MagFil Datasheet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Excellence in Magnetic Filtration<br />

www.magfil.com<br />

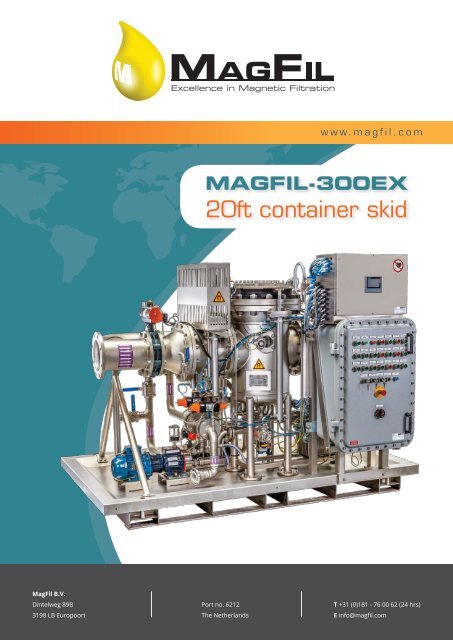

MAGFIL-300EX<br />

20ft container skid<br />

<strong>MagFil</strong> B.V.<br />

Dintelweg 89B Port no. 6212 T +31 (0)181 - 76 00 62 (24 hrs)<br />

3198 LB Europoort The Netherlands E info@magfil.com<br />

Excellence in Magnetic Filtration

MAGFIL-300EX filtration unit is the world’s first mobile ATEX<br />

certified self-cleaning magnetic filtration unit, designed for on-site<br />

filtration for the oil and petrochemical industries in both up, mid &<br />

downstream production and storage terminals.<br />

With a maximum capacity of 350 m³/hr and a patented ‘’PREMAG’’ treatment, this stainless-steel ATEX<br />

magnetic unit is designed to effectively remove ferrous particulate contamination to sub-micron level, including<br />

black powder.<br />

(Black powder is the industry name for the abrasive particulates present in all gas and hydrocarbon fluid<br />

transmission lines due to corrosion and erosion of pipeline walls)<br />

Filtration using the MAGFIL-300EX filtration unit is a cleanable, reusable technology that offers a sustainable<br />

alternative to disposable cartridge/bag media filtration.<br />

Magnetic filtration technology can remove contamination to sub-micron level with minimal flow restriction,<br />

maximizing efficiency and avoiding pressure drop.<br />

With both “PREMAG” and 19 pieces of strong neodymium magnets combined, the MAGFIL-300EX filtration unit<br />

is powerful enough to filter both ferrous and (some) non-ferrous contamination to sub-micron level.<br />

Filtration is also possible in the suction side, avoiding contaminated product entering rotating equipment like<br />

pumps and compressors.<br />

The MAGFIL-300EX is equipped with an on-board industrial PLC for stand-alone operations. Depending on the<br />

rate of pollution the MAGFIL-300EX is automatically drained and rinsed at a configurable frequency using a fully<br />

integrated spray cleaning system.<br />

In the matrix of contaminant filtered out, numerous non-magnetic particles like Sulphur, Aluminum and Silicon<br />

can be found.<br />

For more information please feel free to contact us at info@magfil.com or + 31 (0)181- 760062<br />

DATA<br />

SHEET<br />

Type : MAGFIL-300EX - 20ft container skid<br />

Ex classification : II 3G IIB Ex h T3<br />

Nominal capacity : 300 m³/hr<br />

Maximal capacity : 350 m³/hr<br />

Induced magn. flux density : 1.28 Tesla (12800 Gauss)<br />

Effective magn. flux density : 0.6 Tesla (6000 Gauss)<br />

Maximum load FE (dry weight) : 54 kg<br />

Volume : 0.140 m³ including PREMAG<br />

Drained Volume :<br />

• Single drain = 210 litre<br />

• Double drain = 40 litre<br />

Weight unit : 2.400 kg | including 200 kg mounting frame<br />

Weight 20ft container : 3.300 kg<br />

Total weight : 5.700 kg<br />

Material : • Filter housing and pipe work = Stainless steel 304<br />

► 2006/42/EC<br />

► 2014/68/EU<br />

► 2014/34/EU<br />

► 2014/30/EU<br />

► NEN-EN 13445-1:2014 (issue 5:2018)<br />

► EN-ISO 13850:2015<br />

► EN-IEC 60204-1:2018<br />

► EN-ISO 13857:2008<br />

Power Supply : 3 phases 400 VAC / 50 Hz<br />

Consumption : 13.5 kW<br />

Current : 6 kA<br />

Design pressure : 10 bar<br />

Test pressure : 14 bar<br />

Design standard : EN 13445 / Module A<br />

Design temperature : 60°C (140°F)<br />

Dimensions : L 6058 cm | W 2438 cm | H 2896 cm<br />

Jointing : Compressed asbestos-free jointing based upon glass<br />

and aramid fibres with a nitrile rubber binder - 550x457x2 mm.<br />

Finish UNIT :<br />

• Filter housing, pipe work, pallet = Ceramic shot blasted<br />

• Magnetic elements = Corrosion- & wear resistant treatment<br />

• Hydraulics & spray pump = Paint coated<br />

• Tubes to insert magnetic elements = Stainless steel 316Ti<br />

Machinery Directive<br />

Pressure Equipment Directive (PED)<br />

ATEX Product Directive<br />

Directive Electromagnetic Compatibility (EMC)<br />

Safety of Machinery - General principles for design<br />

Safety of Machinery - Emergency stop function<br />

Safety of Machinery - Electrical Equipment of Machines<br />

Safety of Machinery - Safety distances<br />

► EN-IEC 60079-14:2014 + C1:2016 Explosive atmospheres - Part 14<br />

► EN-ISO 80079-36:2016 Explosive atmospheres - Part 36<br />

► EN-ISO 80079-37:2016 Explosive atmospheres - Part 37<br />

The object of the declaration described above is in conformity with the relevant Union<br />

harmonization legislation.<br />

This datasheet is issued under the sole responsibility of <strong>MagFil</strong> B.V.<br />

<strong>MagFil</strong><br />

Excellence in Magnetic Filtration

Excellence in Magnetic Filtration<br />

<strong>MagFil</strong> B.V.<br />

Dintelweg 89B<br />

3198 LB Europoort<br />

Port no. 6212<br />

The Netherlands<br />

T +31 (0)181 - 76 00 62 (24 hrs)<br />

E info@magfil.com<br />

www.magfil.com<br />

<strong>MagFil</strong>