m] 170 160 170 150 160 150<br />

Coercive force, Oe 2.10 1.95 2.10 1.85 2.05 1.90<br />

Grade Ancorsteel 45P<br />

Compaction pressure, MPa (tsi) 415 (30) 550 (40) 690 (50)<br />

Sintering temperature, ˚C (˚F) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300)<br />

Sintered density, g/cm 3 6.84 7.15 7.12 7.35 7.27 7.45<br />

[Relative] maximum<br />

permeability, G/Oe<br />

2800 4200 2900 4000 3600 4500<br />

Maximum flux density, [T] 1.10 1.30 1.25 1.32 1.30 1.39<br />

Maximum flux density, G 11000 13000 12500 13200 13000 13900<br />

Residual induction, [T] 0.95 1.10 1.07 1.05 1.14 1.19<br />

Residual induction, G 9500 11000 10700 10500 11400 11900<br />

Coercive force, [A/m] 140 110 140 110 140 100<br />

Coercive force, Oe 1.80 1.40 1.80 1.35 1.75 1.30<br />

Grade Ancorsteel 80P<br />

Compaction pressure, MPa (tsi) 415 (30) 550 (40) 690 (50)<br />

Sintering temperature, ˚C (˚F) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300) 1120 (2050) 1260 (2300)<br />

Sintered density, g/cm 3 6.86 7.15 7.16 7.30 7.34 7.41<br />

[Relative] maximum<br />

permeability, G/Oe<br />

3800 4800 4500 5700 4500 6000<br />

Maximum flux density, [T] 1.20 1.38 1.32 1.38 1.30 1.40<br />

Maximum flux density, G 12000 13800 13200 13800 13000 14000<br />

Residual induction, [T] 1.05 1.10 1.12 1.18 1.15 1.25<br />

Residual induction, G 10500 11000 11200 11800 11500 12500<br />

Coercive force, [A/m] 120 110 120 100 110 100<br />

Coercive force, Oe 1.50 1.35 1.45 1.30 1.40 1.30<br />

Sintering was done in a synthetic dissociated ammonia atmosphere for 30 minutes at temperature.<br />

Typical magnetic properties were tested at a peak drive field of 1200 A/m (15 oersteds).<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com

0810-ASPA-D-2<br />

Tensile Strength (MPa)<br />

Transverse Rupture Strength (MPa)<br />

Apparent Hardness (HRB)<br />

Data Sheet<br />

Ancorsteel ®<br />

Sintering Temperature (˚F)<br />

<strong>Phosphorus</strong> <strong>Alloys</strong><br />

550<br />

500<br />

450<br />

2100 2200 2300 2400<br />

400<br />

350<br />

60<br />

300<br />

250<br />

200<br />

40<br />

150<br />

100<br />

50<br />

20<br />

0<br />

1100 1150 1200 1250 1300<br />

0<br />

1350<br />

Sintering Temperature (˚C)<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

1100 1150 1200 1250 1300 1350<br />

Sintering Temperature (˚C)<br />

80<br />

70<br />

60<br />

50<br />

UTS<br />

Yield (0.2% offset)<br />

Sintering Temperature (˚F)<br />

2100 2200 2300 2400<br />

Sintering Temperature (˚F)<br />

2100 2200 2300 2400<br />

40<br />

1100 1150 1200 1250 1300 1350<br />

Sintering Temperature (˚C)<br />

Mechanical Properties - Ancorsteel 45P<br />

140<br />

120<br />

Tensile Strength (10 3 psi)<br />

Transverse Rupture Strength (10 3 psi)<br />

Dimensional Change (% from die size)<br />

Elongation [% in 25.4 mm (1 incn)]<br />

Impact Energy (Joules)<br />

20<br />

15<br />

10<br />

5<br />

0.25<br />

Sintering Temperature (˚F)<br />

2100 2200 2300 2400<br />

Pg 4 3 of 43<br />

0<br />

1100 1150 1200 1250 1300 1350<br />

Sintering Temperature (˚C)<br />

0<br />

-0.25<br />

-0.5<br />

-0.75<br />

-1<br />

Sintering Temperature (˚F)<br />

2100 2200 2300 2400<br />

-1.25<br />

1100 1150 1200 1250 1300 1350<br />

Sintering Temperature (˚C)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Sintering Temperature (˚F)<br />

0<br />

0<br />

1100 1150 1200 1250 1300 1350<br />

Sintering Temperature (˚C)<br />

Samples compacted at 550 MPa (40 tsi) and sintered in a synthetic dissociated ammonia atmosphere<br />

for 45 minutes at temperature.<br />

2100 2200 2300 2400<br />

IMPORTANT NOTICE: The data shown are based on laboratory processing standard test specimens. Results may vary from those obtained in production processing.<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Impact Energy (ft. lbf)<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com