food Marketing - Technology 2/2023

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2/23<br />

Vol. 37 • 31377<br />

ISSN 0932-2744<br />

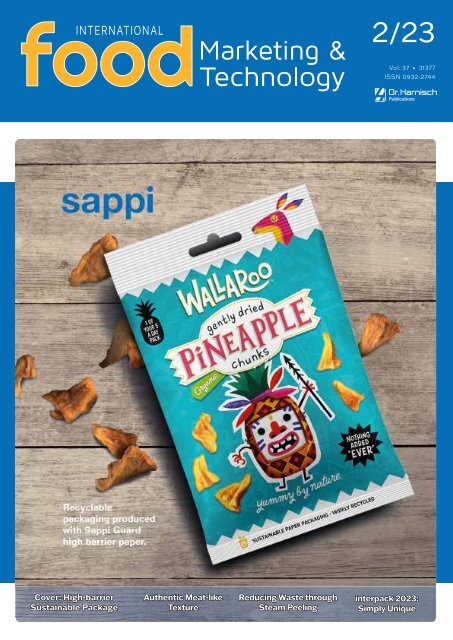

Cover: High-barrier<br />

Sustainable Package<br />

Authentic Meat-like<br />

Texture<br />

Reducing Waste through<br />

Steam Peeling<br />

interpack <strong>2023</strong>:<br />

Simply Unique

We understand how you strive for constant<br />

product quality and optimized costs.<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality requirements<br />

while optimizing resources and securing process repeatability.<br />

Endress+Hauser helps you to improve your processes:<br />

• With a hygienic, robust product portfolio that meets international standards<br />

• With access to traceable, reliable and real-time data<br />

• With a network of industry application experts that help you ensure greater<br />

plant availability throughout the product life cycle<br />

Key No. 103856<br />

Do you want to learn more?<br />

www.eh.digital/3G9EUcK

Editorial<br />

Many sides to sustainable <strong>food</strong> packaging<br />

Food packaging today is about more<br />

than protecting the product. This may<br />

still be the most important function.<br />

However, design and material also have<br />

a large influence on buying decisions,<br />

because more consumers want <strong>food</strong><br />

that comes in a sustainable package.<br />

Without any packaging, however, most<br />

<strong>food</strong>s cannot be transported, stored<br />

or sold, and in their unpackaged state<br />

they would prematurely spoil. The<br />

protective wrapping keeps harmful<br />

influences like light, oxygen or humidity<br />

away and prevents soiling or damage.<br />

But packaging is not only there to<br />

extend freshness and shelf-life.<br />

Consumers are increasingly demanding<br />

environmentally friendly packaging. It is<br />

supposed to be recyclable or made from<br />

sustainable materials, yet offer optimal<br />

protection for perishable products. And<br />

this means that especially today <strong>food</strong><br />

packaging is a real high-tech product.<br />

For aroma-proof <strong>food</strong> packaging,<br />

suitable materials are polyamide films<br />

with so-called bi-axial orientation,<br />

used for example to package oily, fatty<br />

<strong>food</strong>s or frozen <strong>food</strong>s. The demand for<br />

these films, which owe their special<br />

properties to a certain stretching<br />

process, continues to rise and so does<br />

the demand for relevant film stretching<br />

lines.<br />

Packaging manufacturers in the <strong>food</strong><br />

industry are obliged to follow strict<br />

legal regulations which among other<br />

things demand a high level of hygiene.<br />

But hygiene is more than just cleaning<br />

and disinfecting. Many applications,<br />

for example in the <strong>food</strong> sector, use<br />

compressed air. If this comes into<br />

direct contact with <strong>food</strong> or is used for<br />

cleaning, it must not be contaminated<br />

with germs, either.<br />

The upcoming interpack event in<br />

Dusseldorf, Germany, will cover all<br />

these packaging topics and many more!<br />

interpack is an important building block<br />

in the innovation cycle of the packaging<br />

and related process industries. After a<br />

six-year break, numerous innovations<br />

for all user areas will be on display,<br />

including <strong>food</strong>, beverage, confectionery<br />

and bakery products.<br />

Megatrends such as sustainability and<br />

digitalization, numerous economic<br />

and ecological, but also political and<br />

social changes and challenges are of<br />

concern for companies and provide<br />

a boost to innovation this year. The<br />

circular economy will be a top issue:<br />

seemingly a simple model but also<br />

all-encompassing and posing major<br />

challenges in many areas. In the<br />

age of climate change, the goal is to<br />

Ian Healey<br />

Editor-in-Chief<br />

produce as little unrecyclable waste<br />

as possible. Hand in hand with this<br />

goes the need to conserve resources.<br />

When it comes to transformation<br />

processes, little can be done<br />

without digital technologies. Big<br />

data, augmented reality and remote<br />

machine maintenance have long since<br />

found their way into assembly shops<br />

and machine fleets.<br />

Whatever your special focus, the<br />

interpack is a must for industry leaders.<br />

We look forward to seeing you there!<br />

Photo: GS<br />

Cheers<br />

If you like it – subscribe!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

3<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

<strong>Technology</strong> & <strong>Marketing</strong><br />

International Magazine September 2022 ISSN 2628-5851<br />

your easy way to stay updated<br />

Contents<br />

<strong>Technology</strong> & <strong>Marketing</strong> 3/22<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> April <strong>2023</strong><br />

1 Editorial<br />

58 Impressum<br />

Ingredients<br />

8 Black Swan Hydrocolloid Events<br />

11 Bespoke Solutions for Soothing Colic<br />

12 Easy Way to an Authentic, Meat-Like Texture<br />

15 Variety of Chilies: Something for Every Taste<br />

Ingredients: Plant-Based Food, Black Soldier Flies, Fibers and Cellulose, Grain Acceptability<br />

Processing: Wet Pet<strong>food</strong> Processing, Quality Control, Heat Exchangers, Mixing<br />

Packaging: Pouches and Alutrays, No Waste, Weighing Investment<br />

Free trial issue at <strong>food</strong>@harnisch.com<br />

PetFood PRO magazine<br />

wants to emphasize the<br />

high level of quality and<br />

care in the production of pet<br />

<strong>food</strong> through the choice of<br />

ingredients, the choice of<br />

technology and the choice<br />

of packaging materials.<br />

Processing<br />

24 Behind the Scenes of Your Favorite Sweets: The<br />

Intricate Process to Create Classic Desserts<br />

28 How the Best Steam Peelers can Significantly Reduce<br />

Food Waste on Vegetable Processing Lines<br />

34 New Micropilot Radar Level Sensor: Designed for<br />

Special Demands<br />

38 Bag Intake and Control Screening Machine Vib &<br />

Press – New Generation Even More Efficient<br />

39 New Advanced Benchtop Meter Series Extended with<br />

3 New Models<br />

Packaging<br />

ine March 2022 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

1/22<br />

International Magazine May 2022 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong> 2/22<br />

6 A ‘Fruitful’ Collaboration to Sustainably Package<br />

Healthy Organic Snacks New High-Barrier Paper<br />

Delivers Great Impact for Wallaroo Foods<br />

44 The Pinnacle of Food Packaging<br />

52 Consolidated Competence for the Process Industry<br />

54 Baked Goods: Automated Packaging for Sensitive<br />

Goods<br />

Departments<br />

Ingredients: Insect Proteins, More Sustainable BARF, Pet Nutrition, Plant-Based Food<br />

Processing: Healthy Kibbles, Hygienic Cooking, Modular and Flexible Solutions<br />

Packaging: Recyclable Packaging and Bags, Inline Tray Sealer<br />

<strong>Marketing</strong>: Vet's Corner, Pet Food Competence Network, Anuga FoodTec, IFFA, Interzoo<br />

Ingredients: Trusting Suppliers, Stress Relief, Humic Acids for Gut Health, Wheat Textures<br />

www.pet<strong>food</strong>pro-mag.com<br />

Processing: Customized Solutions for BARF, Safe Processing, Cutting, Grinding and Mixing<br />

Packaging: Perfect Packs, Fastening Solutions, Bags and Pouches, Sustainable Sealing<br />

<strong>Marketing</strong>: Interzoo 2022, Insect Breeding, Competence in Packaging, Too Much Protein?<br />

18 Vita<strong>food</strong>s Europe<br />

22 CFIA<br />

40 Firms<br />

44 Interpack

1/20/23 1:31 PM<br />

Vol. 37 • 31377<br />

ISSN 0932-2744<br />

ting <strong>Technology</strong><br />

ur product.<br />

rschel.com<br />

Cover: High-barrier<br />

Sustainable Package<br />

Authentic Meat-like<br />

Reducing Waste through<br />

Texture<br />

Steam Peeling<br />

2/23<br />

interpack <strong>2023</strong>:<br />

Simply Unique<br />

Cover:<br />

Wallaroo Foods was driven by its conviction<br />

to being sustainable in every respect<br />

and to package its products using only<br />

paper-based material. “We’ve seen other<br />

small brands attempt to master the<br />

transition, but they soon run out of steam<br />

on their quest to find paper-based packaging<br />

material. However, going down<br />

the plastic route was never an option for<br />

us,” remembers Abhisek Kanoi. The OPM<br />

Group, Wallaroo’s label and packaging<br />

partner, introduced the company to<br />

Sappi’s Guard Gloss 4-OHG paper-based<br />

high-barrier product.<br />

Our Cover Story starts on page 6.<br />

Photo: SAPPI Europe<br />

Ingredients: Meat-free texture<br />

There’s no denying that the market for plant-based meat<br />

alternatives is booming. Entering the segment may still feel like<br />

a huge step for meat-processing companies, or <strong>food</strong> manufacturers.<br />

That’s because, the ease with which plant-based<br />

alternatives can be produced may not be immediately obvious.<br />

However, it’s entirely possible for the processing of meatalternative<br />

ingredients to closely resemble that of conventional<br />

meat mixtures. See page 12<br />

Processing: Steam peeling success<br />

Food waste is financial waste, yet when processing lines peel<br />

vegetables, they often throw away huge amounts of raw material.<br />

Food losses can be as high as 30% during mechanical<br />

peeling and 20% with low-tech steam peelers – and much of<br />

this lost revenue is preventable. Rather than accepting this,<br />

vegetable processors can do something about it. There are<br />

four compelling reasons to do this. Eamonn Cullen shares his<br />

experience on page 28<br />

Packaging: Simply Unique<br />

The <strong>food</strong> sector is among the most favored target groups of<br />

visitors to interpack, and this shows in the breadth of their<br />

presentation. The global demand for packaged <strong>food</strong>s is increasing.<br />

In saturated markets with strong incomes, conscious<br />

consumption and consumer behavior also shifts towards<br />

sustainability, regional produce, organic <strong>food</strong> or fair trade,<br />

and this includes packaging. Find out what the Exhibition<br />

Director, <strong>food</strong> Thomas <strong>Marketing</strong> Dohse, & <strong>Technology</strong> has to say, • on February page 46 2016<br />

Key No. 102163

Cover Story<br />

A ‘Fruitful’ Collaboration to Sustainably<br />

Package Healthy Organic Snacks<br />

New High-Barrier Paper Delivers Great<br />

Impact for Wallaroo Foods<br />

One hundred percent product-safe packaging, meeting high consumer expectations in terms of sustainability<br />

and the need for appealing, high-impact design were the challenges Oxfordshire-based Wallaroo Foods<br />

was up against. Sappi, the leading manufacturer of packaging and specialty papers, contributed to an ideal<br />

solution with its Guard Gloss 4-OHG high-barrier paper.<br />

Sustainable through and through<br />

“To encourage young people to make<br />

better <strong>food</strong> choices by questioning<br />

where their <strong>food</strong> comes from, what<br />

it is made of and its impact on our<br />

environment,” is Wallaroo Foods’ stated<br />

mission. The producer of organic<br />

tropical fruit snacks creates tasty, fun<br />

<strong>food</strong> for kids that is healthy, nutritious<br />

and guilt-free.<br />

Since it was established in 2018,<br />

Wallaroo has focused on sustainability<br />

throughout its entire production<br />

process. The company works with<br />

small community producers in Africa to<br />

ensure that their organic fruit is grown<br />

with respect for the environment, and<br />

to guarantee a fair and sustainable<br />

livelihood for growers. Only perfectly<br />

ripe fruit is harvested and moved<br />

directly to a certified drying facility<br />

located right next to the fields. This<br />

ensures that only the freshest fruit<br />

is used and that <strong>food</strong> waste during<br />

transportation is reduced to a minimum.<br />

The fruit is cut and then dried using<br />

solar power in state-of-the-art drying<br />

facilities. No sugar, salt, preservatives<br />

or sulphites are added and consumers<br />

can enjoy the pure taste of fruit. To keep<br />

the company’s carbon footprint as low<br />

as possible, the dried and packed fruit<br />

is forwarded by ship.<br />

Sustainability in content and<br />

packaging<br />

Wallaroo had been searching for a<br />

packaging solution for its dried fruit<br />

snacks to meet its exceptionally high<br />

standards. This turned out to be<br />

quite a challenge. Wallaroo wanted<br />

Abhisek Kanoi, Co-Founder of Wallaroo<br />

Foods<br />

an affordable recyclable solution<br />

avoiding the use of any synthetic<br />

materials. “It was a difficult process for<br />

us,” says Abhisek Kanoi, Co-Founder of<br />

Wallaroo Foods. “In the UK, there are<br />

no common standards and so many<br />

differences between the many options<br />

After three months of trials, the quality offered by the 91 g/m² grammage proved to be the perfect choice. The pouches demonstrated excellent stability<br />

while filling. Sappi’s Guard Gloss also excelled in terms of barriers and sealing.<br />

6<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Cover Story<br />

we investigated. Even some of the<br />

best recyclable solutions we examined<br />

contained a large share of plastics –<br />

something we wanted to pare down to<br />

the absolute minimum.”<br />

Wallaroo was driven by its conviction<br />

to being sustainable in every respect<br />

and to package its products using only<br />

paper-based material: “Four years ago,<br />

this was a rarity in the UK,” remembers<br />

Abhisek Kanoi. “We’ve seen other small<br />

brands attempt to master the transition,<br />

but they soon run out of steam on their<br />

quest to find paper-based packaging<br />

material. However, going down the<br />

plastic route was never an option for<br />

us.” The OPM Group, Wallaroo’s label<br />

and packaging partner, introduced the<br />

company to Sappi’s Guard Gloss 4-OHG<br />

paper-based high-barrier product.<br />

Impeccable printing, processing<br />

and sealing results<br />

Arnie Ellison, New Business Development<br />

Director at OPM, was<br />

immediately impressed with Sappi’s<br />

Guard Gloss: “We were surprised to<br />

experience outstanding runnability<br />

using normal inks or matt finish. With<br />

its glossy premium look and feel,<br />

Sappi’s one side single-coated paper<br />

made quite an impression on us.”<br />

Guard Gloss’ processing properties<br />

are also exceptional. The small,<br />

irregularly shaped fruit pieces proved<br />

difficult to process and it took some<br />

time to adjust the machines. Wallaroo<br />

never lost sight of its goal and finally<br />

succeeded in packaging the fruit<br />

snacks in paper at a processing<br />

speed of 40 bags a minute. “Initially,<br />

Oxfordshire-based Wallaroo Foods had<br />

been searching for an affordable recyclable<br />

packaging solution for its dried fruit snacks to<br />

meet its exceptionally high standards.<br />

we tested only one line with dried<br />

fruit such as mango and pineapple,”<br />

remembers Abhisek Kanoi. “After<br />

three months of trials, the quality<br />

offered by the 91 g/m² grammage<br />

proved to be the perfect choice.” The<br />

pouches demonstrated excellent<br />

stability while filling. Sappi’s Guard<br />

Gloss also excelled in terms of sealing.<br />

“The high-barrier paper is significantly<br />

better than all other materials we<br />

tested. It not only prevents the<br />

package from popping open, it can<br />

also be sealed using less heat, which<br />

saves energy during the process,”<br />

confirms Parminder Singh, Director<br />

of Complete Packaging Solutions<br />

Ltd., carrying out the packaging for all<br />

Wallaroo products.<br />

An Aha moment for consumers<br />

with Guard Gloss<br />

Wallaroo’s customers, who can now<br />

purchase the fruit snacks in selected<br />

organic supermarkets in the UK and<br />

Switzerland, online, in cafes, offices and<br />

hotels, as well as in venues targeted to<br />

The OPM Group, Wallaroo’s label and<br />

packaging partner, introduced the company to<br />

Sappi’s Guard Gloss 4-OHG paper-based highbarrier<br />

product.<br />

children such as zoos, were initially<br />

sceptical about the sustainability of the<br />

solution due to the glossy premium look<br />

of the packaging: “They were surprised<br />

to find out that the package is entirely<br />

paper-based. They literally experienced<br />

an Aha moment – especially when<br />

tearing open the package,” remembers<br />

Abhisek Kanoi.<br />

After successfully deploying the<br />

high-barrier paper for its fruit snacks,<br />

Wallaroo now has ambitious plans<br />

to use it for even more challenging<br />

applications: “We are currently<br />

testing Guard Gloss with naturally oily<br />

products such as roasted corn, beans<br />

and nuts, which usually leave greasy<br />

spots on paper. If everything works<br />

out as planned, we will be introducing<br />

a new generation of pouches to our<br />

customers by early next year,” confirms<br />

Abhisek Kanoi. A promise Wallaroo<br />

Foods is confident it can keep thanks<br />

to Sappi’s Guard Gloss paper-based<br />

solution featuring a heat-sealable, highbarrier<br />

coating that also guarantees<br />

effective grease barrier properties.<br />

grease barrier properties.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

7

Ingredients<br />

Black Swan Hydrocolloid Events<br />

by Dennis Seisun & Nesha Zalesny<br />

Some developments in hydrocolloids<br />

are hard to believe even if there is no<br />

question that we are living them. Some<br />

prices have reached levels unheard or<br />

undreamt of. There is tightness if not<br />

outright shortage in supply of some<br />

key hydrocolloids. The pandemic and<br />

other factors have resulted in delivery<br />

delays of many months, not to mention<br />

shipping charges increased by a factor<br />

of 10 or more in 2020-2021. Regulatory<br />

issues combined with political<br />

actions have resulted in nightmarish<br />

documentation and compliance<br />

requirements. These were a fact<br />

of life over several recent years for<br />

both, a supplier of hydrocolloids and<br />

a user/buyer of hydrocolloids. They<br />

can be considered black swan events<br />

which, until they happened would have<br />

been deemed highly improbable if<br />

not impossible. For those not familiar<br />

with the term, swans were believed<br />

to be ONLY white. Black swans were<br />

thought to be non-existent until they<br />

were discovered in Australia. What<br />

was deemed impossible for many<br />

hydrocolloids became reality. The<br />

years 2020-2022 are the peak of ‘covid<br />

19’ years with special considerations.<br />

The covid pandemic itself, cannot<br />

really be called a Black Swan event.<br />

Similar if not worse pandemics<br />

have been experienced and a future<br />

one has been forecast with some<br />

certainty. The pandemic, however, did<br />

enable and accelerate the advent of<br />

several hydrocolloid Black Swans. An<br />

interesting book on the subject of Black<br />

Swans is titled, “The Black Swan: The<br />

Impact of the Highly Improbable” by<br />

Nassim Taleb. Let us consider in more<br />

detail now, some Black Swan events in<br />

hydrocolloids.<br />

Pricing is a key factor of interest to<br />

buyers and producers of hydrocolloids.<br />

Producers wonder, “How much can<br />

I get for my hydrocolloid….” And<br />

buyers think, “How little can I offer to<br />

get the hydrocolloid I need?”. Several<br />

years ago at one of IMR’s hydrocolloid<br />

conferences, the theme of “Open<br />

Innovation” was the buzz phrase du jour.<br />

Closer co-operation between supplier<br />

and buyer would not only result in a<br />

better business model for both parties,<br />

it would offer stability in supply and<br />

price. Most important, it would foster<br />

an environment of innovation on both<br />

sides of the transaction. Dynamics of<br />

today’s supply chain have changed this<br />

short lived philosophy. Negotiations<br />

are back to more traditional adversarial<br />

negotiations. Of course, contracts<br />

continue to be negotiated but they are<br />

not set in stone and indeed are not set<br />

at all in cases of force majeur. Annual<br />

contracts and multi-year contracts<br />

were common in the past. Now many<br />

Table 1: Source: IMR Quarterly Review of Food Hydrocolloids – Tableau Analysis<br />

contracts, if offered are for 6 months<br />

or 3 months only.<br />

A few black swans in pricing have<br />

appeared for several hydrocolloids<br />

including for example, LBG, xanthan<br />

gum and some of the more popular<br />

starches. LBG is used nearly exclusively<br />

in <strong>food</strong> and pet <strong>food</strong> applications.<br />

Xanthan gum and starches, however,<br />

have very large industrial and oilfield<br />

applications. The historical pricing<br />

of these three key hydrocolloids was<br />

relatively steady until a few years ago.<br />

Nothing in past pricing trends could<br />

have allowed a supplier or user to<br />

envision the dramatic changes which<br />

occurred in 2020-2022 and continue<br />

into <strong>2023</strong>.<br />

Each hydrocolloid ‘Black Swan’ is<br />

discussed below:<br />

There was an LBG crisis in 1994-1995<br />

which was a first in the history of LBG<br />

until then. Previous prices tripled<br />

and quadrupled. In Q1-1993 LBG enduser<br />

prices were about US$6.50/kg<br />

(roughly 2 ½ kg of seeds are needed<br />

per kg of LBG). By Q1-1994, the price<br />

of LBG had more than quadrupled to<br />

US$12.75/kg. (Source IMR’s Quarterly<br />

Review of Food Hydrocolloids). There<br />

was a dramatic drop by 1996 and<br />

then a continued price drop. By early<br />

1999, market pressures had driven<br />

LBG prices back down to $6.60/kg<br />

and even a little below the pre-crisis<br />

levels of 1993. Things remained<br />

steady for several years. Although<br />

there was some fluctuation, LBG<br />

prices never exceeded US$10.00/kg.<br />

Never until 2020 that is. Starting in<br />

2017-2018 a steady price increase led<br />

to a crescendo of increases in 2020<br />

through 2022. The LBG situation of<br />

2020-2022 made the prior “crisis”<br />

of 1994-1995 seem like a blip. The<br />

situation for LBG became so dire in<br />

2020-2022 that spot prices reached<br />

a peak of €100.00/kg ($105/kg) IF one<br />

could get it. Of course prices have<br />

since crashed albeit remaining well<br />

above the $6.60/kg of decades ago. A<br />

black swan event which no producer<br />

8 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

The world’s most successful IBC system.<br />

Now with double protection.<br />

FOODCERT + DUALPROTECT<br />

Dual leakage protection through liner and inner bottle<br />

Delivered “ready to fill” for the highest<br />

degree of user friendliness<br />

The liner automatically unfolds as the container is filled<br />

The irradiated liner protects the filling product<br />

against contact with oxygen or condensate<br />

Prevents oxidation, vitamin depletion<br />

and microbial contamination<br />

Extends product shelf life – without<br />

the need for preservatives<br />

Secure protection of the filling product quality<br />

Key No. 104139<br />

BAUCH & MÜLLER WERBEAGENTUR GMBH<br />

4 – 10 MAY <strong>2023</strong><br />

DÜSSELDORF<br />

HALL 10<br />

BOOTH D22|E34<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

Discover the new SCHÜTZ packaging with dual filling product protection<br />

for your <strong>food</strong> applications. ECOBULK FOODCERT + DUALPROTECT are supplied<br />

ex-works with a high-quality LDPE liner including an oxygen barrier. Filling can take<br />

place through the top opening or the outlet valve. Your filling product is hermetically<br />

sealed in the liner and completely protected against ambient conditions. The robust<br />

outer bottle provides the highest level of safety and dependability – even for the<br />

most tough transportation conditions – UN hazardous goods approval included.<br />

Find out more at www.schuetz-packaging.net<br />

Schütz GmbH & Co. KGaA<br />

Schützstraße 12<br />

D-56242 Selters<br />

Phone +49 2626 77 0<br />

info1@schuetz.net<br />

www.schuetz.net<br />

9

Ingredients<br />

or user of LBG would have forecast<br />

the 2020-2022 scenario for LBG. LBG<br />

prices are heading back down as<br />

shown in table 1.<br />

Another Black Swan event was the<br />

case of guar gum in 2011-2013 when<br />

it’s use in fracking combined with<br />

horizontal drilling resulted in undreamt<br />

of prices. Tara gum has always been<br />

viewed as a lower priced cousin of LBG.<br />

The guar crisis, however, seemed to<br />

have caused a temporary inversion<br />

between LBG and tara prices during<br />

2011-2013. Tara is now back at its<br />

trailing LBG position as shown in table<br />

2 below.<br />

Xanthan prices have been through<br />

strong cycles since its introduction to<br />

<strong>food</strong> users in the early 1970’s. Prices<br />

were very firm in the 1970’s and ‘80’s<br />

when there was only one supplier in the<br />

world and it’s use started to become<br />

ubiquitous. Then came European<br />

competition in the 1980’s and then<br />

came Chinese competition in the<br />

late 1990’s which drove prices down<br />

even further. Prices plummeted from<br />

over $13.00/kg in the 1980’s to about<br />

$4.00/kg in mid-2000’s. One Chinese<br />

producer had a ‘xanthan special’<br />

sign at an FIE exhibition around that<br />

time, offering xanthan at $2.00/KG!!<br />

By 2020 xanthan prices had slowly<br />

edged back up to around $10.00/kg<br />

before starting a rapid increase to the<br />

current $20.00/kg, again, IF supply<br />

can be found. Different reasons for<br />

this difficult situation to those which<br />

caused the LBG scenario. The net<br />

result, however, is the same, very high<br />

prices and poor availability, neither of<br />

which was expected or forecast by any<br />

of the players in this market.<br />

In the case of starches and to<br />

quote past IMR reports, “There are<br />

hydrocolloid of cyclic availability<br />

and price, and those with assured<br />

availability and steady price.”<br />

Starches of all types have always,<br />

until now, been in the latter category<br />

i.e. no problem in availability and<br />

steady in price. Indeed, starches and<br />

starch supply was so reliable that<br />

some contracts were established on<br />

verbal agreements based on historical<br />

past use. This is no longer the case<br />

for several workhorse starches, a<br />

shortage of which would have been<br />

unthinkable until it happened, another<br />

Black Swan event in hydrocolloids.<br />

The reasons for these unpredictable<br />

scenarios are varied, and now in<br />

hindsight may seem evident, but then<br />

hindsight is always much clearer than<br />

the hazy future. In the case of LBG<br />

an increase in demand in plant based<br />

beverages, poor raw material harvests<br />

and production issues which caused<br />

a reduction in supply. For xanthan<br />

gum the explanation is primarily<br />

related to Chinese supply issues<br />

combined with regulatory and political<br />

considerations. Lack of investment<br />

in capacity by Western producers left<br />

them ill prepared to satisfy a rapid<br />

increase in demand. The reason(s) for<br />

Table 2: Source: IMR Quarterly Review of Food Hydrocolloids – Tableau Analysis<br />

Dennis Seisun and Nesha Zalesny are partners<br />

with IMR International LLC and authors of the<br />

Quarterly Review of Food Hydrocolloids, as well<br />

as hosts of the annual Global Food Hydrocolloid<br />

Conference, this year in Malta<br />

the tight situation in some starches<br />

is more difficult to explain. Lack of<br />

capacity increases perhaps. A strong<br />

demand in industrial packaging, the<br />

Amazon effect. Poor crop harvests.<br />

Reduced raw material from Ukraine.<br />

The net result is a tightness which has<br />

forced some supply agreements to be<br />

cancelled or re-negotiated.<br />

These events in hydrocolloids over<br />

the last few years, have taken a<br />

market estimated at about $7.0-8.0<br />

billion in value to over $15.0 billion. Of<br />

course, much of this value increase is<br />

directly related to price and is likely to<br />

decline as sky high prices abate. There<br />

are, however, dynamics of volume<br />

increases that have contributed to this<br />

unpredictable growth in market value.<br />

With this brief look at a few hydrocolloid<br />

Black Swans, is it possible to look to<br />

the future and predict any other similar<br />

events that could upend the status<br />

quo? One can try but the very concept<br />

of Black Swans is that they are deemed<br />

improbable or impossible, until that is,<br />

they happen. A safer strategy would be<br />

a closer and more trusting association<br />

between supplier and buyer whereby<br />

the pain AND the gain, when Black<br />

Swans arrive, are shared equitably. An<br />

idyllic concept but worth aspiring to. Do<br />

you have any Black Swan hydrocolloid<br />

stories? Please share.<br />

fmt<br />

10 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Bespoke Solutions for Soothing Colic<br />

Laïta Nutrition are putting their expertise to good use<br />

New-born babies have very specific<br />

nutritional requirements, in order to<br />

help them grow and develop. Parents<br />

are increasingly demanding when it<br />

comes to the quality and <strong>food</strong> safety<br />

credentials of the products they give to<br />

their children. They are looking for real<br />

solutions capable of soothing the most<br />

common ailments suffered by babies,<br />

such as reflux and colic. Studies<br />

show that between 20% and 25% of<br />

babies suffer from colic in their first<br />

four months, with 66% experiencing<br />

problems with regurgitation. Acutely<br />

aware of the impact these conditions<br />

can have on babies and their families,<br />

the experts at Laïta Nutrition has a<br />

range of special recipes designed to<br />

help reduce colic in infants.<br />

Chief among these solutions is<br />

Laïta’s AC milk, available in a range<br />

of formulation options. The formula<br />

may include FOS and GOS for their<br />

prebiotic properties, Omega 3 oils,<br />

not always found in baby formula and<br />

a low-lactose formula, which helps<br />

limit fermentation and gas production<br />

in the intestine, another common<br />

symptom of colic.<br />

Laïta Nutrition’s breadth of expertise<br />

is also reflected in the company’s<br />

anti-reflux solutions. Laïta’s AR<br />

powdered milk (FSMP) is designed<br />

for infants displaying symptoms<br />

of gastro-oesophageal reflux or<br />

regurgitation. This product uses<br />

carob as a thickening agent, and can<br />

be combined with starch to delay the<br />

onset of hunger between feeds. It can<br />

be customized as required, with the<br />

addition of probiotics, FOS and GOS.<br />

• Reduced-lactose formulations are<br />

available, with the option to include<br />

partially hydrolysed whey protein.<br />

All in all, Laïta Nutrition offers a wide<br />

range of products designed to help<br />

reduce regurgitation and colic and<br />

improve the digestive comfort of infants.<br />

The many customization options on<br />

offer ensure that clients can choose the<br />

right forms, textures and compositions<br />

to suit their exact requirements. fmt<br />

Take your Gummy<br />

to the Next Level<br />

Beauty gummies<br />

Sugar reduction and<br />

protein enrichment<br />

Starch-free gelatin<br />

gummy production<br />

Laïta also help industrial partners to<br />

create specialized products such as<br />

milk formulas thickened with starch.<br />

Laïta has the flexibility and knowhow<br />

to tailor formulations to clients’<br />

precise requirements, incorporating:<br />

• DHA, EPA, ARA, Vitamins A, C<br />

and D, plus Iron, FOS/GOS to help<br />

reduce reflux and ensure maximum<br />

digestive comfort.<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong><br />

GELITA AG · Uferstr. 7 · 69412 Eberbach · Germany · www.gelita.com<br />

Key No. 104787

Ingredients<br />

Easy Way to an Authentic, Meat-Like<br />

Texture<br />

How texturates made from wheat, soy and pea proteins can be used to produce authentic plant-based meat<br />

alternatives<br />

There’s no denying that the market<br />

for plant-based meat alternatives<br />

is booming. However, entering the<br />

segment may still feel like a huge<br />

step for meat-processing companies,<br />

butchers or other <strong>food</strong> manufacturers,<br />

who have not previously considered<br />

expanding their offerings to include<br />

vegan and vegetarian products. That’s<br />

because, the ease with which plantbased<br />

alternatives can be produced<br />

may not be immediately obvious to<br />

traditional processors. Yet, depending<br />

on the raw material, it’s entirely possible<br />

for the processing of meat-alternative<br />

ingredients to closely resemble that of<br />

conventional meat mixtures.<br />

Meat-like processing<br />

With GoodMills Innovation’s VITATEX®<br />

line of texturates made from wheat,<br />

soy and pea proteins, this process is<br />

particularly straightforward. That’s<br />

because the texturates have many<br />

similarities to a conventional meat<br />

mass, which means manufacturers<br />

can use machines commonly used in<br />

the meat industry to produce plantbased<br />

ground beef, patties, nuggets or<br />

cutlets as they do for meat processing.<br />

The texturates pre-swell with<br />

water. In a mixer, for example, the<br />

binding system, oil, flavoring and, if<br />

required, further water is added until<br />

a homogeneous and pleasant-tasting<br />

mass is obtained. In a similar manner<br />

to minced meat mass, the mixture is<br />

processed in a cutter or mincer until<br />

it is the appropriate size for the final<br />

application. The resulting basic mass<br />

is now ready to be formed.<br />

As VITATEX® can be used to produce<br />

vegetable products in meat processing<br />

plants, there’s no need to invest in<br />

new machinery and, in addition, the<br />

manufacturer benefits from the<br />

processing know-how of the product<br />

developers and application engineers<br />

at raw material stage. The range<br />

is suitable for various vegan and<br />

vegetarian applications, replicating<br />

the authentic sensory profile of<br />

conventional pork, beef, poultry and<br />

fish-based products.<br />

Why texture is key<br />

Consumers – especially flexitarians –<br />

still expect a realistic meat-like culinary<br />

experience from meat substitutes.<br />

The task for <strong>food</strong> manufacturers,<br />

therefore, is to authentically replicate<br />

the original product in terms of<br />

texture, sensory characteristics and<br />

appearance. This is called “meat<br />

mimicking”. Texture plays a vital<br />

role in this process, is crucial for<br />

an authentic meat alternative and<br />

decisive in consumer purchasing<br />

decisions: If the texture is not right,<br />

the product will not be perceived to<br />

be a realistic meat alternative and will<br />

have no ‘shelf appeal’ as a result. So<br />

there is no room for compromise and<br />

special attention to the fibrousness<br />

of the components used is therefore<br />

vital for processors.<br />

In the production of the VITATEX®<br />

range, GoodMills Innovation has drawn<br />

on more than 20 years of experience<br />

in the texturization of vegetable<br />

proteins. These insights are a crucial<br />

part of the company’s texturizing<br />

expertise, for example when it comes<br />

to authentically recreating a chicken<br />

nugget with long fibers or a burger<br />

patty with short fibers. The bite and<br />

mouthfeel are completely different<br />

for each product and so, accordingly,<br />

12 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Innovation in a<br />

Time of Crisis:<br />

Can We Future-Proof the Food System?<br />

IFT FIRST Registration Is Now Open!<br />

Be FIRST to<br />

Save Your Seat!<br />

Register today at iftevent.org.<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

13<br />

Key No. 104910

Ingredients<br />

carefully selected flavors and spices,<br />

convincing results can be achieved.<br />

the texturate used must be<br />

carefully selected. Its fibrousness is<br />

determined in part by the properties<br />

of the protein, which affect elasticity,<br />

structure-forming capabilities and<br />

general texture. Some texturates are<br />

particularly suitable for short-fibered<br />

masses such as minced meat, while<br />

others are perfect for fibrous end<br />

products such as poultry or cutlets.<br />

Long-fiber protein structures are best<br />

achieved with wheat and soy proteins.<br />

Nevertheless, it is not just the starting<br />

material that’s important, as expertise<br />

in the extrusion process determines<br />

bite, texture and mouthfeel, which are<br />

all vital too.<br />

Convincing results<br />

Even though VITATEX® texturates<br />

are particularly convincing with their<br />

texture and fiber-like mouthfeel, taste<br />

and appearance are also key. That’s<br />

why it’s important to realize that<br />

off-flavors of vegetable texturates<br />

can be a challenge. Depending on<br />

the raw material, cereal and earthy<br />

notes must be minimized or masked.<br />

VITATEX® texturates have a neutral<br />

to raw material-typical taste. However,<br />

depending on customer expectations<br />

and product concept, this can be<br />

masked.<br />

Careful pre-selection of raw materials<br />

enables higher product quality.<br />

GoodMills Innovation works with<br />

selected farmers across projects to<br />

source the best raw materials with<br />

defined quality characteristics. But an<br />

almost “real” imitation meat product<br />

will not work without flavor. Yet with<br />

Whether <strong>food</strong> manufacturers choose<br />

the wheat, soy or pea variety, or a<br />

mixture, depends largely on the<br />

product concept and positioning<br />

they are aiming for. Wheat and soy<br />

extrudates are already established,<br />

and the fact that the products are also<br />

available with EU origin brings obvious<br />

advantages. Peas combine regionality,<br />

sustainable cultivation and tradition,<br />

and are thus particularly suitable for a<br />

target group that makes its purchasing<br />

decisions very consciously. With all<br />

three raw materials, common meat<br />

and fish applications can be faithfully<br />

imitated.<br />

Recognizing demand, retaining<br />

customers<br />

Demand for alternative products<br />

based on vegetable proteins has<br />

been rising steadily in recent years,<br />

and further growth is foreseeable.<br />

The most relevant target group<br />

is “flexitarians” - people who want<br />

to reduce their meat consumption<br />

for health, ethical or environmental<br />

reasons, but do not follow a consistent<br />

vegan or vegetarian diet and<br />

are open to new product concepts.<br />

Accordingly, in multi-person households,<br />

statistically there are almost<br />

always people who prefer to reach for<br />

plant-based alternatives. So, in order<br />

to offer the right solution for everyone<br />

at the dinner table, <strong>food</strong> and meat<br />

manufacturing companies should<br />

seriously consider expanding their<br />

portfolios to include authentic plantbased<br />

concepts.<br />

fmt<br />

14 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Variety of Chilies:<br />

Something for Every Taste<br />

Anyone who enjoys spicy <strong>food</strong> likes to reach for chili peppers. But not all chilies are the same: there are<br />

countless chili varieties and offshoots. They differ in color, shape, taste and degree of spiciness. Hotness<br />

is measured on a scale of 0 to 10, or in Scoville units, which range from 0 to the millions. Chili peppers are<br />

therefore very rich in variation, and their range of application in the kitchen and in the <strong>food</strong> industry is also<br />

diverse. In dried form, chili peppers are used to spice up seasonings, frozen <strong>food</strong>s and convenience <strong>food</strong>s.<br />

In addition, chili peppers are an important ingredient in many sauces and pastes. Import Promotion Desk<br />

(IPD), a project of the German Federal Ministry for Economic Cooperation and Development, supports<br />

chili producers from South America in bringing their products to the European market. One of them is the<br />

company “Uchu Spice” from Ecuador, which specializes in the cultivation and production of a wide range of<br />

chili varieties.<br />

Hot peppers<br />

Both chili peppers and sweet peppers<br />

are descended from the bell pepper<br />

plant genus (Capsicum). Chili peppers<br />

grow on shrubby plants that can reach<br />

a height of up to one and a half feet. We<br />

usually call the fruit a pod, even though<br />

botanically it is a berry. Chili peppers<br />

are rich in vitamins – especially vitamin<br />

C and B1.<br />

The best known characteristic of the<br />

chili pepper is its spiciness. However,<br />

it not only dominates the taste, it also<br />

has an antibacterial effect. Capsaicin<br />

and other substances in the flesh of the<br />

fruit are responsible for the spiciness<br />

of chili. A particularly high proportion<br />

of capsaicin is found in the placenta, i.e.<br />

in the somewhat lighter flesh to which<br />

the seeds are attached. The seeds, on<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

15<br />

Key No. 102618

Ingredients<br />

the other hand, which mistakenly have<br />

the reputation of being “particularly<br />

hot”, contain no capsaicin.<br />

Wide range of varieties and<br />

flavors<br />

Chili peppers come in a variety of<br />

colors – e.g. yellow, orange, green,<br />

red – and in different color intensities.<br />

The shapes also vary – narrow or<br />

bulbous, short or long. Depending on<br />

the variety, there are also differences<br />

in taste, aroma and pungency. The<br />

spiciness is joined by different flavors,<br />

such as fruity, floral, sweet, tangy,<br />

smoky, etc.<br />

Spicy <strong>food</strong> makes you happy<br />

Capsaicin irritates the nerve cells<br />

of the oral mucosa. The cells also<br />

warn us if we burn our mouth<br />

with something too hot. This<br />

is where the burning sensation<br />

comes from when eating a chili<br />

pepper. The body reacts to<br />

capsaicin with increased blood<br />

flow and hot flashes. The pain<br />

stimulus can cause the release<br />

of the happiness hormone<br />

endorphin.<br />

The origin of peppers and chili<br />

peppers is in Central and South<br />

America, and Christopher Columbus<br />

is said to have brought the chili bell<br />

pepper to Europe. Today, there are<br />

a large number of varieties and new<br />

chilies are constantly being created<br />

through breeding. Most commonly<br />

used varieties are descended from<br />

five families of species: Sweet<br />

peppers, as well as “Cayenne” and<br />

“Jalapeño,” belong to the most<br />

common species, Capsicum anuum.<br />

Capsicum baccatum includes the<br />

citrus-flavored chili pepper “Lemon<br />

Drop”. The very hot chili peppers<br />

“Carolina Reaper”, “Scorpion” and<br />

“Habanero” are Capsicum chinense<br />

varieties. The “Tabasco” pod, known<br />

through the sauce of the same name,<br />

is of the Capsicum frutescens species.<br />

The fifth species Capsicum pubescens<br />

is rarely cultivated. “Rocota” is one of<br />

its varieties and very popular among<br />

chili connoisseurs.<br />

+ Markets. “This one-stop chili variety<br />

was met with great demand at recent<br />

trade shows to which we accompanied<br />

the company.”<br />

Developing a high-quality seed<br />

The richness of chili varieties is the<br />

result of cultivation and breeding.<br />

Accordingly, the production of highquality<br />

chili varieties begins with seeds.<br />

“Uchu Spice” puts special emphasis<br />

on seed production, handling and<br />

control in its development center.<br />

The company does not resort to<br />

hybrid seeds but has established<br />

its own seed bank and takes care of<br />

seed management itself. 68 different<br />

varieties of the five Capsicum species<br />

families are currently in the seed<br />

bank. Seed development is a lengthy<br />

process. Each variety goes through<br />

a special development process. For<br />

the development of the “Carolina<br />

Reaper”, for example, five seeds were<br />

available and the company needed<br />

2 ½ years. During the research and<br />

development process, the fruits with<br />

the best genotype and phenotype are<br />

selected to ensure that the chilies<br />

are bred that are the most flavorful,<br />

have the best shape and have the<br />

best organoleptic characteristics.<br />

“Many chili producers don’t pay<br />

enough attention not to mix varieties,”<br />

explains Imelda Echavarria, cofounder<br />

and CEO of Uchu Spice. “We,<br />

on the other hand, take special care<br />

to manage the gene bank so that we<br />

have the best ‘habanero’ or that the<br />

‘scorpion’ pod always has the shape of<br />

a scorpion. Our quality control starts<br />

with the seed.”<br />

The company “Uchu Spice” offers 15<br />

different chili varieties. Among them<br />

are the rather mild “Jalapeño” to the<br />

very hot “Habanero” pods. Many<br />

well-known and often used varieties<br />

are included, such as “Tabasco” and<br />

“Cayenne”, as well as specialties like<br />

“Rocota” and “Scotch Bonnet” chilies.<br />

For the European <strong>food</strong> industry, the<br />

chilies are available in dried form, in<br />

flakes, as powder, puréed or pickled,<br />

depending on their intended use. “The<br />

range of chili varieties, flavors, heat<br />

levels and processing options is very<br />

wide for ‘Uchu Spice’” explains Maria<br />

Paula Gomez, IPD expert for Sourcing<br />

16 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Cultivating a diversity of varieties<br />

For cultivation, “Uchu” works with<br />

about 600 small farmers in Ecuador<br />

and also in Peru. The company itself<br />

has no cultivated land of its own. The<br />

model involves close cooperation with<br />

local growers. They are part of the chili<br />

network with long-term contracts. In<br />

addition to special seeds, the farmers<br />

receive ongoing training and technical<br />

support to further develop quality and<br />

yields - and thus also to secure and<br />

improve their livelihoods.<br />

Engagement of the Import Promotion Desk (IPD) in Ecuador.<br />

The IPD has been active in Ecuador since 2018 and is primarily<br />

involved in the rural and structurally weak regions of Ecuador.<br />

Ecuador's natural wealth holds great potential for the export industry.<br />

For example, pineapples, passion fruits, pitahayas, passion fruit,<br />

mangos, physalis, granadillas are grown in Ecuador. They are offered<br />

both as fresh fruit and in processed form, and the demand for tropical<br />

and subtropical fruits is high. The portfolio of natural ingredients also<br />

includes grains such as amaranth, quinoa and chia, which have found<br />

their way into European cuisine.<br />

By cultivating in different regions,<br />

the company ensures year-round<br />

production. In addition, differences<br />

in climate and soil conditions benefit<br />

varietal diversity and high quality: the<br />

“Escabeche” chili, for example, thrives<br />

well in the sandy soils of northern<br />

Peru, while the “Charapita” pod<br />

“prefers” the moist clay soils of the<br />

Amazon basin.<br />

fmt<br />

The goal is to work with small and medium-sized enterprises to<br />

harness the country's natural potential, as well as to open up Europe<br />

as a new sales market and win partners for sustainable business<br />

relationships. The IPD is supported by the German Federal Ministry for<br />

Economic Cooperation and Development (BMZ).<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

17<br />

Key No. 102979

Events<br />

Experience the World’s Nutraceutical<br />

Event: Registration is open for<br />

Vita<strong>food</strong>s Europe <strong>2023</strong><br />

The much-loved nutraceutical event returns both in person and online this May with an expanded offering<br />

including new, premium content<br />

Registrations are now open for<br />

Vita<strong>food</strong>s Europe <strong>2023</strong>, the leading<br />

global platform for nutraceutical,<br />

functional <strong>food</strong> and beverage, and<br />

dietary supplement professionals.<br />

The event, which features Title<br />

Sponsor KSM-66 Ashwagandha, is<br />

set to welcome over 15,000 attendees<br />

from around the globe to the Palexpo<br />

Convention Centre in Geneva (9-11<br />

May) and online (1-12 May). Visitors<br />

can experience exclusive expertled<br />

content on consumer trends,<br />

market opportunities and scientific<br />

innovations, as well as connect with<br />

like-minded peers and suppliers<br />

to inspire new collaborations and<br />

finished products.<br />

In addition to returning favorites,<br />

this year’s event will offer brand new<br />

show features – such as the new<br />

Sustainability Resource Centre and<br />

the Startup Innovation Challenge –<br />

plus premium content offerings via the<br />

Future of Nutrition Summit (8 May)<br />

and the Vita<strong>food</strong>s Europe Conference<br />

(9-10 May) which are designed to keep<br />

businesses at the leading-edge of the<br />

industry.<br />

Speaking on the return of the event<br />

and the addition of new premium<br />

content offerings, Andy Mather,<br />

Brand Director of Vita<strong>food</strong>s Europe<br />

at Informa Markets, said, “Vita<strong>food</strong>s<br />

Europe <strong>2023</strong> aims to create a unique<br />

experience that visitors will not<br />

just find valuable, but that they will<br />

also really enjoy. This year, we are<br />

introducing a host of new content,<br />

designed to inspire, engage and<br />

provide the spark to propel the<br />

industry forward.<br />

The new Sustainability Resource<br />

Centre will feature innovations and<br />

insights from passionate experts<br />

dedicated to driving sustainable<br />

change in the nutrition industry.<br />

Meanwhile, the Startup Innovation<br />

Challenge provides an opportunity<br />

for upcoming nutraceutical stars to<br />

make their mark on the industry and<br />

develop their innovative projects<br />

through a through a specialized<br />

support programme. We are excited<br />

to welcome everyone in the Vita<strong>food</strong>s<br />

community back for <strong>2023</strong> both<br />

in Geneva and online – including<br />

those joining us for the first time<br />

– to experience the creativity and<br />

collaborations on offer.”<br />

Show highlights<br />

Offering a huge range of new and<br />

returning content for visitors to<br />

18 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Events<br />

explore, including a mix of premium<br />

paid-for and free-to-attend sessions,<br />

the Vita<strong>food</strong>s Europe <strong>2023</strong> agenda<br />

will explore everything from market<br />

trends, sustainability, women in<br />

nutraceuticals, and more. Highlights<br />

of this year’s event include:<br />

• NEW: Future of Nutrition Summit (8<br />

May, Marriott Hotel, Geneva) – join<br />

a diverse range of C-suite industry<br />

leaders and futurist thinkers for<br />

an exclusive, paid-for one-day<br />

summit discussing the trends and<br />

technologies that will shape the<br />

nutrition industry in 5+ years’ time<br />

– from precision nutrition and the<br />

digitalization of health management<br />

to sustainable supply chain<br />

solutions.<br />

• NEW: Vita<strong>food</strong>s Europe Conference<br />

(9-10 May) – this premium, two-day<br />

conference returns in a new format,<br />

focused on current challenges and<br />

opportunities in sports and active<br />

nutrition; cognitive and emotional<br />

health; metabolic and immune<br />

health; life stages and healthy<br />

ageing. Now located in a purposebuilt<br />

theater on the Vita<strong>food</strong>s<br />

Europe show floor, visitors can<br />

easily combine attending the<br />

conference alongside their regular<br />

show floor and expo experience.<br />

• The Vita<strong>food</strong>s Insights Theater –<br />

returning for <strong>2023</strong>, the Vita<strong>food</strong>s<br />

Insights Theater offers free-toattend<br />

expert sessions diving into<br />

current global consumer trends,<br />

updates on regulatory and supply<br />

chain issues, as well as insights into<br />

delivery formats and packaging.<br />

• NEW: Startup Innovation Challenge<br />

– discover cutting-edge innovations<br />

from the most exciting health and<br />

nutraceutical startups as they<br />

pitch their ideas live. Together<br />

with the popular Startup Pavilion,<br />

this challenge provides a unique<br />

opportunity for companies to<br />

find innovative ingredients,<br />

technologies, services, and finished<br />

products to help their businesses<br />

grow.<br />

• NEW: Sustainability Resource<br />

Center – dedicated to driving<br />

sustainable change in the nutrition<br />

industry, this resource center<br />

offers expert presentations and<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April<br />

insights into the full spectrum of<br />

sustainability issues, including<br />

supply chain traceability, regulatory<br />

compliance, certifications, carbon<br />

offsetting, alignment with the UN<br />

Sustainable Development Goals,<br />

and gender and LGBTQ+ inclusivity.<br />

Experience innovations, ideas<br />

and insights yourself<br />

“Standing still simply isn’t an option<br />

in this industry; people return to<br />

Vita<strong>food</strong>s Europe year-after-year to<br />

drive their businesses forward and<br />

be inspired.” says Mather. “This year,<br />

we are offering another lively agenda,<br />

packed full of exciting opportunities to<br />

Key No. 104845<br />

Vita<strong>food</strong>s Europe is<br />

connect and gather knowledge. This<br />

includes both new and re-imagined<br />

premium, paid-for events that will dive<br />

deeper into current trends and future<br />

industry predictions; the Vita<strong>food</strong>s<br />

Europe Conference and the Future of<br />

Nutrition Summit. The latter joins the<br />

Vita<strong>food</strong>s Europe <strong>2023</strong> family after<br />

being a huge success at previous<br />

Food Ingredients Europe events. We<br />

truly believe that Vita<strong>food</strong>s Europe<br />

<strong>2023</strong> in Geneva, Switzerland, has<br />

something for everyone, and that this<br />

year’s attendees will experience the<br />

very best in industry innovations and<br />

insights to keep their businesses at<br />

the leading-edge of nutrition.” fmt<br />

Every year, thousands of nutraceutical experts look forward to joining friends,<br />

colleagues and suppliers at Vita<strong>food</strong>s Europe. They love tasting new<br />

products, listening to world-class speakers, discovering new ingredients and<br />

connecting with fantastic people from across our industry.<br />

Experience it for yourself<br />

9-11 May Geneva<br />

1-12 May Online<br />

Register now at vita<strong>food</strong>s.eu.com

Events<br />

Supporting both Human Health and that<br />

of the Planet<br />

AstaReal at Vita<strong>food</strong>s Europe <strong>2023</strong>, booth H100<br />

AstaReal continues its mission to<br />

be a planet-friendly and sustainable<br />

business by launching Astaxin®<br />

VEGAN. The new product containing<br />

natural algal astaxanthin aims to<br />

promote good health while alleviating<br />

environmental concerns.<br />

With its scientifically proven<br />

antioxidant and anti-inflammatory<br />

properties, natural microalgaederived<br />

AstaReal® astaxanthin is well<br />

positioned to satisfy current consumer<br />

demands: supporting health via<br />

effective and sustainable solutions.<br />

Demand for vegetarian- and vegancompliant<br />

supplements is increasing<br />

globally. To complement daily diets<br />

and maintain well-being, many people<br />

seek plant-based supplements that<br />

promote both physical and mental<br />

health. Meanwhile, consumers are<br />

increasingly concerned about the<br />

origins of their purchases and their<br />

impact on climate and ecosystems.<br />

At Vita<strong>food</strong>s Europe, AstaReal will<br />

exhibit its extended product range,<br />

and demonstrate how supplement<br />

manufacturers can better address the<br />

current consumer concerns.<br />

An innovative finished formulation will<br />

also be launched at the show. Astaxin®<br />

VEGAN, an antioxidant formula that<br />

taps into the plant-based market,<br />

with the content mirroring Astaxin®<br />

Original – including vitamin C and<br />

natural vitamin E – but in a vegan<br />

softgel made of carrageenan and<br />

modified starch. Astaxin® VEGAN will<br />

be available in bulk from June and as a<br />

retail product from October <strong>2023</strong>.<br />

In addition, expo visitors can try<br />

samples of the next-generation vegan<br />

starch-based astaxanthin gummies<br />

that are sugar-free. Moreover, they<br />

will get to know about AstaReal’s bulk<br />

products that are registered with the<br />

Vegan Society and that are applicable<br />

in various supplement dosage forms,<br />

including but not limited to, hard<br />

capsules, softgels, sachet/stick<br />

powder mixes and gels, gummies, and<br />

liquid shots.<br />

AstaReal is a global pioneer in<br />

microalgae cultivation, and the<br />

first producer of human nutritional<br />

supplements containing natural<br />

astaxanthin. The company believes<br />

in transparency that better enables<br />

informed choices, especially with<br />

regards to sustainability. Peter Ahlm,<br />

Head of <strong>Marketing</strong> and Sales at<br />

AstaReal, says: “Sustainability is not<br />

only a core value for us at AstaReal,<br />

but also one of the key considerations<br />

among today’s consumers. This is<br />

reflected in the supplements market,<br />

with environmentally sound products<br />

growing in popularity. Also, in terms<br />

of ecosystem preservation, natural<br />

astaxanthin is a promising ingredient,<br />

as it is derived from fast-regrowing<br />

microalgae which are planet-friendly,<br />

natural resources. Our mission is to<br />

offer the carotenoid in its natural,<br />

purest and most stable form to pave<br />

the way for truly healthy products with<br />

proven sustainability credentials.” fmt<br />

Gut Health Innovations<br />

FrieslandCampina Ingredients at Vita<strong>food</strong>s Europe <strong>2023</strong>, booth H270<br />

FrieslandCampina Ingredients, a<br />

global leader in protein and prebiotics,<br />

will return to Vita<strong>food</strong>s Europe (9 – 11<br />

May) in Geneva, Switzerland. The<br />

company is launching a brand-new<br />

ingredient at the New Product Zone,<br />

with details to be revealed closer<br />

to the show, as well as showcasing<br />

its latest prebiotic and sustainable<br />

ingredient innovations.<br />

In <strong>2023</strong>, people overwhelmingly<br />

see living and eating well as a top<br />

priority and gut health remains high<br />

on the consumer agenda for <strong>2023</strong>.<br />

But with increasingly busy schedules,<br />

consumers are looking for convenient<br />

gut health applications to meet their<br />

health goals with ease.<br />

To inspire brands to create convenient<br />

gut health solutions,<br />

FrieslandCampina Ingredients will<br />

showcase its recently launched<br />

Biotis® GOS-OP High Purity, including<br />

its new gummy concept. Designed<br />

to help manufacturers overcome<br />

common challengers associated with<br />

formulating prebiotic supplements,<br />

this ingredient is efficacious in doses<br />

as low as two grams, opening up a<br />

range of new opportunities for brands<br />

to develop effective and convenient<br />

holistic health solutions.<br />

Sustainably feeding the future<br />

Health and planet-conscious consumers<br />

are actively looking for more<br />

environmentally-friendly products –<br />

and reducing carbon is a top priority,<br />

with 63% of consumers having taking<br />

action to reduce their personal carbon<br />

footprint.<br />

FrieslandCampina Ingredients is<br />

committed to helping brands create<br />

sustainably nutritious solutions and<br />

will be showcasing its new suite of<br />

20 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Events<br />

carbon-neutral solutions at Vita<strong>food</strong>s<br />

Europe – including its new carbonneutral<br />

protein powder.<br />

Vicky Davies, Global Senior <strong>Marketing</strong><br />

Director, Performance and Active<br />

Nutrition at FrieslandCampina<br />

Ingredients, said:<br />

“This year’s Vita<strong>food</strong>s Europe is going<br />

to be a big one for FrieslandCampina<br />

Ingredients! We’ll be launching a<br />

brand-new ingredient at the show<br />

and it’s one that breaks new ground<br />

for us and the industry. We can’t wait<br />

for brands to discover our newest<br />

offering, as well as our wider portfolio<br />

of nutritious and sustainable proteins<br />

and prebiotics. I’m looking forward<br />

to collaborating with our customers<br />

in person. Vita<strong>food</strong>s Europe gives us<br />

a great opportunity to work together<br />

with our customers and partners to<br />

create tasty, efficacious and sustainable<br />

solutions, so that people can<br />

get the most out of life, always.” fmt<br />

Solutions for Well-being Benefits and<br />

Innovative Delivery<br />

Rousselot at Vita<strong>food</strong>s <strong>2023</strong>, booth I114<br />

Darling Ingredients’ Health Brand<br />

Rousselot®, a global leader in collagen<br />

peptides and gelatin solutions, invites<br />

Vita<strong>food</strong>s <strong>2023</strong> attendees to discover<br />

the ‘game-changing’ benefits and<br />

trending applications of its full range of<br />

collagen and gelatin solutions.<br />

Maintaining a healthy lifestyle remains<br />

a priority for consumers worldwide and<br />

the use of supplements for enhancing<br />

health and wellness is becoming<br />

an increasingly popular solution to<br />

achieve this goal. As a more holistic<br />

view of health and well-being gains<br />

momentum, brands are placing a<br />

greater emphasis than ever before<br />

on adding ingredients with multiple<br />

benefits into their products.<br />

Among the key solutions Rousselot<br />

will spotlight, collagen peptides brand<br />

PEPTAN® is the ingredient to watch<br />

to tap into this trend. From helping<br />

shoppers stay active and mobile at<br />

every stage of life, to boosting beauty<br />

from within, or improving sports<br />

recovery, this premium ingredient<br />

combines multiple science-backed<br />

benefits with versatile formulation<br />

properties.<br />

COLARTIX®, a unique hydrolyzed<br />

cartilage matrix for joint health, made of<br />

naturally occurring collagen peptides<br />

and glycosaminoglycans (GAGs) will<br />

also be a key highlight at the event.<br />

In a recently published consumer<br />

study, performed in a real-life setting,<br />

Colartix was shown to decrease joint<br />

discomfort across gender, age and<br />

sport intensity.<br />

Attendees will experience the endless<br />

versatility of these ingredients firsthand<br />

thanks to a range of samples from<br />

Rousselot’s application center. These<br />

include a peach-flavored “Beyond<br />

Beauty” drink featuring Peptan and<br />

probiotics, as well as mobility gummies<br />

featuring Colartix.<br />

In addition to the collagen products<br />

on display, Rousselot will showcase<br />

its world-class gelatin solutions;<br />

Stabicaps, specifically designed<br />

to achieve more stable softgels and<br />

SiMoGel, a unique gelatin technology<br />

solution which enables the production of<br />

nutraceutical gummies in a starch-free<br />

environment. Rousselot’s formulation<br />

experts will be available to discuss with<br />

supplement, capsule, and confectionery<br />

manufacturers how these solutions<br />

unlock the innovative delivery forms<br />

needed to meet the ‘pillars’ of consumer<br />

experience: good taste, convenience,<br />

new shapes and naturalness.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

21

Events<br />

Sobriety and Performance on the Menu,<br />

at CFIA - Food Exhibition in France<br />

The CFIA is a major <strong>food</strong> fair in France, the crossroads of suppliers to the <strong>food</strong> industry. It takes place every<br />

year in Rennes, Brittany, core region of French agricultural <strong>food</strong> production. But this has become a major<br />

meeting place, gathering 1600 exhibitors and nearly 20,000 visitors. For its 26th edition, on everyone’s lips,<br />

there was talk of sobriety, frugality and innovation in manufacturing processes as well as in ingredients and<br />

packaging. This report from Dominique Huret, Cape Decision, who was on the spot for Food <strong>Marketing</strong> &<br />

<strong>Technology</strong>.<br />

“Essentially manufacturers who come<br />

here are looking for either the recipe of<br />

tomorrow, the machine that will allow<br />

them to improve their production while<br />

saving energy, or a better package<br />

for their products or to finalize their<br />

projects”, explains Sébastien Gillet<br />

CFIA director.<br />

Between hygiene constraints and<br />

growing environmental challenges,<br />

suppliers of solutions for the quality<br />

department are stepping up their<br />

efforts to reconcile sobriety and <strong>food</strong><br />

safety. This is evidenced by about 100<br />

new products put forward by exhibitors<br />

at this <strong>2023</strong> edition.<br />

Innovations in process , quality<br />

and with sobriety<br />

The specialist in industrial water<br />

treatment ChemDoc Water is<br />

deploying a project to recycle wash<br />

water. In <strong>food</strong> production processes,<br />

tanks and lines are washed with<br />

softened water. This water is then<br />

loaded with organic matter and sent<br />

for biological purification before<br />

being discharged into the natural<br />

environment. ChemDoc offers a<br />

process that allows total recycling (or<br />

zero liquid discharge) of manufacturing<br />

washing water. Two processes are<br />

combined: a recycling unit for the salt<br />

(up to 85% recovery) and a membrane<br />

separation unit of the effluents which<br />

allows a reuse of the water for cleaning<br />

with <strong>food</strong> contact guarantee.<br />

Cabinplant automates the dosing of<br />

sticky or even liquid products. Called<br />

MHW SF Extreme, this multi head<br />

weigher weighs and packages products<br />

that are still often added manually,<br />

such as mixed salads, coleslaw, tuna<br />