Green Tech Magazine

The new Green Tech Magazin is focusing on the green tech boom in Austria.

The new Green Tech Magazin is focusing on the green tech boom in Austria.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

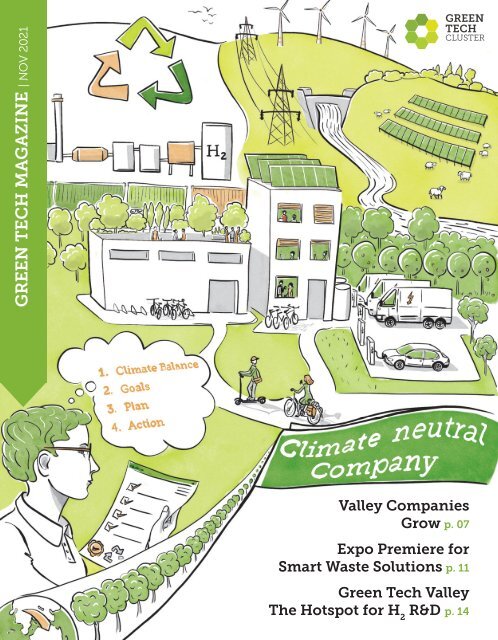

GREEN TECH MAGAZINE | NOV 2021<br />

Cover photo: iStock<br />

Valley Companies<br />

Grow p. 07<br />

Expo Premiere for<br />

Smart Waste Solutions p. 11<br />

<strong>Green</strong> <strong>Tech</strong> Valley<br />

The Hotspot for H 2<br />

R&D p. 14

04<br />

2 GREEN TECH 3<br />

DEAR READERS,<br />

07<br />

“<strong>Green</strong> <strong>Tech</strong> is Booming:<br />

<strong>Green</strong> transformation creates jobs”<br />

the statistics from the <strong>Green</strong> <strong>Tech</strong> Cluster<br />

economic survey have a clear message:<br />

The <strong>Green</strong> <strong>Tech</strong> sector is booming.<br />

Every tenth company in the green<br />

tech sector plans to double in size this<br />

year. The sector has left the crisis behind<br />

it faster than others.<br />

11<br />

12<br />

08<br />

14<br />

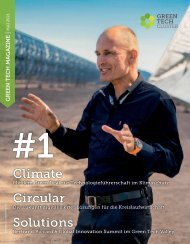

The former EU Commissioner<br />

for Climate Protection<br />

Connie Hedegaard in<br />

an expert talk.<br />

The opportunities to be part of this rapid<br />

sprint to catch up are open to all of industry<br />

– all it requires is the decision to<br />

transform to a climate neutral company.<br />

The <strong>Green</strong> <strong>Tech</strong> Cluster demonstrates<br />

both the potential for savings and the<br />

huge business opportunities that can be<br />

expected. Examples of three flagship enterprises<br />

show how the transformation<br />

to a CO 2<br />

neutral business is a recipe for<br />

success.<br />

Today, we stand on the brink of another<br />

major transformation in the energy<br />

sector: New doors are opening in hydrogen<br />

technology, in the energy economy,<br />

trading and industry, and in the mobility<br />

sector. And Southern Austria is in pole<br />

position, as can be seen from the Hydrogen<br />

Research Map of Austria – it is the #1<br />

Hotspot for R&D!<br />

Once again, a lot has been happening<br />

down in the <strong>Green</strong> <strong>Tech</strong> Valley. So, you<br />

can look ahead to even more fascinating<br />

innovations and collaboration projects.<br />

Yours,<br />

Bernhard Puttinger<br />

and the <strong>Green</strong> <strong>Tech</strong> Cluster team<br />

Climate Neutral<br />

Industry and its Path<br />

to Zero CO 2<br />

Page 04<br />

Innovation Booster<br />

<strong>Green</strong> <strong>Tech</strong> Valley as an Engine<br />

for Growth<br />

Page 07<br />

Fresh <strong>Green</strong> <strong>Tech</strong><br />

Innovation from the<br />

<strong>Green</strong> <strong>Tech</strong> Valley<br />

Page 08<br />

Smart Waste Solutions<br />

Expo Premiere for Saubermacher,<br />

Komptech and REDWAVE<br />

Page 11<br />

Partners: Austrian Ecolabel, PEFC, FSC<br />

Latest<br />

Highlights<br />

Energy Communities<br />

From Consumer to Generator<br />

Page 12<br />

Home-Grown Lead<br />

<strong>Green</strong> <strong>Tech</strong> Valley is<br />

the Hydrogen Hotspot<br />

Page 14<br />

Imprint: Media holder and publisher: <strong>Green</strong> <strong>Tech</strong> Cluster Styria GmbH, Waagner-Biro-Straße 100, 8020 Graz, Austria,<br />

Tel.: +43 316 40 77 44-0, welcome@greentech.at, www.greentech.at. Content and Project Coordination:<br />

Christina Kropf, Bernhard Puttinger | Support: www.diesteirerin.at | Printing: Schmidbauer GmbH,<br />

www.derschmidbauer.at<br />

Photo credit: Stella, Shutterstock, Andrea Renault<br />

Photo credit: Connie Hedegaard<br />

The <strong>Green</strong> <strong>Tech</strong> companies in Southern Austria<br />

are proof that the <strong>Green</strong> <strong>Tech</strong> sector continues<br />

to be stable and growing despite the<br />

crisis. Employment in the <strong>Green</strong> <strong>Tech</strong> sector<br />

is booming. Former EU Commissioner for<br />

Climate Protection Connie Hedegaard, who<br />

as a board member of the European Climate<br />

Foundation is still committed to green transformation,<br />

knows all about the potential for<br />

industry. She actually sees the opportunities<br />

for employment in the green transformation.<br />

Her term of office as climate commissioner<br />

began in the stormy times of 2010, in the<br />

middle of a full-blown financial crisis. At the<br />

time, climate protection was not the topic at<br />

the top of the political agenda.<br />

Ms. Hedegaard, at that time, how did you<br />

convince your fellow Commissioners of the<br />

urgency of the energy transition?<br />

Connie Hedegaard: As a consequence of<br />

the financial crisis, we faced an unemployment<br />

level of 26 million in Europe. So, we<br />

needed economic growth in areas that also<br />

created jobs. The <strong>Green</strong> <strong>Tech</strong> sector has<br />

enormous potential for the labour market,<br />

so we needed to make sure that Europe was<br />

making the most of it. Using this line of argument,<br />

it was possible to anchor climate<br />

measures in the EU budget. For the first time<br />

in the history of the EU, 20 percent of the<br />

entire budget has been allocated specifically<br />

to the fight against climate change. At a time<br />

when no one else paid any attention to the<br />

issue, the EU kept the discussion alive.<br />

Today you sit on the supervisory board of<br />

the European Climate Foundation. What<br />

are your key priorities?<br />

As the issue of climate change is widely accepted<br />

as fact today, now comes the really<br />

difficult part: We need to accelerate the implementation<br />

of measures. Companies play<br />

a vital role in this by driving new technologies.<br />

VW and other car manufacturers, for<br />

example, have started converting their business<br />

model to electromobility. They are also<br />

driven by EU regulations, with the effect that<br />

there are already voices of serious influence<br />

talking about the end of the combustion engine<br />

by 2035. Five years ago, such a suggestion<br />

would have been laughed at. But today<br />

it can be clearly shown that the green transformation<br />

is feasible, without people losing<br />

their jobs, as long as we train them appropriately.<br />

The potential for growth in green jobs,<br />

however, is still viewed with scepticism in<br />

certain places. Justifiably so?<br />

I like to make reference to the past. We have<br />

continuously seen changes in the manner<br />

in which people go about their work.<br />

In the same way that digital transformation<br />

has both eliminated jobs and created new<br />

ones, the green transformation will also follow.<br />

Renovating and insulating buildings will<br />

play a key role in the fight against climate<br />

change, as will the circular economy with<br />

the recycling of raw materials. Both of these<br />

areas are extremely labour-intensive areas,<br />

in which a multitude of jobs are being created.<br />

In Europe we can also refer to many<br />

examples of coal mining regions that have<br />

successfully transitioned to <strong>Green</strong> Economies:<br />

Manchester, Northern France, Spain –<br />

all of them have succeeded in replacing old<br />

jobs with new ones. Now we have to become<br />

better at learning from these examples.<br />

What can Europe learn from the <strong>Green</strong> <strong>Tech</strong><br />

Valley?<br />

Bringing together knowledge and resources<br />

is key to success, even if it initially contradicts<br />

business logic. We need a lot more<br />

of such collaboration at the European level,<br />

otherwise we risk losing out to global competition.<br />

Examples such as the <strong>Green</strong> <strong>Tech</strong><br />

Valley demonstrate to us how we can compete<br />

with the strong innovators in the USA<br />

or China by prioritising R&D.<br />

Which innovations will be critical in the decarbonisation<br />

of our economic system?<br />

More powerful batteries are the holy grail<br />

of the mobility transition. If we manage to<br />

use sustainable raw materials for this, we will<br />

also make ourselves less dependent on foreign<br />

imports. I also believe that the circular<br />

economy will be decisive, as Europe is a relatively<br />

low-resource continent. This means<br />

companies need to work hard to incorporate<br />

the circular economy into their business<br />

strategy. That will help the environment and<br />

society, because it creates green and secure<br />

jobs.

4 GREEN TECH 5<br />

Climate Neutral:<br />

<strong>Green</strong> <strong>Tech</strong> Radar: Your <strong>Tech</strong>nology and Business Opportunities with Zero CO2<br />

Industry on the Path<br />

to Zero CO 2<br />

The Paris climate goals and the EU's <strong>Green</strong> Deal are intended to curb climate<br />

change. At the same time, they pose major challenges for indigenous companies.<br />

However, this change in direction also harbours great business opportunities.<br />

A total of 45 percent of greenhouse<br />

emissions in Austria are caused by industry<br />

and the energy sector. That is around<br />

40 million tonnes of CO 2<br />

per annum. This<br />

is the amount that must be saved by 2040<br />

in order to achieve the specific climate targets<br />

of the current government. There is<br />

great potential for reducing CO 2<br />

in individual<br />

sections of a company, giving rise to<br />

a whole range of new business opportunities.<br />

This is also indicated by the <strong>Green</strong><br />

<strong>Tech</strong> Radar.<br />

The specific measures to reduce emissions<br />

are partly technical and partly non-technical<br />

in nature. There are specific improvement<br />

opportunities in the following areas:<br />

• Company premises: e.g. switching to<br />

green electricity, saving office space, lighting<br />

using LEDs,<br />

• Production: using process heat from renewable<br />

sources and more efficient processes,<br />

• Climate-conscious procurement: e.g. in<br />

supplier selection and integration in ERP<br />

systems, and<br />

• Company mobility: e.g. e-mobility, corporate<br />

car sharing and increased online<br />

meetings.<br />

There are already technologies within these<br />

areas offered by the companies in the <strong>Green</strong><br />

<strong>Tech</strong> Valley in order to achieve the goal of<br />

CO 2<br />

neutrality. Taking production, for example,<br />

green mechanical energy and process<br />

heat can already be generated using stationary<br />

electric motors and fully electric units.<br />

Furthermore, many other technologies and<br />

services are on the horizon, where there is a<br />

particularly relevant need for R&D.<br />

While the challenge is great, companies<br />

in the <strong>Green</strong> <strong>Tech</strong> Valley are already working<br />

full steam ahead to achieve climate targets.<br />

One of them is Magna International.<br />

This globally active automotive supplier and<br />

manufacturer, with over 350 locations worldwide,<br />

runs its largest facility in Graz and this<br />

requires over 200 gigawatt hours of electricity,<br />

natural gas and thermal energy per annum.<br />

“The most important step on our path<br />

to CO 2<br />

neutrality is energy efficiency. We are<br />

working on reducing our energy consumption<br />

while at the same time switching our<br />

energy supply to renewable sources – either<br />

by purchasing or in-house generation,”<br />

explains Markus Binder, Sustainability & Energy<br />

Manager for Magna across Europe. Under<br />

his umbrella comes the installation of a<br />

heat pump at the Graz facility, which uses a<br />

groundwater well to provide heat or cooling<br />

for the entire painting section of the car factory.<br />

E-trucks, waste heat recovery and photovoltaic<br />

systems on top of the large factory<br />

halls are further climate protection measures<br />

that Binder has pushed not just in Graz, but<br />

also at other European Group sites. These extensive<br />

measures have been preceded by detailed<br />

studies of the energy consumption. All<br />

processes and systems have been subjected<br />

to in-depth energy monitoring: “Transparency<br />

is the key to success in energy efficiency<br />

– high-tech solutions can only be used viably<br />

when you know how much energy you<br />

are consuming,” explains Binder, noting that<br />

the Graz site will be CO 2<br />

neutral as early as<br />

2022. But one can't do it all alone. This is the<br />

reason for using an international network of<br />

partners. It was already possible during the<br />

first <strong>Green</strong> <strong>Tech</strong> Cluster <strong>Tech</strong>nology Day to<br />

make appropriate new contacts.<br />

Evaluate first, then invest – this is how sustainable<br />

development works. Johannes Fresner<br />

Photo credit: <strong>Green</strong> <strong>Tech</strong> Cluster<br />

from STENUM Unternehmensberatung und<br />

Forschungsgesellschaft, a consulting and research<br />

company for environmental issues, is<br />

also networked in the <strong>Green</strong> <strong>Tech</strong> Valley. As<br />

a Climate Alliance enterprise since 2004, the<br />

company committed itself to climate neutrality<br />

at an early stage. Lights in the office have<br />

been converted to LEDs, while paper documents<br />

and printouts have been reduced to<br />

virtually zero. Last but not least, the greatest<br />

CO 2<br />

factor has been addressed: mobility. “Due<br />

to our international projects, we had clocked<br />

up quite a lot of air travel, which of course had<br />

a negative effect on the CO 2<br />

balance. But even<br />

before Corona we started reducing air travel,”<br />

states Fresner. The pandemic then accelerated<br />

this process: Suddenly it was no longer a<br />

problem to get international partners to con-

6 GREEN TECH 7<br />

duct video conferences. In the meantime, the<br />

STENUM employees make specific selected<br />

site visits, seminars have been redesigned as<br />

webinars, and regional appointment schedules<br />

are being optimised to also reduce the<br />

number of kilometres travelled by car. However,<br />

the consulting advice does not suffer as<br />

a result: “We are still in a position to raise the<br />

awareness of our customers to potential savings<br />

and provide an overview of where and at<br />

what level energy is consumed in the company,”<br />

says Fresner. His approach: first identify<br />

the starting points with greatest leverage be-<br />

<strong>Tech</strong>nology Days<br />

fore making a large investment, and always<br />

keep an eye on profitability.<br />

Be willing, be bold and be inquisitive –<br />

these are the top three factors on the path<br />

to CO 2<br />

neutrality for Petra Busswald. As<br />

Managing Director of the sustainability hothouse<br />

software company akaryon she deals<br />

with web tools, sustainability management<br />

and digital communication. “I don't know of<br />

any other company that works as decentrally<br />

as we do – for the last 20 years, from<br />

home, without commuting,” says Busswald.<br />

akaryon is also a Climate Alliance enterprise<br />

and uses public transport for 90 percent<br />

of its appointments, uses electricity from<br />

PV systems and only takes flights “if there<br />

really is no other way”. “All of the digital<br />

products that we develop are designed for<br />

sustainability,” says Busswald. She always<br />

recommends that companies and organisations<br />

follow through with the next steps<br />

when developing concepts. Monitoring and<br />

documentation are key and facilitate control:<br />

“We know the roof is on fire, so it's time<br />

to act.”<br />

<strong>Green</strong>house gas balance determines direct and indirect emissions<br />

Engine for Growth<br />

<strong>Green</strong> <strong>Tech</strong> Valley<br />

Southern Austria is an extraordinary<br />

fertile soil for green tech companies. And despite the crisis, a large<br />

number of companies are doubling in size this year.<br />

The <strong>Green</strong> <strong>Tech</strong> Valley is growing. The energy<br />

and green tech sector in Styria and<br />

Carinthia is flourishing. With revenues of<br />

€5.6 bn and employing some 24,400 people,<br />

it has come through the current crisis<br />

better than the economy in general. Over<br />

2,000 research workers are currently employed<br />

in developing fresh, green innovations.<br />

This was the conclusion of the recent<br />

economic survey of the <strong>Green</strong> <strong>Tech</strong> Cluster.<br />

On average, the green tech sector expects<br />

to see double-digit growth this year, while<br />

every tenth company plans to actually double<br />

its sales of green tech.<br />

but found what they were looking for in Austria<br />

– or more precisely in the <strong>Green</strong> <strong>Tech</strong><br />

Valley. KWB, the provider of total solutions<br />

for renewable heating systems, was able to<br />

land the contract for a number of schools<br />

without even having to meet the customer<br />

in person – all made possible through digitalisation.<br />

“This demonstrates just how well<br />

Austria is competing as a global technology<br />

leader in renewable energy. That is something<br />

we can be proud of,” comments managing<br />

director Helmut Matschnig.<br />

Johann Koinegg<br />

<strong>Green</strong> <strong>Tech</strong> Cluster<br />

Tel.: +43 316/40 77 44-22<br />

koinegg@greentech.at<br />

The <strong>Green</strong> <strong>Tech</strong> Cluster provides<br />

support to help you on<br />

your path towards climate neutrality.<br />

As part of the <strong>Tech</strong>nology<br />

Days, we networked large international<br />

companies with total<br />

solution providers from the<br />

<strong>Green</strong> <strong>Tech</strong> Valley, whose technologies<br />

are tailored to individual<br />

requirements.<br />

A range of measures – one goal. The climate<br />

balance of industry must be improved. At the<br />

end of the day, from a physical perspective,<br />

economic activity should no longer generate<br />

any net greenhouse gas emissions or unavoidable<br />

emissions should be “neutralised” by carbon<br />

sinks (both natural, e.g. forests, and manmade,<br />

e.g. carbon capture and storage). A subset<br />

of this is CO 2<br />

neutral production.<br />

The path to zero CO 2<br />

begins with drawing up<br />

the current GHG balance and determining the<br />

primary emission sources and areas. Based<br />

on international standards, Scope 1 includes<br />

the production facility, Scope 2 covers energy<br />

generation outside of the company, and<br />

Scope 3 is for all other upstream and downstream<br />

processes in the value chain (e.g. raw<br />

material extraction, recycling, etc.). When the<br />

largest emitters are identified, short, medium<br />

and long-term measures to reduce CO 2<br />

up to<br />

climate neutrality can be planned. In designing<br />

the measures, public funding is available,<br />

together with support from research partners<br />

and service providers.<br />

Further information can be found in the <strong>Green</strong><br />

<strong>Tech</strong> Radar “ZERO CO 2<br />

business opportunities<br />

and your path to becoming a climate neutral<br />

company” at www.greentech.at/print. At our<br />

<strong>Tech</strong>nology Days, we bring you together with<br />

the right solution providers.<br />

Photo credit: Stella<br />

Photo credit: Michaela Nutz, mnutzDesign, Jorj Konstantinov/GEOPHO<br />

Within this, there is great potential in the<br />

field of renewable electricity. This is indicated<br />

by the success stories of technology<br />

leaders. The Carinthian PV module manufacturer<br />

KIOTO SOLAR has just put Austria's<br />

largest solar roof into operation on its own<br />

company premises. The company intends to<br />

double its production capacity in just a few<br />

months. This is not only good for the company<br />

coffers, but also for the climate.<br />

The heating sector also holds enormous potential<br />

in the fight against climate change:<br />

According to the national energy and climate<br />

plan for Austria, the building sector must<br />

save three million tonnes of CO 2<br />

by 2030.<br />

Biomass plays an important role in this reduction,<br />

and the opportunities that currently<br />

lie dormant for industry are enormous. Due<br />

to booming global demand, things are going<br />

well for companies in Southern Austria – including<br />

the Styrian biomass pioneer KWB.<br />

The New Zealand government wanted to<br />

get rid of the large number of oil heaters in<br />

school buildings and replace them with renewable<br />

alternatives. The officials responsible<br />

scanned options from all over the world,<br />

KWB managing director Helmut Matschnig<br />

The manufacturing company employs<br />

some 350 staff and in 2020 it recorded<br />

sales growth of over 40%. KWB has just<br />

invested €10 m in the expansion of production<br />

capacity, adding 5,000 square<br />

metres of shop floor space, “and even that<br />

is already too little, so we are now adding<br />

another 2,000 square metres,” says<br />

Matschnig. To mitigate the issue of sealing<br />

off ground surface, a two-story construction<br />

was executed when building the<br />

new production hall, which used regionally<br />

sourced timber. As more and more national<br />

governments sign up to the end of oil heating,<br />

as part of the European <strong>Green</strong> Deal,<br />

the order book for the East Styrian company<br />

continues to grow. France and Germany<br />

in particular are currently the largest<br />

growth drivers for the company, but<br />

demand is increasing worldwide. This year<br />

KWB expects a similarly strong growth to<br />

2020.

8 GREEN TECH 9<br />

Fresh <strong>Green</strong> <strong>Tech</strong><br />

Pure compost from the <strong>Green</strong> <strong>Tech</strong> Valley<br />

The biowaste and fertilizer act makes the following provision: Compost<br />

should also be particularly clean. However, it is often contaminated<br />

with glass, metals, solid plastic waste and film. A remedy for<br />

this in compost processing is being offered by the two Styrian technology<br />

companies Komptech and Binder + Co. A joint reference plant<br />

will allow more foreign matter to be separated in the future, which<br />

is a challenge for the technology, as moist organic material is not<br />

easy to sieve and separate. In addition, the foreign particles are tiny.<br />

www.komptech.com, www.binder-co.at<br />

Forbes: Top 30 AI Startups<br />

The ideal man-machine interface – that is the stated aim of the Graz based<br />

technology startup LEFTSHIFT ONE. The five-man team has recently received<br />

the accolade, from the renowned Forbes magazine, of one of the top<br />

30 AI companies in Europe. AIOS (Artificial Intelligence Operating System)<br />

is the name of the operating system developed by the Styrian company for<br />

the application of artificial intelligence and hyper-automation. “The operating<br />

system is a technical development environment on which a range of<br />

applications, or Skills, can be run. The smart services embody the symbiosis<br />

of man and machine, while also ensuring data protection,” explains CEO<br />

Patrick Ratheiser. www.leftshiftone.at<br />

CCC - Celestial ceramics from Carinthia<br />

The Carinthia based Treibacher AG, from the <strong>Green</strong> <strong>Tech</strong> Valley, is currently<br />

undertaking research into a solution for outer space. In collaboration with<br />

the University of Nottingham the company is applying artificial intelligence<br />

to make rocket drives for space shuttles even more durable and extend the<br />

mission capability. It is intended to achieve this through a special ultra-thin<br />

insulating layer made of ceramic. Such ceramic coating materials have been<br />

in use in aircraft jet engines for a number of years to improve durability and<br />

minimise CO 2<br />

emissions. In a similar manner to aircraft turbine engines, but<br />

using a modified chemical composition, ceramic thermal insulation layers<br />

have the potential to increase the heat resistance of rocket engines and<br />

extend their life-cycle. www.treibacher.com<br />

More air miles with Graz shark fin<br />

The Lufthansa cargo fleet is looking to reduce kerosene consumption by<br />

3,700 tonnes annually in the future. This improvement is achieved by covering<br />

the fleet aircraft with a surface film modelled on the skin of a shark. The<br />

Graz-based company Bionic Surface <strong>Tech</strong>nologies is behind the development.<br />

Bionic Surface has taken the so-called riblet effect of shark skin and<br />

applied it to a reproducible riblet film. The target is to reduce air friction<br />

by around one percent. This should result in a significant reduction in fuel<br />

consumption for the airline and save some 11,700 tonnes of CO 2<br />

emissions<br />

per annum. www.bionicsurface.com<br />

Photo credit: Wolfram Scheible, Adobe Stock, Bionic Surface technologies GmbH, Treibacher Industrie AG<br />

Photo credit: BDI-BioEnergy International GmbH, LINETECHNOLOGY GmbH, SETCON, Andritz, Stella/<strong>Green</strong> <strong>Tech</strong> Cluster<br />

Biodiesel production from<br />

saturated fats<br />

BDI-BioEnergy International’s commitment to developing<br />

innovative technologies goes back decades.<br />

The RepCAT (Repeatable Catalyst) process,<br />

for example, is based on a sustainable technology<br />

that uses a recyclable catalyst to produce biodiesel.<br />

The company has now clocked up a further milestone:<br />

The BDI research team has also been able to<br />

convince the European Food Safety Agency (EFSA)<br />

that the RepCAT process is suitable for the recycling<br />

of saturated (high-risk) fat materials. This means<br />

the process can now be used for safe manufacture<br />

of biodiesel from heavily polluted animal fats,<br />

which are otherwise hazardous to the environment.<br />

www.bdi-bioenergy.com<br />

Recycling in a container<br />

The international technology group ANDRITZ has signed<br />

a cooperation agreement for container-based recycling<br />

systems with the Austrian company LINETECHNOLOGY<br />

GmbH. Marketed under the BLUELINE brand, these processing<br />

plants are modular for flexible configuration and facilitate<br />

decentralised recycling and cost effective processing<br />

of small amounts of industrial residual waste fractions. The<br />

shredding technology required for this will be provided by<br />

ANDRITZ using the ADuro product line for universal and fine<br />

shredding. www.andritz.com<br />

32,000 t less CO 2<br />

through<br />

energy efficiency<br />

The <strong>Green</strong> <strong>Tech</strong> Valley based SET company<br />

specialises in innovative drive technology<br />

for speed control. The technology<br />

has recently been applied, in a pilot<br />

project, at the Mittelbüren power station<br />

in Bremen. The bottom line: The efficiency<br />

of the entire power station plant<br />

has been increased by approximately<br />

one percent. Furthermore, the energy<br />

company, swb Generation AG & Co. KG,<br />

was able to significantly reduce its electrical<br />

energy consumption and greenhouse<br />

gas emissions by using the variable-speed<br />

gearbox. Specifically, due to<br />

the new technology, an energy saving of<br />

some 12,815 MWh per annum have been<br />

achieved, equivalent to the energy consumption<br />

of around 4,250 households<br />

in Germany. In addition, there are annual<br />

savings in CO 2<br />

emissions of 32,000<br />

tonnes. www.set-solutions.net<br />

More about the #greentechvalley<br />

Stories from the<br />

#greentechvalley<br />

Where green innovation grows<br />

Register now for our newsletter at<br />

www.greentech.at or follow <strong>Green</strong><br />

<strong>Tech</strong> Cluster on LinkedIn. We are happy<br />

to answer any questions you may<br />

have personally.<br />

Christina Kropf<br />

Communication<br />

Project Manager<br />

kropf@greentech.at

10<br />

PLASTECO: Round it Goes<br />

Plastic Circular Economy<br />

Just short of 26 million tonnes of plastic<br />

waste. That is how much Europeans produce<br />

in just one year. According to the<br />

EU Commission, less than 30% of this is<br />

currently collected for recycling. The rest<br />

is sent to landfill, incinerated or ends up<br />

in the sea. That is harmful for the environment<br />

and the economy. The solution: Transformation<br />

towards a circular economy. This<br />

requires community involvement. The two<br />

factors are brought together through the<br />

Interreg Europe Project PLASTECO.<br />

It is aimed at promoting the exchange of<br />

knowledge between eight European countries,<br />

including Greece, Italy, Bulgaria, Germany,<br />

France, Romania and Lithuania,<br />

which can learn from the Styrian companies.<br />

The focus is on creating regional action<br />

plans to anchor a “new plastics recycling<br />

economy” for the long-term, and to<br />

develop effective measures for practical<br />

implementation.<br />

Reuse – don't throw away<br />

Avoiding all aspects of plastic waste – that<br />

is the aim of PLASTECO. This is also supported<br />

by the European Circular Economy<br />

Initiative and the European <strong>Green</strong> Deal.<br />

However, the EU has set ambitious recy-<br />

cling rates, especially for plastic packaging.<br />

To achieve these targets, comprehensive<br />

separate waste collection and treatment of<br />

plastic waste in a recycling-oriented manner<br />

are essential. Many European countries<br />

are only just at the start of this. The companies<br />

and research institutions in Southern<br />

Austria demonstrate how it can be done.<br />

<strong>Green</strong> <strong>Tech</strong> Valley as a role model on the<br />

international stage<br />

The <strong>Green</strong> <strong>Tech</strong> Valley already has an impressive<br />

record through its innovative<br />

strength in the areas of waste collection<br />

logistics, advanced sorting and processing<br />

technology and the generation of<br />

high-quality secondary raw materials, as<br />

well as the opportunities for recycling. It<br />

also scores highly through its expertise in<br />

the fields of digitisation, AI and new technologies<br />

for waste and resource management.<br />

The companies in the Valley have the<br />

necessary tools on the path towards a circular<br />

economy. Within the context of PLASTE-<br />

CO, they are demonstrating just what they<br />

can do. And the State of Styria is a stage for<br />

these players. The plastics value chain, long<br />

established here as a role model, is now being<br />

communicated to an international audience<br />

in a brand new Competence Atlas.<br />

PLASTECO Competence Atlas to take away<br />

The PLASTECO Competence Atlas sets out<br />

the current technological and structural status<br />

of the plastics industry in the <strong>Green</strong> <strong>Tech</strong><br />

Valley and provides a future outlook on various<br />

technologies and their potential.<br />

It is available as a free download in German<br />

and English at www.abfallwirtschaft.steiermark.at<br />

and www.greentech.at . If you would<br />

rather have a printed copy, just send us an<br />

email to: welcome@greentech.at.<br />

Abfall- und Ressourcenwirtschaft<br />

Info & contact<br />

Dr. Ingrid Winter<br />

Land Steiermark, A14 – Referat<br />

Abfall- und Ressourcenwirtschaft<br />

Bürgergasse 5a, 8010 Graz<br />

E-Mail: abfallwirtschaft@stmk.gv.at<br />

Tel.: 0316/877-2153<br />

www.abfallwirtschaft.steiermark.at<br />

www.interregeurope.eu/plasteco<br />

Photo credit: Land Steiermark, Shutterstock<br />

Photo credit: Shutterstock, Stella/<strong>Green</strong> <strong>Tech</strong> Cluster<br />

Three Styrian recycling companies team<br />

up in single project. Saubermacher,<br />

Komptech and REDWAVE have combined<br />

forces to spread their expertise in resource<br />

conservation throughout the world. And as<br />

a bonus, they are driving forward digitalisation<br />

for waste management. They currently<br />

have a joint presentation of their Smart<br />

Waste Solutions in the i-Lab at Expo Dubai,<br />

where international visitors can benefit from<br />

the expertise of the Valley partners.<br />

A waste bin that recognises when it is full<br />

and notifies the waste collection service that<br />

it is ready to be picked up. Waste management<br />

stands before a paradigm shift that is<br />

being driven by data: “Continuous data collection<br />

enables huge improvements along<br />

the entire disposal chain, starting out from<br />

the customer's waste container, through<br />

to waste collection and processing in recycling<br />

plants,” comments Peter Schmid.<br />

Schmid is the coordinator of the EcoSENSE<br />

project, which is run jointly by three specialist<br />

companies; in waste management,<br />

Saubermacher, in processing technology,<br />

Komptech, and in waste sorting, REDWAVE.<br />

The companies have joined forces both to<br />

advance new digital technologies in waste<br />

management and to pass on their existing<br />

know-how.<br />

The Terra Sustainability Pavilion<br />

at the Dubai Expo 2020<br />

Expo Premiere for<br />

Smart Waste Solutions<br />

Saubermacher, Komptech and REDWAVE in Dubai<br />

The main focus of EcoSENSE is on providing<br />

practical data from experience:<br />

“Saubermacher has been operating hightech<br />

recycling plants for decades. From inhouse<br />

application, practical knowledge has<br />

been built up that companies operating such<br />

systems for the first time simply cannot have,”<br />

notes Schmid. Komptech and REDWAVE sell<br />

their recycling systems all over the world and<br />

use the lessons learned as part of the value<br />

added and pass on their experience to customers.<br />

The result: optimised procedures<br />

for plant operation, less resources used, and<br />

a higher quality of recycled raw materials.<br />

“With EcoSENSE we have been able to take<br />

waste management to the next level. For example,<br />

we are already working on potential<br />

projects in Italy, North Macedonia, Kosovo<br />

and the Ukraine, where our knowledge makes<br />

a contribution,” says Schmid. Saubermacher,<br />

REDWAVE and Komptech are planning to<br />

launch a joint venture as soon as the concept<br />

can stand on its own two feet.<br />

The collaboration between the three companies<br />

started in the <strong>Green</strong> <strong>Tech</strong> Cluster, specifically<br />

within the Circular Future Solution<br />

Group. They have been developing it since<br />

January 2020, culminating in the launch of<br />

EcoSENSE this year. Schmid estimates it will<br />

take a further five to seven years before the<br />

second phase of the project can be implemented:<br />

By then the intelligent waste bin will<br />

herald a new age of continuous data flow that<br />

will subsequently allow a higher recycling<br />

rate to be achieved. “Some of the modules for<br />

this are already running, such as waste bins<br />

that record the fill level and report it centrally.<br />

We are also in the first phase of running recycling<br />

scanners, which use image recognition<br />

and machine learning to detect miss-sorting<br />

of waste and determine the quality of<br />

the waste. All of this raw data can be used<br />

to give feedback to customers and waste<br />

collection route management,” says Schmid.<br />

www.ecosense-advisory.com<br />

Contact<br />

Birgit Harg<br />

Circular Solutions Project Manager<br />

Tel.: +43 316/40 77 44-13<br />

harg@greentech.at

<strong>Green</strong> Lifestyle<br />

12 GREEN TECH 13<br />

From Consumer<br />

to Power Generator<br />

Energy communities are an important building block<br />

in bringing about the energy transition. Businesses also benefit<br />

as new business opportunities and services arise.<br />

An additional 27 TWh of green electricity<br />

are required to achieve the Austrian target<br />

of 100% electricity from renewable sources<br />

by 2030. This is a huge amount, but following<br />

the recently passed renewable energy<br />

expansion act this is achievable with the<br />

help of the general public. Locally produced,<br />

green electricity can soon be passed on in<br />

a climate-friendly manner and consumed<br />

locally – under the framework for Energy<br />

Communities.<br />

New business opportunities and services<br />

Businesses will also benefit from participating<br />

in an Energy Community (EC). They will<br />

be able to produce excess<br />

electricity in-house, using<br />

a large PV plant, and potentially<br />

even sell it on at<br />

better conditions than is<br />

possible with current feedin<br />

tariffs or credits. Alongside<br />

this, new business areas<br />

and services are opening<br />

up. New green jobs<br />

are emerging. <strong>Tech</strong>nology<br />

providers in the <strong>Green</strong><br />

<strong>Tech</strong> Valley are able to support<br />

establishing an EC using<br />

their energy solutions.<br />

Certain providers focus on<br />

technology, for example, in<br />

the visualisation of power<br />

generation, consumption<br />

analysis and forecasting,<br />

together with billing services.<br />

While with others,<br />

the focus is on the community.<br />

Energy Communities<br />

are also an important research<br />

topic at JOANNEUM<br />

RESEARCH. LIFE, the Insti-<br />

Getting you<br />

on the path to a sustainable<br />

energy community!<br />

The experts from LIFE - Institute for<br />

Climate, Energy and Society will help<br />

you collaborate together to become<br />

a self-sufficient power generator and<br />

retain the resultant value added<br />

energy output in the region.<br />

Analysis, consulting advice and<br />

implementation strategy – all from<br />

a single source.<br />

Take your first step now ...<br />

... and book a no-obligation consultation!<br />

andreas.tuerk@joanneum.at<br />

tute for Energy, Climate and Society, offers<br />

comprehensive advice on setting up Energy<br />

Communities and monitors their development<br />

under an EU comparison program. As<br />

Andreas Türk, Researcher for International<br />

Climate Policy and Economics at LIFE, points<br />

out, Austria ranks at the forefront of implementation<br />

of the EU requirements: “Only a<br />

few countries have started reforming their<br />

electricity markets in such a manner to allow<br />

Energy Communities to develop their full<br />

potential as new market players. There are<br />

currently only a handful across Europe that<br />

meet EU requirements. By 2030, it is estimated<br />

that market penetration could be 5 to<br />

10%. This is where Austria is one step ahead,”<br />

notes Türk. However, there are still practical<br />

details to resolve, such as access to real-time<br />

smart meter data for Energy Communities.<br />

From analysis to implementation<br />

When it comes to statutory prerequisites<br />

for Energy Communities, these are often<br />

very complex. For this reason, LIFE offers a<br />

comprehensive Energy Community Check,<br />

including supporting and assisting municipalities<br />

from initial awareness of this topic<br />

through to implementation strategy.<br />

STARTER PACK<br />

For those new to the topic of<br />

energy communities, such as for<br />

municipalities, we provide the<br />

solid background knowledge on<br />

which to build a project.<br />

INITIAL SCOPING<br />

In a workshop format, we help you<br />

develop specific proposals for<br />

solutions and business models<br />

for a planned energy community.<br />

This includes opportunities for<br />

localisation, depicting specific usage<br />

cases and identifying the strengths<br />

of the players participating.<br />

ADVANCED SCOPING<br />

Following thorough preparation, we<br />

present detailed case models, which<br />

include profitability and target group<br />

analyses, PV output forecasts and<br />

the decarbonisation potential.<br />

Photo credit: Shutterstock<br />

Photo credit: Woodcessories, Papair, Stephen Verstraete, Füllett<br />

Straw into Gold<br />

Bio-plastics are finding more and more areas of application. The<br />

German startup Woodcessories is making use of straw and cereal<br />

crop residues, left over from harvesting, which previously could<br />

not be used. The residues are used to produce a plastic based on<br />

plant starch, which is then used to make smartphone cases that are<br />

compostable. Tested by TÜV, the Woodcessories Bio-Case is free of<br />

harmful additives and is currently available for smartphones from<br />

manufacturers Huawei, Apple and Samsung. The price starts at € 20<br />

for a biodegradable Airpod cover, smartphone covers are available<br />

from € 25. www.woodcessories.com/bio-produkte<br />

Cockroach Basking in the Sun<br />

A robot that looks like an oversized cockroach could soon become<br />

a saviour for neglected houseplants: The inspiration of the<br />

Belgian sculptor Stephen Verstraete, this is a novel application<br />

to make life easier for plant lovers who don’t have green fingers.<br />

The robot cockroach is programmed to manoeuvre plants placed<br />

in it to sunny positions. The cockroach is not yet able to water<br />

the plants independently, however, it is available for free – as<br />

an online instruction manual for DIY enthusiasts with a floral<br />

inclination.<br />

www.instructables.com/id/Plant-Host-Drone<br />

Sustainable Bubble Wrap<br />

They do exist: environmental aficionados, people who meticulously<br />

separate paper and plastic from the bubble wrap envelopes<br />

they receive their goods in. But with Papair this task becomes<br />

superfluous: This bubble wrap is made from recycled paper, so<br />

the environmental balance for shipping fragile goods can be<br />

greener. The company promises a 75 percent reduction in CO 2<br />

compared to the use of conventional plastic bubble wrap – that is,<br />

so long as its crowdfunding goals can be achieved, as the young<br />

entrepreneurs are still seeking investors.<br />

www.papair.de<br />

Tasty Dishes<br />

Mix wheat or rye flour with rapeseed oil and salt – and, hey presto,<br />

an edible dish for serving all types of food is ready. The German<br />

company Füllett specialises in bakeware that is intended to curb<br />

plastic waste in the catering sector. The edible containers are available<br />

in three sizes and are suitable for holding every imaginable dish,<br />

from salad and snacks to finger food and soups. The light bread<br />

flavoured dishes can either be eaten or composted. According to<br />

the company, the dishes taste so good that 80 percent of them<br />

end up in the stomach instead of in the waste bin.<br />

www.fuellett.de

14 GREEN TECH 15<br />

H 2<br />

Research:<br />

<strong>Green</strong> <strong>Tech</strong> Valley<br />

is The Hydrogen Hotspot<br />

The Hydrogen Research Map Austria sets out the national<br />

technological advantage in hydrogen research.<br />

H 2<br />

is considered to be one of the energy sources of the future.<br />

However, there are still a number of unresolved questions. Companies in the<br />

<strong>Green</strong> <strong>Tech</strong> Valley are working on the answers and some innovative solutions.<br />

19 institutes and 313 research workers<br />

are concentrated in one location: When it<br />

comes to researching hydrogen as an energy<br />

source, Austria is clearly in the top European<br />

league. The hotspots for national hydrogen<br />

research are located in Graz with the<br />

<strong>Tech</strong>nical University, the Hydrogen Center<br />

Austria, the Large Engine Competence Center,<br />

the Bioenergy and Sustainable <strong>Tech</strong>nologies<br />

Competence Centre and the Austrian Institute<br />

of <strong>Tech</strong>nology. Further national centres<br />

are located at the Montanuniversität Leoben<br />

and TU Wien. Together, these research beacons,<br />

which provide an umbrella for other university/non-university<br />

R&D hothouses, form<br />

the cornerstones of the Hydrogen Research<br />

Map Austria.<br />

HyCentA and Infineon develop green hydrogen for industrial use<br />

Currently, within the scope the WIVA P&G showcase region, HyCentA<br />

is participating in the construction of a demonstration plant for<br />

high-purity hydrogen production using renewable electricity. The<br />

specific site is the company premises of semiconductor manufacturer<br />

Infineon <strong>Tech</strong>nologies Austria. As demand for microelectronic<br />

The map indicates, at a glance, the level<br />

and concentration of expertise in the country.<br />

The main areas of research centre on<br />

the issues of production, storage and distribution<br />

of green hydrogen, as well as its<br />

use in industry and commerce, mobility<br />

and the energy sector. “Our aim was to<br />

very clearly set out the research competence<br />

in Austria. It is noticeable that most<br />

of the human resources are concentrated<br />

in Styria, around the TU Graz campus,”<br />

says Bernhard Puttinger, Managing Director<br />

of the <strong>Green</strong> <strong>Tech</strong> Cluster.<br />

The <strong>Green</strong> <strong>Tech</strong> Cluster has also evaluated<br />

the specific market opportunities<br />

that are likely to be open to solution providers<br />

in the sector in the future: “The research<br />

today will become the industry of<br />

tomorrow. The market is developing exponentially:<br />

now is the time to be part of it,”<br />

notes Puttinger. There is huge potential in<br />

respect of green hydrogen as an electricity<br />

storage medium. With the aid of this<br />

energy source, excess electricity can be<br />

stored long-term and used at peak times.<br />

Hydrogen is therefore able to stabilise the<br />

power grid without polluting the environment.<br />

Because grey hydrogen needs to be<br />

replaced soon, in the future there will also<br />

be increased demand for green hydrogen<br />

from industry and commerce, for example<br />

for the production of ammonia and in the<br />

petrochemical sector. Demand also comes<br />

from the semiconductor industry, as hy-<br />

solutions has increased, so too has the need for the gases and chemicals<br />

used in manufacture, which includes high-purity hydrogen as a<br />

process gas. Previously this has been delivered by truck from Germany,<br />

but will soon be produced at the manufacturing facility in Villach.<br />

In addition, it should also be possible to recycle the H 2<br />

.<br />

Photo credit: <strong>Green</strong> <strong>Tech</strong> Cluster<br />

Photo credit: Andrea Gruber<br />

drogen plays a central role here as a key<br />

element in the process chain.<br />

However, there is still a lot to do. At<br />

present, 95 percent of the hydrogen used<br />

worldwide still comes from fossil energy<br />

sources, primarily natural gas. It is increasingly<br />

important to replace this grey hydrogen<br />

with green hydrogen from renewable<br />

sources such as solar power or biomass.<br />

H 2<br />

as a climate-friendly energy carrier can<br />

be generated electrolytically, for example.<br />

This is possible, free from emissions, at efficiency<br />

levels of some 60 to 80 %.<br />

At the moment, the production of green<br />

hydrogen is still very expensive. It currently<br />

costs two to three times as much as the<br />

production of grey hydrogen. The storage<br />

of the colourless and odourless gas also<br />

has its pitfalls. Hydrogen compressed in<br />

gaseous form must be stored under high<br />

pressure in resilient containers; liquid cryogenic<br />

hydrogen requires temperatures below<br />

−252.85 °C for transport.<br />

In order to be able to master these challenges<br />

in the best possible way, the companies<br />

and research institutions in the<br />

<strong>Green</strong> <strong>Tech</strong> Valley are already working flat<br />

out researching advanced solutions. The<br />

Graz startup Rouge H 2<br />

Engineering, for example,<br />

is working on containers for mobile<br />

hydrogen production. The plant developer<br />

VTU Engineering is focusing on hydrogen<br />

as an energy storage device. And the Hydrogen<br />

Center Austria is the only non-university<br />

research facility in Austria that specialises<br />

in hydrogen technologies such as<br />

electrolysis, hydrogen storage, fuel cells,<br />

refuelling, measurement and safety systems.<br />

One thing is clear: The use of green hydrogen<br />

is a building block on the path towards<br />

the energy transition.<br />

Further information can also be found at:<br />

www.greentech.at/print

16<br />

Did you know?<br />

Electricity from Body Sweat<br />

The use of human muscle power to generate electricity is already well understood.<br />

But producing electricity from a by-product of physical exertion, sweat, is something<br />

new: Researchers at the University of California in San Diego demonstrated<br />

this by gluing micro biofuel cells to the fingertips of test subjects. The cells absorb<br />

sweat and convert it into electricity, even when the wearer does not move – in<br />

fact even while sleeping. This allows, for example, fitness bands to be run with a<br />

minimal amount of electricity. www.ucsd.edu<br />

E-Charging: Largest Demonstrator in the Valley<br />

The Graz based, high-tech company Easelink is providing support to the world's<br />

largest electric taxi project in Austria using its conductive charging technology.<br />

Within the scope of eTaxi Austria, 66 e-vehicles will be charged at ten wireless and<br />

fully automatic taxi stands, in Graz and Vienna, using conductive charging plates<br />

that connect to a connector on the underbody of the vehicle at the touch of a button.<br />

www.easelink.com<br />

Rock out the Watts<br />

The SWG3 Complex in Glasgow is the first arts and event venue in the world where<br />

energy is harnessed through a body heat system: In the pilot project, the thermal<br />

energy given off by visitors rocking out on the dance floor is transferred through<br />

heat pumps, either to storage systems for heating or to air AC systems for cooling<br />

the club rooms. The nightspot wants to save up to 70 tonnes of CO 2<br />

annually.<br />

The initiative is under the auspices of the United Nations COP26 Climate Change<br />

Conference, which took place in Glasgow on October 31 st . www.ukcop26.org<br />

CO 2<br />

Extractor<br />

The first Climeworks facility is extracting 900 tonnes of CO 2<br />

from the atmosphere<br />

every year. The Swiss company uses large-scale systems to filter<br />

out this harmful greenhouse gas and store it underground. In order to filter<br />

one percent of global CO 2<br />

emissions by 2025, around 250,000 such systems<br />

would have to go into operation. To this end, the company founders are now<br />

gearing up for series production: With an injection of funds totalling €43 m<br />

from development grants and private investment, the Swiss intend to put their<br />

ambitious goal into practice. www.climeworks.com<br />

Photo credit: Lu Yin, Climeworks, swg3glasgow, easelink