Food Marketing & Technology 1/2022

Please find numerous articles, product news and interesting event reports relevant to the food industry in this latest issue. This trade magazine is published in English only.

Please find numerous articles, product news and interesting event reports relevant to the food industry in this latest issue. This trade magazine is published in English only.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1/22<br />

Vol. 36 • 31377<br />

ISSN 0932-2744<br />

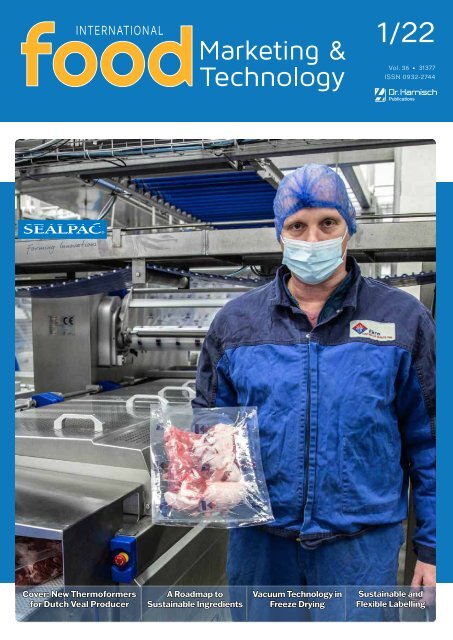

Cover: New Thermoformers<br />

for Dutch Veal Producer<br />

A Roadmap to<br />

Sustainable Ingredients<br />

Vacuum <strong>Technology</strong> in<br />

Freeze Drying<br />

Sustainable and<br />

Flexible Labelling

Solutions that Matter<br />

to People Everywhere<br />

Over the years SPX FLOW has developed cutting-edge solutions that help bring delicious<br />

and healthy dairy and plant-based products to your customers. But our impact goes beyond<br />

dairy. From aerospace to personal care and construction to medicine, our innovative solutions<br />

make life better for people everywhere. Every day. Explore the impact our Solution Makers<br />

have on your daily life at SPXFLOW.com/SolutionsAroundYou, or by scanning the QR code.<br />

Key No. 101490

Editorial<br />

Trends for Twenty Two<br />

There is a well known German comedy<br />

sketch called ‘Dinner for One‘. It’s<br />

about an old lady who enjoys a dinner<br />

party with her friends, who have<br />

unfortunately all died before her. The<br />

butler plays the parts of the missing<br />

guests and asks his mistress “The<br />

same procedure as last year, Miss<br />

Sophie?“ To which the answer is “The<br />

same procedure as every year, James!“<br />

When thinking of the food industry and<br />

what trends are in the market, it often<br />

feels the same way. Trends come and<br />

go, but they mostly feel the same. In<br />

times of covid and climate challenges,<br />

the major trends in the food and<br />

beverage industry centre around<br />

health and sustainability issues. Other<br />

buzz words include plant-based<br />

nutrition and indulgence, as well as our<br />

old favourite: convenience.<br />

Products need to be ready to consume<br />

at any time, provide nutrition and<br />

added value for body, mind and spirit,<br />

whilst tasting good and supporting<br />

the environment. Packaging and<br />

processing methods are also more in<br />

the spotlight than ever before.<br />

Our lifestyle has changed in the past<br />

months. As more people work from<br />

home, so they eat more at home. We<br />

would expect this to lead to a more<br />

balanced and healthy diet, but this<br />

is not always the case. Consumers<br />

want to find healthy and sustainable<br />

products as easily as possible. More<br />

often than not, they are ordered and<br />

delivered by courier, either as fresh<br />

ingredients or finished meals.<br />

Plant-based nutrition is a perceived<br />

answer to the problems around<br />

global warming, as well as health<br />

issues regarding meat consumption.<br />

While there are arguments in both<br />

directions, it remains true that the<br />

consumer focus on plant-based foods<br />

has shifted slightly to include added<br />

benefits of vitamins and minerals.<br />

Optimising the nutritional profile is an<br />

ongoing project.<br />

Indulgence will always be significant.<br />

One constant in our diet, is that we are<br />

always looking for something different.<br />

This may be in a sensory experience,<br />

whether taste, texture, smell or colour,<br />

but also a need to be surprised or<br />

challenged. Beverages are a popular<br />

carrier for a new experience, with<br />

combinations of sweet and creamy or<br />

hot, sour and bitter finding a market in<br />

the Millennial generation.<br />

Ian Healey<br />

Editor-in-Chief<br />

Sustainability is a measure of corporate<br />

responsibility which mirrors consumer<br />

behaviour. The concept is growing<br />

to cover the complete life cycle of a<br />

product, farm to fork, and includes<br />

packaging and use of resources in<br />

processing.<br />

The same procedure as every year?<br />

Trends are, in fact, developing<br />

gradually, so that what was important<br />

five years ago is now a footnote and the<br />

footnotes are becoming mainstream.<br />

But it still has to taste good.<br />

Sincerely,<br />

If you like it – subscribe!<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

3<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

XIX International Trade Fair<br />

for Savoury Snacks & Nuts<br />

6 - 7 July <strong>2022</strong><br />

Hamburg, Germany<br />

Contents<br />

food <strong>Marketing</strong> & <strong>Technology</strong> February <strong>2022</strong><br />

1 Editorial<br />

42 Impressum<br />

Ingredients<br />

Move your<br />

business<br />

forward<br />

at the worldwide fair<br />

for savoury snacks<br />

The only trade fair 100% focused<br />

on savoury snacks and nuts<br />

+ Experience the hottest trends,<br />

tastes and technologies<br />

+ Develop your business with the<br />

industry’s leading suppliers<br />

+ Connect with the decision-makers<br />

of the industry and find<br />

international trade partners,<br />

distributors<br />

+ Meet existing customers and new<br />

prospects from around the world<br />

+ Sell your products to an<br />

audience that is ready to buy<br />

10 A Roadmap to Sustainable Ingredients<br />

13 Creating Classic Confectionery with Gelatin<br />

16 FDA Recognizes <strong>Food</strong> Recognizes the Dietary<br />

Fiber Status of Acacia Gum<br />

18 Cutting Sugar Loads from Hazelnut &<br />

Chocolate Spreads<br />

Processing<br />

20 Creating an Innovative, Healthy, CO 2<br />

-Neutral Snack<br />

22 Breakthrough <strong>Technology</strong> will Produce Green Proteins<br />

Greener - Next Generation Membrane Filtration Systems<br />

are the Key<br />

24 Digitalization Leveraged to Optimize Hygienic<br />

Processing<br />

26 Freeze Drying with the help of Vacuum <strong>Technology</strong><br />

27 Research Holds the Key to more Efficient Crossflow<br />

Membrane Filtration<br />

28 Metal Detection for Fish Sausages, Right on the<br />

Fishing Boat<br />

28 The Perfect Form for the Bakery<br />

29 Automatic WIP-Systems Efficient cleaning of<br />

Ploughshare Mixers<br />

30 Trade Fair Restart at ProSweets: Confectionery Solutions<br />

31 ERP Solution Adds Value to Ham Production<br />

Packaging<br />

6 Renowned Dutch Veal Producer Invests in New<br />

Thermoformers<br />

32 How the Label Becomes more Sustainable and Flexible<br />

36 Haldiram’s Nagpur Goes Live with its Long Shelf-Life<br />

Ethnic Beverages<br />

38 “We support our Customers in Broadening their<br />

Perspective”<br />

Departments<br />

The industry-defining fair for<br />

the savoury snacks sector<br />

40 Events<br />

snackex.com<br />

Key No. 102334

Vol. 36 • 31377<br />

ISSN 0932-2744<br />

Cover: New Thermoformers<br />

for Dutch Veal Producer<br />

A Roadmap to<br />

Sustainable Ingredients<br />

Vacuum <strong>Technology</strong> in<br />

Freeze Drying<br />

1/22<br />

Sustainable and<br />

Flexible Labelling<br />

Cover: Sealpac<br />

The Dutch veal producer, Ekro<br />

decided to invest in four SEALPAC<br />

thermoformers for packaging the<br />

high-quality fresh products in various<br />

weights and sizes, including<br />

entrecote, fillet, escalope, rib-eye<br />

and steak. The packaging primarily<br />

has a protective function, so that a<br />

flexible film is sufficient and sustainable.<br />

By using vacuum technology,<br />

an optimal shelf life is achieved.<br />

Our Cover Story starts on page 6.<br />

Key No. 102203<br />

Ingredients: Natural flavored oil<br />

Infuso is a natural, flavored oil that is set to make snack<br />

production a whole lot easier and help food manufacturers<br />

in their quest for an outstanding snacking experience. It‘s<br />

brilliant in its simplicity and delivers intense, bold flavors and<br />

multi flavored profiles for any savory snack. We talked to the<br />

CEO of the company. Find out more on page 10<br />

Processing: Freeze drying fruits<br />

There are several ways to extend the shelf life of food. Freeze<br />

drying is a modern extension of traditional drying methods<br />

to protect food from spoilage for longer. This process is only<br />

made possible by modern vacuum technology because freeze<br />

drying food takes place under vacuum. Check out the story<br />

on page 26<br />

Packaging: Sustainable labelling<br />

<strong>Food</strong> and beverage industry players are particularly concerned<br />

about the costs of materials and are keen to optimize<br />

their investment while increasing brand recognition. One of<br />

the leading manufacturers in the market shares their expertise<br />

to meet all labelling needs. See page 32<br />

Key No. 102158<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February 2016

Cover Story<br />

Renowned Dutch Veal Producer<br />

Invests in New Thermoformers<br />

The company Ekro in Apeldoorn (NL), part of the VanDrie Group, is a renowned producer of veal. At the<br />

business park along highway A1, approximately 400,000 calves are processed into high-quality meat<br />

products every year, which are mainly distributed in Germany, France and Italy. In 2020, Ekro made<br />

significant investments in its packaging department, resulting in four new thermoformer lines. We spoke<br />

with Christian Scholten, Project Manager a.i. at Ekro, and Anjo Kaatman, Head of Technical Service within the<br />

company, about the recent installation of these lines and the challenges such a project entails.<br />

High-quality veal with attention<br />

to the animal<br />

What once started as a municipal<br />

slaughterhouse in the center of<br />

Apeldoorn is now an ultramodern<br />

production company on the outskirts<br />

of the city with approximately 750<br />

employees. Ekro works in two shifts<br />

per day on the tastiest veal products.<br />

The new building at its current location<br />

along highway A1 was constructed in<br />

1989, not long after the company was<br />

incorporated by the Van Drie family.<br />

Today, the VanDrie Group includes<br />

Dutch companies such as ESA and<br />

T. Boer & zn, but also Sobeval and<br />

Tendriade in France.<br />

‘When you ask for veal, we serve a<br />

concept’, that is the starting point<br />

of Ekro. The company supplies highquality<br />

veal products all over the<br />

world that are tailored to the wishes<br />

of the customer, such as whole veal<br />

Christian Scholten shows the packaged product<br />

Flexible film vacuum packaging protects during storage and transport<br />

breast or veal roulade for the catering<br />

industry, but also consumer products<br />

such as veal burgers or steaks. Animal<br />

welfare, food safety and sustainability<br />

are of utmost importance. This means<br />

that Ekro’s products fully meet the<br />

contemporary requirements of<br />

discerning chefs and consumers. All<br />

employees, but also each supplier<br />

of the calves, work continuously to<br />

improve animal health and welfare.<br />

Full traceability<br />

Veal is an appreciated delicacy due<br />

to its fine structure, high nutritional<br />

value and subtle taste. It is easy to<br />

digest, low in cholesterol and rich in<br />

vitamins and minerals. That is why<br />

the product is widely used and highly<br />

valued in international kitchens. Ekro<br />

works with traditional wholesalers,<br />

retailers, food service and food<br />

manufacturers. Orders range from<br />

the delivery of complete carcasses<br />

to the delivery of kitchen-ready<br />

consumer products.<br />

6<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Cover Story<br />

Christian Scholten, Project Manager at<br />

Ekro: “What makes Ekro unique is the<br />

quality we deliver. Our company is part<br />

of a complete chain, from the feeding<br />

of the calves to the packaged end<br />

product. In addition, Ekro has been<br />

committed to traceability for several<br />

decades. The abattoir and deboning<br />

section are equipped with hightech<br />

hardware and software, which<br />

connect seamlessly to each other, so<br />

that full tracking and tracing of the<br />

products is guaranteed. For example,<br />

the customers of Ekro, primarily the<br />

wholesaler, can always enter the<br />

stated barcode for each product on a<br />

special website to view the complete<br />

life cycle of the meat.”<br />

Impossible to break<br />

As Head of Technical Service, Anjo<br />

Kaatman is responsible for Ekro’s<br />

existing machinery. Within the<br />

company’s Project Office, Christian<br />

Scholten, together with four other<br />

colleagues, is constantly working on<br />

renewal processes in the broadest<br />

sense of the word. Recently, both<br />

men worked together in a large<br />

investment project in the packaging<br />

department of Ekro. The aim was to<br />

modernize a number of existing lines,<br />

so that they could work even more<br />

efficiently. For example, the same<br />

thermoformer has been used since<br />

1999 for packaging the by-products,<br />

especially organs. This machine, an<br />

RE3, was once purchased from the<br />

company Repak B.V. in Emmen (NL),<br />

Anjo Kaatman, Head of Technical Service within Ekro<br />

Christian Scholten, Project Manager a.i. at Ekro<br />

a Dutch family business, just like the<br />

VanDrie Group.<br />

There is a great anecdote about the<br />

installation of the RE3. At the time, the<br />

machine was delivered by truck and<br />

brought to its destination in one piece<br />

on wheels. However, it turned out that<br />

there suddenly was a wall that had not<br />

yet been there at the time of purchase.<br />

With two colleagues quicky gathered<br />

from Emmen, the RE3 was taken apart<br />

and put back together in the right<br />

place, so that it could still be installed<br />

over the weekend. Since 1999, the line<br />

has been running 16 hours a day, where<br />

cleaning takes place every evening<br />

and maintenance is done twice a year.<br />

Anjo Kaatman: “The RE3 has always<br />

functioned without problems in our<br />

challenging production environment<br />

until the end of 2021.”<br />

The importance of good<br />

maintenance<br />

The RE-series thermoformers are still<br />

built in Emmen, but since 2007 they<br />

have been offered in the Benelux<br />

under the brand name SEALPAC. The<br />

advice, sales and maintenance are<br />

done by Ultrapak B.V. in Nijkerk, the<br />

exclusive distributor for SEALPAC<br />

thermoformers and traysealers<br />

in the Netherlands, Belgium and<br />

Luxembourg. Anjo Kaatman: “We<br />

have had an exceptionally good<br />

relationship with Ultrapak from the<br />

start. They take their responsibility<br />

and meet the set deadlines, also with<br />

regard to the agreed service contracts.<br />

Installation of new machines, but also<br />

the maintenance of existing machines,<br />

must take place with us during the<br />

weekend. The requirement is then that<br />

the machines have to be running again<br />

on Monday morning at 6.00 am, and<br />

that has always been successful so far.”<br />

With the RE3 in use for more than 20<br />

years, and a number of other lines<br />

that could use a facelift, the inevitable<br />

question of replacement came in 2020.<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

7

Cover Story<br />

To this end, a large project was started<br />

within Ekro, in which distinct options<br />

were examined. Revision of the<br />

existing machines was still a possibility,<br />

but replacement turned out to offer<br />

the most benefits in the end. Ultrapak,<br />

in the form of contact person Andres<br />

Vos, provided an extensive analysis.<br />

As part of the project, a visit was made<br />

to the factory in Emmen. For Christian<br />

Scholten, it was the first time. He<br />

remarks: “It is a very neat factory, where<br />

you can clearly see the production<br />

process of the machines, from drawing<br />

to assembly. Furthermore, it is obvious<br />

that the factory is constantly investing<br />

in production resources.”<br />

Four new lines<br />

Ultimately, Ekro decided to invest in<br />

four SEALPAC thermoformers: an<br />

RE30 tandem machine for packaging<br />

the by-products and three RE25<br />

thermoformers for packaging fresh<br />

veal in various weights and sizes,<br />

including entrecote, fillet, escalope,<br />

rib-eye and steak. Anjo Kaatman: “The<br />

first two machines were installed in<br />

September 2021, and the last two<br />

followed in November. In both cases<br />

this happened over the weekend, and<br />

in both cases the machines were ready<br />

for production by 6:00 am on Monday<br />

morning. As we are used to from<br />

Ultrapak!”<br />

The three RE25 thermoformers are<br />

located right next to each other in<br />

the same production hall. Because<br />

of the tight space there, including a<br />

few awkward pillars, the machines<br />

were designed to fit. Each of the RE25<br />

thermoformers is suitable for a fixed<br />

packaging format, which is tailored<br />

to the weight and/or dimensions of<br />

the various veal products. The RE30<br />

is located in a separate hall, where<br />

the by-products are packaged, such<br />

as liver, heart, tripe, sweetbreads,<br />

etc. Christian Scholten: “This line<br />

has regular changes during the day.<br />

By choosing a tandem machine with<br />

two forming stations, suitable for two<br />

formats (roughly 4 kg and 5 kg), we can<br />

now change at the touch of a button.<br />

This results in enormous time savings.<br />

Our staff is very economical with and<br />

proud of this line!“<br />

All SEALPAC machines are equipped<br />

with product support due to the heavier<br />

packaging. This prevents the film from<br />

slipping out of the chain. Furthermore,<br />

all machines have central lubrication,<br />

so that maintenance is minimized.<br />

Anjo Kaatman adds: “The SEALPAC<br />

machines are characterized by their<br />

simplicity and reliability. I therefore<br />

know that our staff can quickly<br />

familiarize themselves with these<br />

machines. The touch-screen monitor<br />

of the RE series is also easy to operate.”<br />

The optimal packaging for semifinished<br />

products<br />

Only a small part (about 5%) of the veal<br />

produced stays in the Netherlands.<br />

The remaining 95% is exported to<br />

Ekro produces high-quality veal products for wholesalers and consumers<br />

8<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

31377<br />

Cover Story<br />

about 50 countries, mainly Europe,<br />

China and the US. The primary buyers<br />

are wholesalers, who in turn supply<br />

the catering industry. However, there<br />

is also a growing consumer products<br />

department. Semi-finished products<br />

are packaged on the SEALPAC<br />

thermoformers, which mainly go to the<br />

(catering) wholesaler. The packaging<br />

primarily has a protective function,<br />

so that a flexible film is sufficient<br />

and sustainable. By using vacuum<br />

technology, an optimal shelf life is<br />

achieved. Christian Scholten: “If we<br />

look at the vacuum packaging based<br />

on PA/PE film, such as those that are<br />

run on the SEALPAC machines, we<br />

are actually already at the minimum<br />

packaging level. Thanks to the Rapid<br />

Air Forming concept, standard on the<br />

SEALPAC machines, the film is already<br />

as thin as possible.<br />

Future plans<br />

Of course, the Corona pandemic has<br />

had an impact on Ekro, all the more so<br />

Christian Scholten between two SEALPAC RE25 thermoformers<br />

because the catering sector, and with<br />

it the wholesaler that supplies that<br />

sector with veal, has been hit. Christian<br />

Scholten: “That was especially true in<br />

the first year of the pandemic, when<br />

the catering industry in southern<br />

European countries was closed. Since<br />

then, production has picked up again<br />

and is almost back to the same level.<br />

Fortunately, we can now shift our<br />

attention to other innovation projects<br />

within Ekro.”<br />

fmt<br />

1/22<br />

Vol. 36 •<br />

ISSN 0932-2744<br />

Come and see for yourself:<br />

www.harnisch.com<br />

Cover: New Thermoformers<br />

for Dutch Veal Producer<br />

A Roadmap to<br />

Sustainable Ingredients<br />

Vacuum <strong>Technology</strong> in<br />

Freeze Drying<br />

Sustainable and<br />

Flexible Labe ling<br />

Perfectly positioned.<br />

The international specialist magazines from Dr. Harnisch Publications<br />

You can now explore our newly designed website, with a<br />

clear focus on responsive design and easily usable applications.<br />

Alongside the free-to-use digital magazine editions, you will<br />

find bonus news coverage, events, subscription and<br />

general information on all our magazines. Take a look at<br />

www.harnisch.com for all relevant content.<br />

Our publications include:<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

- <strong>Technology</strong> & <strong>Marketing</strong> -<br />

9

Ingredients<br />

A Roadmap to Sustainable Ingredients<br />

Wim van Roekel, President of Europe & Africa, Griffith <strong>Food</strong>s discusses its ambitious roadmap for growth to<br />

2030, new product launches across countries and continents and why sustainable choices matter now more<br />

than ever.<br />

By Ian Healey<br />

Wim van Roekel<br />

Please tell us a little about Griffith<br />

<strong>Food</strong>s and your background?<br />

Founded in 1919 and now in the fourth<br />

generation of family leadership, Griffith<br />

<strong>Food</strong>s is a global product development<br />

partner specialized in food ingredients.<br />

From farmers to customers, the<br />

relationships it forms with its partners<br />

allow Griffith <strong>Food</strong>s to create better<br />

products that are delicious and<br />

nutritious for consumers, and foster a<br />

better, more sustainable world. Today,<br />

the Griffith <strong>Food</strong>s family of companies<br />

operates in more than 30 countries on<br />

six continents, employing over 4,800<br />

people, including more than 40 chefs<br />

and 340 food scientists.<br />

We collaborate with food companies<br />

worldwide to create fully customized<br />

recipes for the constantly evolving food<br />

marketplace, partnering with you from<br />

ideation to production. Our product<br />

portfolio consists of seasonings, sauces<br />

and dressings, and coatings,<br />

Our mission is to help customers succeed<br />

through collaborative innovation and the<br />

supply of tailored seasonings, sauces,<br />

dressings and premium coatings where<br />

we tailor everything from flavor and<br />

functionality to meet your unique needs.<br />

In many ways our purpose – “we blend<br />

care and creativity to nourish the world”<br />

– captures the essence of our existence<br />

and values as a business.<br />

As President of Europe and Africa<br />

for almost 4 years, we’ve grown<br />

significantly and have put an ambitious<br />

but achievable growth plan in place all<br />

the way to 2030. We’ve taken our core<br />

capabilities as culinary experts and<br />

looked to evolve these through new<br />

partnerships and ecosystems where<br />

shared values and new technologies and<br />

benefit all. Previous to that my career<br />

was been a mix of corporate positions in<br />

the food industry as well as running my<br />

own business.<br />

Describe the Griffith <strong>Food</strong>s<br />

Business Plan for this year and over<br />

the next five?<br />

To continue to grow, we are constantly<br />

evolving our Health and Nutrition,<br />

Alternative Proteins, and sustainable<br />

sourcing even more deeply and are<br />

making great progress. By partnering<br />

with others, we can knowledge share<br />

our expertise and expand into new<br />

areas, and this may mean start-ups with<br />

great ideas as well as more established<br />

entities. Overall, it’s been a tough year<br />

initially, but business has bounced back<br />

to to 2019 top-line levels after a tough<br />

first half of 2021. We’ve also extended<br />

our purpose driven strategy to 2030<br />

with ambitious goals to ensure the entire<br />

business will be net zero and a superior<br />

example of sustainable best practice.<br />

What is novel about Griffith <strong>Food</strong>s<br />

as a food service provider?<br />

At our heart we are still a family<br />

business, one that acts and functions<br />

like a family whilst behaving as owners.<br />

I think our value system is very strong<br />

as we are true collaborators who take<br />

in customers, always as family. It’s one<br />

reason we have great retention rates.<br />

We always innovate, inspire and<br />

collaborate to create products and<br />

concepts that drive customer success,<br />

and we remain keen to have early<br />

conversations with customers so that<br />

needs are understood and aspirations<br />

delivered.<br />

One of our other key differentiators is our<br />

mission to be more sustainable in all our<br />

decisions and actions. People, Planet<br />

and Performance make up the pillars of<br />

10 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Ingredients<br />

Registration opens March 1<br />

July 10–13, <strong>2022</strong><br />

McCormick Place | Chicago, IL<br />

Reconnect Learn Innovate<br />

Stay connected with the latest<br />

IFT FIRST updates at iftevent.org.<br />

Key No. 102109<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

11

Ingredients<br />

our sustainability strategy. For example,<br />

by 2025, 100% of our herbs, spices and<br />

vegetables will be from certified sources<br />

and a 100% of our supply base will be<br />

EcoVadis certified. We constantly look at<br />

how to engage with more suppliers with<br />

a focus on regenerative farming. On that<br />

subject, with Platinum in Belgium and<br />

Spain and Gold in the UK, our Ecovadis<br />

awards put us in the top 1% category of<br />

all global suppliers.<br />

Growth also means new partners,<br />

ecosystems, territories, we know<br />

there are major opportunities in<br />

existing markets such as the UK,<br />

Spain, and Germany. Additional<br />

investments there are paying<br />

dividends, as our Poland office was<br />

successfully opened as a bridge to<br />

Eastern Europe, a key new territory<br />

where we saw immediate growth.<br />

We also launched and seeded our<br />

Africa strategy in Kigali, Rwanda.<br />

Operationally, we set up and source<br />

locally using immediate values chains<br />

to design products that work in local<br />

markets for both African consumers<br />

and businesses – it’s an Africa for<br />

Africa approach.<br />

Broadly speaking what’s your new<br />

product approach to <strong>2022</strong>?<br />

At Griffith <strong>Food</strong>s, we will be focussing<br />

as ever on Health and Nutrition,<br />

Sustainable sourcing, and best practice<br />

in keeping with consumer demand.<br />

We know that new products need to<br />

have a nutritious advantage as well<br />

as great taste and texture. All our six<br />

product launches next year will be a<br />

mix of improved nutrition, even better<br />

sustainability creds and more natural,<br />

cleaner label propositions, depending<br />

on the product in question. We are very<br />

excited about the Alternative Protein<br />

space especially.<br />

What is Infuso and why is it a<br />

breakthrough savoury snacks<br />

innovation?<br />

Infuso is a customisable flavored oil that<br />

delivers an impressive taste in a one<br />

single way process with a clean label<br />

benefit – especially interesting to boost<br />

the taste of healthier snacks. Griffith<br />

<strong>Food</strong>s Sensory and Consumer insights<br />

capabilities have proven that creating<br />

bold and unique flavor profiles that are<br />

also natural is a way to differentiate in<br />

the market besides branding<br />

In what way can Infuso improve the<br />

production process?<br />

One of the best examples of innovation<br />

at work is Infuso because it delivers on<br />

taste in a single step process with clean<br />

label benefits. It offers options to create<br />

multi flavour bold profiles and new taste<br />

experiences.<br />

What specific properties of this oil<br />

can attract consumers who want to<br />

innovate their portfolio?<br />

Infuso is cleaner and more cost effective.<br />

The standard two step seasoning<br />

process is replaced by an energy saving<br />

smoother, less complex single step<br />

application. Infuso replaces the oil that is<br />

sprayed on the snack substrate before<br />

seasoning so it can be used without<br />

disruption or extra cost as it requires a<br />

single sprayer, often already installed on<br />

the line.<br />

In which flavors is infuso available?<br />

The Infuso product range offers flavored<br />

oils in various flavor buckets: from green<br />

herbs to Chili flavored oil and even a<br />

Peking Duck style. And it can be applied<br />

to a huge range of snacks including<br />

premium crisps, veggie extruded snacks,<br />

pop chips, breadsticks, pretzels, rice<br />

cakes, nuts, seeds and tortillas.<br />

What are the advantages of using<br />

Infuso – for human health, food<br />

production and the environment?<br />

As the solution provides less, up to no<br />

dust on site, that means less product<br />

waste. Customers can experiment with<br />

a variety of processes as well as salt<br />

reduction, Gluten elimination, and an<br />

absence of anti caking agents which<br />

strengthens health profiles from a<br />

nutritional point of view. Its heavy<br />

concentrations mean easy and less<br />

storage requirements, making infuso<br />

a highly sustainable choice with light<br />

weight jerry cans that can support easier<br />

transport.<br />

How do you see the market<br />

developing in the next 2 to 5 years?<br />

Raw materials are still seeing some<br />

major price increases and supply is tight.<br />

Obviously, all business is operating in<br />

an inflationary environment, so costs<br />

are being passed on and that won’t<br />

change back quickly. Beyond that,<br />

health and product transparency will<br />

become even more important in <strong>2022</strong><br />

and beyond.<br />

Clearly, consumers want to have a<br />

healthier lifestyle so healthier snacks<br />

without compromise on taste and<br />

texture make sense. We believe there<br />

will be an opening up of non-plant-based<br />

AP where the first products will hit the<br />

shelves next year and that will trigger<br />

more investment, a larger market and<br />

with it more opportunities for Griffith<br />

as we look to expand our presence and<br />

customer base.<br />

fmt<br />

12 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Ingredients<br />

Creating Classic Confectionery with<br />

Gelatin<br />

Gelatin is a versatile hydrocolloid that<br />

provides various functional benefits to<br />

confectionery manufacturers<br />

Gelatin, derived from the Latin term<br />

gelatus – meaning stiff or frozen – has<br />

a long and successful history as a<br />

multifunctional ingredient. Today,<br />

it’s one of the most important<br />

hydrocolloids for food and beverage<br />

products. And even though gelatin<br />

is usually associated with the<br />

characteristic texture, form and bite<br />

of gummy bears, this highly purified<br />

collagen protein can be applied<br />

to many other applications. As a<br />

texturizer, gelatin acts as an excellent<br />

gelling, binding and whipping agent,<br />

stabilizer and emulsifier, and as a<br />

perfect film and foam former. It can<br />

also be used as a fat replacer and to<br />

improve the nutritional properties of<br />

various foodstuffs.<br />

Unlike its carbohydrate-based hydrocolloid<br />

counterparts, gelatin is a natural<br />

and easily digested protein. Being nonallergenic<br />

and free from E-numbers,<br />

it’s clean label, it’s compatible with<br />

most food and functional ingredients<br />

and can be formulated with other<br />

hydrocolloids to produce different<br />

textures or improve thermal resistance.<br />

The multipurpose hydrocolloid<br />

In its natural state, gelatin is a dry,<br />

white powder that is free from fat,<br />

cholesterol, purines and additives. It<br />

comprises 86–90% protein and 8–15%<br />

water. In water, gelatine swells rapidly<br />

and, after heating, dissolves to form<br />

a clear, viscous solution, followed by<br />

gelation after cooling.<br />

As a flexible ingredient, it’s easy to<br />

incorporate gelatin into a wide variety<br />

of production processes. However,<br />

the critical issue is choosing the most<br />

appropriate gelatin for each product<br />

and application. When choosing<br />

confectionery products, for example,<br />

consumers are predominantly looking<br />

for a treat. As such, taste and texture<br />

are key. It’s also crucial to understand<br />

the specific preferences of the target<br />

market. Some countries generally<br />

prefer firmer textures than others, and<br />

the range of shapes, flavors, colors or<br />

other critical determinants is almost<br />

limitless. Thus, to create a suitable and<br />

market-driven product concept, the<br />

corresponding formulation needs to<br />

be based on solid industry experience.<br />

Getting gummies right<br />

A traditional gummy candy is<br />

characterized by its texture, its<br />

gum-like “bite,” mouthfeel, taste and<br />

color, as well as its clear and shiny<br />

appearance. To achieve these product<br />

properties, gelatin is mandatory.<br />

Although other gelling agents are<br />

available, none of them is as effective<br />

as gelatin, which plays a key role in<br />

When choosing confectionery products, consumers look out for great taste and mouth-watering<br />

textures. Copyright: ©dusk_AdobeStock_172081133<br />

both the production process and<br />

the quality of the end product. So,<br />

whereas the fundamentals of gummy<br />

candy formulation are relatively<br />

straightforward, multiple factors need<br />

to be considered when producing a<br />

high-standard gummy product that<br />

meets both consumer – and producer<br />

– demands.<br />

One important parameter is the<br />

“Bloom value,” which indicates the<br />

gelatin’s gelling properties and the gel<br />

strength. For gummy candies, gelatin<br />

with a Bloom value of 160–280g Bloom<br />

must be used to achieve the desired<br />

bite, texture and mouthfeel. In addition,<br />

some ingredient interactions and/<br />

or production-induced artefacts or<br />

effects can be remedied by choosing<br />

the right type of gelatin.<br />

To unfold the functionality of gelatin,<br />

its complete dissolution is necessary.<br />

Therefore two parts of water and one<br />

part of gelatin are needed. Due to this<br />

low water content less water needs to<br />

evaporate during processing and, as<br />

such, production times are shorter.<br />

In addition, gelatin requires lower<br />

dissolution temperatures than other<br />

hydrocolloids and when it comes to the<br />

end product only gelatin provides that<br />

unique melt in your mouth experience,<br />

typical elastic texture and brilliant clarity.<br />

“Manufacturing issues like recrystallization<br />

can occur when the sucrose<br />

content is too high or not dissolved in<br />

enough water. This adversely affects<br />

the product’s characteristic clear and<br />

glossy look. Moreover, ingredients<br />

such as fructose can influence the<br />

color and lead to a yellowing of the<br />

product. Deformations, cloudiness and<br />

undesired textures may be the result<br />

of incorrect production and recipe<br />

parameters. This is why our experts<br />

offer all the advice needed to get it<br />

right,” explains Dr Johanna Schmidgall,<br />

Global Head of Application <strong>Technology</strong><br />

and New Product Development<br />

Nutrition and Health Ingredients from<br />

GELITA.<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

13

Ingredients<br />

Marshmallow production<br />

The first whipped marshmallows<br />

appeared in France in the 19th century<br />

when marsh mallow sap was combined<br />

with egg white and sugar. Seeking a<br />

more efficient manufacturing process,<br />

candy makers in Europe developed<br />

the starch mogul system, in which a<br />

mixture of marsh mallow root, sugar,<br />

egg white and water was heated<br />

and then poured into corn starch<br />

moulds. Then, in 1948, marshmallow<br />

production was revolutionized when<br />

the extrusion process was patented:<br />

the marshmallow mass is passed<br />

through tubes and then cut into pieces,<br />

which are then cooled and packaged,<br />

ready for consumption.<br />

Although marshmallow production<br />

has come a long way since the 1900s,<br />

these two processes are still used<br />

today. The most significant change is<br />

the formulation. Marsh mallow plant<br />

(Althea officinalis) is no longer used<br />

as a gelling agent. Instead, of course,<br />

it’s gelatin. Although other ingredients<br />

can be used as foaming agents, none<br />

of them gives marshmallows its<br />

typical fluffy and elastic structure,<br />

which remains intact for considerable<br />

periods of time. Quite simply, without<br />

gelatin, modern-day marshmallows<br />

couldn’t be produced.<br />

Foaming it right<br />

To produce high quality foamed<br />

confectionery, the right type of<br />

gelatin is necessary. It must be able<br />

Gelatin creates and stabilizes the foamy texture of marshmallows.<br />

Copyright: ©Ekaterina_Molchanova_AdobeStock_262119180<br />

One of a kind: Only gelatin gives gummies their characteristic elastic texture and their shiny, clear<br />

appearance. Copyright: ©Gelita<br />

to promote foam building and, at the<br />

same time, inhibit any processes that<br />

could destabilize the foam. Incorrect<br />

ingredient selection could result in<br />

non-homogenous bubbles, an unstable<br />

foam structure or products with the<br />

wrong density, which subsequently<br />

leads to the marshmallow losing its<br />

shape and texture. Foam formation<br />

and stabilization are complex procedures;<br />

but, owing to gelatin’s<br />

ability to lower the surface tension of<br />

aqueous systems, it’s relatively simple<br />

to introduce air into a whipped gelatin<br />

solution.<br />

Additionally, because air has a lower<br />

density than water and doesn’t<br />

dissolve, it tends to form larger<br />

bubbles that rise up and separate from<br />

the water phase. Gelatin’s ability to<br />

form elastic and flexible films around<br />

these bubbles and to stabilize them,<br />

makes it an optimal foaming agent and<br />

stabilizer.<br />

Expert help and know-how<br />

There are numerous aspects that<br />

affect a product’s success and<br />

many obstacles to overcome. In the<br />

end, though, it’s the know-how that<br />

determines a product’s success. With<br />

its expertise, GELITA acts as a gelatin<br />

solution provider, delivering clientspecific<br />

advice and services along<br />

with tailor-made gelatine types. To<br />

make the most of the multifunctional<br />

benefits of gelatin and retain control<br />

of the production processes, a<br />

comprehensive background knowledge<br />

of this versatile ingredient is<br />

essential. GELITA’s technological<br />

experts are available throughout<br />

the entire development process to<br />

offer professional advice, like recipe<br />

development, reformulation support<br />

and on-site technical service. The<br />

company’s expertise also extends to<br />

regulatory requirements, with help<br />

and advice available for both local and<br />

global markets.<br />

fmt<br />

14 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Ingredients<br />

Connect with<br />

nutraceutical<br />

experts<br />

This year, Vitafoods Europe <strong>2022</strong> returns to its annual<br />

May slot in your diary. As it’s a hybrid event you’ll be<br />

able to join us in person and online to share ideas,<br />

see new products, source ingredients and innovate<br />

with an inspiring community of experts. This is your<br />

chance to connect with industry-leading buyers,<br />

suppliers and manufacturers from over 110 countries,<br />

so don’t miss it.<br />

Register for your free<br />

badge now and save €160*<br />

Geneva: 10-12 May<br />

Online: 2-13 May<br />

For more details visit<br />

vitafoods.eu.com<br />

*Onsite visitor registration will cost €160<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

Key No. 102200<br />

15

Ingredients<br />

FDA Recognizes the Dietary Fiber Status<br />

of Acacia Gum<br />

International leader in natural gums Alland & Robert is delighted that acacia gum can be classified as a fiber<br />

for nutrition labelling purposes in the United States.<br />

This decision from the FDA was made<br />

public on December 17, 2021, and will<br />

consequently allow acacia gum to<br />

count as a dietary fiber on American<br />

Nutrition and Supplement Facts labels.<br />

Acacia gum is an ingredient or additive<br />

used worldwide in a wide range of<br />

products. Strong scientific literature<br />

demonstrates that acacia gum is a<br />

fiber. Today, the FDA agreed that<br />

acacia gum has physiological effects<br />

beneficial to human health, such as the<br />

reduction of blood glucose and insulin<br />

levels after it is eaten with a meal<br />

containing a carbohydrate that raises<br />

blood glucose levels.<br />

Alland & Robert, along with a<br />

work group of other acacia gum<br />

stakeholders, has submitted two<br />

science-backed citizen petitions in<br />

2019 and 2020, in order to provide<br />

the FDA with data showing proof that<br />

acacia gum has indeed “physiological<br />

benefits to human health”. Dr. Isabelle<br />

Jaouen, R&D Director at Alland &<br />

Robert said: “We have provided the<br />

FDA with numerous data coming from<br />

several clinical trials to support our<br />

request that acacia gum be recognized<br />

as a dietary fiber. Two laboratories that<br />

specialize in clinical nutrition, including<br />

one university, have been mandated<br />

for the design and realization of the<br />

clinical tests. Our citizen petitions<br />

included data showing the benefits of<br />

acacia gum on blood glucose levels”.<br />

Commenting on the FDA decision,<br />

Mr. Frédéric Alland, CEO at Alland<br />

& Robert said : “We are extremely<br />

satisfied that the FDA agrees with us<br />

that acacia gum is a fiber and can be<br />

labelled as such. It’s a great news for<br />

the American consumers, who will be<br />

able to enjoy this natural ingredient<br />

in their daily food. Alland & Robert<br />

remains committed to providing the<br />

highest quality of natural and non-<br />

GMO Acacia Fiber”.<br />

16 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Ingredients<br />

Acacia gum, also known as gum Arabic<br />

or E414, is a natural, vegetal, safe,<br />

functional and healthy additive used<br />

in flavors, beverages, confectionery,<br />

dairy, bakery, dietary products, pharma<br />

and cosmetics among others. Acacia<br />

gum is today found in thousands of<br />

day to day products all over the world.<br />

Alland & Robert guarantees a minimum<br />

fiber content of 90% for all products of<br />

its Acacia Fiber range (international<br />

method AOAC 985-29).<br />

fmt<br />

Flavor Study Shows can Optimize the<br />

use of Flavors in Chewy Candies<br />

Optimizing production and improving<br />

product quality are key issues for<br />

every producer of chewy candies.<br />

The present study shows impressive<br />

potential. The use of starch and gelatin<br />

as hydrocolloids is widespread in<br />

the manufacture of chewy candies.<br />

Together with a reputable flavor<br />

developer Norevo conducted a joint<br />

study to find out how alternative use<br />

of Norevo Quick Chew affects the use<br />

and development of flavors.<br />

The study evaluates the sensory<br />

impact using:<br />

• different hydrocolloids (Quick Chew,<br />

modified starch, gelatin)<br />

• different manufacturing methods<br />

(kneading, pulling)<br />

• different flavors (apple, lemon, milk)<br />

• Based on these different variants,<br />

we then tested the following criteria:<br />

1. Flavor intensity<br />

2. „Release“ or flavor development<br />

3. Chewing perception<br />

The subsequent blind tasting was<br />

carried out by a professional panel<br />

consisting of 21 trained panelists in 4<br />

intervals reflecting different ripening<br />

times and also storage temperatures.<br />

The results of this joint study confirm<br />

the hypothesis initially set out in<br />

almost all areas:<br />

By using Quick Chew as the<br />

texturizing component in the recipe,<br />

manufacturers can use flavors more<br />

efficiently, while also enhancing the<br />

chewing experience.<br />

fmt<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

17

Ingredients<br />

Cutting Sugar Loads from Hazelnut &<br />

Chocolate Spreads<br />

CAMBYA tackles the sugar-reduction challenges in sweet spreads and filling, naturally<br />

As children head back to schools,<br />

monitoring their sugar consumption<br />

in food and beverages becomes more<br />

challenging. <strong>Food</strong>-tech start-up B.T.<br />

Sweet, Ltd. introduces CAMBYA,<br />

its plant-based, sweetening platform<br />

to cut loads of sugar from favorite<br />

treats, such as hazelnut and chocolate<br />

spreads.<br />

B.T. Sweet cracked the code on<br />

helping manufacturers create tasty<br />

hazelnut and chocolate spreads with<br />

less sugar. The company offers leading<br />

sweet spread, filling, and coating<br />

companies’ new abilities to meet<br />

their sugar-reduction targets without<br />

compromising on much loved flavor<br />

qualities (especially those imposed by<br />

new regulations).<br />

According to the UK’s National Health<br />

Service, while it is recommended that<br />

adults have no more than 30g of free<br />

sugars daily, children ages 7 to 10<br />

should have no more than 24g per day.<br />

And children ages 4 to 6 should have<br />

no more than 19g of free sugars in a<br />

day.<br />

CAMBYA is a plant-based, one-toone<br />

drop-in sugar replacer for use<br />

in multiple food & applications.<br />

The proprietary formula, based<br />

on soluble fibers, monk fruit, and<br />

select botanicals, is a 1:1 equivalent<br />

to sugar both in function and flavor,<br />

while acting as a source of naturally<br />

derived beneficial fibers. CAMBYA<br />

delivers optimal sweetening capacity,<br />

without the need for masking agents.<br />

It is ideal for lowering sugar levels in<br />

confectionary, cereals and ice cream.<br />

Most importantly, it does not leave any<br />

lingering aftertastes.<br />

“For many, a breakfast or school<br />

sandwich is incomplete without<br />

chocolate hazelnut spread,” confesses<br />

Yoav Gaon, CEO of B.T. Sweet.<br />

“Parents struggle with their kids’<br />

demands for it and have a hard time<br />

resisting it themselves. We succeeded<br />

in developing a tasty solution that kids<br />

of all ages love simply by switching<br />

white sugar with CAMBYA.”<br />

Shockingly, sweet spreads typically<br />

contain up to 50% sucrose. The startup’s<br />

food technology team and chief<br />

confectioner tested the sweetening<br />

platform in several spread formulations<br />

with the goal of creating low sugar<br />

spread applications that cut the sugar<br />

load by at least fifty percent according<br />

to clients’ requests. The challenge was<br />

to perfectly mimic the flavor, color, and<br />

texture of a traditional category leading<br />

sweet spread, without any change to<br />

the mass of the product. In addition to<br />

extensive sensory lab testing across<br />

all parameters, the start-up trialed<br />

the products among children and their<br />

parents.<br />

Kids are the primary market for<br />

chocolate spreads, birthday cakes,<br />

cookies filled with cream and similar<br />

products,” explains Dagi Pekatch,<br />

Founder and Chairman of B.T Sweet.<br />

“We received excellent feedback from<br />

them. They loved the taste of our<br />

CAMBYA sweetened hazelnut and<br />

chocolate spreads, and we all know<br />

kids are hard to fool,” Pekatch grins.<br />

Since CAMBYA is one-to-one<br />

equivalent to sugar in taste, body and<br />

texture, there is no need for additives to<br />

keep the same weight of the product. A<br />

low-sugar spread with CAMBYA, offers<br />

a rich, chocolatey, nutty taste with<br />

a creamy sensation, without adding<br />

any colors, preservatives, or added<br />

flavorings. Moreover, it is enriched in<br />

fiber and is low in calories.<br />

CAMBYA’s “plug and play” sweetening<br />

platform allows food companies to<br />

reformulate their spreads, as well as<br />

other products with less white sugar.<br />

Manufacturers have the flexibility<br />

to completely switch to BT Sweet’s<br />

natural sweetening system, or balance<br />

it with sugar and other sweeteners<br />

according to desired levels without any<br />

adjustment to the recipe, thus saving<br />

R&D time and money.<br />

fmt<br />

18 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Ingredients<br />

www.anugafoodtec.com<br />

International<br />

supplier fair for the<br />

food and beverage industry<br />

ONE FOR ALL.<br />

ALL IN ONE.<br />

<strong>Food</strong> Processing | <strong>Food</strong> Packaging | Safety & Analytics | Intralogistics<br />

Digitalisation | Automation | Environment & Energy | Science & Pioneering<br />

COLOGNE, GERMANY<br />

26.–29.04.<strong>2022</strong><br />

Special Edition!<br />

Be part of it -<br />

find out more here!<br />

Koelnmesse GmbH<br />

Messeplatz 1<br />

50679 Köln, Germany<br />

Tel. +49 1806 578 866<br />

Fax +49 221 821 99-1020<br />

anugafoodtec@visitor.koelnmesse.de<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong><br />

19<br />

Key No. 102134

Processing<br />

Creating an Innovative, Healthy,<br />

CO 2<br />

-Neutral Snack<br />

Austrian start-up Selectum and Swiss technology group Bühler have jointly created a new, healthy snack<br />

category – small, crunchy wafer pillows with a creamy dip inside. Selectum has successfully launched this<br />

innovative snack at the end of 2019 under the brand name Paddies. Paddies have a 90-degree twisted bitesize<br />

shape, and, thanks to Bühler’s induction baking technology, they are produced 100% CO 2<br />

emission-free.<br />

Camilo Wolff, CEO and Founder of Selectum<br />

Richard Haubenberger, <strong>Food</strong> Technologist at<br />

the Bühler Wafer Innovation Center<br />

Selectum factory: Camilo Wolff and Richard Haubenberger test the product.<br />

“I wanted to bring a new product to<br />

the market with wafer technology. I<br />

envisioned an innovative, healthier<br />

snack. A snack that is gluten-free,<br />

palm oil-free, not fried, with 40% less<br />

fat than chips and nachos and on top<br />

of that, with a high protein content,”<br />

says Camilo Wolff, CEO and Founder<br />

of Selectum GmbH. “To develop this<br />

product, I approached Bühler as I knew<br />

they have the expertise and a technical<br />

laboratory for product development<br />

trials.” Together with the experts of<br />

the Bühler Wafer Innovation Center<br />

in Leobendorf, Wolff and his team<br />

created a completely novel recipe for a<br />

Emanuel Hoeckner, Product Manager at Bühler, and Camilo Wolff, CEO and Founder of Selectum<br />

snack with a dip inside, eliminating the<br />

need to buy a separate dip.<br />

Searching for the perfect mix<br />

Selectum and Bühler ran product<br />

development trials and assessed their<br />

results in the Bühler Wafer Innovation<br />

Center’s technical laboratory. It offers<br />

special services to start-ups like<br />

Selectum, with full support from the<br />

idea creation until after the product is<br />

running on the production line.<br />

Camilo Wolff had precise requirements<br />

for his snack to be rich in protein<br />

and nutrients. He spent almost a<br />

year conducting hundreds of trials<br />

and tasting sessions at the Bühler<br />

Wafer Innovation Center to develop<br />

the dough and the cream. Richard<br />

Haubenberger, <strong>Food</strong> Technologist at<br />

the Bühler Wafer Innovation Center,<br />

says: “The first challenge was to find<br />

the right ingredients to use. So, we<br />

were working with different starches,<br />

such as gluten-free wheat starch, rice<br />

starch, or corn starch. We looked into<br />

rice flour and chickpea flour, which<br />

20 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Processing<br />

have the benefit of a higher protein<br />

level. It was a challenge to find the<br />

right raw materials. But thanks to<br />

our experience and the collaboration<br />

with our suppliers, we found the right<br />

ingredients for the best recipe.”<br />

The laboratory is equipped with<br />

Bühler’s latest technologies, various<br />

solutions for batter and flour mixing,<br />

baking and cream refining. It offers the<br />

services of food technologists, training<br />

courses, and even virtual trials.<br />

Produced with zero emissions<br />

Another factor that was important<br />

to Camilo Wolff was for Selectum<br />

to produce its Paddies sustainably.<br />

One of Bühler’s solutions at the<br />

Wafer Innovation Center is inductive<br />

technology currently used in its<br />

wafer stick oven Franz Haas EWB<br />

which allows customers a CO 2<br />

-free<br />

production.<br />

Emanuel Hoeckner, Product Manager<br />

at Bühler, says: “The inductive<br />

heating system has a lot of benefits.<br />

The production with this new heating<br />

system is not just CO 2<br />

-neutral but<br />

completely CO 2<br />

-free.” The EWB<br />

inductive oven is 100% powered by<br />

electrical energy, it uses no gas at<br />

all. Therefore, no CO 2<br />

is emitted into<br />

the atmosphere. It also has higher<br />

energy efficiency in general. With<br />

Bühler’s optional power pack for<br />

the EWB inductive oven, customers<br />

have the option to increase the<br />

output capacity of the EWB oven in<br />

order to adapt the production output<br />

perfectly to the respective customer<br />

requirements.<br />

Selectum’s factory in Wolkersdorf, Austria, produces around 1.5 million 30-gram packages per month.<br />

in three flavors – cheese, toffee, and<br />

peanut butter, all with a dip inside.<br />

Selectum’s factory in Wolkersdorf,<br />

Austria, produces around 1.5 million<br />

30-gram packages per month.<br />

Paddies are already available on the<br />

shelves of Billa and Spar supermarkets<br />

in Austria and are sold in Germany,<br />

Italy, Finland, Spain, Hungary, and<br />

Poland. “I am very proud of the product.<br />

We entered the market as a start-up,<br />

and we are already selling our product<br />

internationally. Two years ago, it was<br />

just an idea. Bühler has been a very<br />

supportive partner all the way.” fmt<br />

Paddies are now available in three flavors – cheese, toffee, and peanut butter, all with a dip inside.<br />

Bühler has modernized the EWB<br />

inductive heating oven by adding a<br />

special coating ring to deal with the<br />

higher salinity and lower pH-values of<br />

the wafer batter used for the Paddies.<br />

This new coating of the baking ring<br />

enables Bühler to work with new<br />

types of ingredients and recipes and<br />

therefore increase the range of the<br />

EWB customer base.<br />

On supermarket shelves<br />

throughout Europe<br />

Paddies, a unique combination of rice<br />

and chickpea flour, are now available<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong> 21

Processing<br />

Breakthrough <strong>Technology</strong> will Produce<br />

Green Proteins Greener - Next<br />

Generation Membrane Filtration Systems<br />

are the Key<br />

SiccaDania Filtration and the SiccaDania group will supply key technology for a protein factory in Hedensted,<br />

Denmark, for the extraction of green proteins from fava beans. A number of Danish investors and global<br />

supplier of plant-based ingredients Meelunie will invest 250 million DKK in the factory. A new membrane<br />

filtration solution offers a wide range of advantages over traditional systems.<br />

LeanFlux® is a brand new developed,<br />

next-generation membrane filtration<br />

system that create significant<br />

reductions in operating costs, energy<br />

consumption, and CO 2<br />

emissions.<br />

The technology is patent-pending and<br />

challenges the well-known MF/UF<br />

membrane filtration plants, which have<br />

been used as a standard solution in the<br />

dairy and food industry for decades.<br />

SiccaDania Filtration, a subsidiary<br />

of the SiccaDania Group, will<br />

deliver LeanFlux processors for the<br />

new factory, Meelunie GPI A/S, in<br />

Hedensted, Denmark. This is the<br />

company’s first major order for<br />

LeanFlux and in addition, so-called<br />

RO plants are supplied for efficient<br />

evaporation of residual products, as<br />

well as recycling of process water.<br />

The driver behind the factory project<br />

is the desire to increase the local<br />

production of proteins to ensure a<br />

significant reduction in CO 2<br />

emissions<br />

and to contribute to the green<br />

transition of the agriculture sector.<br />

LeanFlux sets a new standard for<br />

efficient extraction of green proteins<br />

from fava beans and the production will<br />

replace soybeans from South America<br />

and protein powder from China.<br />

LeanFlux – a greener solution<br />

A very important step in protein<br />

extraction is two LeanFlux processors<br />

(each about 35 tons/hour). Here,<br />

valuable proteins from fava beans<br />

are concentrated in an ultrafiltration<br />

process (UF) and via subsequent spray<br />

drying transformed to high-quality<br />

protein powder. LeanFlux operates at<br />

30-40 percent lower operating costs<br />

compared to traditional plants.<br />

SiccaDania Filtration also supplies the<br />

RO plants, which reap further savings<br />

on energy and investment. This is<br />

done through reverse osmosis (RO),<br />

which concentrates the partial flow (UF<br />

permeate/residual products) from the<br />

UF processing plants.<br />

At the same time, the consumption<br />

of water is reduced, as an efficient<br />

purification of the process water<br />

means that it can be recycled within<br />

the factory.<br />

Contribution to greater<br />

sustainability<br />

With LeanFlux, SiccaDania Filtration<br />

introduces a completely new system<br />

Morton Tordrup Andersen, Sales Director and Michael Mortensen, Process Manager in front of a LeanFlux solution<br />

Photos: SiccaDania Filtration<br />

22 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Processing<br />

design, which means that the<br />

processing plants can be dimensioned<br />

more efficiently and constructed with<br />

a smaller footprint than before, thus<br />

saving operating costs as well as<br />

valuable square meters.<br />

LeanFlux is a good example of putting<br />

innovation and forward thinking first.<br />

- It is amazing what you can achieve if<br />

you break down the traditional MF/<br />

UF solution into its basic building<br />

blocks and components and redefine<br />

the solution from the ground up, says<br />

Morten Tordrup Andersen, Sales<br />

Director at SiccaDania Filtration,<br />

based in Stilling, Denmark.<br />

- Our new solution makes the production<br />

of green proteins even greener. We owe<br />

it to the next generations that production<br />

takes place as sustainably as possible,<br />

and we are very happy to be able to make<br />

our contribution, concludes Lars Bo<br />

Fredsted, CEO of SiccaDania Filtration.<br />

Advantages for dairies<br />

Traditional MF and UF crossflow<br />

membrane filtration systems are<br />

installed at most dairies. As the dairy<br />

and food industry focus heavily on<br />

production costs and environmental<br />

impact, SiccaDania Filtration also sees<br />

great potential in LeanFlux for the<br />

dairy sector. LeanFlux is also suitable<br />

for concentrating and fractionating<br />

proteins in other food categories. fmt<br />

LeanFlux® - next-generation MF / UF membrane filtration<br />

Segmented design solves challenges<br />

The well-known challenge in crossflow membrane filtration is the traditional "loop design", where the parallel construction of<br />

pressure pipes requires a very high circulation flow to maintain the necessary crossflow.<br />

LeanFlux solves this by using a unique system design with segmented modules and an application software that ensures<br />

optimal control of key parameters in the process.<br />

With LeanFlux, SiccaDania Filtration introduces a completely new system design primarily for MF and UF applications, which<br />

means that the systems can be dimensioned and constructed more efficiently with consequent significant operating savings.<br />

The efficient construction means that the system takes up much less space, and thus has a smaller footprint.<br />

Optimized operation and lower costs<br />

Operating costs are up to 40 percent lower with LeanFlux compared to traditional crossflow filtering because the segmented<br />

design is significantly more efficient. It reduces energy consumption, water consumption and the use of cleaning agents, just<br />

as it provides less wear and tear on the membranes.<br />

The LeanFlux solution is based on proven technologies, standard components and known flow principles. This makes it easy<br />

to implement LeanFlux® in existing production lines and plants.<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong> 23

Processing<br />

Digitalization Leveraged to Optimize<br />

Hygienic Processing<br />

The new Alfa Laval CM Connect marks the next step in the digitalization journey to drive innovation and<br />

growth for customers in the hygienic processing industries. The CM Connect is a subscription-based condition<br />

monitor and cloud gateway. It enables plant operators to access data of rotating equipment on processing<br />

lines from a remote location.<br />

With data on actual runtime, trend<br />

analysis, and time to next service<br />

close at hand, plant operators can<br />

make informed maintenance decisions<br />

using their personal computers<br />

and mobile devices. This protects<br />

process continuity and critical assets,<br />

improves workplace safety, saves time<br />

and money, and delivers competitive<br />

advantage.<br />

Maximize plant efficiency,<br />

minimize unplanned downtime<br />

As Industry 4.0 evolves, the CM<br />

Connect is a natural next step on<br />

the customer digitalization journey,<br />

expanding the Alfa Laval range of<br />

condition monitoring solutions. With<br />

complete visibility of all connected<br />

assets, plant operators can detect<br />

issues that impact future performance,<br />

prevent unplanned downtime, and<br />

improve asset management.<br />

Acting as a gateway communicating via<br />

Bluetooth, the CM Connect can link up<br />

to 10 Alfa Laval CM wireless vibration<br />

monitors launched last year. It then<br />

transmits the data over a 4G cellular<br />

network to the cloud for review and<br />

analysis on an intuitive, user-friendly<br />

dashboard.<br />

Advanced real-time notifications<br />

Advanced vibration analysis enables<br />

detection of any deviation from<br />

pre-set equipment threshold values.<br />

Should deviations occur, an SMS or<br />

e-mail notifies users who can take<br />

action in real time based on data<br />

analysis.<br />

“Focus on what matters. The CM<br />

Connect lets plant operators plan<br />

and prioritize maintenance based on<br />

actionable data,” says John Walker,<br />

Portfolio Manager, Pumps, Alfa Laval.<br />

“Rather than replacing wear parts in<br />

advance of their useful service life,<br />

operators can spend time and money<br />

when and where maintenance is<br />

required.”<br />

Besides linking the CM wireless<br />

vibration monitors, the CM Connect<br />

can also act as a sensor.<br />

It measures vibration, inboard<br />

temperature, and total runtime when<br />

mounted on Alfa Laval LKH, SRU, SX<br />

and DuraCirc pumps, or other rotating<br />

machines, such as agitators or mixers.<br />

Towards enhanced digitalization<br />

As part of the company’s commitment<br />

to pioneering digital transformation<br />

in the hygienic industries, Alfa Laval<br />

explores and develops Industry 4.0<br />

solutions to advance competitive<br />

advantage for customers.<br />

fmt<br />

24 food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong>

Processing<br />

SIMULATE WHOLE MUSCLE MEATS<br />

IN LOOK, TASTE AND NUTRITION.<br />

For meat analog and extender production,<br />

rely on the pioneer of the process for textured<br />

vegetable proteins by extrusion. Wenger began<br />

the worldwide initiative over 50 years ago, and<br />

continues to lead with ever expanding options<br />

today.<br />

High moisture meat analogs (HMMAs) produced on<br />

Wenger twin screw extruders mimic whole muscle<br />

meat, with similar characteristics for moisture,<br />

protein and fat contents, as well as a densely<br />

layered, somewhat fibrous structure.<br />

After extrusion, HMMAs may be cut, sliced or<br />

shredded – and then further processed or frozen.<br />

In addition to soy proteins or wheat gluten<br />

ingredients, alternative protein sources can be used<br />

for texture, mouthfeel and appearance objectives.<br />

Discover the latest in cutting edge extrusion<br />

processing and product development assistance.<br />

Email info@wenger.com now.<br />

Key No. 101822<br />

PHONE: 785.284.2133 | EMAIL: INFO@WENGER.COM | WENGER.COM<br />

USA | BELGIUM | TAIWAN | BRASIL | CHINA<br />

food <strong>Marketing</strong> & <strong>Technology</strong> • February <strong>2022</strong> 25

Processing<br />

Vacuum Preserves <strong>Food</strong><br />

Freeze Drying with the help of Vacuum<br />

<strong>Technology</strong><br />

There are several ways to extend the<br />

shelf life of food. One of the oldest<br />

methods belong of smoking and salting<br />

is drying – which was used long before<br />

freezing, boiling or vacuum packaging.<br />

Freeze drying is a modern extension of<br />

traditional drying methods to protect<br />

food from spoilage for longer. This<br />

process is only made possible by modern<br />

vacuum technology because freeze<br />

drying food takes place under vacuum.<br />

FrostX produces such freeze dryers with<br />

small dimensions to make them ideally<br />

suitable for bakeries and restaurants. It<br />

enables freeze drying of many kinds of<br />

fruits, vegetables, herbs, mushrooms,<br />

meat and even ready meals.<br />

The process of freeze drying<br />

Freeze drying is a purely physical<br />

process that uses the principle of<br />

sublimation. Due to the vacuum in<br />

the drying chamber, the frozen water<br />

sublimates into water vapor. The ice<br />

skips the “liquid” state and becomes<br />

directly “gaseous” from “solid”.<br />

Before the actual drying process, the<br />

product must be deep-frozen. The<br />

frozen product will then be dried<br />

FrostX freeze dryer with included vacuum<br />

technology by Busch.<br />

Freeze-dried strawberries.<br />

afterwards. After cooling, the actual<br />

drying process takes place in the<br />

air-tight chamber by reducing the air<br />

pressure in the chamber via a vacuum<br />

pump until a vacuum of 1 to 0.5 mbar<br />