Built-in Units and Control Centres fo Hall MiltPro - catalogue EN

The MiltPro built-in units and control centres for halls allow you to build a new working space (not only) in a production hall. Speed of the assembly and the modular design allow for easy changes and the price is also very favourable. If in future you need a change, they can easily be rearranged.

The MiltPro built-in units and control centres for halls allow you to build a new working space (not only) in a production hall. Speed of the assembly and the modular design allow for easy changes and the price is also very favourable. If in future you need a change, they can easily be rearranged.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

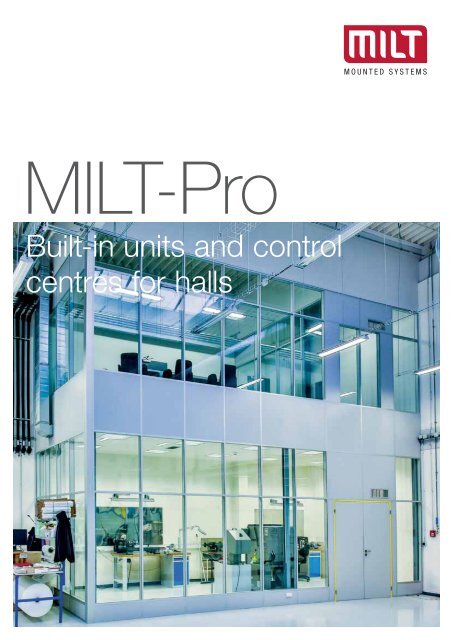

MILT-Pro<br />

<strong>Built</strong>-<strong>in</strong> units <strong>and</strong> control<br />

centres <strong>fo</strong>r halls

Space<br />

The MILT-Pro built-<strong>in</strong> units provide<br />

its design solution offer a large<br />

range of applications <strong>in</strong> commercial,<br />

manufactur<strong>in</strong>g <strong>and</strong> warehouse spaces.<br />

Their variability provides the user with<br />

wide possibilities how to use <strong>in</strong>terior<br />

spaces accord<strong>in</strong>g to actual requirements<br />

both technical <strong>and</strong> visual ones. The<br />

comb<strong>in</strong>ation with other MILT products<br />

guarantees a design clear <strong>and</strong> practical<br />

solution <strong>fo</strong>r all users.<br />

Practical<br />

<strong>and</strong> clear

Quality<br />

The production of components <strong>fo</strong>r<br />

built-<strong>in</strong> units <strong>and</strong> control centres use<br />

the high technologies environmentally<br />

friendly. A 5-year guarantee is provided<br />

to delivered units. Thus, the designed<br />

<strong>and</strong> delivered solutions meet the highest<br />

per<strong>fo</strong>rmance requirements. We provide<br />

the guarantee <strong>and</strong> after-guarantee<br />

services to all our deliveries.<br />

Implied quality<br />

assurance

Colourity<br />

The materials used allow us<strong>in</strong>g a wide<br />

variety of colours, natural veneers,<br />

<strong>and</strong> metallic surfaces <strong>and</strong> lam<strong>in</strong>ated<br />

decors on customer request. Us<strong>in</strong>g<br />

a comb<strong>in</strong>ation of colours <strong>and</strong> other<br />

materials the built-<strong>in</strong> units can be<br />

adapted to any exist<strong>in</strong>g <strong>in</strong>terior <strong>and</strong> to<br />

ensure its harmonic <strong>in</strong>tegration.<br />

No limitation

Fast<br />

The MILT built-<strong>in</strong> units are very popular<br />

among customers <strong>fo</strong>r their versatility<br />

<strong>and</strong> practicality. Speed, effi ciency, <strong>and</strong><br />

easy <strong>in</strong>stallation of built-<strong>in</strong> unit reduce<br />

the costs of downtime. Electrical wir<strong>in</strong>g,<br />

MaR, heat<strong>in</strong>g, <strong>and</strong> air-condition<strong>in</strong>g <strong>in</strong><br />

built-<strong>in</strong> units can be implemented easily<br />

<strong>and</strong> effi ciently. The built-<strong>in</strong> units are<br />

easily adjustable on customer actual<br />

request without long downtime.<br />

Practical,<br />

effective.

Variability<br />

The MILT-Pro built-<strong>in</strong> units are quickly<br />

adjustable, thanks to used MILT<br />

components. Replac<strong>in</strong>g a full panel <strong>fo</strong>r<br />

glass panel, the extension of control<br />

room or the modifi cation of the <strong>in</strong>ternal<br />

layout is not any problem. Thanks<br />

to the detachable system of used<br />

elements the costs on construction<br />

changes are reduc<strong>in</strong>g. The modifi cation<br />

of cladd<strong>in</strong>g panels is then really easy.<br />

Dry prefabricated built-<strong>in</strong> unit does not<br />

apply a load to environment <strong>and</strong> it allows<br />

practically an immediate full-valued use.<br />

Advantage <strong>fo</strong>r<br />

future changes

Vision<br />

Thanks to our design department we<br />

are able to customize the MILT-Pro built<strong>in</strong><br />

units on customer specifi c requests.<br />

The overall design is subsequently<br />

adapted to the design pr<strong>in</strong>ciples, new<br />

requirements <strong>and</strong> experience so that<br />

the result<strong>in</strong>g solution meets all future<br />

requirements of the customer <strong>and</strong> a<br />

modern <strong>and</strong> functional development site<br />

would be created.<br />

Development<br />

<strong>and</strong> <strong>in</strong>novation

Construction<br />

The MILT-Pro built-<strong>in</strong> units <strong>and</strong> control<br />

centres are optimally designed <strong>fo</strong>r any<br />

type of object. The only limitation is the<br />

space, where you want to use the built<strong>in</strong><br />

unit. The height does not represent<br />

any problem. The built-<strong>in</strong> units can be<br />

construct as elevated or multi-deck. The<br />

tailor-made steel construction guarantees<br />

its functionality over the lifetime of the<br />

built-<strong>in</strong> unit.<br />

Strength<br />

<strong>and</strong> stability

Development<br />

Thanks to its speed of <strong>in</strong>stallation<br />

<strong>and</strong> modifi ability the product of MILT-<br />

Pro built-<strong>in</strong> units <strong>and</strong> control centres<br />

very popular <strong>fo</strong>r fast construction of<br />

laboratories or development centre near<br />

the production hall. In the case of a<br />

request to change the layout or division<br />

the construction rema<strong>in</strong>s <strong>and</strong> the fi ll<strong>in</strong>gs<br />

are changed. A dust-free assembly<br />

compared to brick technology is an<br />

advantage.<br />

Centre <strong>and</strong><br />

laboratories

Acoustics<br />

The optimal mix of wall, fl oor <strong>and</strong> roof<br />

layers is designed accord<strong>in</strong>g to the<br />

customer’s requirements on reduction<br />

of noise levels <strong>in</strong> the future control room<br />

eventually noise source to the hall. The<br />

entire construction then per<strong>fo</strong>rms the<br />

required, possibly normalized values<br />

<strong>fo</strong>r sound attenuation. <strong>Control</strong> centres<br />

solution with the requirement <strong>fo</strong>r sound<br />

attenuation has to be coord<strong>in</strong>ated<br />

with projects of professions so that<br />

the usability of the space control<br />

centres has been met the customer<br />

requirements. The acoustic parameters<br />

can be improved by us<strong>in</strong>g acoustic tiles,<br />

per<strong>fo</strong>rated panels, acoustic pyramids,<br />

<strong>and</strong> suspended ceil<strong>in</strong>gs.<br />

Protection<br />

aga<strong>in</strong>st noise

Visibility<br />

The MILT-Pro system built-<strong>in</strong> units can<br />

be made without roofi ng, what reduces<br />

the costs on possible A/C, lighten<strong>in</strong>g<br />

<strong>and</strong> EPS <strong>in</strong> the hall. For easy visibility<br />

<strong>and</strong> provid<strong>in</strong>g easy communication<br />

between separated spaces the glazed<br />

modules should be chosen. The<br />

entire space is becom<strong>in</strong>g clear <strong>and</strong><br />

purposeful. At any moment you can<br />

see what’s go<strong>in</strong>g on <strong>in</strong> your facility.<br />

Under all<br />

circumstances

We divide<br />

Us<strong>in</strong>g transferable modular walls<br />

you can easily separate different<br />

production or storage facilities. The<br />

<strong>in</strong>terior designed modular construction<br />

from th<strong>in</strong>-walled profi les show<strong>in</strong>g high<br />

stiffness allows the construction of<br />

walls up to 7 m high without the use<br />

of additional re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g construction.<br />

Sectional gates <strong>and</strong> double doors<br />

can also be a part of the wall. In the<br />

future the partition walls may be simply<br />

rebuild<strong>in</strong>g to the new layout. These<br />

walls are very popular <strong>in</strong> already exist<strong>in</strong>g<br />

facilities, where it is not possible to<br />

implement new walls us<strong>in</strong>g classic<br />

brick technology characterized by<br />

considerable dust nuisance <strong>and</strong><br />

dem<strong>and</strong> <strong>in</strong> time.<br />

the<br />

spaces<br />

Transferable walls<br />

up to 7 m high

Cleanl<strong>in</strong>ess<br />

The transferable high walls are<br />

designed to allow quick <strong>and</strong> easy<br />

<strong>in</strong>stallation with m<strong>in</strong>imum impact on<br />

the environment dur<strong>in</strong>g <strong>in</strong>stallation.<br />

The construction is designed as<br />

mounted so that its <strong>in</strong>stallation is<br />

practically dust-free <strong>and</strong> without<br />

impurities aris<strong>in</strong>g. The built-<strong>in</strong> units<br />

are often use <strong>in</strong> areas where a great<br />

emphasis is laid on environmental<br />

cleanl<strong>in</strong>ess. Any <strong>in</strong>terventions with<strong>in</strong><br />

later adjustments <strong>in</strong> the construction<br />

do not require wet processes.

HEIGHT ARRANGEM<strong>EN</strong>T OF MILT-Pro BUILT-IN UNITS<br />

S<strong>in</strong>gle deck<br />

<strong>Built</strong>-<strong>in</strong> unit located <strong>in</strong> a hall or storage area allows improv<strong>in</strong>g<br />

work<strong>in</strong>g environment of workers whose work requires work<strong>in</strong>g at a<br />

quieter environment while ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g contact with the production<br />

area. In the case of a requirement to significantly reduce noise<br />

levels <strong>in</strong> the <strong>in</strong>terior office, we can supply walls <strong>and</strong> ceil<strong>in</strong>g <strong>in</strong> the<br />

design which meets stricter values. The surface of office ceil<strong>in</strong>g<br />

can be practically used <strong>fo</strong>r storage of lightweight materials, too.<br />

Elevated control centre<br />

Us<strong>in</strong>g a re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g steel construction it is possible to create a new<br />

office space while us<strong>in</strong>g the floor space <strong>in</strong> the hall to the maximum<br />

extent at the same time. The built-<strong>in</strong> unit always <strong>in</strong>cludes a s<strong>in</strong>gle<br />

or double staircase giv<strong>in</strong>g access to a raised floor. The higher level<br />

of the office will allow better control <strong>and</strong> overview <strong>fo</strong>r employees<br />

sitt<strong>in</strong>g <strong>in</strong> the built-<strong>in</strong> area giv<strong>in</strong>g them better way of controll<strong>in</strong>g what<br />

happens <strong>in</strong> the production or storage area.<br />

Two-deck<br />

LOCATION OF BUILT-IN UNIT IN THE FACILITY<br />

In the case of requirement to maximize the use of built-<strong>in</strong> floor<br />

space, it is preferable to build the office <strong>in</strong> more levels. Re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g<br />

construction can be either visible or hidden. The two-deck built-<strong>in</strong><br />

unit always <strong>in</strong>cludes m<strong>in</strong>imally one access-giv<strong>in</strong>g s<strong>in</strong>gle or double<br />

staircase. Walls of the built-<strong>in</strong> unit are made of modules with the<br />

function of noise <strong>in</strong>sulation which meets the required parameters.<br />

Re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g construction can be either visible or hidden.<br />

Free-st<strong>and</strong><strong>in</strong>g <strong>Built</strong>-<strong>in</strong> wall <strong>Built</strong>-<strong>in</strong> corner<br />

TECHNICAL DESCRIPTION<br />

The MILT-Pro modular built-<strong>in</strong> unit consists of<br />

re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g construction, external <strong>and</strong> <strong>in</strong>terior wall<br />

modules, roof<strong>in</strong>g <strong>and</strong> floor<strong>in</strong>g with <strong>in</strong>tegrated glass<br />

w<strong>in</strong>dows <strong>and</strong> door modules. The re<strong>in</strong><strong>fo</strong>rc<strong>in</strong>g steel<br />

construction consists of purl<strong>in</strong>s, columns <strong>and</strong> auxiliary<br />

small purl<strong>in</strong>s.<br />

Wall modules: are made of visible alum<strong>in</strong>ium<br />

profiles, hidden <strong>in</strong>ner th<strong>in</strong>-walled steel elements, full<br />

<strong>and</strong> glazed panels.<br />

Alum<strong>in</strong>ium profiles: natural anodized f<strong>in</strong>ish or RAL,<br />

Tiger metallic colours<br />

1 Full wall panels: gypsum or fermcell wall boards<br />

with lam<strong>in</strong>ated Dura<strong>fo</strong>rt <strong>fo</strong>il (250 colours), lam<strong>in</strong>ated<br />

boards (pastel colours <strong>and</strong> wood decors, veneered<br />

boards, metallic surfaces, with <strong>in</strong>ner sound <strong>in</strong>sulation.<br />

2 Glazed wall panels: clear double or s<strong>in</strong>gle<br />

glaz<strong>in</strong>g unit. S<strong>and</strong>ed panels or covered with<br />

matt or colour <strong>fo</strong>ils, glass with white or coloured<br />

electrolum<strong>in</strong>escent diodes.<br />

3 Doors: s<strong>in</strong>gle or double-hung (with head panel),<br />

slid<strong>in</strong>g manually as well as a proximity sensor, sw<strong>in</strong>g<br />

doors. Production <strong>in</strong> st<strong>and</strong>ard sizes; can also be<br />

atypical. For s<strong>in</strong>gle doors axial module width 915<br />

mm (doorway width 800 mm), <strong>fo</strong>r double doors axial<br />

module width 1,715 mm (doorway width 1,600 mm)<br />

Widths of wall modules: st<strong>and</strong>ard full <strong>and</strong> glazed<br />

modules <strong>in</strong> widths of 600, 1,000, 1,200 mm, on<br />

request can be up to 1,500 mm, with glass walls of<br />

horizontal division up to 2,500 mm. On customer<br />

request.<br />

Jo<strong>in</strong><strong>in</strong>g of modules: The modules are jo<strong>in</strong>ed with a<br />

hidden vertical th<strong>in</strong>-wall profile V-Beam with visible<br />

vertical alum<strong>in</strong>ium profile 35 mm wide. To re<strong>in</strong><strong>fo</strong>rce<br />

an <strong>in</strong>ternal brac<strong>in</strong>g grid the vertical V-Beams are<br />

re<strong>in</strong><strong>fo</strong>rced by hidden <strong>in</strong>ternal H-Beams.<br />

Inter-glass bl<strong>in</strong>ds: horizontal controlled by wheel,<br />

cord (cha<strong>in</strong>), with electric control, possibility of<br />

remote central control, controlled by rod + cord.<br />

Fitt<strong>in</strong>gs: on customer request, split sta<strong>in</strong>less steel<br />

knobs as st<strong>and</strong>ard, h<strong>and</strong>le - h<strong>and</strong>le.<br />

Lock: HOBES as st<strong>and</strong>ard, electromechanical<br />

Abloy or Be<strong>fo</strong> lock on customer request.<br />

1<br />

2<br />

3<br />

4 Ceil<strong>in</strong>g: On customer request <strong>fo</strong>r load bear<strong>in</strong>g capacity (can be<br />

also used a storage space) <strong>and</strong> sound <strong>in</strong>sulation the optimal mix<br />

of ceil<strong>in</strong>g is designed.<br />

5 Floor + ceil<strong>in</strong>g: On customer request <strong>fo</strong>r load bear<strong>in</strong>g capacity<br />

<strong>and</strong> sound <strong>in</strong>sulation the optimal mix of ceil<strong>in</strong>g, <strong>in</strong>clud<strong>in</strong>g trafficable<br />

cover<strong>in</strong>g (PVC, load carpet) is designed.<br />

6 Floor: On customer request <strong>in</strong> PVC floor<strong>in</strong>g, wooden or<br />

lam<strong>in</strong>ate float<strong>in</strong>g floor<strong>in</strong>g). The sta<strong>in</strong>less steel floor <strong>in</strong>cl. <strong>in</strong>ner wall<br />

surfaces <strong>fo</strong>r built-<strong>in</strong> units request<strong>in</strong>g high cleanl<strong>in</strong>ess of <strong>in</strong>ternal<br />

environment.<br />

Staircase: Steel s<strong>in</strong>gle or double-flight stairs (as per project<br />

specifications). The RAL surface f<strong>in</strong>ishes (possibly hot-dip<br />

galvanized). Walk<strong>in</strong>g surfaces designed either as grates, tear<br />

sheets, possibly wood. Metal rail<strong>in</strong>gs with st<strong>and</strong>ard column of<br />

1,000 mm height (jäkl 40 x 20 mm, O 40 mm), RAL colour.<br />

4<br />

5<br />

6

BASIC WALL AND DOOR MODULES<br />

CONFIGURATION OG MILT PARTITION WALLS (selected)<br />

Connection of two full modules<br />

with vertical alum<strong>in</strong>ium<br />

profile 35 mm wide – MILT<br />

system<br />

Connection of two full<br />

modules – wall with higher<br />

sound transmission loss<br />

Rw= 49 dB – MILT TOP<br />

system<br />

MODULE A MODULE B MODULE C MODULE D MODULE E<br />

Comb<strong>in</strong>ation of full <strong>and</strong> glazed<br />

modules – MILT system<br />

Connection of two glazed<br />

modules with vertical<br />

alum<strong>in</strong>ium profile 35 mm<br />

wide – MILT system<br />

Partition wall corners – connection<br />

of full <strong>and</strong> glazed<br />

modules – MILT system<br />

Connection of glazed<br />

module with door module<br />

– MILT system<br />

MODULE F MODULE G MODULE H MODULE I MODULE J<br />

CONFIGURATION OF FLOOR STRUCTURES (vertical sections)<br />

Not trafficable A.1 t<strong>and</strong>ard versions<br />

Trafficable B.1 st<strong>and</strong>ard version<br />

MODULE K MODULE L MODULE M MODULE N MODULE O MODULE P<br />

Not trafficable A.2 with higher requirements on sound <strong>in</strong>sulation<br />

Trafficable B.2 with impact <strong>in</strong>sulation<br />

MODULE Q MODULE R MODULE S MODULE T MODULE U<br />

PARAMETERS OF WALLS AND INNER PARTITIONS<br />

GLASS PANEL FULL WALL DOOR<br />

Width of modules st<strong>and</strong>ard 100-1200 mm st<strong>and</strong>ard 100-1200 mm<br />

(až 1500 mm)<br />

s<strong>in</strong>gle 700, 800, 900 mm<br />

double 1600-3000 mm<br />

Height of modules < 4500 mm < 7000 mm 2100; 2500; 3000; 3500 mm<br />

Partition thickness<br />

100 mm (R w<br />

< 49 dB)<br />

170 až 230 mm (R w<br />

> 48 dB)<br />

Sound transmission loss Rw 42 dB; 45 dB 44 dB; 49 dB*; (až 52 dB**) 19 dB; 22 dB; 32 dB; 40 dB<br />

*Wall modules MILT TOP<br />

** partitions of 170–230 mm thickness<br />

Sound propagation by other ways<br />

• For projects with high dem<strong>and</strong>s on the result<strong>in</strong>g<br />

reduction of noise level <strong>in</strong>doors of the built-<strong>in</strong> unit<br />

it is imperative to take measures to reduce the<br />

transmission ratio of noise not only by “secondary<br />

l<strong>in</strong>es”, but also <strong>in</strong> contact of built-<strong>in</strong> unit with<br />

exist<strong>in</strong>g floor construction.<br />

Technical details<br />

(CAD)<br />

In<strong>fo</strong>rmation on send<strong>in</strong>g<br />

the documents with<br />

processed st<strong>and</strong>ardized<br />

solutions <strong>and</strong> details<br />

from our technical<br />

library are available on<br />

request.

EXAMPLES OF DESIGNED MILT-Pro BUILT-IN UNITS<br />

S<strong>in</strong>gle deck – MILT-Pro 5,0 × 3,8<br />

S<strong>in</strong>gle deck – MILT-Pro 5,0 × 7,4<br />

C<br />

GROUND FLOOR PLAN<br />

C<br />

B<br />

SIDE VIEW<br />

D<br />

B<br />

3800<br />

B<br />

SIDE VIEW<br />

D<br />

E<br />

B<br />

5000<br />

D<br />

SIDE VIEW<br />

5000<br />

A<br />

7400<br />

A<br />

C REAR VIEW A FRONT VIEW D SIDE VIEW<br />

A<br />

FRONT VIEW E INNER WALL C REAR VIEW<br />

S<strong>in</strong>gle deck – MILT-Pro 9,8 × 8,6<br />

Two-deck – MILT-Pro 6,2 × 5,0<br />

E<br />

GROUND FLOOR PLAN<br />

B<br />

SIDE VIEW<br />

1. NP<br />

D<br />

2. NP<br />

C<br />

B<br />

D<br />

SIDE VIEW<br />

5000<br />

D<br />

MOBILE WALL<br />

C<br />

B<br />

8600<br />

A<br />

C<br />

INNER WALL<br />

950 6200<br />

A<br />

A FRONT VIEW B SIDE VIEW D REAR VIEW C SIDE VIEW<br />

9800<br />

E<br />

REAR VIEW<br />

A<br />

FRONT VIEW

PRAHA<br />

Phone: (+420) 602 748 936<br />

www.milt.cz<br />

BRNO<br />

Phone: (+420) 547 223 240<br />

www.milt.cz<br />

BRATISLAVA<br />

Phone: (+421) 233 00 4383<br />

www.milt.sk