Edition 63 (July-September, 2021)

GLASS BULLETIN is a publishing company, managed by a highly experienced editorial and administrative staff. It has a dedicated and responsible team for providing quality journals and related services to its readers. The company publishes GLASS BULLETIN which is the fastest growing top-notch journal of India for the global glass industry. It is published quarterly and circulated among glass manufacturers, glass processors, glass-machinery & tool manufacturers, art glass processors, glass dealers, architects, builders, aluminium fabricators, interior decorators and the automobile industry across the globe. GLASS BULLETIN is the ideal platform, both in the print and digital media, for worldwide exposition of news, reports, products and exhibitions related to the glass industry. It is a one-stop solution for all queries and needs related to glass–machinery and technology, its innovation, product-procession and marketing in India. By its permanent columns, it enjoys the status of highest readership among all Indian glass journals. GLASS BULLETIN is the media partner for international glass exhibitions in Beijing, Shanghai and Guangzhou in China besides in other parts of the world, including Europe, India and the Middle East. GLASS BULLETIN e-magazine, the first glass-related e-magazine of India, is also available online and on mobile phone, free of cost at http://www.glassbulletin.com

GLASS BULLETIN is a publishing company, managed by a highly experienced editorial and administrative staff. It has a dedicated and responsible team for providing quality journals and related services to its readers. The company publishes GLASS BULLETIN which is the fastest growing top-notch journal of India for the global glass industry. It is published quarterly and circulated among glass manufacturers, glass processors, glass-machinery & tool manufacturers, art glass processors, glass dealers, architects, builders, aluminium fabricators, interior decorators and the automobile industry across the globe.

GLASS BULLETIN is the ideal platform, both in the print and digital media, for worldwide exposition of news, reports, products and exhibitions related to the glass industry. It is a one-stop solution for all queries and needs related to glass–machinery and technology, its innovation, product-procession and marketing in India. By its permanent columns, it enjoys the status of highest readership among all Indian glass journals.

GLASS BULLETIN is the media partner for international glass exhibitions in Beijing, Shanghai and Guangzhou in China besides in other parts of the world, including Europe, India and the Middle East.

GLASS BULLETIN e-magazine, the first glass-related e-magazine of India, is also available online and on mobile phone, free of cost at http://www.glassbulletin.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

06

Intelligent Unit of Automatic Insulating Glass Production<br />

Automatic glass<br />

unloading machine<br />

Insulating glass<br />

sealing robot<br />

Automatic cork<br />

pad applicator<br />

Press machine<br />

Spacer attaching section<br />

Flexible spacer applicator<br />

Washing machine<br />

Automatic glass<br />

loading machine<br />

Low-E glass film<br />

removing machine<br />

Automatic Low-E<br />

glass loading machine<br />

Spacer moving machine<br />

Automatic aluminum<br />

Desiccant automatic<br />

spacer bending machine filling machine Automatic butyl<br />

extruder<br />

Two component<br />

sealants extruder<br />

Rotating table<br />

High stability<br />

with continuous<br />

running<br />

Collect raw<br />

material<br />

consumption data<br />

Warm edge<br />

spacer function<br />

is available<br />

Automatic<br />

adjust pressure<br />

accurately<br />

Data transmission &<br />

remove communication<br />

system<br />

Now HANJIANG is moving to industry 4.0, can be connected with MES/ERP system, in order to do production sequentially and update production data to the system easily.<br />

We have developed machine from automatic glass loading machine, automatic Low-E edge deletion machine, automatic online gas filling IG line, automatic cork pad<br />

applicator, sealing robot to automatic glass unloading machine.<br />

Plus, fully automatic IGU production solution with one labor is coming now.<br />

TPS-Thermo plastic spacer robotic line & Super spacer robotic line.<br />

BEIJING HANJIANG AUTOMATIC GLASS MACHINE EQUIPMENTS CO.,LTD<br />

Add: No.7 Tengren Road, Niulanshan Industrial Zone, Shunyi District, Beijing, P.R.China<br />

Tel: +86-10-89411982 Fax: +86-10-89411980<br />

Website: www.hjglass.com.cn<br />

India office:<br />

Sales-Ms.Ashley Quan<br />

Email: Asia@hjglass.com.cn<br />

Cell/WhatsApp:+8613910174313<br />

Service-Mr.Deepak Dubey<br />

Email: India@hjglass.com.cn<br />

Cell/WhatsApp: +91 7007421673<br />

WhatsApp<br />

We Chat<br />

Website<br />

09

TPS ® . The Original<br />

from the Inventor.<br />

With Thermo Plastic Spacer TPS ® it is possible to<br />

achieve a winning combination of a high quality,<br />

tight edge seal, increased insulating glass energy<br />

efficiency and a differentiated aesthetic advantage –<br />

a fact that has been proven more than a million times<br />

over worldwide!<br />

With more than 30 years of experience in the<br />

field of warm edge spacers you can trust the<br />

Original Inventor!<br />

Get your IG manufacturing business on<br />

the road to success — Download the<br />

IG Manufacturing Line Guide here<br />

www.glastory.net<br />

Machinery, services and solutions designed with the future in mind for<br />

the architectural, automotive, solar and appliance industries.<br />

info@glaston.net | www.glaston.net | www.glastory.net | www.gpd.fi<br />

11

13

ERFOR<br />

ANCE<br />

INTERMAC.COM<br />

READY TO HANDLE<br />

ANY WORK LOAD.<br />

Genius CT-RED is designed for high performance cutting lines and<br />

ensures reliability over time thanks to top quality components and<br />

technological solutions that guarantee accuracy and results with a<br />

continuous, maintenance-free cycle.<br />

Genius CT-RED<br />

UNIQUE AND UNPARALLELED<br />

FOR QUALITY ANDPERFORMANCE.<br />

The Master One is a 3 or 4 axis machining centre for processing glass capable of<br />

executing a wide range of machining operations using the best technology, with<br />

no compromise on performance. The Master One boasts an unbeatable balance<br />

of quality and market competitiveness, making it the perfect investment.<br />

MASTER ONE<br />

14

NEW<br />

the revolution in water filtration has arrived<br />

m 2<br />

+ FILTER<br />

SURFACE<br />

+ SAVINGS<br />

+ WATER<br />

FLOW<br />

- AIR<br />

CONSUMPTION<br />

100%<br />

Check out our<br />

latest video<br />

www.filtraglass.com · info@filtraglass.com<br />

15

17

High Purity<br />

Insulating Glass<br />

ALUMINIUM SPACER BARS<br />

SMOOTH WELDING LINE | SHINING SURFACE<br />

NO CORROSION | NO OXIDATION | NO DEFORMATION<br />

LOGO MARKING AVAILABLE @ Minimum 20 Boxes<br />

<br />

<br />

<br />

<br />

18<br />

BLG International Pvt. Ltd.<br />

From the house of<br />

Lakshmi Float Glass Ltd.<br />

Warehouse: Delhi/Mumbai<br />

Contact : Aditya Gupta +91-99562-95454<br />

E-mail : sales@biginternational.in

INTERNATIONAL<br />

BUSINESS LEADER IN GLASS<br />

FROM THE HOUSE OF LAKSHMI FLOAT GLASS LTD.<br />

IG SECONDARY SEALANT<br />

FT-997<br />

IG PRIMARY SEALANT<br />

FT-301<br />

FT-997<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

A-2/30-31, W.H.S, DDA Marble Market Kriti Nagar,<br />

New Delhi-110015, INDIA<br />

L-135, Midc, Taloja, Raigarh, Maharashtra,<br />

MUMBAI-410208, INDIA<br />

Aditya Gupta +91-99562-95454 | www.lakshmifloat.com | E-mail : sales@biginternational.in<br />

19

25

26

31

32<br />

14

If you are looking for safety, Look for us<br />

www.safexglass.com<br />

Hindustan Glass Works Ltd. is an ISO 9001: 2015, TS 16949 : 2009<br />

<br />

<br />

<br />

HINDUSTAN GLASS WORKS Ltd.<br />

Head Office : A2/30-31 whs Dda Marble Market, Kirti Nagar - 110015,<br />

New Delhi | Contact : Kunal Gupta +91-9794-852213<br />

E-mail : sales@safexhgw.com<br />

Plant address: Hindustan Glass Works Ltd. Prayagraj - 211012<br />

(U.P), India | Contact : A.S Ganguly +91-99562-95451<br />

E-mail : ganguly@safexhgw.com<br />

33

35

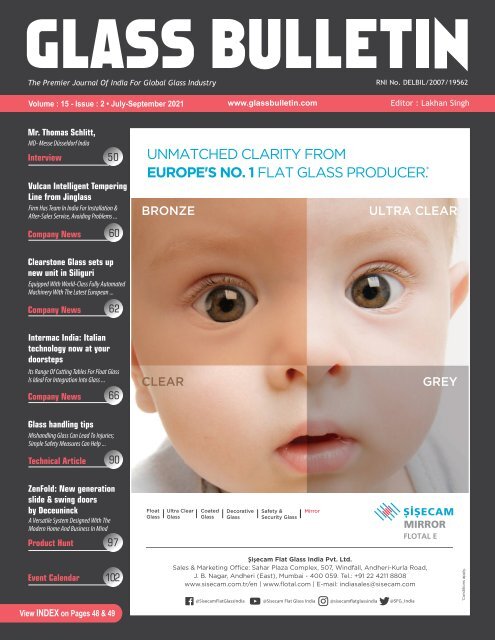

Interview<br />

With SOPs in place, we’re convinced to<br />

open our shows in 1st half of ‘22: Thomas<br />

Schlitt, MD- Messe Düsseldorf India<br />

Schlitt Talks To GB About How Exhibition Industry Is Recovering From<br />

COVID-19 Onslaught<br />

Ahead of glasspro INDIA and glasspex INDIA slated for March 2022, Messe Düsseldorf<br />

India MD Thomas Schlitt explains to Glass Bulletin how the sector is emerging from the<br />

shadow of the pandemic and what steps are being taken to ensure safety and hygiene at<br />

these events.<br />

Mr. Thomas Schlitt,<br />

MD of Messe Düsseldorf India<br />

Thomas Schlitt joined Messe Düsseldorf India as Managing Director in 2015. During his tenure at Messe<br />

Düsseldorf India, he has focused on the core sectors, strengthened the existing trade fairs in India and<br />

also extended the event portfolio. Previously, Thomas Schlitt held management positions in international<br />

business development and sales in the MICE industry at renowned German trade fair organizations, i.e.<br />

Messe München and Nürnberg Messe.<br />

Please tell us about Messe<br />

Düsseldorf GmbH & its<br />

exhibitions in India?<br />

Messe Düsseldorf GmbH is one<br />

of the world’s largest trade fair<br />

organizers with its own exhibition<br />

grounds and offers its presence in<br />

more than 150 countries around the<br />

globe. We organize 50 international<br />

trade fairs, among these are 24<br />

leading events in the respective<br />

industry sector.<br />

Messe Düsseldorf India Pvt. Ltd.<br />

is a fully owned subsidiary of Messe<br />

Düsseldorf GmbH which is a global<br />

player both as a trade fair organizer<br />

and provider of trade fair-related<br />

services for exhibitors and visitors.<br />

Messe Düsseldorf India has been<br />

successfully staging established trade<br />

fairs like In-Store Asia, Medical Fair<br />

India, FAMDENT Shows & Awards,<br />

glasspex India, glasspro India,<br />

pacprocess & food pex Mumbai,<br />

India Essen Welding & Cutting, wire<br />

India, Tube India, METEC India<br />

and ProWine Mumbai. Besides<br />

organizing successful trade fairs<br />

in India, the company is also the<br />

exclusive sales representative of<br />

the Messe Düsseldorf Group for the<br />

Indian Market and is canvassing<br />

Indian customers to events of the<br />

Messe Düsseldorf Group worldwide.<br />

– India and the whole world<br />

faced a very difficult time during<br />

the pandemic in the last 18<br />

months. The exhibition industry<br />

is one the most affected. What<br />

50 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Interview • 2<br />

are your views about this?<br />

Exhibitions and tradeshows have<br />

survived, adapted and thrived despite<br />

unprecedented times like pandemics<br />

and other global challenges during the<br />

past several centuries. However, the<br />

COVID-19 situation has affected the<br />

business adversely, particularly the<br />

trade fair sector, not only in India but<br />

across the world. We have witnessed<br />

many trade shows being either<br />

postponed or cancelled internationally<br />

in the past 18 months.<br />

Due to this situation new kinds<br />

of platforms have been invented<br />

in order to keep in touch with the<br />

industry. Messe Düsseldorf India<br />

has successfully developed and<br />

implemented virtual events for<br />

several industrial sectors. As industry<br />

stakeholders, we are grateful to our<br />

customers for their continued support<br />

in our events.<br />

– After a long period of pandemic,<br />

things are getting better day<br />

by day. When do you think<br />

exhibitions in India will resume<br />

normally?<br />

Keeping in view the intensive<br />

vaccination drive in India coupled<br />

with the adoption of COVIDappropriate<br />

behaviour with defined<br />

Standard Operation Procedures<br />

(SOP) at our trade fairs, we are<br />

convinced to open our shows in the<br />

first half of 2022.<br />

– What are the new protocols to<br />

be followed as an organizer of an<br />

exhibition?<br />

Messe Düsseldorf Group,<br />

together with Messe Düsseldorf<br />

India, has elaborated under the<br />

title ‘PROTaction’, a comprehensive<br />

hygiene and infection protection<br />

concept in order to safeguard the<br />

health of our customers, partners and<br />

employees.<br />

This hygiene and infection<br />

protection concept has been<br />

submitted to the Indian Authorities<br />

for consideration at SOPs for reopening<br />

of trade fairs in India.<br />

– As we all know India has the<br />

fastest growing economy in the<br />

world. How can exhibitions play a<br />

vital role for the industry?<br />

India’s progressive economy is<br />

anticipated to reach around $5 trillion<br />

in the next few years with active<br />

contribution from the manufacturing,<br />

technology and services sectors.<br />

The exhibition industry has always<br />

played a pivotal role in strengthening<br />

and growing the economy. Messe<br />

Düsseldorf exhibitions worldwide,<br />

including those in India, are of worldclass<br />

reputation. Many of our events<br />

have already established themselves<br />

as leading events and are platforms<br />

for the industry to create business<br />

opportunities, to build cooperations<br />

and to network.<br />

– glasspro INDIA and glasspex<br />

INDIA will be held in March 2022.<br />

What are your plans to bring in<br />

maximum exhibitors and visitors?<br />

The tailor-made trade fair concepts<br />

complement each other and create a<br />

unique platform for the glass industry.<br />

Comprehensive sales, marketing and<br />

communication measures will ensure<br />

that decision makers, stakeholders<br />

and relevant media representatives<br />

attend the events.<br />

– You have added a new<br />

segment to glasspro India i.e<br />

fenestrationpro India. Tell us<br />

about this new segment.<br />

fenestrationpro INDIA is a show colocated<br />

with glasspro INDIA to unite<br />

the architects, fabricators, developers,<br />

policymakers, façade consultants,<br />

engineers, and stakeholders from the<br />

Indian industry to drive discussions<br />

on the design trends considering<br />

energy-efficient building technologies.<br />

– It is a very good coincidence<br />

that United Nations has<br />

announced 2022 as the<br />

international year for glass. We<br />

have glasspro India and glasspex<br />

India in same year. Do you have<br />

any plan to promote IYOG in your<br />

glass exhibition?<br />

By announcing the year 2022 as the<br />

International Year of Glass (IYOG),<br />

the United Nations underlined the<br />

scientific, economic and cultural roles<br />

of glass. Glass supports many vital<br />

technologies, facilitates sustainability<br />

and enriches our lives.<br />

Messe Düsseldorf India, along with<br />

its partners, is proud to host the IYOG<br />

during our exhibitions - glasspex<br />

INDIA and glasspro INDIA. We will<br />

promote the importance of glass usage<br />

along with AIGMF and International<br />

Commission of Glass.<br />

– You are organizing glasspro<br />

India in close cooperation with<br />

Glass Bulletin. Share your<br />

thoughts on your association with<br />

Glass Bulletin?<br />

Glass Bulletin is India’s premier<br />

journal for the global glass industry.<br />

It is the ideal platform to publish<br />

news, reports, product details, and<br />

information about glass industry, both<br />

in print and online.<br />

Messe Düsseldorf India is proud<br />

to be associated with Glass Bulletin.<br />

This association of the leading media<br />

and trade fair organizer is the perfect<br />

combination, and it guarantees a<br />

platform where business is generated.<br />

Website: www.md-india.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 51

Event<br />

Glass in our lives: AIGMF names<br />

photography contest winners on<br />

Int’l Youth Day<br />

Contest Was Announced As Part Of Activities After UN Approved 2022 As<br />

International Year Of Glass<br />

In May <strong>2021</strong>, the General Assembly of the UNITED NATIONS approved 2022 as the<br />

International Year of Glass. Many glass-related activities are planned worldwide. Among<br />

these, AIGMF announced its first photography contest for the age group of 7-24 years on<br />

the theme: Glass in our Lives.<br />

Distinguished jury members<br />

representing a cross section<br />

of glass sectors and regions<br />

decided the top thee photographs<br />

out of approximately 7,000 entries<br />

received from educational institutes<br />

and the youth across India.<br />

The jury comprised Mr Sanjay<br />

Somany, former president of AIGMF<br />

and CMD HNG Inds. Ltd; Mr Sanjay<br />

Ganjoo, former president of AIGMF<br />

and COO Asahi India Ltd; Dr Suman<br />

Kumari Mishra, FNASc, Director<br />

CSIR-Central Glass and Ceramic<br />

Research Institute and Adjunct<br />

Prof. AcSIR and Ex-Dean Eng. Sc.<br />

AcSIR; Professor Manoj Choudhary,<br />

former president of Int’l Commission<br />

on Glass, Adjunct Prof. Materials<br />

Science & Engineering, The Ohio<br />

State University and President, MKC<br />

Innovations, LLC (USA); Dr Arun<br />

K. Varshneya, Emeritus Professor<br />

(Glass Science) Alfred University and<br />

President Saxon Glass Technologies,<br />

Inc. (USA); and Mr Dave Fordham,<br />

publisher of Glass Worldwide (UK).<br />

The first prize of Rs 20,000 was<br />

given to S Christy Laura, aged<br />

15 years, Class 10 student of Sri<br />

Akilandeswari Vidyalaya, (Trichy)<br />

Tamil Nadu. The second prize of Rs<br />

10,000 went to Medhansh Singhla,<br />

aged 8 years, Class 3 student of Delhi<br />

Public School (Vasant Vihar) New<br />

Delhi, and the third prize of Rs 5,000<br />

was awarded to Brijesh Jethva, aged<br />

22 years, from Junagadh, Gujarat.<br />

“The AIGMF’s 1st Photography<br />

Contest proved a worthy kickstart to<br />

the Federation’s planned activities<br />

for the International Year of Glass<br />

2022 and Glass Worldwide was very<br />

pleased to be involved in the process,”<br />

said Mr Fordham, publisher of Glass<br />

Worldwide.<br />

“The jury were presented with<br />

a vast selection of wide-ranging<br />

photographs to evaluate under the<br />

‘Glass in our Lives’ theme, many of<br />

which were of a very high standard.<br />

52 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

AIGMF• 2<br />

<strong>September</strong> 10, where an online<br />

exhibition of selected photos of<br />

the event would also be unveiled,<br />

which would form a part of a touring<br />

exhibition on the theme ‘Glass in our<br />

Lives’.<br />

Detailed coverage and best entries<br />

will be published in Kanch (Glass)<br />

and Glass Worldwide, preferred<br />

international journal of AIGMF in<br />

association with Kanch (a quarterly<br />

journal of AIGMF).<br />

Lucky 500 entries will be given<br />

a specially designed empty Glass<br />

Bottle made out of recycled glass<br />

(manufactured by Hindustan National<br />

Glass & Industries Ltd., under its<br />

CSR initiative), carrying logos of<br />

International Year of Glass 2022 and<br />

Swachh Bharat Abhiyaan (Clean India<br />

Campaign).<br />

The winning entries can be<br />

viewed at www.aigmf.com<br />

Email: info@aigmf.com<br />

Website: www.aigmf.com<br />

All entrants should be commended<br />

for supporting the initiative and<br />

following a thorough judging process,<br />

I offer sincere congratulations to the<br />

winners,” he added.<br />

“The enthusiasm shown by the<br />

youth through a large participation<br />

highlights the importance of glass in<br />

our daily lives. Not just photographs<br />

but some very good artwork of glass<br />

decorations, paintings were also<br />

submitted by the school children,<br />

emerging out of this interesting<br />

project. AIGMF would sincerely like<br />

to thank the Education departments<br />

of the Delhi government and other<br />

states who helped us connect<br />

with thousands of children on this<br />

educative project,” commented<br />

AIGMF Secretary Mr Vinit Kapur.<br />

A formal award ceremony would<br />

be held parallel to the virtual Annual<br />

General Meeting of the AIGMF on<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 53

Event<br />

Successful premiere<br />

for Glaston<br />

Innovation Days<br />

Several Current & Potential Customers From<br />

Across The World Registered For The Six Sessions<br />

Glaston successfully organized the first-ever Glaston<br />

Innovation Days, a virtual customer event on the latest<br />

innovations and trends in architectural, automotive and<br />

display glass processing from June 16-18.<br />

Several hundreds of Glaston<br />

current and potential customers<br />

from all over the world registered<br />

for the total of six sessions in which<br />

Glaston’s product and industry experts<br />

shared their insights on the latest<br />

developments in glass processing<br />

technologies.<br />

Hosted from a production hall at<br />

Glaston’s premises in Neuhausen-<br />

Hamberg, Germany, two live stream<br />

sessions were run daily: one on the<br />

latest developments in architectural<br />

glass and the other focusing on the<br />

latest news from Glaston’s automotive<br />

and display glass technologies.<br />

Digitalization and automation<br />

In the architectural glass session, the<br />

digitalization of the flat tempering<br />

process was demonstrated with the<br />

latest innovations such as online<br />

fragmentation prediction for every<br />

glass and the white haze detection<br />

54 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Glaston • 2<br />

using Artificial Intelligence (AI).<br />

In addition, integrated lines and<br />

a tempering process autopilot were<br />

introduced. The autopilot reduces the<br />

operator’s influence and offers process<br />

control without parameters. A higher<br />

degree of automation is also on the<br />

agenda for the laminating process and<br />

with the autopilot, the furnace will<br />

learn to achieve the most optimal way<br />

of running instead of operators having<br />

to do adjustments manually.<br />

The trend in flat lamination is a<br />

growing use of structural interlayers<br />

and for that Glaston introduced the<br />

new convection control technology,<br />

offering a significantly wider operating<br />

window even with complex laminates.<br />

For the insulating glass<br />

manufacturing process, the new<br />

arrissing machine MULTI’ARRISSER<br />

was introduced via live demonstration<br />

from the factory floor. Combining edge<br />

arrissing, arrissing of the flat edge<br />

and corner dubbing into one single<br />

machine, the MULTI’ARRISSER<br />

represents the proven cup wheel<br />

technology for homogeneous and<br />

uniform arrissing quality even at the<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 55

Event<br />

beginning and the end with a 5 to 10<br />

times higher lifetime for glass edge<br />

arrissing than any other arrissing<br />

systems.<br />

With a maximum speed of 60<br />

m/min, the MULTI’ARRISSER is<br />

the fastest single-head machine<br />

worldwide.<br />

In addition, the new<br />

CORNER’REFINER for sealed<br />

insulating glass units was<br />

demonstrated, an automatic corner<br />

treatment with spatula system and<br />

corner roll for finishing to reveal<br />

unloading operator from this work.<br />

For swift customer support,<br />

Glaston Virtual Engineer service was<br />

presented with a Glaston specialist<br />

advises and support customer’s<br />

workforce virtually on-site using<br />

mixed reality (MR) headset. The<br />

solution gives cost savings of 10% -<br />

40% per intervention as e.g. no travels<br />

are required.<br />

Highlights of automotive & display<br />

glass session<br />

In the automotive industry, thin glass<br />

applications are a continuing trend.<br />

For thin glass pre-processing Glaston’s<br />

thin glass kit that can be installed as<br />

an upgrade kit on new and existing<br />

cells, was presented.<br />

With significantly improved<br />

performance parameters, the<br />

new HYPERFEX grinding wheels<br />

represents a revolution in edge<br />

grinding, with a holistic view of the<br />

overall process in pre-processing of<br />

glasses for different application areas.<br />

Furthermore, the new automotive<br />

machine generation CHAMP Evo<br />

with two optimization features was<br />

introduced to the audience with the<br />

first being a linear drive instead of the<br />

spindle on the grinding machine for<br />

higher precision and more dynamic<br />

movements, and the other one a<br />

honeycomb table on grinding machine<br />

for higher precision and more<br />

dynamic movements.<br />

Showcasing developments in<br />

Heat Treatment automotive glass<br />

processing showed how Glaston’s<br />

active convection technology improves<br />

the process with coated, printed and<br />

complex glass types and enables faster<br />

heating.<br />

The advantages of the new Matrix<br />

Evo bending furnace, available<br />

with different size and capacity<br />

configurations to reduce cycle times,<br />

was introduced, as well as the new<br />

HTBS bending and tempering system<br />

with the most dense control matrix in<br />

the market to meet the highest quality<br />

standards with bent tempered glass.<br />

Included in the subscription-based<br />

services, the digital upgrade packages<br />

for operator and production support,<br />

the Glaston Insight Automotive<br />

PLUS as well as various Apps were<br />

presented.<br />

About Glaston Corporation<br />

Glaston is the glass processing<br />

industry’s innovative technology<br />

leader supplying equipment, services<br />

and solutions to the architectural,<br />

automotive, solar and appliance<br />

industries. The company also supports<br />

the development of new technologies<br />

integrating intelligence to glass.<br />

Email: info@glaston.net<br />

Website: www.glaston.net<br />

56 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Company News<br />

Naitri Enterprise scales new heights of<br />

success<br />

Has Installed Over 100 Glass Processing Machines, Along With Tempering,<br />

Laminating Lines, In Just 3 Years<br />

Surat-based glass tools supplier Naitri Enterprise is the authorized agent of Guangdong<br />

Fushan Technology Co. Ltd in India since 2018.<br />

Established in 2007, Naitri<br />

Enterprise has now ventured into<br />

glass machine parts like wheels,<br />

drill bits, rubber parts, electric parts<br />

and other accessories.<br />

The company already deals in glass<br />

processing tools like glass cutting, glass<br />

polishing and glass designing materials,<br />

and provides installation and after-sales<br />

service.<br />

It has been a Guangdong Fushan<br />

authorised agent since 2018, and has<br />

already installed more than 100 sets of<br />

glass processing machines along with<br />

tempering and laminating lines.<br />

Initially, Naitri Enterprise began<br />

its journey with supply of all kinds of<br />

indigenous and imported glass tools and<br />

glass machinery accessories. It offered<br />

its customers a full range of products,<br />

including glass cutters, wheel cutters,<br />

glass drill bits, pliers, polishing belts,<br />

grinding wheels, UV glue, UV light,<br />

glass etching sticker rolls, design books,<br />

glass bevel clusters in various sizes and<br />

colours, t-cutters, glass vacuum lifters<br />

and all kinds of glass cutting, polishing<br />

and designing material.<br />

It also dealt in glass machinery<br />

accessories like diamond wheels, resin<br />

wheels and polishing wheels etc. with<br />

other glass machine accessories.<br />

Its sales network covers many cities<br />

in India. Its customer relationship<br />

is based on commitment, mutual<br />

trust, openness and co-evolution. The<br />

firm knows its customers’ needs and<br />

responds to them quickly. It also offers<br />

new product training services.<br />

Naitri Enterprise firm was founded<br />

by Mr Suresh Patel, Mr Vipul Patel<br />

and Mr Bhavesh Sheta jointly. Their<br />

joint efforts have paid them well with<br />

the result that this firm is well known<br />

across the country for its high quality<br />

products.<br />

Email: bsheta@yahoo.com,<br />

info@naitriglasstools.com<br />

Website: www.naitriglasstools.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 57

Company News<br />

Bharat Safety Glass<br />

forays into architectural<br />

glass processing<br />

Invests Heavily In Machinery For New Venture,<br />

Sets Up Unit In Jamshedpur<br />

Safety glass manufacturer Bharat Safety Glass Pvt Ltd<br />

recently ventured into architectural glass processing.<br />

soon.<br />

The company organised puja for<br />

the new venture on <strong>July</strong> 16, <strong>2021</strong>.<br />

Bharat Safety Glass had started its<br />

safety glass business in 1988. Initially,<br />

it had vertical toughened glass plant<br />

setup for the automotive industry.<br />

The company imported a laminated<br />

machine from world famous brand<br />

Tamglass (Finland) in 1998.<br />

After its installation, the company<br />

started to supply automotive glass as<br />

OEM to Tata Motors, Bajaj, Mahindra,<br />

Hindustan Motors and many more.<br />

BSG then set up a horizontal<br />

flat and bend furnace of LandGlass<br />

(China) in 2012. The company got the<br />

furnace customised from LandGlass<br />

to produce the best quality automotive<br />

glass. Along with CNC cutting<br />

machine from Intermac, BSG also<br />

installed a CNC work station from the<br />

same company.<br />

BSG Managing Director Tulsi<br />

Ram Bhalotia is known as very a<br />

caring and down-to-earth individual<br />

in the industry. Since long, he has<br />

taken utmost care of every employee<br />

of the company, treating them as<br />

family members. He provides them<br />

accommodation, food, all type of<br />

medical facility, among others.<br />

Even amid the crises posed by the<br />

COVID-19 pandemic, the company<br />

stood firmly with its employees, as a<br />

result of which no one has left the<br />

company since joining. This type of<br />

example is very rare for any industry.<br />

Bharat Safety, a well-known<br />

entity in the automotive glass<br />

segment, recently invested<br />

heavily in machinery for architectural<br />

glass processing, setting up a new unit<br />

in Jamshedpur, Jharkhand.<br />

The new setup is equipped with<br />

the latest force convection tempering<br />

furnace which is capable of tempering<br />

9*16 feet jumbo size glass. It can<br />

temper all types of high performance<br />

glass available in the country.<br />

It also has a jumbo size CNC<br />

cutting line sourced from Intermac, a<br />

double-edger for fast pre-processing<br />

of glass, and the company has ordered<br />

a high quality DGU (insulating)<br />

machine which will be installed very<br />

58 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Bharat Safety Glass• 2<br />

Mr. Tulsi Ram Bhalotia,<br />

Managing Director of BSG<br />

Mr Bhalotia is has very rich<br />

technical expertise and knowledge. He<br />

had built an autoclave by himself. At<br />

that time, people doubted its efficacy,<br />

the autoclave is working even today<br />

without any trouble. He also designed<br />

and made from scratch his clean room<br />

for lamination at a very low cost.<br />

Technical Director Kartar Verma<br />

first met Mr Bhalotia in 2006, and<br />

they became good friends. Since<br />

joining BSG, Mr Verma brought with<br />

him his immense technical expertise<br />

which provided a massive boost to the<br />

Mr. Kartar Verma,<br />

Technical Director of BSG<br />

company.<br />

During the Covid lockdown, even<br />

though machines import was going<br />

on but the lack of international travel<br />

meant technicians and installation<br />

executives were unavailable. But Mr<br />

Verma intervened to prevent any delay<br />

and himself guided the installation<br />

process of all new machinery without<br />

any trouble.<br />

BSG’s product portfolio includes<br />

fused glass, decorative glass and<br />

high-performance architectural and<br />

automotive safety glass, kiln formed<br />

glass, fused glass, insulated glass,<br />

laminated glass, fire-proof glass,<br />

bullet-proof glass, reflective glass,<br />

ceramic fritted glass, tempered glass,<br />

low-E glass and so on.<br />

Bharat Safety Glass Pvt Ltd is<br />

known as a leading solution partner<br />

in the glass processing industry for<br />

tempered, laminated safety and<br />

designer glass. It is an ISO 9001:2008,<br />

ARAI, AIS-037, and E-certified<br />

company.<br />

It employs the latest glass<br />

processing technology equipped<br />

with CNC (CAD-CAM) glass cutting<br />

machine for accurate profile cutting<br />

and diamond edging, horizontal glass<br />

bending and flat glass toughening<br />

and laminating with force convection<br />

technology.<br />

Email: bsgpl_glass@hotmail.com<br />

Website: www.bharatsafetyglass.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 59

Company News<br />

Vulcan Intelligent Tempering Line:<br />

latest smart furnace from Jinglass<br />

Firm Has Team In India For Installation & After-Sales Service, Avoiding<br />

Problems Faced Due To Lockdown<br />

The Vulcan Intelligent Tempering line recognizes glass and layouts, matches processing<br />

settings from the cloud, and processes the glass, eliminating human errors entirely and<br />

cutting operational costs.<br />

Jinglass developed Vulcan, an<br />

intelligent glass tempering<br />

furnace in 2020, which improves<br />

the quality of tempered glass,<br />

especially in terms of flatness, stress<br />

eveness and optical quality.<br />

The latest Vulcan Intelligent<br />

Tempering line, a Glass Industry 4.0<br />

product, recognizes glass and layouts,<br />

matches processing settings from the<br />

cloud , processes the glass, and also<br />

traces the quality, power consumption<br />

and loss of productions.<br />

It eliminates human errors entirely,<br />

rendering glass processing enjoying<br />

and relaxing.<br />

The characteristics of the smart<br />

control system include:<br />

Huge database, automatic recipe<br />

setting, frees the operator.<br />

Recipe database keeps upgrading,<br />

providing higher tempering flatness,<br />

surface pressure evenness, and<br />

optical quality.<br />

All processing data saved in cloud<br />

can be traced back even after glass is<br />

delivered.<br />

Detailed database; managing<br />

required diagram becomes easy, and<br />

with the help of iTemper app, clients<br />

can easily get online support from<br />

Jinglass professional technical team.<br />

Can be upgraded for borosilicate<br />

4.0 glass and high pressure fireresistant<br />

glass tempering.<br />

Jinglass mid-infrared jet-convection<br />

60 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Jinglass• 2<br />

glass tempering furnace was warmly<br />

welcomed by the market once it was<br />

promoted in 2012. The mid-infrared<br />

heating technology rapidly became the<br />

best solution for high quality Low-E<br />

glass tempering.<br />

Jinglass in India<br />

Jinglass entered the Indian market in<br />

2015 and gained the confidence from<br />

more and more clients in the country.<br />

At present, more than 30 furnaces<br />

from the company are running<br />

steadily and reliably in here.<br />

During the COVID-19 pandemic,<br />

conduct of business became difficult<br />

in India due to the lockdowns. In the<br />

Indian flat glass market, maximum<br />

machinery is imported from China.<br />

And since international travel is<br />

prohibited because of the lockdown,<br />

installation of machinery became a<br />

huge problem.<br />

But not for Jinglass. The company<br />

has a team in India which provides<br />

professional installation, adjustment<br />

and after-sales service of tempering<br />

furnace to ensure their long-term<br />

stable running.<br />

This was an advantage Jinglass had.<br />

It has installed a record 14 furnaces<br />

since January 2020 in comparison<br />

with any other international<br />

toughened plant machinery supplier.<br />

Jinglass won the trust and<br />

confidence of the Indian glass<br />

processing industry within a very<br />

short span of time by supplying best<br />

quality machines and giving worldclass<br />

after-sales and service support to<br />

its customers.<br />

About the company<br />

Jinglass Technology Co. Ltd. is a<br />

high-tech enterprise specialised in<br />

the development, manufacturing and<br />

marketing of glass tempering furnaces<br />

since 2003.<br />

Email: young@jinglass.com<br />

Website: http://en.jinglass.com<br />

Facebook: JinGlass Machinery Co., LTD<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 61

Company News<br />

Clearstone Glass sets up new unit in<br />

Siliguri, West Bengal<br />

Equipped With World-Class Fully Automated Machinery With The Latest<br />

European Technology<br />

Clearstone’s new unit is located strategically to cater to the entire eastern Indian region,<br />

and the neighbouring countries of Bhutan, Nepal and Bangladesh.<br />

Mr. Raj Kumar Agarwal,<br />

Director<br />

Clearstone Glass, one of the<br />

fastest growing glass companies<br />

of eastern India, sets up the<br />

most technologically advanced and<br />

state-of-the-art glass processing unit<br />

for manufacturing toughened glass,<br />

heat strengthened glass, insulated<br />

glass, laminated glass and decorative<br />

glass.<br />

The unit has a well-planned layout<br />

for machines and working space for<br />

minimum handling of glass during<br />

movement from one section to<br />

another.<br />

The plant also has complete DG<br />

power backup setup.<br />

It is completely equipped<br />

with a reverse osmosis (RO) and<br />

demineralisation water (DM) plant<br />

specially designed for handling high<br />

performance coater glasses.<br />

Specially planned for high<br />

performance glasses, the<br />

unit boasts of world-class<br />

fully automated machinery<br />

with the latest European<br />

technology:<br />

;;<br />

Cutting line with 4 station Automatic<br />

loader from Yinrui.<br />

;;<br />

Automatic Double edger from Hongda.<br />

;;<br />

Fabrication machines from Foshan<br />

Global.<br />

;;<br />

Glass Washing machine from Junya –<br />

designed for High Performance Glass.<br />

;;<br />

Jumbo Glass tempering furnace from Jin<br />

Glass - Latest Convection technology.<br />

;;<br />

Insulating line from Weili with<br />

Automatic Argon Gas filling.<br />

;;<br />

Lamination line from Fanding<br />

Technology.<br />

62 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Clearstone Glass Industry• 2<br />

Mr. Anup Goyal,<br />

Managing Director<br />

Mr. Lalit Kumar Agarwal, Director<br />

Mr. Jaydeep Agarwal, Director<br />

Very strategically located in Siliguri<br />

– the chicken’s neck connecting the<br />

north eastern states – will be catering<br />

to the entire eastern Indian region,<br />

along with the neighbouring countries<br />

of Bhutan, Nepal and Bangladesh.<br />

"We have planned and designed<br />

this plant in such a way that we<br />

can handle the most sensitive high<br />

performance coater glasses with much<br />

ease and perfection," Clearstone Glass<br />

GM Bimal Dubey said.<br />

The company is headed by its<br />

directors – Mr Raj Kumar Agarwal,<br />

Mr Lalit Agarwal, Mr Anup Goyal<br />

and Mr Jaydeep Agarwal. In addition,<br />

the company has a very experienced<br />

and professional team with a<br />

proven record of experience in glass<br />

processing.<br />

“Very rapid development and<br />

innovation is happening in the glass<br />

industry worldwide, our vision is to<br />

manufacture the best quality glasses<br />

and innovative glass products in<br />

India along with creating awareness<br />

regarding use of safety glasses,” said<br />

Anup Goyal, the young and dynamic<br />

managing director of Clearstone<br />

Glass.<br />

In a built-up area of over 45,000<br />

sq ft, the plant has been established<br />

with a vision of future expansion and<br />

growth with a few advanced machines<br />

lined up for future growth.<br />

The international standards<br />

of quality followed by Clearstone<br />

Glass is as follows:<br />

;;<br />

Tempered: en12150<br />

;;<br />

HS: en18<strong>63</strong><br />

;;<br />

Insulated: en1279<br />

;;<br />

Laminated: en12543<br />

;;<br />

Coated Glass: en 1096<br />

;;<br />

Fully equipped with BIS<br />

standard quality and testing lab.<br />

Email: admin@clearstoneglass.com<br />

Website: www.clearstoneglass.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> <strong>63</strong>

Company News<br />

WERU & LiSEC: Decades<br />

of success based on deep<br />

trust<br />

A History Rich In Experience, Sustainable<br />

Thinking & Attitude Of Never Being Satisfied With<br />

Standards Achieved<br />

WERU, a traditional German company that started out as<br />

a carpenter’s workshop, is the oldest window production<br />

factory in the country. The WERU GROUP’s more than<br />

1,000 employees produce over 400,000 sashes and<br />

around 10,000 front doors every year.<br />

Behind WERU’s success<br />

lies a history that is rich in<br />

experience, sustainable thinking<br />

and the attitude of never being<br />

satisfied with the standards achieved.<br />

WERU performs continuous quality<br />

assurance from production to<br />

installation, certified by the RAL<br />

Quality Mark. Production takes place<br />

at the three German locations in<br />

Rudersberg (Baden-Württemberg),<br />

Triptis (Thuringia) and Salmtal<br />

(Rhineland-Palatinate).<br />

WERU quality made exclusively in<br />

Germany<br />

WERU GmbH is one of Europe’s<br />

leading manufacturers of windows<br />

and front doors and can reflect back<br />

on a success story of over 175 years.<br />

WERU was founded in 1843 and<br />

the product portfolio was expanded<br />

through the merger with UNILUX<br />

GmbH in 2014, to include wood and<br />

wood-aluminium products and create<br />

a comprehensive full range.<br />

Behind the success of the<br />

64 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

LiSEC • 2<br />

companies lies a history that is rich in<br />

experience, sustainable thinking and<br />

the attitude of never being satisfied<br />

with the standards achieved. Today,<br />

the WERU Group positions itself<br />

as a future-oriented company that<br />

demands maximum individuality.<br />

Modern windows, large lift-slide<br />

combinations, front doors in all<br />

material variants bring dynamics to<br />

the home and in doing so enrich both<br />

the façade as well as personal life.<br />

WERU & LiSEC<br />

WERU distinctly positions itself as a<br />

complete solution provider. True to<br />

the motto: Everything from a single<br />

source. With LiSEC as a long-standing<br />

business partner, the decision was<br />

made in favour of a company with the<br />

same objective.<br />

The cooperation between WERU<br />

and LiSEC began when WERU<br />

started to manufacture insulating<br />

glass. At that time (and still today),<br />

LiSEC was the only company on the<br />

market to offer complete systems,<br />

from glass cutting to logistics,<br />

including its own LiSEC software.<br />

“Business is always conducted<br />

between people. When two<br />

strong brands come together for a<br />

joint project, this means mutual<br />

professional planning and concept<br />

design, clean implementation by<br />

both parties, and the pleasure of<br />

being successful together,” said<br />

Clemens Macarei, head of Product<br />

Management at LiSEC and point of<br />

contact for WERU for decades.<br />

Trust as the basis for purchasing<br />

decisions: WERU continues to invest<br />

in LiSEC systems<br />

In 2020, a new high-performance<br />

machine for automatic laminated<br />

glass cutting was put into operation:<br />

the VSL-A. Following WERU’s<br />

decision to invest further in the<br />

laminated safety glass (LSG) sector,<br />

the decision was very quickly made<br />

in favour of a LiSEC system. The<br />

purchase was made directly at the<br />

trade fair.<br />

“Data, facts and figures were very<br />

important to us, in particular the<br />

issue of material savings and how<br />

the system adds up, in other words<br />

the profitability. The confidence that<br />

the machine would be a success was<br />

very high, thanks to our experience of<br />

outstanding cooperation with LiSEC<br />

in the past,” says Jens Reimann.<br />

VSL-A: High-performance system for<br />

automatic laminated glass cutting<br />

The VSL-A combines state-of-the-art<br />

laminated glass cutting technology<br />

and decades of LiSEC know-how in<br />

automatic laminated glass processing.<br />

Depending on the optimisation, up to<br />

30 per cent higher cutting capacities<br />

are possible. Automatic rotation of<br />

the sub-plates is part of the standard<br />

equipment, as is automatic residual<br />

cut disposal, and reduces operator<br />

intervention to a minimum. In<br />

addition, two cutting heads ensure an<br />

automatic tool change.<br />

WERU places great value on<br />

sustainability<br />

The topic of sustainability is very<br />

important to WERU. The traditional<br />

company focuses on sustainable<br />

production and material processes,<br />

as well as smart, future-oriented<br />

products. Not only when it comes to<br />

glass, but across the entire production<br />

process. The VSL-A supports this<br />

by reducing glass consumption. On<br />

average, 6 % glass consumption can<br />

be saved by the VSL-A.<br />

Future prospects: Mutual further<br />

development of LiSEC & WERU to<br />

continue<br />

“Our cooperation with WERU is<br />

characterised by a strong sense of<br />

partnership. Both companies benefit<br />

from the advantages of the other and<br />

further develop together,” says Markus<br />

Ensafi, LiSEC Sales Manager.<br />

About LiSEC<br />

LiSEC, with headquarters in<br />

Hausmening/Amstetten, is a globally<br />

operating group, and has been offering<br />

individual and complete solutions in<br />

the field of flat glass processing and<br />

finishing for 60 years. The service<br />

portfolio comprises machines,<br />

automation solutions and services.<br />

CREATING VISIONS, PROVIDING SOLUTIONS.<br />

–Claudia Guschlbauer<br />

Email: claudia.guschlbauer@lisec.com<br />

Website: www.lisec.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 65

Company News<br />

Intermac India: Italian<br />

technology now at your<br />

doorsteps<br />

Its Range Of Cutting Tables For Float Glass Is Ideal<br />

For Integration Into Glass Cutting Lines Across All<br />

Sizes<br />

Achieving yet another remarkable milestone, Intermac<br />

is now manufacturing state-of-the-art glass processing<br />

machines with the same Italian quality workmanship and<br />

precision at Biesse India’s Bengaluru facility.<br />

Having launched the first-ever<br />

glass-processing machine<br />

range manufactured in India:<br />

the Genius 38 and 61 CT-A Tech Glass<br />

Cutting tables, makes Biesse India the<br />

first and only manufacturer in India<br />

to locally produce and export this<br />

technology.<br />

Intermac’s range of cutting tables<br />

for float glass is ideal for integration<br />

into glass cutting lines across all size<br />

businesses. Intermac is a 35-year-old<br />

division of Biesse Group that handles<br />

the production and sale of machinery<br />

for processing glass, stone and metal,<br />

catering to a plethora of industries<br />

from construction to interior design<br />

and from automotive industry to<br />

aviation. It also offers attentive,<br />

personalised assistance to customers,<br />

from pre-sales consultation to postsales<br />

and spare parts services.<br />

Intermac offers technical expertise<br />

and benefits from a large network<br />

that comes with the global industrial<br />

leadership of the Biesse Group. Since<br />

1969, the Group has been designing,<br />

manufacturing and distributing<br />

66 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Intermac • 2<br />

machines, integrated systems and<br />

software to process wood, advanced<br />

material, glass, stone, and metal.<br />

Biesse’s investment in India has<br />

reached a whopping €20 million over<br />

the last decade to better serve our<br />

customers. Today the subsidiary has a<br />

headcount of more than 700+ highskilled<br />

employees and comprises two<br />

plants at Nelamangala and Makali that<br />

are spread over a sprawling 30,000+<br />

square meters, equipped with the<br />

most advanced minds, machinery and<br />

manpower to design and manufacture<br />

cutting-edge technology.<br />

Intermac machines, now being<br />

manufactured at the Bengaluru<br />

facility of Biesse India, are all set to<br />

fulfil and go beyond all its customers’<br />

needs!<br />

The main driving force for Biesse<br />

India has always been the care for<br />

customers. Biesse India identifies<br />

quality, product value and customer<br />

service as being essential for achieving<br />

utmost customer satisfaction.<br />

–Santosh B Holeyachi<br />

Email: santosh.bh@biessemnfg.com<br />

Website: www.intermac.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 67

Company News<br />

Şişecam reported investments of<br />

TRY 838 million in first half of <strong>2021</strong><br />

Company’s Net Sales Have Reached TRY 13 Billion In The First Half Of<br />

The Year<br />

International sales accounted for 64 per cent of Şişecam’s total sales during this period.<br />

Capital expenditures were recorded at TRY 838 million and exports reached USD 327<br />

million in the first half of the year.<br />

A<br />

global player in the glass and<br />

chemicals industries with<br />

production activities spanning<br />

14 countries in four continents and<br />

with sales to more than 150 countries,<br />

Şişecam reported consolidated net<br />

sales of TRY 13 billion for the six<br />

months ending June <strong>2021</strong>.<br />

Şişecam CEO Görkem Elverici<br />

commented on the company’s<br />

results: “Despite the climate of<br />

uncertainty caused by the pandemic,<br />

Şişecam delivered a strong financial<br />

performance in the first half of the<br />

year, exceeding its performance in the<br />

same period of the previous year.”<br />

“Şişecam continued to create value<br />

for its stakeholders with its proactive<br />

decisions and practices that generate<br />

value for its entire ecosystem. In the<br />

coming period, we aim to continue<br />

moving forward toward our global<br />

goals. We plan to take the next steps<br />

on our sustainable growth journey<br />

with our transformation projects that<br />

will render Şişecam future-ready,<br />

our investment plans, and our robust<br />

governance capabilities,” Elverici said.<br />

Şişecam’s <strong>2021</strong> first half-year<br />

consolidated net sales grossed TRY 13<br />

billion and international sales of the<br />

company – comprising exports from<br />

Turkey and sales from non-Turkey<br />

facilities – accounted for 64 per cent<br />

of total revenue.<br />

In the first half of the year,<br />

Şişecam produced 2.7 million tons<br />

of glass, 1.2 million tons of soda,<br />

and 2.5 million tons of industrial<br />

raw materials. During this period,<br />

thanks to its proactive decisions and<br />

practices that generate value for its<br />

entire ecosystem, Şişecam achieved a<br />

strong half-year financial performance<br />

exceeding the same period of the<br />

previous year, the era just prior to and<br />

at the start of the pandemic.<br />

As evidenced by the solid results it<br />

recorded in the first half of the year,<br />

Şişecam once again demonstrated<br />

its strong corporate governance<br />

capabilities by achieving a financial<br />

performance that also exceeded<br />

the same period of 2019, the prepandemic<br />

period.<br />

Despite the climate of uncertainty<br />

caused by the pandemic, the<br />

company delivered a strong financial<br />

performance.<br />

In his statement on the financial<br />

results, Şişecam CEO Elverici<br />

indicated that the company created<br />

sustainable value for its entire<br />

ecosystem in the first half of <strong>2021</strong>, a<br />

time when global pandemic-rooted<br />

extraordinary conditions sustained<br />

and in a climate marked by ongoing<br />

uncertainty.<br />

He added: “With consolidated<br />

net sales totalling TRY 13 billion in<br />

the first half of the year, we further<br />

contributed to the macro economy<br />

and the growth of anchor industries<br />

to which we provide input with<br />

our products, investments, and<br />

employment opportunities. Şişecam<br />

successfully reached its ambitious<br />

targets in the first half of the year<br />

thanks to its robust corporate<br />

governance capabilities and agile<br />

practices. Moreover, it delivered<br />

a strong financial performance,<br />

exceeding that of the previous<br />

year which coincided with the prepandemic<br />

period. Şişecam recorded<br />

financial success that surpassed<br />

not only the same period of the<br />

previous year but also the half-year<br />

results of 2019, which refers prior<br />

to the outbreak of the pandemic.<br />

We will continue to conduct our<br />

business activities by leveraging our<br />

robust competencies and agility. At<br />

Şişecam, we aim to create value for<br />

all our stakeholders by modifying<br />

our business processes and plans<br />

as needed in the coming period, for<br />

which the extent of the impact of the<br />

global pandemic remains uncertain.”<br />

Thanks to the company’s functionbased<br />

governance model, it will<br />

more effectively manage its business<br />

operations across four continents, the<br />

CEO said.<br />

In its 85th anniversary year,<br />

Şişecam made one of the most<br />

important decisions in its history:<br />

To merge all of its business activities<br />

under a single roof.<br />

Görkem Elverici stated the<br />

following about the transformation<br />

initiatives that Şişecam has designed<br />

to better prepare itself for the future:<br />

“We have successfully completed<br />

the merger process. This large-scale<br />

consolidation was a crucial turning<br />

point in terms of our long-term<br />

strategies and competitive targets<br />

in global markets. Immediately<br />

afterwards, we focused on<br />

implementing transformation projects<br />

aimed at creating a more integrated,<br />

digital, optimized, operationally<br />

efficient organizational structure and<br />

building Şişecam of the future.”<br />

“To this end, we made a strategic<br />

decision to introduce significant<br />

changes to our governance model.<br />

At Şişecam, different business fields<br />

68 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Şişecam• 2<br />

– such as glass packaging, glassware<br />

and chemicals – were formerly<br />

managed independently within a<br />

field of activity-based organizational<br />

structure. Now, we have a functionbased<br />

organization and management<br />

approach,” he said.<br />

“As a result, we no longer manage<br />

our business processes on a business<br />

line-basis, but rather based on<br />

functions, such as Sales-Marketing<br />

or Production. I firmly believe that<br />

our new organizational structure<br />

will ensure more effective and agile<br />

management across our region of<br />

operation spanning four continents<br />

in various lines of business. The<br />

experience and competencies we have<br />

gained with a focus on product groups<br />

will further expand Şişecam domain<br />

of influence,” Elverici added.<br />

Reaping rewards of strategic<br />

decisions and best practices<br />

Elverici stated that Şişecam is<br />

currently reaping the rewards of its<br />

Mr. Görkem Elverici, CEO of Şişecam<br />

transformation efforts, digitalization<br />

practices, and strategic decisions<br />

during a time when business models<br />

have changed profoundly due to the<br />

global pandemic.<br />

He elaborated: “As a result of the<br />

challenges accompanying it, the global<br />

pandemic offered organizations an<br />

opportunity to test their decisions<br />

and practices and revamp their<br />

structure to align with the new<br />

market conditions. During this period,<br />

Şişecam also had the opportunity<br />

to test once again its readiness for<br />

the unanticipated developments, its<br />

ability to make fast decisions, and<br />

adaptability skills.”<br />

“The successful projects and<br />

competencies we developed on<br />

our digitalization journey played a<br />

critical role in managing this process<br />

effectively. In addition, our strategic<br />

positioning with respect to our<br />

production activities spread across 14<br />

countries on four continents enabled<br />

us to navigate the negative effects<br />

of the disrupted global supply chain<br />

much more easily. In the coming<br />

period, we plan to further boost the<br />

economic value we generate and<br />

our global competitive edge with<br />

investments and projects that will<br />

prepare Şişecam for the future,” the<br />

CEO said.<br />

Creating value for stakeholders with<br />

new investments<br />

Şişecam, the founder of the Turkish<br />

glass industry and a global pioneer,<br />

remains committed to making<br />

uninterrupted investments that will<br />

create value for all of its stakeholders<br />

and supporting the growth of the<br />

industries to which it provides input.<br />

Elverici added: “Despite<br />

the climate of uncertainty and<br />

extraordinary conditions created by<br />

the global pandemic, we continued<br />

our investments without interruption<br />

in line with our priority to meet our<br />

customers’ glass demand and to<br />

create value for the economies.”<br />

“In the coming period, we aim<br />

to create sustainable value for<br />

our stakeholders while expanding<br />

Şişecam’s global footprint with<br />

strategic moves we will make in<br />

the right areas by continuing our<br />

investments with the same approach.<br />

As part of these efforts, we announced<br />

that start of our first European<br />

facility investment in glass packaging<br />

industry, in Hungary,” he said.<br />

“We expect this greenfield facility<br />

investment with a capacity of 330,000<br />

tons to be online 2023 and to reach<br />

its full capacity by the year-end<br />

2025. Capital expenditures focusing<br />

on increasing our existing 2 million<br />

ton flat glass production capacity<br />

in Turkey by 25 percent are also<br />

underway. We expect to achieve this<br />

goal by both improving our existing<br />

lines and investing in two new float<br />

lines,” the CEO added.<br />

Email: baharyasli@lobby-pr.com<br />

Website: www.sisecam.com<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 69

Company News<br />

Ground-breaking ceremony for the new headquarters of ISRA VISION AG in Darmstadt.<br />

(From left, CFO Martin Heinrich, mayor Jochen Partsch, company founder Enis Ersü, CEO Tomas Lundin, architect Gregor Kahlau)<br />

ISRA VISION begins construction<br />

of new HQ<br />

Company Marks Dawn Of New Era With Traditional Ground-Breaking<br />

Ceremony In Darmstadt, Germany<br />

More than three decades ago, ISRA VISION was founded as a spin-off of TU Darmstadt<br />

and developed into a world-leading machine vision technology company in the<br />

subsequent years.<br />

The founder and CEO of ISRA<br />

VISION, Enis Ersü, stepped<br />

back from active professional<br />

life at the end of June <strong>2021</strong>. As<br />

part of the company’s succession<br />

planning, ISRA VISION entered into a<br />

strategic partnership with the Swedish<br />

industrial group Atlas Copco, forming<br />

the heart of the new Machine Vision<br />

Solutions division. With a strong new<br />

management team, the foundations<br />

are now being laid for the successful<br />

future development of the company.<br />

ISRA VISION AG is marking the<br />

dawn of a new era of growth with a<br />

traditional ground-breaking ceremony<br />

to mark the start of construction<br />

of its new headquarters building in<br />

Darmstadt, Germany.<br />

The new headquarters is located on<br />

a property measuring around 15,000<br />

square metres in the city’s “Knell”<br />

development district with its historic<br />

water tower at Frankfurter Straße. Set<br />

to be constructed in two stages, it will<br />

consist of three connected buildings<br />

housing offices and development<br />

laboratories, as well as demonstration<br />

and assembly halls.<br />

The project was designed by the<br />

local architecture firm fs Architekten.<br />

It will give ISRA VISION the space<br />

it needs for future development<br />

and a constantly growing workforce.<br />

Designed to the latest energy<br />

standards, the building will grow over<br />

time and will offer space for around<br />

960 employees once fully constructed.<br />

As construction begins, the<br />

company owes special thanks to<br />

the mayor of Darmstadt Jochen<br />

Partsch and the city of Darmstadt,<br />

who provided excellent support in<br />

the search for a suitable location.<br />

The plans for the new headquarters<br />

were put in place several years ago<br />

by company founder Enis Ersü,<br />

who recently retired from active<br />

professional life.<br />

In 2020, the globally active Atlas<br />

Copco group joined forces with ISRA<br />

VISION as a strategic partner, while<br />

also remaining committed to the<br />

plans for the new headquarters. The<br />

70 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

ISRA VISION• 2<br />

What it will look like: the new company headquarters of ISRA VISION AG in Darmstadt.<br />

preliminary work was done with the<br />

help of Felix Schneider from Gerhard.<br />

Architekten in Darmstadt and Horst<br />

Ulrich Werb on behalf of Schindler<br />

& Werb AG, allowing the foundation<br />

stone of the new building to be placed<br />

together with the planners and<br />

tradespeople involved in the project.<br />

ISRA VISION’s new chairman of<br />

the Executive Management Team,<br />

Tomas Lundin, was joined for the<br />

ceremony by company founder Enis<br />

Ersü, Chief Financial Officer Martin<br />

Heinrich and Mayor of Darmstadt<br />

Jochen Partsch.<br />

The start of construction of the<br />

new headquarters represents not only<br />

the beginning of a new chapter in the<br />

company’s history, but is also a sign<br />

of its dedication to the city and the<br />

local area. ISRA VISION was formed<br />

in 1985 as a spin-off of the Technical<br />

University of Darmstadt. Together<br />

with its subsidiaries, ISRA VISION AG<br />

has grown to become the world leader<br />

in surface inspection of web materials.<br />

It is also one of the world’s leading<br />

providers of image processing<br />

(machine vision), specializing in 3D<br />

machine vision, especially for 3D robot<br />

vision. With its new strategic partner<br />

Atlas Copco, the ambitious company<br />

has big plans. The ground-breaking<br />

ceremony is therefore also the start of<br />

a promising and successful future.<br />

Despite its status as a global<br />

More space for ISRA VISION AG: New headquarters in Darmstadt<br />

with 960 workspaces.<br />

Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong> 71

Company News<br />

High-tech and sustainable: ISRA VISION AG is building its new<br />

headquarters in Darmstadt in keeping with ecological principles.<br />

player, ISRA feels right at home<br />

in Darmstadt. The company has<br />

maintained close relations with<br />

the Technical University and the<br />

Darmstadt University of Applied<br />

Sciences, along with other research<br />

institutions like the Fraunhofer<br />

Institute.<br />

The start of construction also<br />

helps ISRA VISION position itself<br />

as an employer with an exciting<br />

future in the region, creating the best<br />

conditions to promote young talent.<br />

The new site is set to create countless<br />

new jobs, with the company looking<br />

for both fully trained specialists and<br />

talented youngsters in particular.<br />

Alongside this, consideration is also<br />

being given to providing a home and<br />

space to develop for start-ups that<br />

represent a good technological match<br />

for ISRA VISION at the premises.<br />

For staff, the building will provide<br />

an inspiring work environment that is<br />

in harmony with the company’s values<br />

and responds to ecological challenges.<br />

Designed with environmental<br />

protection in mind, the headquarters<br />

will be built in line with the<br />

Effizienzhaus 55 standards (an energy<br />

standard for buildings, introduced by<br />

KfW).<br />

It will also feature a high proportion<br />

of green spaces and charging facilities<br />

for electric vehicles and bicycles,<br />

and will be constructed using clean,<br />

low-noise methods. The completion<br />

of the first construction section and<br />

moving in to the new headquarters are<br />

planned for the turn of 2022-2023.<br />

–Nicole Rüffer<br />

Email: nrueffer@isravision.com<br />

Website: www.isravision.com<br />

Construction begins on the ISRA VISION AG headquarters in Darmstadt: Offices,<br />

development labs and demonstration and assembly halls for the growing company.<br />

72 Glass Bulletin | <strong>July</strong> - <strong>September</strong>, <strong>2021</strong>

Company News<br />

Şişecam Neutral 70/37<br />

wins Facade Material of<br />

Year Award 2020<br />

Product Maximizes Energy Savings By Providing<br />

Outstanding Thermal Insulation, Efficient Solar<br />

Control<br />

One of the largest flat glass manufacturers in Europe,<br />

Şişecam Flat Glass continues its R&D and investment<br />

activities without slowing down.<br />

Şişecam offers innovative solutions<br />

to the changing and developing<br />

needs of the market. It received<br />

the “Facade Material of the Year<br />

Award” for the eighth time with its new<br />

product, Şişecam Temperable Solar<br />

Control Low-E Glass Neutral 70/37<br />

which is developed for architectural<br />

category as a result of R&D studies.<br />

With 1.0 U value, Şişecam<br />

Temperable Solar Control Low-E<br />

Glass Neutral 70/37 maximizes energy<br />

savings by providing outstanding<br />

thermal insulation and efficient solar<br />

control.<br />

Neutral 70/37 provides high light<br />

transmittance while reducing the need<br />

for artificial lighting. Also shows all<br />

the details of nature thanks to its low<br />

reflection and transparency.<br />

Neutral 70/37 has also the same<br />

colour and performance in annealed<br />

form that provides solutions for<br />

residential buildings, villas and store<br />

front glazing where transparency and<br />

low reflection are required.<br />

With its outstanding thermal<br />

insulation and solar control<br />

performance, Neutral 70/37 reduces<br />

heat loss and decreases solar energy<br />