4.2 - VSL

4.2 - VSL

4.2 - VSL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

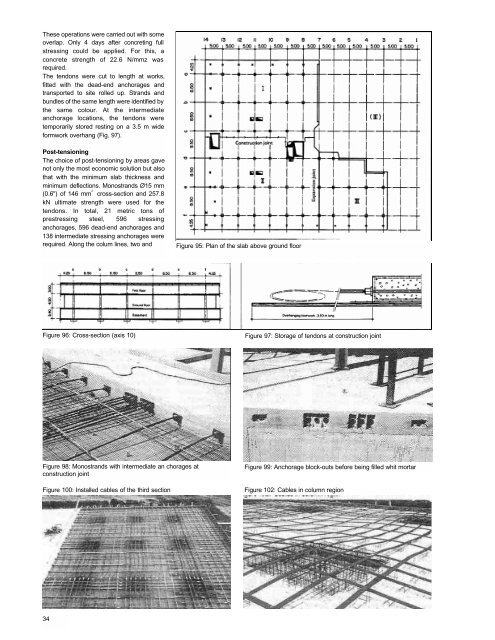

These operations were carried out with some<br />

overlap. Only 4 days after concreting full<br />

stressing could be applied. For this, a<br />

concrete strength of 22.6 N/mmz was<br />

required.<br />

The tendons were cut to length at works,<br />

fitted with the dead-end anchorages and<br />

transported to site rolled up. Strands and<br />

bundles of the same length were identified by<br />

the same colour. At the intermediate<br />

anchorage locations, the tendons were<br />

temporarily stored resting on a 3.5 m wide<br />

formwork overhang (Fig. 97).<br />

Post-tensioning<br />

The choice of post-tensioning by areas gave<br />

not only the most economic solution but also<br />

that with the minimum slab thickness and<br />

minimum deflections. Monostrands Ø15 mm<br />

(0.6") of 146 mm 2<br />

cross-section and 257.8<br />

kN ultimate strength were used for the<br />

tendons. In total, 21 metric tons of<br />

prestressing steel, 596 stressing<br />

anchorages, 596 dead-end anchorages and<br />

138 intermediate stressing anchorages were<br />

required. Along the colum lines, two and Figure 95: Plan of the slab above ground floor<br />

Figure 96: Cross-section (axis 10)<br />

Figure 98: Monostrands with intermediate an chorages at<br />

construction joint<br />

Figure 97: Storage of tendons at construction joint<br />

Figure 99: Anchorage block-outs before being filled whit mortar<br />

Figure 100: Installed cables of the third section Figure 102: Cables in column region<br />

34