“Super-A” JO-BLOCK® Sets Steel - Swiss Instruments Ltd

“Super-A” JO-BLOCK® Sets Steel - Swiss Instruments Ltd “Super-A” JO-BLOCK® Sets Steel - Swiss Instruments Ltd

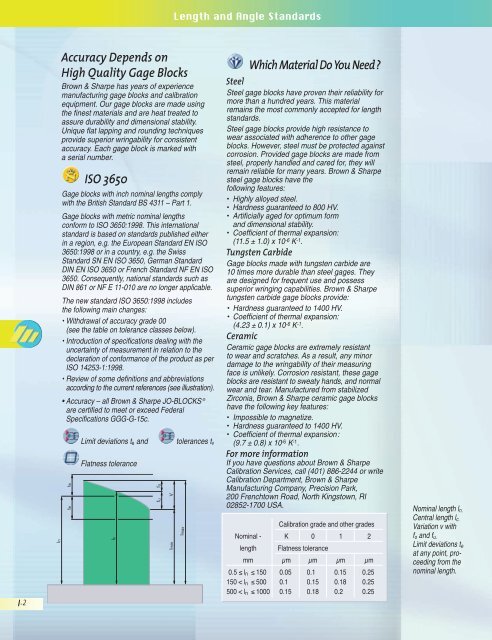

I-2 ln Accuracy Depends on High Quality Gage Blocks Brown & Sharpe has years of experience manufacturing gage blocks and calibration equipment. Our gage blocks are made using the finest materials and are heat treated to assure durability and dimensional stability. Unique flat lapping and rounding techniques provide superior wringability for consistent accuracy. Each gage block is marked with a serial number. te te ISO 3650 Gage blocks with inch nominal lengths comply with the British Standard BS 4311 – Part 1. Gage blocks with metric nominal lengths conform to ISO 3650:1998. This international standard is based on standards published either in a region, e.g. the European Standard EN ISO 3650:1998 or in a country, e.g. the Swiss Standard SN EN ISO 3650, German Standard DIN EN ISO 3650 or French Standard NF EN ISO 3650. Consequently, national standards such as DIN 861 or NF E 11-010 are no longer applicable. The new standard ISO 3650:1998 includes the following main changes: • Withdrawal of accuracy grade 00 (see the table on tolerance classes below). • Introduction of specifications dealing with the uncertainty of measurement in relation to the declaration of conformance of the product as per ISO 14253-1:1998. • Review of some definitions and abbreviations according to the current references (see illustration). Accuracy – all Brown & Sharpe JO-BLOCKS ® are certified to meet or exceed Federal Specifications GGG-G-15c. Limit deviations te and tolerances tv Flatness tolerance lc fu fo V lmin Length and Angle Standards lmax Which Material Do You Need? Steel Steel gage blocks have proven their reliability for more than a hundred years. This material remains the most commonly accepted for length standards. Steel gage blocks provide high resistance to wear associated with adherence to other gage blocks. However, steel must be protected against corrosion. Provided gage blocks are made from steel, properly handled and cared for, they will remain reliable for many years. Brown & Sharpe steel gage blocks have the following features: • Highly alloyed steel. • Hardness guaranteed to 800 HV. • Artificially aged for optimum form and dimensional stability. • Coefficient of thermal expansion: (11.5 ± 1.0) x 10 -6 K -1. Tungsten Carbide Gage blocks made with tungsten carbide are 10 times more durable than steel gages. They are designed for frequent use and possess superior wringing capabilities. Brown & Sharpe tungsten carbide gage blocks provide: • Hardness guaranteed to 1400 HV. • Coefficient of thermal expansion: (4.23 ± 0.1) x 10 -6 K -1. Ceramic Ceramic gage blocks are extremely resistant to wear and scratches. As a result, any minor damage to the wringability of their measuring face is unlikely. Corrosion resistant, these gage blocks are resistant to sweaty hands, and normal wear and tear. Manufactured from stabilized Zirconia, Brown & Sharpe ceramic gage blocks have the following key features: • Impossible to magnetize. • Hardness guaranteed to 1400 HV. • Coefficient of thermal expansion: (9.7 ± 0.8) x 10 -6 K -1. For more information If you have questions about Brown & Sharpe Calibration Services, call (401) 886-2244 or write Calibration Department, Brown & Sharpe Manufacturing Company, Precision Park, 200 Frenchtown Road, North Kingstown, RI 02852-1700 USA. Calibration grade and other grades Nominal - K 0 1 2 length Flatness tolerance mm μm μm μm μm 0.5 ≤ ln ≤ 150 0.05 0.1 0.15 0.25 150 < ln ≤ 500 0.1 0.15 0.18 0.25 500 < ln ≤ 1000 0.15 0.18 0.2 0.25 Nominal length ln. Central length lc. Variation v with fo and fu. Limit deviations te at any point, proceeding from the nominal length.

- Page 2 and 3: Length and Angle Standards Which Gr

- Page 4 and 5: Length and Angle Standards Inch “

- Page 6 and 7: Length and Angle Standards Inch Rec

- Page 8 and 9: Length and Angle Standards Metric R

- Page 10 and 11: Length and Angle Standards Micromet

- Page 12 and 13: ✓ BS 4311 Part 1 BS 870 for the s

- Page 14 and 15: ✓ Hardened steel 30" Width: 6.35

I-2<br />

ln<br />

Accuracy Depends on<br />

High Quality Gage Blocks<br />

Brown & Sharpe has years of experience<br />

manufacturing gage blocks and calibration<br />

equipment. Our gage blocks are made using<br />

the finest materials and are heat treated to<br />

assure durability and dimensional stability.<br />

Unique flat lapping and rounding techniques<br />

provide superior wringability for consistent<br />

accuracy. Each gage block is marked with<br />

a serial number.<br />

te<br />

te<br />

ISO 3650<br />

Gage blocks with inch nominal lengths comply<br />

with the British Standard BS 4311 – Part 1.<br />

Gage blocks with metric nominal lengths<br />

conform to ISO 3650:1998. This international<br />

standard is based on standards published either<br />

in a region, e.g. the European Standard EN ISO<br />

3650:1998 or in a country, e.g. the <strong>Swiss</strong><br />

Standard SN EN ISO 3650, German Standard<br />

DIN EN ISO 3650 or French Standard NF EN ISO<br />

3650. Consequently, national standards such as<br />

DIN 861 or NF E 11-010 are no longer applicable.<br />

The new standard ISO 3650:1998 includes<br />

the following main changes:<br />

• Withdrawal of accuracy grade 00<br />

(see the table on tolerance classes below).<br />

• Introduction of specifications dealing with the<br />

uncertainty of measurement in relation to the<br />

declaration of conformance of the product as per<br />

ISO 14253-1:1998.<br />

• Review of some definitions and abbreviations<br />

according to the current references (see illustration).<br />

Accuracy – all Brown & Sharpe <strong>JO</strong>-BLOCKS ®<br />

are certified to meet or exceed Federal<br />

Specifications GGG-G-15c.<br />

Limit deviations te and tolerances tv<br />

Flatness tolerance<br />

lc<br />

fu fo<br />

V<br />

lmin<br />

Length and Angle Standards<br />

lmax<br />

Which Material Do You Need?<br />

<strong>Steel</strong><br />

<strong>Steel</strong> gage blocks have proven their reliability for<br />

more than a hundred years. This material<br />

remains the most commonly accepted for length<br />

standards.<br />

<strong>Steel</strong> gage blocks provide high resistance to<br />

wear associated with adherence to other gage<br />

blocks. However, steel must be protected against<br />

corrosion. Provided gage blocks are made from<br />

steel, properly handled and cared for, they will<br />

remain reliable for many years. Brown & Sharpe<br />

steel gage blocks have the<br />

following features:<br />

• Highly alloyed steel.<br />

• Hardness guaranteed to 800 HV.<br />

• Artificially aged for optimum form<br />

and dimensional stability.<br />

• Coefficient of thermal expansion:<br />

(11.5 ± 1.0) x 10 -6 K -1.<br />

Tungsten Carbide<br />

Gage blocks made with tungsten carbide are<br />

10 times more durable than steel gages. They<br />

are designed for frequent use and possess<br />

superior wringing capabilities. Brown & Sharpe<br />

tungsten carbide gage blocks provide:<br />

• Hardness guaranteed to 1400 HV.<br />

• Coefficient of thermal expansion:<br />

(4.23 ± 0.1) x 10 -6 K -1.<br />

Ceramic<br />

Ceramic gage blocks are extremely resistant<br />

to wear and scratches. As a result, any minor<br />

damage to the wringability of their measuring<br />

face is unlikely. Corrosion resistant, these gage<br />

blocks are resistant to sweaty hands, and normal<br />

wear and tear. Manufactured from stabilized<br />

Zirconia, Brown & Sharpe ceramic gage blocks<br />

have the following key features:<br />

• Impossible to magnetize.<br />

• Hardness guaranteed to 1400 HV.<br />

• Coefficient of thermal expansion:<br />

(9.7 ± 0.8) x 10 -6 K -1.<br />

For more information<br />

If you have questions about Brown & Sharpe<br />

Calibration Services, call (401) 886-2244 or write<br />

Calibration Department, Brown & Sharpe<br />

Manufacturing Company, Precision Park,<br />

200 Frenchtown Road, North Kingstown, RI<br />

02852-1700 USA.<br />

Calibration grade and other grades<br />

Nominal - K 0 1 2<br />

length Flatness tolerance<br />

mm μm μm μm μm<br />

0.5 ≤ ln ≤ 150 0.05 0.1 0.15 0.25<br />

150 < ln ≤ 500 0.1 0.15 0.18 0.25<br />

500 < ln ≤ 1000 0.15 0.18 0.2 0.25<br />

Nominal length ln.<br />

Central length lc.<br />

Variation v with<br />

fo and fu.<br />

Limit deviations te<br />

at any point, proceeding<br />

from the<br />

nominal length.

Length and Angle Standards<br />

Which Grade Do You Need?<br />

Grade 2<br />

These gage blocks are commonly used as<br />

Working Standards in inspection rooms to set<br />

and calibrate measuring instruments and other<br />

equipment as well as to inspect tools,<br />

fixtures and machines.<br />

Grade 1<br />

Gage blocks of this class are mainly used as<br />

Working Standards to set and calibrate plug<br />

gages and measuring instruments in measuring<br />

rooms or inspection areas.<br />

Grade 0<br />

These gage blocks are designated for use as<br />

Company Standards in calibration labora tories<br />

or environmentally-controlled inspection rooms<br />

to set and calibrate plug gages and measuring<br />

equipment.<br />

Calibration Grade K<br />

Gage blocks of this tolerance class are<br />

intended for use as Reference Standards<br />

in metrology-oriented laboratories of National<br />

Institutes, precision measuring rooms and<br />

laboratories of National Calibration Services,<br />

whether officially accredited or not. They<br />

should be used as masters to calibrate gage<br />

blocks, length standards of same accuracy and<br />

measuring instruments.<br />

Grade 00<br />

The new standard ISO 3650 does not take this<br />

accuracy grade into consideration as the<br />

uncertainties of measurement achieved with<br />

the procedure applied for calibration usually<br />

lead to a disparity with specified tolerances.<br />

The rules of uncertainty of measurement, for<br />

proving the conformance or non-conformance<br />

of the product with the standard ISO 14253-<br />

1:1998, have determined the withdrawal of the<br />

accuracy grade 00.<br />

Wide experience in practical use of gage<br />

blocks have proven that gages of the calibration<br />

class K could easily replace those of accuracy<br />

grade 00 used until now.<br />

Gage blocks of grade 00 remain, however,<br />

available upon request.<br />

Certificate of Calibration<br />

and Traceability<br />

All gage blocks from Brown & Sharpe are<br />

supplied with a Certificate of Calibration issued<br />

by the accredited calibration laboratory of a<br />

national calibration service. Depending on<br />

where they are purchased, this service can<br />

either be the <strong>Swiss</strong> Calibration Service (SCS),<br />

British Calibration Service (UKAS) or Comité<br />

Français d’Accréditation (COFRAC).<br />

Accreditation is the authentic assurance of the<br />

skills, standards and testing procedures of the<br />

calibration laboratories and the full documentation<br />

of national standards that conform with the<br />

International System of Units (SI). This applies<br />

to any reference standard or measuring equipment<br />

used.<br />

Owing to a multilateral agreement (MLA),<br />

all Certificates of Calibration issued by the<br />

members of the European Cooperation<br />

for Accreditation of Laboratories (EA) as listed<br />

below are internationally accepted.<br />

Belgium – BKO / OBE<br />

Denmark – DANAK<br />

Germany – DKD / DAR<br />

Finland – FINAS<br />

France – COFRAC<br />

United Kingdom – UKAS<br />

Ireland – NAB<br />

Italy – SIT<br />

Netherlands – RvA<br />

Norway – NA<br />

Austria – MBwA<br />

Portugal – IPQ<br />

Sweden – SWEDAC<br />

Switzerland – SCS / SAS<br />

Spain – ENAC<br />

Other related countries:<br />

Australia – NATA<br />

New Zealand – IANZ<br />

South Africa – SANAS<br />

Czechia – CAI<br />

Deliveries<br />

Brown & Sharpe gage blocks are available in<br />

full sets or individually with nominal lengths or<br />

within set compositions as listed on the following<br />

pages. Other gage sets and lengths can<br />

also be made available upon request.<br />

Since individual gage blocks cannot be<br />

listed entirely here, any information requests<br />

or purchase orders should specify:<br />

• desired nominal length<br />

• material<br />

• calibration grade or any other grade<br />

I-3

I-4<br />

Length and Angle Standards<br />

Inch <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCK ® <strong>Sets</strong><br />

<strong>Steel</strong> – Rectangular<br />

Manufactured from Class I steel to Grade 2 (A+) accuracy. Every gage<br />

block is certified, calibrated and serialized. Every set of Brown & Sharpe<br />

<strong>JO</strong>-BLOCKS ® comes with its own fitted wooden case and a Cer tif i cate<br />

of Calibration and Traceability.<br />

Inch Rectangular Gage Block Sizes:<br />

For gaging length “L” less than .200": L x .35" x 1.18"<br />

For gaging length “L” .200" and above: L x .35" x 1.38"<br />

598-88-14 43265 88 Block Set (Federal Spec. Set #4-88)<br />

4 Blocks: .0625 /.078125 / .09375 /.109375"<br />

3 Blocks: .100025 / .100050 / .100075"<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

4 Blocks: 1.000 thru 4.000 by 1"<br />

598-85-14 43263 85 Block Set<br />

4 Blocks: .0625 / .078125 / .09375 / .109375"<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

4 Blocks: 1.000 thru 4.000 by 1"<br />

598-84-14 43261 84 Block Set<br />

3 Blocks: .100025 / .100050 / .100075"<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

4 Blocks: 1.000 thru 4.000 by 1"<br />

598-81-14 43258 81 Block Set (Federal Spec. Set #1-81)<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

4 Blocks: 1.000 thru 4.000 by 1"<br />

598-36-14 43256 36 Block Set<br />

1 Block: .10005"<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

9 Blocks: .101 thru .109 by .001"<br />

9 Blocks: .110 thru .190 by .010"<br />

5 Blocks: .100 thru .500 by .100"<br />

3 Blocks: 1.000 / 2.000 / 4.000"<br />

598-35-14 43254 35 Block Set<br />

1 Block: .05005"<br />

9 Blocks: .0501 thru .0509 by .0001"<br />

9 Blocks: .051 thru .059 by .001"<br />

5 Blocks: .050 thru .090 by .010"<br />

5 Blocks: .110 thru .150 by .010"<br />

4 Blocks: .100 / .200 / .300 / .500"<br />

2 Blocks: 1.000 / 2.000"<br />

598-7-14 43252 7 Block Set<br />

1 Block: .03125"<br />

1 Block: .0625"<br />

3 Blocks: .125 / .250 / .500"<br />

2 Blocks: 1.000 / 2.000"<br />

598-5-14 43251 5 Block Set<br />

1 Block: .0625"<br />

3 Blocks: .125 / .250 / .500"<br />

1 Block: 1.000"

Length and Angle Standards<br />

Inch <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCK ® <strong>Sets</strong><br />

Tungsten Carbide – Rectangular<br />

Three times more wear resistant than chrome carbide. Man u fac tured from<br />

Class III Type 2 Tungsten Carbide to Grade 2 (A+) accuracy. Each gage block<br />

is certified, cal i brat ed and serialized. Every set of Brown & Sharpe <strong>JO</strong>-BLOCKS ®<br />

is sup plied with its own fitted wooden case and a Certificate of Calibration and<br />

Traceability.<br />

Like all of Brown & Sharpe's gage block sets, this set is man u fac tured to meet<br />

or exceed Federal Spec i fi ca tion GGG-G-15c. Pre ci sion is Federal Grade 2<br />

(A+) accuracy.<br />

598-81-18 43259 81 Block Set (Federal Spec. Set #1-81)<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

4 Blocks: 1.000 thru 4.000 by 1"<br />

598-35-18 43255 35 Block Set<br />

1 Block: .05005"<br />

9 Blocks: .0501 thru .0509 by .0001"<br />

9 Blocks: .051 thru .059 by .001"<br />

11 Blocks: .050 thru .150 by .010"<br />

3 Blocks: .200 / .300 / .500"<br />

2 Blocks: 1.000 / 2.000"<br />

598-28-18 43253 28 Block Set (Federal Spec. Set #6-28)<br />

1 Block: .02005"<br />

9 Blocks: .0201 thru .0209 by .0001"<br />

9 Blocks: .021 thru .029 by .001"<br />

9 Blocks: .010 thru .090 by .010"<br />

Inch <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCK ® <strong>Sets</strong><br />

Carbide/<strong>Steel</strong> – Rectangular<br />

Tungsten Carbide Durability and Performance with the Econ o my of <strong>Steel</strong>!<br />

Finally – a gage block set that combines the long-lasting per for mance of<br />

tungsten carbide with the economy of steel.<br />

Brown & Sharpe's Carbide/<strong>Steel</strong> <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCK ® set in cludes 78<br />

tungsten carbide gage blocks in the most frequent ly used sizes and three steel<br />

gage blocks in the largest sizes, allowing us to price this set significantly less<br />

than our 81-piece tung sten carbide gage block set.<br />

598-81-20 51834 81 Block Set<br />

Solid Tungsten Carbide Blocks<br />

9 Blocks: .1001 thru .1009 by .0001"<br />

49 Blocks: .101 thru .149 by .001"<br />

19 Blocks: .050 thru .950 by .050"<br />

1 Block: 1.000"<br />

<strong>Steel</strong> Blocks<br />

3 Blocks: 2.000 / 3.000 / 4.000"<br />

I-5

I-6<br />

Length and Angle Standards<br />

Metric Gage Block <strong>Sets</strong><br />

<strong>Steel</strong> or Tungsten Carbide – Rectangular<br />

Metric Gage Block sets meet or exceed Federal Specifica tion GGG-G-15c.<br />

Grade 2 (A+) accuracy. Every block is cer ti fied, calibrated and se ri al ized.<br />

Each set includes a fitted wooden case and a Cer tif i cate of Calibration<br />

and Traceability.<br />

Metric Rectangular Gage Block Sizes:<br />

For gaging length “L” less than 10 mm: L x 9 mm x 30 mm<br />

For gaging length “L” 10 mm and above: L x 9 mm x 35 mm<br />

597-112-34 43009 112 Block <strong>Steel</strong> Set<br />

597-112-38 43010 112 Block Tungsten Carbide Set<br />

3 Blocks: 0.5 / 1.00 / 1.0005 mm<br />

9 Blocks: 1.001 thru 1.009 by 0.001 mm<br />

49 Blocks: 1.01 thru 1.49 by 0.01 mm<br />

47 Blocks: 1.5 thru 24.5 by 0.5 mm<br />

4 Blocks: 25 / 50 / 75 / 100 mm<br />

597-88-34 43001 88 Block <strong>Steel</strong> Set<br />

597-88-38 43002 88 Block Tungsten Carbide Set<br />

3 Blocks: 0.5 / 1.00 / 1.0005 mm<br />

9 Blocks: 1.001 thru 1.009 by 0.001 mm<br />

49 Blocks: 1.01 thru 1.49 by 0.01 mm<br />

17 Blocks: 1.5 thru 9.5 by 0.5 mm<br />

10 Blocks: 10 thru 100 by 10 mm<br />

597-47-34 45371 47 Block <strong>Steel</strong> Set<br />

597-47-38 43000 47 Block Tungsten Carbide Set<br />

1 Block: 1.005 mm<br />

9 Blocks: 1.01 thru 1.09 by 0.01 mm<br />

9 Blocks: 1.1 thru 1.9 by 0.1 mm<br />

24 Blocks: 1.0 thru 24.0 by 1.0 mm<br />

4 Blocks: 40 / 60 / 80 / 100 mm

Length and Angle Standards<br />

Inch Rectangular <strong>JO</strong>-BLOCKS ®<br />

<strong>Steel</strong> – Individual<br />

in<br />

598-3125-14 .03125<br />

598-5000-14 .05000<br />

598-5005-14 .05005<br />

598-6000-14 .06000<br />

598-6250-14 .06250<br />

598-7000-14 .07000<br />

598-7812-514 .078125<br />

598-8000-14 .08000<br />

598-9000-14 .09000<br />

598-9375-14 .09375<br />

598-10000-14 .10000<br />

598-10002-514 .100025<br />

598-10005-14 .10005<br />

598-10007-514 .100075<br />

598-10010-14 .10010<br />

598-10020-14 .10020<br />

598-10025-14 .10025<br />

598-10030-14 .10030<br />

598-10040-14 .10040<br />

598-10050-14 .10050<br />

598-10060-14 .10060<br />

598-10070-14 .10070<br />

598-10075-14 .10075<br />

598-10080-14 .10080<br />

598-10090-14 .10090<br />

598-10100-14 .10100<br />

598-10200-14 .10200<br />

598-10300-14 .10300<br />

598-10400-14 .10400<br />

598-10500-14 .10500<br />

598-10600-14 .10600<br />

598-10700-14 .10700<br />

598-10800-14 .10800<br />

598-10900-14 .10900<br />

598-10937-514 .109375<br />

598-11000-14 .11000<br />

598-11100-14 .11100<br />

598-11200-14 .11200<br />

598-11300-14 .11300<br />

598-11400-14 .11400<br />

598-11500-14 .11500<br />

598-11600-14 .11600<br />

598-11700-14 .11700<br />

598-11800-14 .11800<br />

598-11900-14 .11900<br />

598-12000-14 .12000<br />

598-12100-14 .12100<br />

598-12200-14 .12200<br />

598-12300-14 .12300<br />

598-12400-14 .12400<br />

in<br />

598-12500-14 .12500<br />

598-12600-14 .12600<br />

598-12700-14 .12700<br />

598-12800-14 .12800<br />

598-12900-14 .12900<br />

598-13000-14 .13000<br />

598-13100-14 .13100<br />

598-13200-14 .13200<br />

598-13300-14 .13300<br />

598-13400-14 .13400<br />

598-13500-14 .13500<br />

598-13600-14 .13600<br />

598-13700-14 .13700<br />

598-13800-14 .13800<br />

598-13900-14 .13900<br />

598-14000-14 .14000<br />

598-14100-14 .14100<br />

598-14200-14 .14200<br />

598-14300-14 .14300<br />

598-14400-14 .14400<br />

598-14500-14 .14500<br />

598-14600-14 .14600<br />

598-14700-14 .14700<br />

598-14800-14 .14800<br />

598-14900-14 .14900<br />

598-15000-14 .15000<br />

598-16000-14 .16000<br />

598-17000-14 .17000<br />

598-18000-14 .18000<br />

598-19000-14 .19000<br />

598-20000-14 .20000<br />

598-25000-14 .25000<br />

598-30000-14 .30000<br />

598-35000-14 .35000<br />

598-40000-14 .40000<br />

598-45000-14 .45000<br />

598-50000-14 .50000<br />

598-55000-14 .55000<br />

598-60000-14 .60000<br />

598-65000-14 .65000<br />

598-70000-14 .70000<br />

598-75000-14 .75000<br />

598-80000-14 .80000<br />

598-85000-14 .85000<br />

598-90000-14 .90000<br />

598-95000-14 .95000<br />

598-901-14 1.0000<br />

598-902-14 2.0000<br />

598-903-14 3.0000<br />

598-904-14 4.0000<br />

All <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCKS are calibrated, serialized and certified to meet or exceed<br />

Federal Specifications GGG-G-15c for Grade 2 (A+) accuracies.<br />

I-7

I-8<br />

Length and Angle Standards<br />

Inch Rectangular <strong>JO</strong>-BLOCKS ® Tungsten<br />

Carbide – Individual<br />

in<br />

in<br />

598-1000-18 .010<br />

598-10700-18 .107<br />

598-2000-18 .020<br />

598-10800-18 .108<br />

598-2005-18 .02005<br />

598-10900-18 .109<br />

598-2010-18 .0201<br />

598-11000-18 .110<br />

598-2020-18 .0202<br />

598-11100-18 .111<br />

598-2030-18 .0203<br />

598-11200-18 .112<br />

598-2040-18 .0204<br />

598-11300-18 .113<br />

598-2050-18 .0205<br />

598-11400-18 .114<br />

598-2060-18 .0206<br />

598-11500-18 .115<br />

598-2070-18 .0207<br />

598-11600-18 .116<br />

598-2080-18 .0208<br />

598-11700-18 .117<br />

598-2090-18 .0209<br />

598-11800-18 .118<br />

598-2100-18 .021<br />

598-11900-18 .119<br />

598-2200-18 .022<br />

598-12000-18 .120<br />

598-2300-18 .023<br />

598-12100-18 .121<br />

598-2400-18 .024<br />

598-12200-18 .122<br />

598-2500-18 .025<br />

598-12300-18 .123<br />

598-2600-18 .026<br />

598-12400-18 .124<br />

598-2700-18 .027<br />

598-12500-18 .125<br />

598-2800-18 .028<br />

598-12600-18 .126<br />

598-2900-18 .029<br />

598-12700-18 .127<br />

598-3000-18 .030<br />

598-12800-18 .128<br />

598-4000-18 .040<br />

598-12900-18 .129<br />

598-5000-18-1 .050<br />

598-13000-18 .130<br />

598-5005-18 .05005<br />

598-13100-18 .131<br />

598-5010-18 .0501<br />

598-13200-18 .132<br />

598-5020-18 .0502<br />

598-13300-18 .133<br />

598-5030-18 .0503<br />

598-13400-18 .134<br />

598-5040-18 .0504<br />

598-13500-18 .135<br />

598-5050-18 .0505<br />

598-13600-18 .136<br />

598-5060-18 .0506<br />

598-13700-18 .137<br />

598-5070-18 .0507<br />

598-13800-18 .138<br />

598-5080-18 .0508<br />

598-13900-18 .139<br />

598-5090-18 .0509<br />

598-14000-18 .140<br />

598-5100-18 .051<br />

598-14100-18 .141<br />

598-5200-18 .052<br />

598-14200-18 .142<br />

598-5300-18 .053<br />

598-14300-18 .143<br />

598-5400-18 .054<br />

598-14400-18 .144<br />

598-5500-18 .055<br />

598-14500-18 .145<br />

598-5600-18 .056<br />

598-14600-18 .146<br />

598-5700-18 .057<br />

598-14700-18 .147<br />

598-5800-18 .058<br />

598-14800-18 .148<br />

598-5900-18 .059<br />

598-14900-18 .149<br />

598-6000-18 .060<br />

598-15000-18 .150<br />

598-6250-18 .0625<br />

598-20000-18 .200<br />

598-7000-18 .070<br />

598-25000-18 .250<br />

598-8000-18 .080<br />

598-30000-18 .300<br />

598-9000-18 .090<br />

598-35000-18 .350<br />

598-10000-18-1 .100<br />

598-40000-18 .400<br />

598-10010-18 .1001<br />

598-45000-18 .450<br />

598-10020-18 .1002<br />

598-50000-18 .500<br />

598-10030-18 .1003<br />

598-55000-18 .550<br />

598-10040-18 .1004<br />

598-60000-18 .600<br />

598-10050-18 .1005<br />

598-65000-18 .650<br />

598-10060-18 .1006<br />

598-70000-18 .700<br />

598-10070-18 .1007<br />

598-75000-18 .750<br />

598-10080-18 .1008<br />

598-80000-18 .800<br />

598-10090-18 .1009<br />

598-85000-18 .850<br />

598-10100-18 .101<br />

598-90000-18 .900<br />

598-10200-18 .102<br />

598-95000-18 .950<br />

598-10300-18 .103<br />

598-901-18 1.000<br />

598-10400-18<br />

598-10500-18<br />

598-10600-18<br />

.104<br />

.105<br />

.106<br />

598-902-18<br />

598-903-18<br />

598-904-18<br />

2.000<br />

3.000<br />

4.000<br />

All <strong>“Super</strong>-<strong>A”</strong> <strong>JO</strong>-BLOCKS are calibrated, serialized and certified to meet or exceed<br />

Federal Specifications GGG-G-15c for Grade 2 (A+) accuracies.

Length and Angle Standards<br />

Metric Rectangular Gage Blocks<br />

<strong>Steel</strong> – Individual<br />

mm<br />

mm<br />

597-5000-34 0.50<br />

597-15000-34 1.50<br />

597-10000-34 1.00<br />

597-16000-34 1.60<br />

597-10005-34 1.0005<br />

597-17000-34 1.70<br />

597-10010-34 1.0010<br />

597-18000-34 1.80<br />

597-10020-34 1.002<br />

597-19000-34 1.90<br />

597-10030-34 1.003<br />

597-20000-34 2.00<br />

597-10040-34 1.004<br />

597-25000-34 2.50<br />

597-10050-34 1.005<br />

597-30000-34 3.00<br />

597-10060-34 1.006<br />

597-35000-34 3.50<br />

597-10070-34 1.007<br />

597-40000-34 4.00<br />

597-10080-34 1.008<br />

597-45000-34 4.50<br />

597-10090-34 1.009<br />

597-50000-34 5.00<br />

597-10100-34 1.01<br />

597-55000-34 5.50<br />

597-10200-34 1.02<br />

597-60000-34 6.00<br />

597-10300-34 1.03<br />

597-65000-34 6.50<br />

597-10400-34 1.04<br />

597-70000-34 7.00<br />

597-10500-34 1.05<br />

597-75000-34 7.50<br />

597-10600-34 1.06<br />

597-80000-34 8.00<br />

597-10700-34 1.07<br />

597-85000-34 8.50<br />

597-10800-34 1.08<br />

597-90000-34 9.00<br />

597-10900-34 1.09<br />

597-95000-34 9.50<br />

597-11000-34 1.10<br />

597-100-34 10.00<br />

597-11100-34 1.11<br />

597-105-34 10.50<br />

597-11200-34 1.12<br />

597-110-34 11.00<br />

597-11300-34 1.13<br />

597-115-34 11.50<br />

597-11400-34 1.14<br />

597-120-34 12.00<br />

597-11500-34 1.15<br />

597-125-34 12.50<br />

597-11600-34 1.16<br />

597-130-34 13.00<br />

597-11700-34 1.17<br />

597-135-34 13.50<br />

597-11800-34 1.18<br />

597-140-34 14.00<br />

597-11900-34 1.19<br />

597-145-34 14.50<br />

597-12000-34 1.20<br />

597-150-34 15.00<br />

597-12100-34 1.21<br />

597-155-34 15.50<br />

597-12200-34 1.22<br />

597-160-34 16.00<br />

597-12300-34 1.23<br />

597-165-34 16.50<br />

597-12400-34 1.24<br />

597-170-34 17.00<br />

597-12500-34 1.25<br />

597-175-34 17.50<br />

597-12600-34 1.26<br />

597-180-34 18.00<br />

597-12700-34 1.27<br />

597-185-34 18.50<br />

597-12800-34 1.28<br />

597-190-34 19.00<br />

597-12900-34 1.29<br />

597-195-34 19.50<br />

597-13000-34 1.30<br />

597-200-34 20.00<br />

597-13100-34 1.31<br />

597-205-34 20.50<br />

597-13200-34 1.32<br />

597-210-34 21.00<br />

597-13300-34 1.33<br />

597-215-34 21.50<br />

597-13400-34 1.34<br />

597-220-34 22.00<br />

597-13500-34 1.35<br />

597-225-34 22.50<br />

597-13600-34 1.36<br />

597-230-34 23.00<br />

597-13700-34 1.37<br />

597-235-34 23.50<br />

597-13800-34 1.38<br />

597-240-34 24.00<br />

597-13900-34 1.39<br />

597-245-34 24.50<br />

597-14000-34 1.40<br />

597-250-34 25.00<br />

597-14100-34 1.41<br />

597-300-34 30.00<br />

597-14200-34 1.42<br />

597-400-34 40.00<br />

597-14300-34 1.43<br />

597-500-34 50.00<br />

597-14400-34 1.44<br />

597-600-34 60.00<br />

597-14500-34 1.45<br />

597-700-34 70.00<br />

597-14600-34 1.46<br />

597-750-34 75.00<br />

597-14700-34 1.47<br />

597-800-34 80.00<br />

597-14800-34 1.48<br />

597-900-34 90.00<br />

597-14900-34 1.49<br />

597-1000-34 100.00<br />

Brown & Sharpe's Metric Gage Blocks are calibrated, serialized and certified to meet or<br />

exceed Federal Specifications GGG-G-15c for Grade 2 (A+) accuracies.<br />

I-9

I-10<br />

Length and Angle Standards<br />

Metric Rectangular Gage Blocks<br />

Tungsten Carbide – Individual<br />

mm<br />

mm<br />

597-5000-38 .50<br />

597-15000-38 1.50<br />

597-10000-38 1.00<br />

597-16000-38 1.60<br />

597-10005-38 1.0005<br />

597-17000-38 1.70<br />

597-10010-38 1.001<br />

597-18000-38 1.80<br />

597-10030-38 1.003<br />

597-19000-38 1.90<br />

597-10040-38 1.004<br />

597-20000-38 2.00<br />

597-10050-38 1.005<br />

597-25000-38 2.50<br />

597-10060-38 1.006<br />

597-30000-38 3.00<br />

597-10070-38 1.007<br />

597-35000-38 3.50<br />

597-10080-38 1.008<br />

597-40000-38 4.00<br />

597-10090-38 1.009<br />

597-45000-38 4.50<br />

597-10100-38 1.01<br />

597-50000-38 5.00<br />

597-10200-38 1.02<br />

597-55000-38 5.50<br />

597-10300-38 1.03<br />

597-60000-38 6.00<br />

597-10400-38 1.04<br />

597-65000-38 6.50<br />

597-10500-38 1.05<br />

597-70000-38 7.00<br />

597-10600-38 1.06<br />

597-75000-38 7.50<br />

597-10700-38 1.07<br />

597-80000-38 8.00<br />

597-10800-38 1.08<br />

597-85000-38 8.50<br />

597-10900-38 1.09<br />

597-90000-38 9.00<br />

597-11000-38 1.10<br />

597-95000-38 9.50<br />

597-10020-38 1.1002<br />

597-100-38 10.00<br />

597-11100-38 1.11<br />

597-105-38 10.50<br />

597-11200-38 1.12<br />

597-110-38 11.00<br />

597-11300-38 1.13<br />

597-115-38 11.50<br />

597-11400-38 1.14<br />

597-120-38 12.00<br />

597-11500-38 1.15<br />

597-125-38 12.50<br />

597-11600-38 1.16<br />

597-130-38 13.00<br />

597-11700-38 1.17<br />

597-135-38 13.50<br />

597-11800-38 1.18<br />

597-140-38 14.00<br />

597-11900-38 1.19<br />

597-145-38 14.50<br />

597-12000-38 1.20<br />

597-150-38 15.00<br />

597-12100-38 1.21<br />

597-155-38 15.50<br />

597-12200-38 1.22<br />

597-160-38 16.00<br />

597-12300-38 1.23<br />

597-165-38 16.50<br />

597-12400-38 1.24<br />

597-170-38 17.00<br />

597-12500-38 1.25<br />

597-175-38 17.50<br />

597-12600-38 1.26<br />

597-180-38 18.00<br />

597-12700-38 1.27<br />

597-185-38 18.50<br />

597-12800-38 1.28<br />

597-190-38 19.00<br />

597-12900-38 1.29<br />

597-195-38 19.50<br />

597-13000-38 1.30<br />

597-200-38 20.00<br />

597-13100-38 1.31<br />

597-205-38 20.50<br />

597-13200-38 1.32<br />

597-210-38 21.00<br />

597-13300-38 1.33<br />

597-215-38 21.50<br />

597-13400-38 1.34<br />

597-220-38 22.00<br />

597-13500-38 1.35<br />

597-225-38 22.50<br />

597-13600-38 1.36<br />

597-230-38 23.00<br />

597-13700-38 1.37<br />

597-235-38 23.50<br />

597-13800-38 1.38<br />

597-240-38 24.00<br />

597-13900-38 1.39<br />

597-245-38 24.50<br />

597-14000-38 1.40<br />

597-250-38 25.00<br />

597-14100-38 1.41<br />

597-300-38 30.00<br />

597-14200-38 1.42<br />

597-400-38 40.00<br />

597-14300-38 1.43<br />

597-500-38 50.00<br />

597-14400-38 1.44<br />

597-600-38 60.00<br />

597-14500-38 1.45<br />

597-700-38 70.00<br />

597-14600-38 1.46<br />

597-750-38 75.00<br />

597-14700-38 1.47<br />

597-800-38 80.00<br />

597-14800-38 1.48<br />

597-900-38 90.00<br />

597-14900-38 1.49<br />

597-1000-38 100.00<br />

Brown & Sharpe's Metric Gage Blocks are calibrated, serialized and certified to meet or<br />

exceed Federal Specifications GGG-G-15c for Grade 2 (A+) accuracies.

Length and Angle Standards<br />

Micrometer Checking Set<br />

The First Complete Set!<br />

The Brown & Sharpe Micrometer Checking Set has all the necessary<br />

components to check the accuracy of your micrometers, ensuring you<br />

that they are performing to their optimum specifications.<br />

Features:<br />

Set assists you in meeting Federal Spec. GGG-C-15c for flatness<br />

and parallelism and conforms to MIL-STD-45662A.<br />

Ten-piece selection of gage blocks allows checking of various<br />

spindle positions over the complete micrometer range.<br />

Two optical flats: .500" diameter and .5125" diameter which<br />

allow checking anvil faces at half revolutions of the spindle for<br />

measuring flatness.<br />

Each set and each block is individually serialized.<br />

Gage blocks include Certificate of Calibration.<br />

Includes fitted wooden case.<br />

598-10-18 27076 Micrometer Checking Set<br />

I-11

I-12<br />

Length and Angle Standards<br />

ETALON ® Basic Metric Gage <strong>Sets</strong><br />

<strong>Steel</strong> – Rectangular<br />

mm<br />

Steps<br />

mm<br />

Pieces<br />

32- Piece <strong>Sets</strong><br />

06519000 06519010 1 1.005 1<br />

06519001 06519011 2 1.01 - 1.09 0.1 9<br />

1.1 - 1.9 0.1 9<br />

1 - 9.0 1.0 9<br />

47- Piece <strong>Sets</strong><br />

10, 20, 30 and 50 4<br />

06519002 06519012 1 1.005 1<br />

06519003 06519013 2 1.01 - 1.09 0.01 9<br />

1.1 - 1.9 0.1 9<br />

1.0 - 24.0 1.0 24<br />

25 - 100 25 4<br />

88- Piece <strong>Sets</strong><br />

06519004 06519014 1 1.0005 1<br />

06519005 06519015 2 1.001 - 1.009 0.001 9<br />

1.01 - 1.49 0.01 49<br />

0.5 - 9.5 0.5 19<br />

10 - 100 10 10<br />

✓<br />

ISO 3650<br />

Stable, highly<br />

alloyed steel,<br />

resistant to wear<br />

(11.5 ± 1.0)<br />

x 10 -6 K -1<br />

See page I-2<br />

Wooden case<br />

Identification<br />

number<br />

SCS<br />

calibration certificate<br />

COFRAC<br />

calibration certificate

✓<br />

BS 4311 Part 1<br />

BS 870 for the set<br />

compositions.<br />

<strong>Steel</strong> type:<br />

tungsten carbide<br />

providing stability as well<br />

as high resistance to wear<br />

Ceramic type:<br />

extremely resistant<br />

Zirconia<br />

Tugnsten<br />

carbide:<br />

(4.23 ± 0.1) x 10-6 K-1 Ceramic:<br />

(9.7 ± 0.8) x 10-6 K-1 See BS 4311<br />

Part 1<br />

Supplied as<br />

single gage<br />

blocks or in sets<br />

Wooden case<br />

Identification<br />

number<br />

UKAS calibration<br />

certificate<br />

Tungsten<br />

Carbide<br />

Length and Angle Standards<br />

Limit Deviations and Tolerances According<br />

to BS 4311 : Part 1 : 1993<br />

Calibration Grade K Grade 0 Grade 1 Grade 2<br />

Limit deviation Tolerance Limit deviation Tolerance Limit deviation Tolerance Limit deviation Tolerance<br />

of length at for the of length at for the of length at for the of length at for the<br />

any point from variation any point from variation any point from variation any point from variation<br />

Nominal nominal in length nominal in length nominal in length nominal in length<br />

length length length length length<br />

± te tv ± te tv ± te tv ± te tv<br />

in μin μin μin μin μin μin μin μin<br />

ln ≤ 0.4 5 2 5 4 10 6 20 12<br />

0.4 < ln ≤ 1 6 2 6 4 12 6 25 12<br />

1 < ln ≤ 2 8 3 8 4 15 7 30 12<br />

2 < ln ≤ 3 10 3 10 5 20 7 40 14<br />

3 < ln ≤ 4 12 3 12 5 25 8 50 14<br />

TESA ® Mikechex Inch<br />

Gage Block <strong>Sets</strong><br />

Designed to calibrate and set the indication of external micrometers.<br />

Ceramic<br />

8- Piece <strong>Sets</strong> – Mikechex E8<br />

0652526023 0652536014 K 0.130 0.250 0.385 0.500 0.615 0.750<br />

0652525023 0652535014 0 0.870 1.000<br />

0652521023 0652531015 1<br />

0652522023 0652532015 2<br />

10- Piece <strong>Sets</strong> – Mikechex E10<br />

0652526022 0652536013 K 0.105 0.210 0.315 0.420 0.500 0.605<br />

0652525022 0652535013 0 0.710 0.815 0.920 1.000<br />

0652521022 0652531014 1<br />

0652522022 0652532014 2<br />

11- Piece <strong>Sets</strong> – Mikechex E11<br />

0652521021 0652531013 1 0.130 0.250 0.385 0.500 0.615 0.750<br />

0652522021 0652532013 2 0.870 1.000 2.000 3.000 4.000<br />

in<br />

I-13

I-14<br />

Length and Angle Standards<br />

TESA ® Maintenance Kit for Gage Blocks<br />

65.2500450 TESA maintenance kit for gage blocks<br />

Supplied with the following items :<br />

0652500452 1 Arkansas stone<br />

0652500453 1 Soft tipped tweezers<br />

0652500454 1 Pneumatic vacuum pen<br />

0652500455 1 Nanofiber cleaning cloth<br />

0652500456 1 Pair of cotton gloves<br />

0652500457 1 Acid-free solvent<br />

0652500458 1 Box with protective grease<br />

02530050 1 50 mm dia. optical flat<br />

0652500460 1 Solvent container<br />

0652500461 1 Dust remover<br />

0652500462 1 Dust brush<br />

0652500463 1 Bottle of super-fine, acid-free oil<br />

0652500451 1 Wooden case<br />

TESA ® Optical Flats<br />

Used for examining flatness and wringability of the gage blocks or any other<br />

test pieces having flat faces with same high grade of accuracy.<br />

mm mm μm<br />

02530050 50 15 0.125<br />

02530075 75 20 0.125<br />

✓<br />

Full set in<br />

a wooden case<br />

✓<br />

✓<br />

Diameter<br />

and thickness<br />

as shown on the table<br />

Optical flats<br />

with 2 flat<br />

measuring faces.<br />

Parallelism cannot be<br />

guaranteed.<br />

Wooden case<br />

Declaration<br />

of conformity

✓<br />

Hardened steel<br />

30"<br />

Width:<br />

6.35 mm (1/4 in)<br />

Length: ≥ 76.2 mm (3 in)<br />

Plastic case<br />

Length and Angle Standards<br />

Ultra Precision 12-Piece Angle Block Set<br />

Complete with a protective “shop-hardened” molded case.<br />

Precision ground hardened steel.<br />

Angular accuracy .0001" per inch, ± 30 arc seconds.<br />

3" long x 1/4" thick.<br />

Simple, quick angle setups.<br />

Eliminate calculations and avoid errors.<br />

599-921-18 26883 Set consists of: 1/4°, 1/2°, 1°, 2°, 3°, 4°, 5°, 10°, 15°, 12<br />

20°, 25°, 30°<br />

Total<br />

Pieces<br />

Ultra Precision 17-Piece Angle Block Set<br />

Complete with a protective wood case.<br />

Made from hardened steel.<br />

Ideal for grinding and milling machine applications.<br />

Furnished in custom wooden case.<br />

599-921-17 26693 Set consists of: 1/4°, 1/2°, 1°, 2°, 3°, 4°, 5°, 10°, 15°, 20°, 17<br />

25°, 30°, 35°, 40°, 45°, plus two riser blocks<br />

599-750-25 27397<br />

Total<br />

Pieces<br />

Precision Adjustable Angle Block Set<br />

Precision ground angle block -- ideal for drilling, milling, grinding and setup tasks.<br />

3-3/4” wide by 1-3/4” thick by 2” high.<br />

Approximately 1-3/4” work capacity.<br />

Angle accuracy ±10’; squareness within .0002”.<br />

Hardened to 50-55 RC.<br />

Includes fitted wooden case.<br />

I-15

I-16<br />

Length and Angle Standards<br />

Precision Gage Ball Set<br />

26 pairs of precision balls. (inch)<br />

1 pair of each size: 1/8", 9/64", 5/32", 3/16", 7/32", 1/4", 9/32", 5/16", 11/32",<br />

3/8", 13/32", 7/16", 15/32", 1/2", 17/32", 9/16", 19/32", 5/8", 21/32", 11/16",<br />

23/32", 3/4", 13/16", 7/8", 15/16", 1".<br />

25 pairs of precision balls. (metric)<br />

1 pair of each size: 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm,<br />

10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm,<br />

20mm, 21mm, 22mm, 23mm, 24mm, 25mm.<br />

Chrome steel hardened to 63 RC.<br />

Ground and lapped.<br />

Grade 24 Accuracy – AFBMA Certified.<br />

Provided in a “shop-hardened” protective case.<br />

599-766 27034 <strong>Steel</strong> ball set 1/8 - 1 52<br />

599-766m 27178 <strong>Steel</strong> ball set 1mm - 25mm 50<br />

in<br />

Total<br />

Pieces<br />

✓<br />

Special steel,<br />

hardened<br />

3 μm<br />

Not available<br />

individually<br />

Plastic case