National Hardwood Magazine - May 2023

Get the latest hardwood news in the May 2023 issue of National Hardwood Magazine! This issue features stories on Oak Pointe, Gates Milling, M&M Lumber and much more.

Get the latest hardwood news in the May 2023 issue of National Hardwood Magazine! This issue features stories on Oak Pointe, Gates Milling, M&M Lumber and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SCAN ME<br />

FIRST PLACE IN WOOD PROTECTION<br />

1-888-END-COAT sales@uccoatings.com uccoatings.com<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1

INDUSTRIES<br />

CONTROLS<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1240 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry JoeScan<br />

JS-50X6 Heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 170 systems sold<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

STEFAN DRACOBLY PAUL CLEEREMAN DAN TOOKE<br />

President Of<br />

VP Cleereman Senior Optimization<br />

Controls<br />

Industries & Controls & Controls Engineer<br />

2 MAY <strong>2023</strong> n NATIONAL HARDWOOD Sales MAGAZINE info@cleereman.com<br />

www.RealAmerican<strong>Hardwood</strong>.org

Shoo-wee! - Thanks to your support we are<br />

experiencing significant reductions in the<br />

occurrence of splinters and ringworm!<br />

Please...continue to buy loads of lumber from<br />

CLASSIC AMERICAN HARDWOODS, INC.<br />

1245 North 7th St.<br />

Memphis, TN 38107<br />

Please Contact Us!<br />

Phone: (901) 522-9663<br />

Fax: (901) 522-9664<br />

www.cahmemphis.com<br />

Memphis, TN Shanghai, China Ho Chi Minh City, Vietnam<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> MAY <strong>2023</strong> Volume 97 No. 4<br />

Features & Industry Events<br />

24<br />

26<br />

28<br />

Oak Pointe, A Quality Custom<br />

Manufacturer<br />

Gates Milling, Quality Products<br />

From People That Care<br />

Nyle Dry Kilns Innovates With<br />

30 New Kiln Optimization Equipment<br />

32<br />

M&M Lumber: A Legacy Of<br />

Service And Quality<br />

From Dry Kilns To Software,<br />

We’re Priming The Pump To Create<br />

An Ongoing Talent Supply<br />

Departments<br />

34<br />

44<br />

50<br />

52<br />

54<br />

HMA And Nashville Team Up For<br />

“Agents Of Change”<br />

58th Annual KFIA Meeting Features<br />

Exhibits, Legislative Updates<br />

ALC Learns Ways To Attract<br />

Gen Z Employees<br />

SCMA Holds Annual Meeting<br />

NELA Sets Sights On June Meeting<br />

Following Successful Winter<br />

Gathering<br />

8 <strong>Hardwood</strong> Calendar<br />

10 U.S.A. Trends<br />

12 Canadian Trends<br />

14 News Developments<br />

16 HMA Update<br />

18 AHEC Report<br />

20 WCMA Insights<br />

22 NHLA: Why Knot...<br />

79 In Memoriam<br />

80 Who’s Who<br />

84 Trade Talk<br />

90 Classified Profit<br />

Opportunities<br />

92 Advertisers Index<br />

2 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

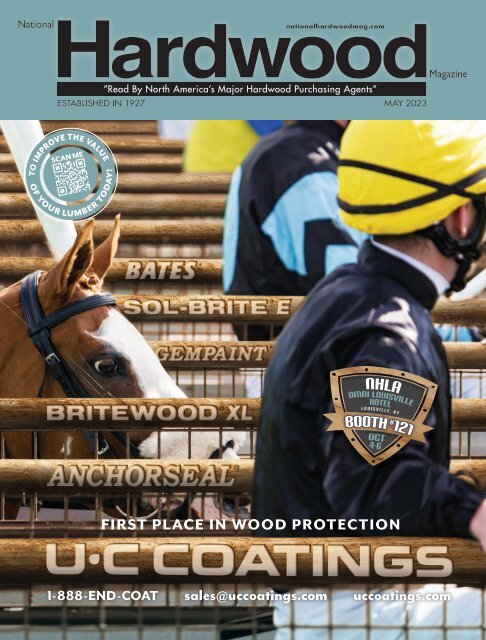

About The Cover<br />

“U-C Coatings is a leading manufacturer and<br />

supplier of premium wood protection products.<br />

For over 50 years, our products have been used<br />

in a variety of industries, including hardwood and<br />

softwood logging and lumber production, wood<br />

products manufacturing, woodworking and wood<br />

decking markets. Our products are used worldwide<br />

to protect, conserve and enhance forest resources.<br />

Our goal is to help our customers achieve more<br />

FIRST PLACE IN WOOD PROTECTION<br />

with less waste and provide the highest level of<br />

1-888-END-COAT sales@uccoatings.com uccoatings.com<br />

protection for their products.<br />

The company offers Anchorseal ® end sealers<br />

and edge sealers for lumber and other wood<br />

products, as well as Gempaint ® for lumber branding. We continue to expand<br />

the Contechem ® product line with Britewood for mold and sapstain control<br />

in softwood and hardwood applications. The Contechem ® Sol-Brite product<br />

line provides excellent iron stain removal and brightening. Seal-Once ® is a<br />

line of eco-friendly, waterbased sealers for wood and concrete that provides<br />

excellent water repellant performance and protection from the elements. The<br />

Eco Chemical ® line of water-based wood stains and other coatings products<br />

is used by the pressure treating and fencing industries, as well as other<br />

prefinished wood manufacturing firms. The Bates line of glue releases help<br />

prevent glue buildup and make cleanup easier wherever adhesives are used<br />

while DPS protects finished parts from checking and delaminating while in<br />

storage.<br />

The company has operations in Buffalo, Portland, and Seattle. Contact us<br />

for any of your wood protection and finishing needs.”<br />

SCAN ME<br />

www.uccoatings.com<br />

U-C COATINGS<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Matthew Fite – Staff Writer<br />

Cadance Hanson - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 3

FOREST PRODUCTS<br />

EXPORT DIRECTORY<br />

TARGETING BUYERS AROUND THE GLOBE!<br />

89% Renewal Rate in the 47th Forest Products Export Directory<br />

*Denotes advertisers that have renewed<br />

**Denotes new advertisers<br />

*Abenaki Timber Corporation<br />

**Almond Brothers Lumber Co.<br />

*Allegheny Wood Products, Inc.<br />

*Ally Global Logistics LLC<br />

*Anderson-Tully Lumber Co.<br />

*Baillie Lumber Co.<br />

**Banks <strong>Hardwood</strong>s Inc.<br />

Bingaman & Son Lumber, Inc.<br />

Broadleaf Lumber Co.<br />

Cardin Forest Products, LLC<br />

Clark Lumber Co., Inc.<br />

*Cole <strong>Hardwood</strong>, Inc.<br />

*Crown <strong>Hardwood</strong> Co., Inc.<br />

*Cummings Lumber Co., Inc.<br />

Deer Park Lumber International<br />

*Devereaux Sawmill, Inc.<br />

East Ohio Lumber Co.<br />

HHP, Inc.<br />

Harold White Lumber Co.<br />

Hanafee Bros. Sawmill Co., Inc.<br />

Hermitage <strong>Hardwood</strong> Lumber<br />

Sales, Inc.<br />

*J.D. Irving Limited<br />

Kamps <strong>Hardwood</strong>s, Inc.<br />

*Kendrick Forest Products<br />

*King City / Northway<br />

Forwarding Ltd.<br />

*Legacy Wood Products LLC<br />

Matson Lumber Company<br />

*McClain Forest Products LLC<br />

*Merrick <strong>Hardwood</strong>s<br />

Midwest <strong>Hardwood</strong> Company<br />

MO PAC Lumber Company<br />

*NELMA (Northeastern Lumber<br />

Manufacturers Assoc.)<br />

*NWH<br />

*Nyle Dry Kilns<br />

*Parton Lumber Co., Inc.<br />

*Penn-Sylvan International, Inc.<br />

Prime Lumber Company<br />

*Primewood<br />

*Ram Forest Products, Inc.<br />

*Ron Jones <strong>Hardwood</strong> Sales, Inc.<br />

*Rossi Group<br />

*Roy Anderson Lumber Company, Inc.<br />

Salamanca Lumber Company, Inc.<br />

*SFPA (Southern Forest Products Assoc.)<br />

Snowbelt <strong>Hardwood</strong>s, Inc.<br />

*Softwood Export Council<br />

*TMX Shipping Company, Inc.<br />

Taner Timber Co., Inc.<br />

Thompson Appalachian <strong>Hardwood</strong>s<br />

*Turman Forest Products<br />

Two Rivers Timber Company, Inc.<br />

*Vexco, Inc.<br />

*Wagner Lumber Company<br />

*Wheeland Lumber Co., Inc.<br />

*WOODBOX<br />

“...the Most Comprehensive Buyer’s Guide for the International Buyer...”<br />

Call NOW to reserve your<br />

space in the 48th EDITION!<br />

Published in FALL <strong>2023</strong><br />

800-844-1280<br />

Full Page Rate: $2,950<br />

Half Page Rate: $2,500<br />

Color Additional<br />

forestproductsexport.com • exd@millerwoodtradepub.com

ONE SOFTWARE PARTNER<br />

FROM TIMBER TO CONSUMER<br />

TIMBER, LOGGING & LUMBER<br />

Handheld & desktop software<br />

DISTRIBUTION AND RETAIL<br />

Inventory and order management<br />

HARDWOOD END TALLIES<br />

Mobile app with A.I.<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

VISIT DMSi.COM TO LEARN MORE<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 5

Vol.49 No.4 Serving Forest Products Buyers Worldwide FEBRUARY/MARCH <strong>2023</strong><br />

The waters are choppy for lumber shipping companies, but they continue<br />

doing their due-diligence and seeing positive results. One shipper stated:<br />

“Our lumber shipments are lagging now, but we remain hopeful they will<br />

continue to increase as we move into the first quarter of <strong>2023</strong>.”<br />

Another shipper mentioned difficulties, adding: “Our team was able to<br />

adapt within the confines of shipping, to not only make it work but to do so<br />

We, at AGL view 2022 as an erratic, yet successful year. The last two and a half<br />

years have posed very difficult challenges from a logistics perspective. Our team<br />

was able to adapt within the confines of shipping, to not only make it work but to<br />

do so successfully. The amount of effort input on a daily basis to accomplish what<br />

we were able to in 2022 was remarkable.<br />

In addition, 2022 was a success, as it opened our eyes in regards to areas of the<br />

supply chain that we previously had taken for granted, specifically the ports and<br />

Michael Snow<br />

By Michael Snow,<br />

Executive Director<br />

American <strong>Hardwood</strong><br />

Export Council<br />

Sterling, VA<br />

703-435-2900<br />

www.ahec.org<br />

Webinars and Zoom calls have let us meet virtually with<br />

anyone in the world from the comfort of our home office,<br />

but as any sales rep will tell you, there’s just no substitute<br />

for meeting with potential customers in person. After a<br />

much more normal year of travel in 2022, The American<br />

<strong>Hardwood</strong> Export Council is looking forward to a busy<br />

schedule of events and opportunities for your company to<br />

meet directly with interested global buyers in <strong>2023</strong>.<br />

successfully. The amount of effort input on a daily basis to accomplish what<br />

we were able to in 2022 was remarkable.” He also said that in <strong>2023</strong>, “I believe<br />

the U.S. economy will head for a mini- (soft) recession before slowly<br />

making its way back.”<br />

If optimism is one part of success and hard work is another, then these<br />

shippers have put themselves in a position to do well in <strong>2023</strong>.<br />

their receiving dates.<br />

Towards the end of 2022, we saw vessel schedules and receiving dates start to<br />

normalize, which was the exact opposite of what we saw at the beginning of 2022.<br />

I anticipate this will continue to be a challenge on certain lanes, specifically for<br />

inland rail shippers.<br />

Another challenge I expect to continue to deal with in <strong>2023</strong> is trucking capacity.<br />

There are only so many trucks, and so many moves drivers can do in a day. If more<br />

drivers aren’t added in the marketplace, I expect this to be a continued hot button<br />

issue.<br />

In 2022, we shipped over 34,000 loads, added 28 team members, moved into a<br />

new office space in our Jacksonville location and opened up a 52,000 square foot<br />

warehouse in Blakeslee, PA.<br />

I do not see any rate increases coming from steamship lines as of January 1st.<br />

We may see certain routings be increased, but as a market, we were at all-time<br />

highs for the last year. As the market normalizes, so will freight rates. In addition,<br />

Continued on page 14<br />

In addition to what we expect to be a full slate of design,<br />

marketing, educational and networking events, AHEC has<br />

also planned pavilions at eight of the largest wood trade<br />

and furniture trade shows in the world in <strong>2023</strong>, as well<br />

as an AHEC Convention in Kuala Lumpur, Malaysia.<br />

These pavilions will make premier representation available<br />

to American companies at the busiest events of the year for<br />

just $500 per booth.<br />

In <strong>2023</strong> we plan to host a U.S. <strong>Hardwood</strong> Pavilion at these events:<br />

DelhiWood, New Delhi, India (Mar. 2-5)<br />

Dubai Woodshow, Dubai, UAE (Mar. 7-9)<br />

Interzum Guangzhou, Guangzhou, China (Mar. 28-31)<br />

(Possibly open to Chinese staff only)<br />

Interzum Cologne, Cologne, Germany (<strong>May</strong> 9-12)<br />

AHEC Convention, Kuala Lumpur, Malaysia (June)<br />

TechnoMueble, Guadalajara, Mexico (Aug. 16-19)<br />

FMC Shanghai, Shanghai, China (Sept. 9-11) (US Participation TBD)<br />

VietnamWood 2022, Ho Chi Minh City, Vietnam (Sept. 20-23)<br />

INTERMOB, Istanbul, Turkey (Sept. 30-Oct 3)<br />

Each year AHEC attends over 40 trade<br />

shows globally to promote American<br />

<strong>Hardwood</strong>s, research market potential<br />

and drive local purchasing behavior. In<br />

our experience these shows we have selected<br />

provide the best opportunity this<br />

year for an American company to connect<br />

with local buyers and build strong<br />

relationships. Of course, our participation<br />

in all of these events is subject to<br />

travel restrictions and health guidelines,<br />

and event dates are subject to change.<br />

Continued on page 16<br />

FIRST PLACE IN WOOD PROTECTION<br />

Photos By Terry Miller<br />

Chris Armanini and Pino Pucci, Tolko Marketing & Sales Ltd., Vernon, BC; and Ken<br />

Hori, BC Wood Specialties Group, Vancouver, BC<br />

Kevin Cheung, Western Wood Products Association, Portland, OR; Jay Poppe, Western<br />

Red Cedar Lumber Association, Vancouver, BC; Jeff Easterling, NELMA, Cumberland,<br />

ME; Butch Bernhardt, Western Wood Preservers Institute, Vancouver, WA;<br />

and Eric Gee, Southern Forest Products Association, Metairie, LA<br />

Las Vegas, NV–Nearly 70,000 home building professionals from around the<br />

globe filled the exhibit halls of the Las Vegas Convention Center recently as<br />

the <strong>National</strong> Association of Home Builders (NAHB) hosted the NAHB International<br />

Builders’ Show® (IBS), the largest annual light construction show in the<br />

world.<br />

Continued on page 24<br />

The Southern Forest Products Association team includes: Rachel Elton, accountant;<br />

Linda Patch, administrative assistant and program coordinator; Eric Gee, executive<br />

director; Alaina Hanson, director of administration; and Christian Moises, communications<br />

manager.<br />

Continued on page 24<br />

Want us in your email inbox?<br />

Scan to get it delivered, monthly - FREE.<br />

SCAN ME<br />

1-888-END-COAT sales@uccoatings.com uccoatings.com<br />

Check out these other titles you may like as well.<br />

IMPORT/EXPORT<br />

www.woodpurchasingnews.com<br />

PRSRT STD<br />

U.S. POSTAGE PAID<br />

JEFFERSON CITY, MO<br />

PERMIT NO. 303<br />

Lumber Shippers View Their Work Realistically<br />

And Optimistically<br />

Stephen Zambo,<br />

Ally Global Logistics<br />

Weymouth, MA<br />

Import/Export Wood Purchasing News<br />

P.O. Box 34908<br />

Memphis, TN 38184-0908<br />

Change Service Requested<br />

By Matthew Fite<br />

<strong>2023</strong> AHEC Events And Pavilions Are Opportunities To Connect With<br />

Customers And Find New Buyers<br />

The<br />

Forest Products<br />

www.softwoodbuyer.com<br />

Vol. 38 No. 2 The Softwood Industry’s Only Newspaper...Now Reaching 36,034 firms (20,000 per issue) March/April <strong>2023</strong><br />

<strong>2023</strong> Builders’ Show Draws Largest<br />

Attendance In More Than 10 Years<br />

A Preview of Forest Products<br />

EXPO <strong>2023</strong><br />

Do you want to be at the center of the forest products community? Are<br />

you ready to see how adaptive technology is influencing manufacturing<br />

decisions? Is your company part of the new manufacturing age at this<br />

critical moment for the industry?<br />

If you answered yes to any of the above questions, don’t second-guess<br />

attending the 37th Forest Products Machinery & Equipment Exposition.<br />

It’s the place to network with leading equipment manufacturing companies<br />

and industry professionals as they develop and share technologies,<br />

which adapt to new markets, adjust quickly to increased demand, and<br />

bolster operations for the future.<br />

EXPO <strong>2023</strong>, set for August 23-25, <strong>2023</strong>, in Nashville will provide you<br />

with solutions for nearly every stage of manufacturing. From raw material<br />

handling to crane operations; metal detection and scanning technologies;<br />

log optimization, drying, grading, sorting, packaging, and distribution,<br />

there’s an exhibiting company representative on site to explore<br />

these solutions with you face to face.<br />

Make no mistake, this new era of work has arrived. An era of connected<br />

systems, responsive manufacturing, and innovative technologies – it<br />

will all be under a single roof at EXPO <strong>2023</strong>.<br />

The Softwood Forest Products Buyer<br />

P.O. Box 34908<br />

Memphis, TN 38184-0908<br />

Change Service Requested<br />

PRSRT STD<br />

U.S. POSTAGE PAID<br />

JEFFERSON CITY, MO<br />

PERMIT NO. 303<br />

6 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

One Success Story<br />

After Another<br />

“We at New River <strong>Hardwood</strong>s have seen the direct results of advertising in the<br />

<strong>Hardwood</strong> Purchasing Handbook, and <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, the<br />

premier publication serving the <strong>Hardwood</strong> industry that targets appearance grade<br />

manufacturers throughout North America. We want to have representation before the<br />

flooring, furniture, and cabinet manufacturers, as well as the millwork and moulding<br />

plants, etc., and the magazine is the publication we advertise in to market our <strong>Hardwood</strong><br />

lumber, which has more than paid for itself! We have developed new customers from<br />

our advertising and know it is a solid investment!”<br />

Wayne Law<br />

New River <strong>Hardwood</strong>s<br />

350 Dry Stone Branch Rd.<br />

Mountain City, TN 37683<br />

Phone: (423) 727-4019 ext. 201<br />

www.newriverhardwoods.com<br />

Advertises in <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> with 6-1/2 Horizontal Ads in four color<br />

and one Full Page, four color Ad in the <strong>Hardwood</strong> Purchasing Handbook.<br />

New River <strong>Hardwood</strong>s operates three modern high-tech sawmills producing 35,000,000 bd. ft. of<br />

Appalachian <strong>Hardwood</strong>s with a drying capacity of 500,000 bd. ft. Species include Red and White<br />

Oak, Hard and Soft Maple, Poplar, Ash, Hickory, Cherry, and Basswood. Specialties offered are KD<br />

Grade Appalachian <strong>Hardwood</strong>s, S2S and S4S products, and ripped to width boards.<br />

NATIONAL HARDWOOD MAGAZINE<br />

P.O. Box 34908 • Memphis, TN 38184-0908 • Toll Free: 800-844-1280<br />

Website: www.millerwoodtradepub.com<br />

Email address: tammy@millerwoodtradepub.com<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

www.nationalhardwoodmag.com<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 7

HARDWOOD CALENDAR<br />

<strong>National</strong> Wood Flooring Association, Expo,<br />

Wisconsin Center, Milwaukee, WI.<br />

www.nwfaexpo.org. <strong>May</strong> 2-4.<br />

<strong>May</strong><br />

Penn-York Lumbermen’s Club, Meeting, Deer<br />

Park Lumber Inc., State College, PA.<br />

www.pennyork.org. <strong>May</strong> 22.<br />

Appalachian Lumbermen’s Club, Annual Beach<br />

Meeting, Avista Resort, North Myrtle Beach, SC.<br />

www.lumberclub.org. <strong>May</strong> 4-7.<br />

<strong>Hardwood</strong> Manufacturers Assoc., Spring<br />

Regional Meeting, Lexington, KY.<br />

www.hmamembers.org. <strong>May</strong> 24-25.<br />

Indiana <strong>Hardwood</strong> Lumbermen’s Assoc.,<br />

<strong>Hardwood</strong> University Class - Forest Taxation,<br />

Hendricks County 4-H Fairgrounds and<br />

Conference Complex, Danville, IN.<br />

www.ihla.org. <strong>May</strong> 17.<br />

Wood Component Manufacturers Association,<br />

European Plant Tour, Northern Italy.<br />

www.wcma.com. June 12-16.<br />

j<br />

June<br />

j j j<br />

j<br />

Penn-York Lumbermen’s Club, Monthly Meeting,<br />

Emporium <strong>Hardwood</strong>s, Emporium, PA.<br />

www.pennyork.org. June 19. n<br />

BINGAMANLUMBER.COM<br />

PO Box 247, Kreamer, PA 17833<br />

☎ 570.374.1108 | 570.374.5341<br />

8 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

www.RealAmerican<strong>Hardwood</strong>.org<br />

(800) 777-NYLE<br />

www.nyle.com<br />

kilnsales@nyle.com<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 9

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

Lumbermen in the Lake States who were recently interviewed<br />

said their business activity was good.<br />

A Michigan sawmill representative remarked that the<br />

market has been steady lately. “Sales have been pretty<br />

good,” he stated.<br />

However, he noted, business is not as good as it was a<br />

year ago. “Six months ago, sales were down,” he added,<br />

so, at the time of this interview, market conditions were<br />

“slightly better” than a half a year ago.<br />

He sells Hard and Soft Maple, Red and White Oak,<br />

Hickory, Walnut and Cherry in No. 3 Common & Better,<br />

NORTHEAST<br />

Throughout the Northeast region sources have said<br />

that their sales are better than they have been.<br />

In Maryland a lumber representative said that his sales<br />

are continuing to strengthen. “The grade lumber has gotten<br />

stronger and there is more demand,” he said. He<br />

believes that the shortage of logs in his area is why the<br />

demand has grown, causing his sales to be better than<br />

they were six months ago.<br />

His company primarily handles Poplar, as well as Red<br />

and White Oak and some mixed <strong>Hardwood</strong>s. They handle<br />

these species in Face and Better, No. 3A Common<br />

Please turn to page 68 Please turn to page 69<br />

JS-50 WX SCAN<br />

HEAD<br />

SIMPLY<br />

BETTER<br />

10 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

SOUTHEAST<br />

Throughout the Southeast region there seems to be<br />

mixed opinions on how the market is doing at the time of<br />

this writing. One source said that his sales aren’t doing<br />

very well, while other sources have said that their sales<br />

are up.<br />

In Kentucky a lumber spokesperson said that his sales<br />

were not doing well. “We can’t sell anything and it’s dirt<br />

cheap when we do,” he commented. He also noted that<br />

despite prices being low his sales are looking better than<br />

they were six months ago.<br />

His company handles all domestic <strong>Hardwood</strong> species<br />

WEST COAST<br />

West Coast lumbermen, when recently interviewed,<br />

voiced positive sentiments about their markets.<br />

“The market is starting to pick up, more so than a couple<br />

of months ago,” stated a lumber provider in California.<br />

“We are getting more business.<br />

“Business activity is the same as six months ago – it’s<br />

continuing to pick up some,” he remarked.<br />

He handles Walnut, White Oak and Hickory in FAS,<br />

No. 1 and No. 2 Common. White Oak was his best seller,<br />

at the time of this interview.<br />

He sells his lumber to flooring companies and retail<br />

Please turn to page 70 Please turn to page 72<br />

Consistency.<br />

Yield.<br />

Trust.<br />

Specializing in Premium Pennsylvania<br />

<strong>Hardwood</strong> Lumber and Logs:<br />

• Red Oak<br />

• White Oak<br />

• Hard Maple<br />

• Soft Maple<br />

• Cherry<br />

• Poplar<br />

• Ash<br />

• Hickory<br />

®<br />

Matson Lumber Company<br />

132 Main St.<br />

Brookville, PA 15825<br />

Phone: (814) 849-5334<br />

Fax: (814) 849-3811<br />

www.MatsonLumber.com<br />

info@MatsonLumber.com<br />

Your trusted source for<br />

exceptional quality and consistency<br />

for more than 200 years.<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 11

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

ONTARIO<br />

QUEBEC<br />

Spring has finally decided to show up, as winter held<br />

its grip longer than many of us preferred. Logging activities<br />

were constrained as a result of heavy snow and<br />

Glen Thompson and Tommy Stiles, A.W. Stiles Contractors Inc.,<br />

spring McMinnville, thaw, TNseen throughout March and April in some<br />

areas.<br />

whose According topic was to several Growing contacts, the Global business Pie. has improved<br />

for At kiln-dried this year’s Ash, IHLA and Convention, inventories multiple have thus networking declined. opportunities<br />

With limited were Ash offered, being produced, and the association’s buyers were board purchasing<br />

developing held a business stock to session. replenish The their 2017 on-hand board supplies. president<br />

of directors<br />

for Prices IHLA were is Shaun stable. Cook, of C.C. Cook & Son Lumber Co., of<br />

Reelsville, Aspen demand IN. Tom is Oilar holding of Cole up, <strong>Hardwood</strong>, however there located are in am- Logansport,<br />

IN, is the 2017 1st vice president and Brett Franklin,<br />

of Tri-State Timber LLC of Bloomington, IN is the IHLA<br />

Business activity varied over the last few months for<br />

secondary wood products manufacturers. Some truck<br />

trailer flooring businesses were busy, as well as moulding<br />

Matt Taylor, U-C Coatings LLC, Buffalo, NY; Damon Graf, DR Graf<br />

Lumber<br />

and<br />

Co.,<br />

millwork<br />

Lexington,<br />

producers.<br />

KY; and<br />

Flooring<br />

Tom Johel,<br />

manufacturers<br />

U-C Coatings LLCre-<br />

ported a slight improvement in sales. There has been<br />

a 2nd slowdown vice president. in the cabinet and furniture manufacturing<br />

sectors Additionally, due to in new conjunction residential with construction the IHLA meeting, being down the<br />

both Fellowship in Canada of Christian and the Lumbermen U.S. held a brief meeting.<br />

Ash<br />

IHLA<br />

orders<br />

is a non-profit<br />

are good<br />

trade<br />

even<br />

organization<br />

though there<br />

comprised<br />

is limited<br />

of sawmills,<br />

wholesale brokers, equipment vendors, secondary<br />

Ash<br />

being produced due to the Emerald Ash Borer having<br />

decimated most stands. Export markets for kiln-dried<br />

manufacturers, loggers and landowners, among others in<br />

stock are good, especially to the Far East, with prices<br />

the industry.<br />

Learn more at www.ihla.org. n<br />

Please turn to page 73 Please turn to page 75<br />

Additional photos on next page<br />

NORTHERN & APPALACHIAN HARDWOOD<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

[ WWW.SIMONLUSSIER.COM ]<br />

[ WWW.SIMONLUSSIER.COM]<br />

MATHIEU LUSSIER - Export Sales Manager m2lussier@simonlussier.com<br />

450.435.6591 - 16 BOUL. DE LA SEIGNEURIE EST, BLAINVILLE, QC CANADA J7C 3V5<br />

12 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE APRIL 2017 n NATIONAL www.RealAmerican<strong>Hardwood</strong>.org<br />

HARDWOOD MAGAZINE 51<br />

[ WWW.SIMONLUSSIER.COM ]<br />

NORTHERN & APPALACHIAN HARDWOOD

WE’RE CONFIDENT OUR<br />

AI FOR HARDWOOD IS #1<br />

WE’VE TACKLED THE COMPLEX ISSUES OF HARDWOOD<br />

AND ARE CONFIDENT OUR AI WILL TAKE YOUR<br />

PRODUCTION TO A SUPERIOR LEVEL!<br />

• Proper defect detection despite dirt, spots, and chain marks<br />

• No bottlenecks at wood grading<br />

• Consistent production quality<br />

• Labour-saving costs<br />

BID is the only company that developed its AI models using hardwood<br />

to offer unmatchable accuracy of defect detection.<br />

SEE OUR AI-POWERED SCANNERS<br />

IN ACTION!<br />

Call now to find out how you can<br />

maximize your production value.<br />

450-435-2121 | www.bidgroup.ca

NEWS DEVELOPMENTS<br />

MULLET CABINET EXPANDS IN OHIO<br />

Mullet Cabinet, Inc., located in Millersburg, OH, in collaboration<br />

with JobsOhio, Ohio Southeast Economic Development<br />

(OhioSE) and the Holmes County Economic<br />

Development Council, recently announced it has committed<br />

to investing at least $3.27 million to expand its existing<br />

manufacturing facility in Hardy Township, Holmes<br />

County.<br />

Mullet Cabinet uses solid U.S. <strong>Hardwood</strong>s in its manufacturing,<br />

which is carried out only in the U.S. Species<br />

of lumber used include Hard and Soft Maple, Red and<br />

White Oak, Cherry, Walnut, Hickory and Aspen.<br />

A family-owned and Ohio-based company founded<br />

in 1975, Mullet Cabinet, Inc. originally made cabinet<br />

drawers and doors for sale to other manufacturers. Over<br />

time, the company has established<br />

a dealer network in 13 states, selling<br />

complete custom-designed cabinets<br />

for residential and commercial<br />

applications. The company has 204<br />

full-time employees at its existing<br />

120,000-square-foot facility.<br />

The company’s manufacturing capacity<br />

is currently strained by business<br />

demands. Mullet Cabinet, Inc.<br />

will construct a 24,000-square-foot<br />

building addition, purchase new machinery<br />

and equipment to double its<br />

output of drawers and doors, and<br />

improve manufacturing flow through<br />

its facility. The project will result in<br />

the creation of 20 new jobs over the<br />

course of three years.<br />

To learn more, visit www.mullet<br />

cabinet.com.<br />

DURA SUPREME PLANS NEW<br />

MANUFACTURING LOCATION<br />

IN NORTH CAROLINA<br />

Dura Supreme Cabinetry, headquartered<br />

in Howard Lake, MN, has<br />

announced a multi-million-dollar<br />

initiative to launch manufacturing<br />

operations in Statesville, NC. The<br />

company expects the new manufacturing<br />

site to create over 200 new<br />

jobs in the first few years including<br />

cabinet making, furniture making,<br />

finishing, woodworking and machining<br />

skills. The North Carolina facility<br />

will enable Dura Supreme to meet<br />

growing demand with a regional<br />

manufacturing site, expanded manufacturing<br />

capacity, and advantageous<br />

delivery times, the company<br />

stated.<br />

14 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

NEWS ABOUT NORTH AMERICAN INDUSTRIAL<br />

HARDWOOD CONSUMERS INCLUDING MERGERS,<br />

PLANT EXPANSIONS & ASSOCIATION ACTIVITIES<br />

Dura Supreme uses solid U.S. <strong>Hardwood</strong>s – including<br />

Cherry, Red Oak, quarter-sawn White Oak, Maple,<br />

Knotty Alder, Hickory and Rustic Hickory – in its manufacturing.<br />

Dura Supreme manufactures only in the United<br />

States.<br />

Recently, Dura Supreme acquired the manufacturing<br />

assets of another cabinet manufacturer and that equipment<br />

and machinery, along with considerable<br />

additional investments,<br />

will be installed in Statesville at the<br />

company’s newest manufacturing<br />

location. Dura Supreme expected<br />

to occupy the Statesville site in April<br />

and has anticipated starting production<br />

in the second half of this year.<br />

For more information, go to www.<br />

durasupreme.com.<br />

dicated in the graph (available when you click on the<br />

link) that compares the total Global Warming Potential<br />

(GWP) of wood flooring against all competing product<br />

categories that have created these tools (tile, vinyl, carpet).<br />

To learn more, visit www.nhla.com. n<br />

NEW STUDIES CONTINUE TO<br />

SHOW SOLID WOOD FLOOR-<br />

ING SUPERIORITY<br />

The <strong>National</strong> <strong>Hardwood</strong> Lumber<br />

Association (NHLA) reported: the<br />

Decorative <strong>Hardwood</strong> Association<br />

(DHA) and the <strong>National</strong> Wood Flooring<br />

Association (NWFA) recently<br />

released a new Life Cycle Analysis/<br />

Environmental Product Declaration<br />

(EPD) for engineered wood floors.<br />

The new edition complements NW-<br />

FA’s previous solid wood flooring<br />

EPD. NHLA asks readers to please<br />

use and source the studies often to<br />

showcase the real scientific proof<br />

that separates our natural product<br />

from unnatural lookalikes.<br />

Both can be downloaded at:<br />

https://nwfa.org/environment/<br />

The new study reports the environmental<br />

impacts of engineered<br />

wood flooring from raw material extraction<br />

to disposal (cradle to grave).<br />

EPDs have quickly become the international<br />

standard for measuring<br />

a product’s total greenhouse gas<br />

emissions, commonly known as carbon<br />

footprint. According to NHLA,<br />

the results couldn’t be better, as in-<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 15

HMA UPDATE<br />

THE HMA ‘BIG PICTURE!’<br />

In today’s confusing and unpredictable<br />

world, I continue to take comfort in the<br />

cyclical nature of HMA’s calendar of<br />

events. Don’t misunderstand. Each day<br />

typically includes a host of surprises that<br />

often makes HMA-life chaotic. But, when<br />

looking at the HMA ‘big picture,’ there is<br />

a systematic and methodical rhythm to<br />

the work we do for our membership that<br />

provides a calming sense of order.<br />

For as long as any of us can remember, March has<br />

been HMA <strong>National</strong> Conference and Expo month, and<br />

March <strong>2023</strong> was no exception. We’ve just closed the<br />

books on NatCon ’23, and based on feedback from<br />

our membership, it was an absolute win. Informative<br />

business sessions! A sold-out Expo! Plenty of networking<br />

and industry comradery! To all involved in making it such<br />

a crowd-pleaser, thank you!<br />

The advent of Spring triggers preparation for an<br />

HMA Regional Meeting. And later this month, <strong>May</strong><br />

24-25 specifically, HMA members will be heading to<br />

the Bluegrass State for HMA’s members’ only Spring<br />

Regional Meeting in Lexington, Kentucky. (Meeting<br />

Registration and tour details are available at www.<br />

HMAmembers.org.)<br />

Many members tell us they belong to<br />

the HMA specifically to participate in the<br />

Regional Meetings. The value is that<br />

great. By touring <strong>Hardwood</strong> sawmills,<br />

concentration yards and secondary<br />

manufacturing facilities, they get to see the<br />

latest technology at work; witness working<br />

solutions to common problems; conduct<br />

their own field research; and exchange<br />

information with seasoned counterparts. (Up close and<br />

personal. It doesn’t get much better than that.)<br />

As summer rolls around, planning for next year’s<br />

<strong>National</strong> Conference and Expo kicks into gear, and so<br />

does the planning and activity involved in finalizing the<br />

details of a Fall Regional. Then before we know it, we’re<br />

closing out the year, and regrouping for what lies ahead.<br />

As I said, the calming cyclical nature of HMA’s calendar<br />

of events.<br />

Considering HMA membership? Visit www.<br />

HMAmembers.org. Then contact me, ljovanovich@<br />

hardwood.org, to discuss membership criteria, member<br />

benefits, and the ins-and-outs of our storied Association.<br />

And yes, there is still time to register to attend our Spring<br />

Regional. It would be great to see you there. n<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

PITTSBURGH, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

16 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

The The Granite Valley Difference<br />

The Granite Valley Difference<br />

Our Sawmills<br />

Our sawmills in<br />

Wisconsin prepare<br />

raw timber for delivery<br />

to our finishing mills.<br />

Quality<br />

Processing<br />

We “rough grade” our kiln-dried<br />

woods to ensure the best appearance.<br />

Quality assurance on every load.<br />

Custom<br />

Work<br />

To help you streamline your<br />

production process, we<br />

can supply custom-cut<br />

pre-production blanks<br />

to your specs.<br />

Ready<br />

Inventory<br />

Our average on-hand<br />

kiln-dried supply is<br />

10 million board feet.<br />

Get the wood you need<br />

with quick turnaround.<br />

Granite Valley Forest Products keeps growing as a single-source supplier to<br />

better serve you. We sell rough, S2S, straight-line ripping, and offer<br />

NHLA grades and customer-proprietary grading based on NHLA guidelines.<br />

Our Sawmills<br />

Our Sawmills<br />

Our sawmills in<br />

Our Wisconsin<br />

Sawmills<br />

in prepare<br />

Our sawmills in<br />

Our raw Our timber sawmills for in in delivery<br />

Wisconsin prepare<br />

raw to Wisconsin our for<br />

finishing<br />

Offices prepare mills.<br />

in Wisconsin, Indiana<br />

raw timber for delivery<br />

to our<br />

raw raw timber timber for to our finishing mills. & for Colorado<br />

delivery<br />

to to our our finishing mills. mills. Quality<br />

sales@granitevalley.com Quality<br />

Processing<br />

Quality<br />

Custom products are available to your exact specs for width, length and color.<br />

Visit our website to learn more or email us at sales@granitevalley.com.<br />

To help you streamline your<br />

granitevalley.com We “rough Work<br />

Processing<br />

grade” our kiln-dried<br />

production process, we<br />

To help you woods to ensure the best appearance. To help To can To help help you supply you you streamline custom-cut streamline your<br />

your<br />

We We “rough we<br />

We Quality We “rough “rough grade” assurance grade” grade” our our kiln-dried<br />

our our on every kiln-dried load. production pre-production production process, process, blanks we we we<br />

Alder | Aromatic woods Cedar can woods woods to | to Black ensure to to &<br />

ensure ensure the White the best best<br />

the the Ash<br />

best appearance.<br />

best | Aspen appearance. | Basswood can can to supply can your supply specs.<br />

custom-cut<br />

Beech | White & Quality Yellow Quality Quality assurance Birch assurance | Bitternut on on every every<br />

on on | every Butternut every load. load.<br />

load. load. | Cherry<br />

pre-production blanks<br />

blanks<br />

Grey & Red Elm | Hard Maple | Hickory | Red Oak | White Oak to to your to your to your your specs.<br />

specs.<br />

Norway<br />

Granite<br />

Pine<br />

Valley<br />

| White<br />

Forest<br />

Pine<br />

Products<br />

| Poplar<br />

keeps<br />

| Red &<br />

growing<br />

Silver Soft<br />

as a<br />

Maple<br />

single-source<br />

| Walnut<br />

supplier to<br />

Granite White better<br />

Granite Granite Valley Valley<br />

Cedar serve<br />

Valley Forest Valley | Rift you.<br />

Forest Forest<br />

&<br />

Products We Quartered sell<br />

Products Products<br />

rough,<br />

keeps Red<br />

keeps keeps<br />

S2S, &<br />

growing White straight-line growing<br />

Oak<br />

as as a as a single-source as a a<br />

ripping, single-source<br />

and<br />

supplier offer<br />

supplier to<br />

to to to<br />

NHLA<br />

better better better serve better<br />

grades serve serve you. serve you. you. We We you.<br />

and<br />

sell We sell We<br />

customer-proprietary<br />

rough, sell sell rough, rough, S2S, S2S, S2S, straight-line S2S, straight-line<br />

grading based<br />

ripping, ripping, ripping,<br />

on NHLA<br />

and and and and offer<br />

offer offer offer<br />

guidelines.<br />

Custom<br />

NHLA NHLA NHLA grades<br />

NHLA grades grades grades<br />

products<br />

and and customer-proprietary and and<br />

are customer-proprietary<br />

available to your exact<br />

grading grading grading<br />

specs<br />

based based based<br />

for width,<br />

on on NHLA on on NHLA NHLA<br />

length<br />

guidelines.<br />

guidelines.<br />

and color.<br />

Visit<br />

Custom Custom Custom Custom<br />

our<br />

products products products<br />

website to<br />

are are available are are<br />

learn<br />

available available<br />

more or<br />

to to your your to to<br />

email<br />

your your<br />

exact exact exact exact<br />

us at<br />

specs specs specs specs<br />

sales@granitevalley.com.<br />

for for width, for width, for width, width,<br />

length length length<br />

and and and and<br />

color.<br />

color.<br />

color.<br />

Visit Visit our Visit our Visit<br />

website website our<br />

Offices our website website<br />

to to learn learn to<br />

in to learn learn<br />

more more Wisconsin,<br />

more more email email or or email email<br />

us us at us at Indiana us<br />

sales@granitevalley.com.<br />

at at sales@granitevalley.com.<br />

& Offices Colorado<br />

in in in Wisconsin, Indiana<br />

Offices in Wisconsin, Indiana<br />

& Colorado<br />

& sales@granitevalley.com<br />

& Colorado<br />

sales@granitevalley.com<br />

sales@granitevalley.com<br />

granitevalley.com<br />

granitevalley.com<br />

Alder | Aromatic Cedar | Black & White Ash | Aspen | Basswood<br />

granitevalley.com<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry<br />

Alder Grey Alder | Aromatic & | Aromatic Red Elm Cedar | Cedar Hard | Black Maple | Black & | Hickory & White<br />

White Ash | Ash Red | | Aspen Oak Aspen | | White | Basswood<br />

Basswood Oak<br />

Alder<br />

Alder<br />

| Aromatic<br />

| Aromatic Cedar | Black & White Ash Aspen | Basswood<br />

Beech Norway Beech | | White Pine White Cedar & | White & | Yellow Black<br />

Yellow Pine Birch & Birch | White Poplar | Bitternut Ash | Bitternut | Red | Aspen | Butternut & | Butternut Silver | Basswood Soft | Cherry<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry | Cherry Maple | Walnut<br />

Beech | Grey<br />

Grey White Grey & & Red<br />

& Red Cedar & Red Yellow Elm Elm<br />

Elm | Rift Birch | Hard | Hard<br />

| Hard & Quartered | Maple Bitternut | | Butternut | Cherry<br />

Maple<br />

Maple | Hickory<br />

| Hickory Red Hickory & | White | Red<br />

Red Oak<br />

Oak Oak Oak | White Oak<br />

| White<br />

| White Oak<br />

Oak<br />

Grey & Norway<br />

Norway<br />

Red Norway Elm Pine Pine<br />

Pine<br />

| Hard | White | White<br />

| White<br />

Maple Pine Pine<br />

Pine<br />

| | Poplar<br />

|<br />

Hickory | Poplar<br />

Poplar | |<br />

|<br />

Red | Red Silver<br />

&<br />

Oak & Silver<br />

Silver<br />

| White Soft Soft<br />

Soft Maple<br />

Maple<br />

Oak Maple | Walnut<br />

| Walnut<br />

| Walnut<br />

Norway White<br />

White Pine Cedar | Cedar White |<br />

| Rift Pine Rift &<br />

& Quartered | Poplar Quartered | Red Red<br />

Red & & Silver White<br />

White Oak Soft OakMaple | Walnut<br />

White White<br />

Cedar Cedar<br />

| Rift | Rift<br />

& &<br />

Quartered Quartered<br />

Red Red<br />

& &<br />

White White<br />

Oak<br />

Oak<br />

Custom<br />

Work Custom<br />

Work<br />

Work<br />

Ready<br />

Inventory<br />

Ready<br />

Inventory<br />

Our average on-hand<br />

kiln-dried supply is<br />

Our 10 Our average million average board on-hand<br />

on-hand feet.<br />

kiln-dried Get is<br />

kiln-dried the supply wood supply you is<br />

isneed,<br />

10 10 10 with 10 million million quick board board turnaround. feet.<br />

feet.<br />

Get Get the Get the the wood wood you you need,<br />

with with quick quick turnaround.

AHEC REPORT<br />

NEW NORDIC DESIGN PROJECT “THREE” TO PROMOTE<br />

RED OAK, MAPLE AND CHERRY<br />

As part of our ongoing promotion of underutilized<br />

species of American <strong>Hardwood</strong>s,<br />

AHEC is working with three designer-makers<br />

from the Nordic regions – Norway, Sweden<br />

and Denmark – in a three-timber making<br />

challenge. They will create a final piece/<br />

object in either Red Oak, Maple or Cherry<br />

to be showcased in an exhibition that will<br />

be held at 3daysofdesign in Copenhagen in<br />

June <strong>2023</strong>. The project aims to shine a light<br />

on these timbers’ versatility, aesthetics, and<br />

technical performance.<br />

To kickstart the project, AHEC hosted a<br />

workshop in Copenhagen to meet the designers<br />

involved and provide them with a<br />

technical briefing for Three. During this session, the designers<br />

were randomly allocated one of the three timbers<br />

to work with and briefed on its performance and characteristics<br />

to help inform their design process. Hand samples<br />

and copies of ‘A guide to sustainable American <strong>Hardwood</strong>s’<br />

were supplied to the designers to provide further<br />

information and reference points.<br />

As part of the design phase, each designer will now<br />

carry out experimental research into their allocated material,<br />

testing its properties and learning more about how<br />

it can be used. They will document their experiences<br />

and process of working with the<br />

material and this content will be used as part<br />

of the exhibition. The 3daysofdesign event<br />

in Copenhagen is the latest in our outreach<br />

to European design, continuing the work of<br />

recent projects like SLOW and Natural Connections<br />

for the Madrid Design Festival earlier<br />

this year.<br />

From 2010 to 2015, the average value of<br />

Red Oak lumber exported to Europe was $8.5<br />

million per year. After years of outreach to the<br />

European industry through design projects,<br />

technical seminars, and industry networking,<br />

the United States doubled our European Red<br />

Oak market to an average of $19.9 million from 2016-<br />

2020, and since 2021, the market has doubled again -<br />

reaching exports of over $37.5 million in Red Oak lumber<br />

to Europe in 2021, and over $56 million in 2022. That’s 50<br />

percent from the previous record high. Compared to the<br />

average value from 2010 to 2015, this growth from $8.5<br />

million per year up to over $56 million has added over<br />

$125 million in new Red Oak exports to Europe since<br />

2010. n<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

18 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 19

WCMA INSIGHTS<br />

BUSY YEAR AHEAD FOR WCMA<br />

It has been a busy spring, and I have<br />

enjoyed being back on the road attending<br />

several industry events and seeing<br />

members in person. I can always tell<br />

when business is good by the attendance<br />

rate at these events, and it has<br />

been a great spring!<br />

<strong>2023</strong> European Plant Tour<br />

Event<br />

The WCMA is excited to once again be hosting our<br />

European Plant Tour event. The WCMA is partnering<br />

with SCM, CMS, Superfici and Friulmac to put together<br />

a truly unique opportunity to visit manufacturing facilities<br />

in Northern Italy. The event is being held June 12-16.<br />

Throughout the week, attendees will get an exclusive<br />

look into state-of-the-art cabinet, furniture, and machinery<br />

manufacturers, giving them an edge in discovering<br />

“what’s next” in the global woodworking industry.<br />

This event also provides an excellent opportunity to<br />

network with your peers. Conversations during the bus<br />

rides, shared meals, and during the debriefing at the end<br />

of each day will allow attendees to build camaraderie<br />

and the learning experience becomes even more valuable.<br />

Below are just a few comments from attendees at previous<br />

European Plant Tour events:<br />

“This was my second trip with the<br />

WCMA group to Europe and it lived up to<br />

our expectations. The combination of the<br />

plant tours, networking with other members,<br />

and just taking the time to see how<br />

other businesses operate was amazing.<br />

This will certainly help me in the future to<br />

make better decisions in our company’s<br />

growth in technology and manufacturing.”<br />

“I found the quality of the plant tours to be excellent.<br />

They offered a diverse view into the European philosophy<br />

of manufacturing by utilizing more automation and<br />

technology, replacing aging equipment quickly, and utilizing<br />

a wide range of wood composite materials. I saw<br />

levels of automation in action that I had often dreamt of<br />

but never believed were being applied in real woodshop<br />

applications. I left my week in Europe inspired and ready<br />

to apply aspects of what I learned in my own business.”<br />

Registration is now open. Maximum number of attendees<br />

for the event is 40 individuals, so visit the website,<br />

www.wcma.com to register today.<br />

<strong>2023</strong> Fall Conference & Plant Tour Event<br />

We will also be collaborating on our <strong>2023</strong> Fall Conference<br />

& Plant Tour Event with WMMA for the third year in<br />

Please turn to page 77<br />

BY AMY K. SNELL, CAE,<br />

EXECUTIVE DIRECTOR,<br />

WOOD COMPONENT MANUFACTURERS ASSOC.,<br />

LINDSTROM, MN<br />

651-332-6332<br />

WWW.WCMA.COM<br />

20 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

BE PART OF<br />

BUILDING<br />

SOMETHING<br />

BIG<br />

Where We’ve Been<br />

It’s no secret, the hardwood industry has been losing market share to<br />

products that look like wood, but have none of the natural benefits or<br />

authentic attributes of Real American <strong>Hardwood</strong>. In order to recapture<br />

market share and improve industry stability, hardwood organizations<br />

united to form the Real American <strong>Hardwood</strong> Coalition.<br />

Where We Are<br />

The goal is to develop a national consumer promotion campaign on a<br />

scale that’s never been seen before. And a lot has been accomplished<br />

in a short period of time—including the completion of an extensive<br />

consumer research initiative, establishing brand guidelines, registering<br />

trademarks, and launching social media profiles.<br />

Where We’re Going, Together<br />

The next steps will have the largest impact on the industry and require<br />

buy-in from all industry stakeholders. The Coalition is preparing to<br />

launch a comprehensive promotion campaign—including a consumeroriented<br />

website, in-store promotion at top big box stores, a broad<br />

media relations campaign, social media influencer partnerships, print<br />

and web advertising, and much more.<br />

How You Can Get Involved<br />

Moving the campaign forward and expanding its reach will take the<br />

support of the entire industry—for the benefit of the entire industry.<br />

■ Make a voluntary contribution to help fund the consumer<br />

promotion campaign.<br />

■ Use the Real American <strong>Hardwood</strong> logo on your sales and<br />

marketing communications, facilities and vehicles, products,<br />

and website.<br />

■ Follow @RealAmerican<strong>Hardwood</strong> on Instagram and Facebook,<br />

and tag #RealAmerican<strong>Hardwood</strong> in your social media posts.<br />

Visit RealAmerican<strong>Hardwood</strong>.org to learn more and get on board.

NHLA: Why Knot...<br />

We tend to offer advice to others,<br />

including employees, even<br />

when it is not wanted. Do you like<br />

unsolicited advice? Me neither,<br />

but we must train employees on<br />

how to be more effective, efficient,<br />

and industrious. So, what<br />

is the best way? I think it’s like guiding a moose hunter.<br />

First, let me say something about hunters. We all know<br />

they think they are the best shooter, have the best gear,<br />

and can hunt better than anyone else, just because they<br />

shot a few deer or something. Most employees are like<br />

that too. The best way to guide an employee, is the<br />

same way to guide a moose hunter. You can tell them<br />

the things to do but, if they don’t care, they will never do<br />

the things you tell them.<br />

When I guide moose hunters, I always start by telling<br />

them why I am there. Seriously, I tell them this is<br />

my family business and I love to get away and have a<br />

chance to relax. I tell them about my family and my job<br />

at NHLA and how important it is for me to leave them to<br />

be a guide. This is true for sawmills and moose hunters;<br />

you must tell them what your business means to you and<br />

what you are sacrificing to build your business and why<br />

they should care. By doing this, you will help them buy<br />

in and establish credibility with them.<br />

I then try to relate with them and build on common<br />

ground. I ask them if they have hunted moose before or<br />

other big game. We share stories and relate to each other’s<br />

experiences. Here I do a lot of listening. You would<br />

be wise to do the same for your staff. Ask them about<br />

themselves and their experiences in their life. Don’t put<br />

down any of their experience’s no matter how crazy they<br />

are, just nod and ask them follow up questions about<br />

how it made them feel or where they went from there.<br />

As I start to share moose hunting advice and explaining<br />

how it is different than other types of hunting, I share<br />

with them the experiences I have had with other hunters<br />

BE AN EXAMPLE<br />

over the years. So and so did<br />

this, what’s his name did that,<br />

and it was crazy, or it was great.<br />

Experiences teach the hunter my<br />

preferred way of hunting without<br />

being bossy. You have had plenty<br />

of good and bad experiences<br />

with employees, tell them those experiences and laugh<br />

about it. And I always say, you can do what you want, it<br />

is your hunt, but my job is to give you the best possible<br />

chance of seeing a moose each time we go out. Your job<br />

is to help employees succeed by giving them the tools<br />

to do so but they must make their own decisions when<br />

grading or milling or selling <strong>Hardwood</strong> lumber.<br />

Most often I tell them about times when a hunter was<br />

not prepared. So, they need to be prepared for anything.<br />

They need to look around and become familiar with their<br />

surroundings. I warn them they have 8 seconds to shoot<br />

when I call a bull in hot, just like riding a bull at the rodeo.<br />

They can relate to that. They get the general idea; nothing<br />

goes as planned for a bull rider.<br />

When you teach employees, you need to share experiences,<br />

good and bad, again and again and again. Your<br />

experiences, your boss’s, your father’s, your past employee’s.<br />

It does not matter whose, it only matters what<br />

principle, habit, or behavior, you are teaching with the<br />

story.<br />

After all that, I tell them how nothing ever goes as<br />

planned when hunting, the moose is smart and never<br />

does what you think it will, so you must adapt. I then take<br />

them to a lake shore and show them how to call moose.<br />

It is an extended “EER—UGH—bellowed into a Birch<br />

bark bullhorn.” Calling a moose to come to you on a lake<br />

shore or in a meadow is the most effective way to hunt,<br />

seeking a moose by walking in the forest is hard, there<br />

are too many trees blocking your view and walking is too<br />

noisy. Finally, when a moose comes, I am prepared to<br />

back them up if they hit the moose.<br />

Please turn to page 83<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

22 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 23

A quick look through the Oak Pointe’s catalogue reveals dozens of species including Red and White Oak, Quartersawn White Oak,<br />

Hard and Soft Maple, Beech, Alder, American Cherry, Walnut, Poplar, Hickory, Jatoba and Sapele, as well as other species upon request,<br />

of which the company purchases over 100,000 board feet annually.<br />

Oak Pointe<br />

A Quality Custom Manufacturer<br />

By Scott Dalton<br />

Newcomerstown, OH – When David Weissman<br />

purchased Oak Pointe, located here, in July<br />

2007, he knew he was buying into a solid company.<br />

Weissman had done business with the company for<br />

some time, having worked for a building components<br />

wholesaler that specialized in windows, doors, stair<br />

components, and other millwork. He knew that Oak<br />

Pointe, which had originally opened in 1996, had quickly<br />

established itself as a regional leader in the manufacturing<br />

of stair parts.<br />

“Prior to Oak Pointe, I had a little wood turning shop<br />

and was trying to grow, and I needed a better facility,”<br />

Weissman recalled, adding that his company, Creative<br />

Custom Components, was focused exclusively on custom-made<br />

products, while Oak Pointe was almost entirely<br />

dedicated to manufacturing parts for stairways. “I<br />

needed an expanded, talented employee base and a<br />

bigger customer base.”<br />

It turned out to be a perfect match, with the re-focused<br />

Oak Pointe building on its reputation for consistent quality,<br />

but now with the additional feature of a dedicated<br />

custom approach. Weissman explained that the shift in<br />

approach provided a welcome jolt to the industry in general.<br />

“Before 2010, if you went and gathered up catalogues<br />

to all the stair component companies, they all looked the<br />

same as they had for years,” he noted. “Now imagine<br />

24 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

“Today, we can offer numerous designs and we have the equipment that<br />

allows us to make whatever a person wants. Just about every week, a customer<br />

finds a picture and wants to duplicate it or modify it. Our approach<br />

is, if you want high quality, if you want something different, here is our<br />

catalogue. If you don’t see it, we can make it for you.”<br />

David Weissman, President of Oak Pointe<br />

“When it comes to custom, not everybody has<br />

the stomach for this kind of business, but at Oak<br />

Pointe, we make parts like these all the time; we<br />

know what we are doing,” said David Weissman,<br />

President of Oak Pointe, located in Newcomerstown,<br />

OH.<br />

if you went into a car dealership and<br />

they were selling the same cars from<br />

10 years ago.” Instead of relying only<br />

on classic stairway components, Oak<br />

Pointe began introducing variations,<br />

driven by a desire to distinguish itself<br />

from the competition, but also by necessity,<br />

as Weissman remembered.<br />

“There was the housing market crash<br />

that came right after buying the company,”<br />

he said, adding that it turned out to<br />

be an opportunity to differentiate Oak<br />

Pointe. “Our business dropped and<br />

many other companies began importing<br />

rather than making their products.<br />

We were small and couldn’t do the im-<br />

ports; we couldn’t compete with imports<br />

from the other companies on<br />

price. We started making new designs<br />

of newels, balusters, and other<br />

components. We did that for several<br />

years and our catalogue ballooned<br />

up. It is an ongoing process.”<br />

A quick look through the company’s<br />

catalogue reveals dozens of<br />

species including Red and White<br />

Oak, Quartersawn White Oak,<br />

Hard and Soft Maple, Beech, Alder,<br />

American Cherry, Walnut, Poplar,<br />

Hickory, Jatoba and Sapele, as well<br />

as other species upon request, of<br />

which Oak Pointe purchases over<br />

Oak Pointe’s operations are housed in a single 30,000 square-foot building that includes<br />

the company’s plant and offices. Across the parking lot is another 15,000 square-foot facility<br />

that handles the warehousing and shipping operations.<br />

100,000 board feet annually.<br />

Weissman quickly pointed out<br />

that as with designs, if a customer<br />

wants something that’s not in<br />

the catalogue, Oak Pointe will do<br />

everything it can to source whatever<br />

wood is desired.<br />

“It changes over time, just like<br />

design changes,” Weissman<br />

said about wood preferences.<br />

“Back in 2007, Jatoba (Brazilian<br />

Cherry) was popular. Then it<br />

was American Cherry that was<br />

popular, and then that faded. Today,<br />

White Oak is very hot; some<br />

days it seems that 50 percent of<br />

the quotes we do are for White<br />

Oak. There’s been a shortage,<br />

however, because in addition to<br />

the construction industry, it’s also<br />

used for bourbon barrels and a<br />

lot of it is being exported.”<br />

He noted that White Oak also<br />

once enjoyed a nice price point<br />

relative to Red Oak, which has<br />

been a staple species for many<br />

years. Now, however, White Oak<br />

is much more than Red Oak.<br />

Hard Maple and Poplar are also<br />

popular, as well as Walnut. In<br />

terms of imported species, there<br />

are a variety of Mahoganies that<br />

are used consistently, including<br />

Sapele Mahogany and Genuine<br />

Mahogany, which is the same<br />

species of tree that used to come<br />

from Honduras. African Mahogany<br />

and European White Oak<br />

have also sparked substantial<br />

consumer interest. Weissman<br />

pointed out that while Oak Pointe<br />

does offer a wide variety of species<br />

and design options, most of<br />

the company’s success can be<br />

traced back to its most valuable<br />

Please turn to page 58<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 25

Gates Milling is family owned and operated, (front row) Nancy Tuck, CEO, Mark Tuck, COO, (back row) Kelsey Kennedy, vice president<br />

of operations and marketing and Kaitlyn Wood, vice president of finance and sales.<br />

Gates Milling<br />

Quality Products From People That Care<br />

By Terry Miller<br />

“We like to operate like a Fortune 500<br />

company with that family feel. We are<br />

committed to the relationships that we have<br />

with our customers. When you buy from<br />

us, you are going to be dealing with a sales<br />

group that knows who else in your market<br />

has your product and where you need to<br />

be competitive. We bring you in on a level<br />

playing field.”<br />

– Gates Milling<br />

Vice President of Operations and Marketing<br />

Kelsey Kennedy<br />

Gatesville, NC – Gates Milling, located here, was<br />

founded in 1978 by Brian H. Martin. Martin bought<br />

an existing operation to become a producer and<br />

reman operation for Atlantic white cedar products. He<br />

envisioned a niche company that would allow him to go<br />

into the bigger mills and buy their products, that could<br />

then be remanufactured into custom millwork that these<br />

larger mills didn’t want to worry with. In 1981 the Gates<br />

facility was set on fire by burglars. This caused the company<br />

to rebuild and begin an expansion. Gates Milling<br />

began producing Poplar products in 1997, and Cypress<br />

products in 1999.<br />

Martin brought his son-in-law, Mark Tuck, on board to<br />

be the vice president of Gates Milling in 1988, and then<br />

his daughter, Nancy Tuck to oversee marketing and finance<br />

in 1992. Mark and Nancy bought the family business<br />

from Martin in 2012, and they now serve as COO<br />

and CEO, respectively. Mark and Nancy’s two daughters<br />

26 MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org

New Cleereman carriage installed in 2022 breaking down a Cypress log.<br />

are the third generation to be deeply imbedded in the<br />

business with Kaitlyn Wood serving as vice president of<br />

finance and sales, and Kelsey Kennedy serving as vice<br />

president of operations and marketing.<br />

Gates Milling isn’t just a family business in the sense<br />

that it is owned and operated by family, but they make it<br />

a point to make each of their employees and customers<br />

feel as if they are family as well! “We like to operate<br />

like a Fortune 500 company with that family feel. We<br />

are committed to the relationships that we have with our<br />

customers. When you buy from us, you are going to be<br />

dealing with a sales group that knows who else in your<br />

market has your product and where you need to be competitive.<br />

We bring you in on a level playing field,” said<br />

Kennedy.<br />

Gates Milling has created their own niche market by<br />

remanufacturing products that other companies weren’t<br />

looking to create, according to Nancy. “This really started<br />

when we brought on Cypress as a green product,<br />

and we sold it all green. We ended up buying kiln-dried<br />

products back. The initial point of the business was to<br />

do the profile side of it and not have the raw material<br />

produced. Then we built the sawmill in ’99 and we were<br />

able to expand on that,” Nancy said. “We’ve found ways<br />

to become the fully integrated mill that we are today, by<br />

reverse engineering,” she continued.<br />

The company just recently, at the beginning of <strong>2023</strong>,<br />

installed two new dry kilns that will have a capacity of<br />

Please turn to page 61<br />

“Our ideal cutting schedule would be two weeks of American Cypress,<br />

one week of Poplar and a week of Atlantic white cedar,”<br />

said COO, Mark Tuck.<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

American Cypress timber being sawn into boards on the CAE<br />

linebar resaw.<br />

MAY <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 27

Most of the M&M Lumber crew are shown in this 2022 Christmas picture.<br />

M&M Lumber:<br />

A Legacy Of Service And Quality<br />

By Scott Dalton<br />

Tulsa, OK—When Jim McKellar Sr. co-founded<br />