Generator_Summer 2021

In the Summer 2021 issue of the Generator magazine: electrical safety on the farm; Reis fabricates equipment for Loup; new electric mower incentive; and tips for saving electricity while doing laundry.

In the Summer 2021 issue of the Generator magazine: electrical safety on the farm; Reis fabricates equipment for Loup; new electric mower incentive; and tips for saving electricity while doing laundry.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

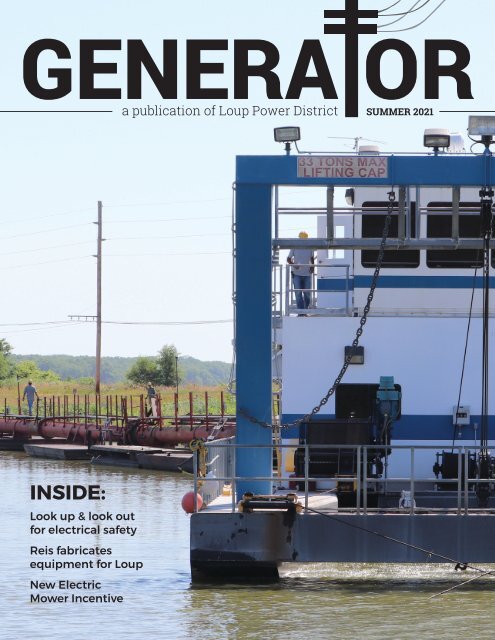

GENERA OR<br />

a publication of Loup Power District SUMMER <strong>2021</strong><br />

INSIDE:<br />

Look up & look out<br />

for electrical safety<br />

Reis fabricates<br />

equipment for Loup<br />

New Electric<br />

Mower Incentive

BOARD OF DIRECTORS<br />

Ross Knott<br />

Chairman<br />

Alan Drozd<br />

First Vice Chairman<br />

Steve Heesacker<br />

Second Vice Chairman<br />

Robert Cerv<br />

Secretary<br />

Dick Tooley<br />

Treasurer<br />

Rich Aerni<br />

Jim Donoghue<br />

Mike Fleming<br />

Chris Langemeier<br />

Larry Zach<br />

EXECUTIVE STAFF<br />

Neal Suess<br />

President/CEO<br />

Walt Williams<br />

Vice President,<br />

Accounting & Finance/CFO<br />

Todd Duren<br />

Vice President,<br />

Corporate Services<br />

Korey Hobza<br />

Vice President, Engineering<br />

Dan Hellbusch<br />

Vice President, Operations<br />

Power Surges & Blinks<br />

Have you ever noticed your lights blink during<br />

a thunderstorm? Or perhaps you’ve noticed a<br />

blinking microwave clock when you arrive home.<br />

When this happens, you’ve likely experienced a<br />

brief disruption to your electric service, which<br />

could result from a power surge or blink.<br />

While the symptoms of surges and blinks can<br />

appear similar, what’s happening behind the<br />

scenes can be quite different.<br />

WHAT’S A POWER SURGE?<br />

Power surges are brief overvoltage<br />

spikes or disturbances<br />

of a power waveform that can<br />

damage, degrade or destroy<br />

electronic equipment within<br />

your home or business.<br />

Most electronics are designed<br />

to handle small variations in<br />

voltage; however, power surges<br />

can reach amplitudes of tens of<br />

thousands of volts — this can<br />

be extremely damaging to your<br />

electronic equipment.<br />

Surges can be caused by<br />

internal sources, like HVAC systems with variable<br />

frequency drives, or external sources, like lightning<br />

and damage to power lines and transformers.<br />

You can install surge protective devices (such<br />

as surge protector power strips) to safeguard<br />

your sensitive electronics. If you’re experiencing<br />

frequent surges in your home or business and you<br />

believe the cause is internal, contact a qualified<br />

electrician to inspect your electrical system.<br />

WHAT’S A POWER BLINK?<br />

Power blinks are also brief service interruptions,<br />

but they’re typically caused by a fault (short<br />

circuit) on a power line or a protective device that’s<br />

working in reaction to the fault.<br />

Faults can occur through a variety<br />

of instances, like squirrels, birds or<br />

other small animals contacting an<br />

energized power line; tree branches<br />

touching a power line; or lightning<br />

and other similar events. In fact,<br />

when it comes to power disruptions<br />

caused by critters, squirrels reign<br />

supreme. In 2019 alone, squirrels<br />

were responsible for more than<br />

1,200 outages.<br />

Any of the events noted above can<br />

cause your power to blink, but you<br />

may also experience a brief interruption<br />

when protective devices<br />

that act like circuit breakers are<br />

working to detect the fault.<br />

Believe it or not, these brief power blinks caused<br />

by protective devices are actually good because<br />

that means the equipment is working as it should<br />

to prevent a prolonged outage.<br />

Regardless of the cause, Loup crews will be on<br />

their way to inspect the damage and make necessary<br />

repairs after a power outage.<br />

The Loup <strong>Generator</strong> is<br />

published quarterly<br />

as a service for Loup<br />

employees, families,<br />

friends and associates.<br />

For feedback, story ideas<br />

and submissions, contact:<br />

Stacy Wemhoff<br />

Communications Coordinator<br />

402-562-5711<br />

swemhoff@loup.com<br />

2 | GENERATOR<br />

COVER: Employees prepare to dock the Pawnee II dredge at the Genoa Headworks.<br />

Dredging at the settling basin halts for part of the summer to protect nesting piping plovers<br />

and interior least terns.

preSIdent’S MessAGe<br />

Loup offers input and insight<br />

to NPPD on several issues<br />

Loup Power District management has been<br />

working with Nebraska Public Power District<br />

(NPPD) — our wholesale supplier of electricity<br />

— on two very different long-term projects.<br />

The first project deals with the effects from the<br />

February <strong>2021</strong> winter weather event. As many<br />

of you are aware, this weather event severely<br />

crippled the Texas electricity grid and created<br />

rolling blackouts throughout the Midwest<br />

United States, including Nebraska and the Loup<br />

Power District service area.<br />

Loup officials have been working with NPPD<br />

management and other wholesale customers<br />

to develop a system in which NPPD will better<br />

inform wholesale customers if this happens<br />

again. The wholesale customers could then<br />

inform retail customers where and when the<br />

outages will occur (as well as the length of the<br />

outages) in the event of a similar event. Obviously,<br />

we all hope a similar event does not occur<br />

again. But if it does, we all want to be better<br />

prepared to give information to those most<br />

affected.<br />

Additionally, Loup Power District is working<br />

internally on systems that can be integrated<br />

with our new automated meter reading<br />

equipment that will provide a better and<br />

more detailed description of areas<br />

affected by outages. More information<br />

will become available as these<br />

systems are developed.<br />

The second project deals with<br />

NPPD’s internal study of carbon<br />

risks associated with their existing<br />

generating facility fleet. This effort<br />

has been ongoing for a couple of years,<br />

as NPPD is trying to determine the<br />

possible long-term effects of<br />

changes in regulation due to<br />

carbon emissions.<br />

Loup management and other<br />

wholesale customers have been<br />

working with the NPPD Board<br />

and management regarding<br />

the study of these risks, as the<br />

federal government mandate on<br />

carbon emissions seems to change at the whim<br />

of whatever administration happens to be in<br />

charge in Washington, D.C.<br />

Because of the ever-moving target on carbon<br />

emissions at the federal level, NPPD has to be<br />

flexible with its plans since energy efficiency<br />

and load growth opportunities, as well as the<br />

retirement of existing resources, can affect the<br />

overall carbon targets. What makes matters<br />

more complicated is the long lead time necessary<br />

for the construction of new generation and<br />

transmission facilities.<br />

Thankfully, NPPD has included wholesale<br />

customers in the discussion and accepted input<br />

to move forward with these two studies. NPPD<br />

values customer input and customers value<br />

providing this input, as it will eventually affect<br />

wholesale and retail rates.<br />

There are similar efforts going on in our<br />

industry, some with NPPD and some without.<br />

We want you to know that the Loup Power<br />

District Board and employees continue to take<br />

an active role in providing input and knowledge<br />

about these decisions that will affect our rates<br />

over the long haul.<br />

NEAL SUESS<br />

President/CEO<br />

SUMMER <strong>2021</strong> | 3

Reis builds concrete<br />

screed from scratch<br />

Jeremy Reis doesn't really need blueprints<br />

or a plan.<br />

When it comes to building something, he<br />

can just see the finished result in his head.<br />

That's exactly what happened when Canal<br />

Foreman Lance Ferris asked if Reis could build<br />

a concrete screed.<br />

“I just got online, looked at a few pictures<br />

here and there and came up with my own<br />

idea,” Reis said.<br />

The resulting product worked exactly as<br />

intended to level and smooth concrete, while<br />

also preventing potential back injuries among<br />

Loup employees.<br />

Ferris said the District was making plans for<br />

several large concrete transformer pads earlier<br />

this year. Because of the size of these pads and<br />

Loup's limited manpower, he thought they<br />

should purchase a large power screed.<br />

That's when Reis said he could build one for<br />

less and got to work. He made everything on<br />

the 14-foot screed himself except the bearings,<br />

engine, and winches.<br />

Cables on each end of the screed hook to<br />

the concrete forms. Employees on each end of<br />

the machine pull it forward with the help of<br />

the cables. The screen vibrates to smooth the<br />

concrete. Employees<br />

can then go over<br />

the concrete with bull floats to smooth it even<br />

more.<br />

"It turned out pretty awesome," Ferris said.<br />

He said Reis also made some new gate<br />

systems for the Columbus Powerhouse and a<br />

special platform for the Monroe Powerhouse.<br />

In fact, he's completed quite a few projects<br />

for Loup — no small feat considering he's been<br />

an employee for less than a year.<br />

"He’s proven himself around here. It’s<br />

great," Ferris said. "He does some very nice<br />

work.”<br />

Fabricating machines and parts is nothing<br />

new at Loup, however.<br />

Loup's employees at the Genoa Headworks<br />

fabricated replacement parts of the Pawnee<br />

dredge for years. That original dredge was built<br />

in 1937 and used for 75 years until a new dredge<br />

was commissioned in 2012.<br />

In the latter years of its use, replacement<br />

parts were no longer available and employees<br />

made their own.<br />

Reis said building and creating is nothing<br />

new to him. "I've built a lot of things like this<br />

over the years," he said.<br />

What is new, however, is the ability to use<br />

those skills more at his job.<br />

"It's what I've always wanted to do," he said.<br />

"I can use my abilities here."<br />

Top and middle right: Reis built the concrete<br />

screed at the Columbus Service Center.<br />

He made the entire project from scratch except<br />

the winches, bearings, and engine.<br />

Bottom right: The screed in use by Loup<br />

employees as they poured a concrete<br />

transformer pad.<br />

4 | GENERATOR

LAUNDRY LIST:<br />

Energy-saving tips<br />

Your clothes washer and dryer account for a significant portion<br />

of energy consumption from major appliances. The good news is<br />

there are several easy ways you can save energy (and money) in the<br />

laundry room.<br />

The Department of Energy recommends the following tips for saving<br />

on suds:<br />

➨ Wash with cold water<br />

Switching from warm water to cold water can cut one load’s energy<br />

use by half. New cold-water detergents ensure laundry gets clean.<br />

➨ Wash full loads<br />

Your washing machine will use the same amount of energy no matter<br />

the size of the clothes load, so fill it up if you can.<br />

➨ Use dryer balls<br />

Dryer balls, usually wool or rubber, will help keep clothes separated<br />

for faster drying, and they can help reduce static, so you can<br />

eliminate dryer sheets.<br />

➨ Lower the heat<br />

Regardless of drying time, you’ll still use less energy.<br />

➨ Use high speed or extended spin cycle<br />

This setting will remove more moisture before drying, reducing<br />

your drying time and the extra wear on clothing.<br />

➨ Switch loads while the dryer is warm<br />

This allows you to take advantage of the remaining heat from the<br />

previous cycle.<br />

➨ Clean the lint filter after each load<br />

And if you use dryer sheets, remember to scrub the filter once a<br />

month with a toothbrush to remove excess buildup that can reduce<br />

air circulation.<br />

➨ Purchase an efficient washers & dryer<br />

When it’s time to purchase a new washer or dryer, look for the<br />

ENERGY STAR ® label. New washers and dryers with that rating use<br />

about 20 percent less energy than conventional models.<br />

Get more energy-saving<br />

tips at the Department<br />

of Energy’s home<br />

efficiency page:<br />

energy.gov/energysaver<br />

➨ Dry heavier cottons separately<br />

Loads will dry faster and more evenly if you separate heavier cottons<br />

like linens and towels from your lightweight clothing.<br />

➨ Use the moisture sensor option<br />

Many new clothes dryers come designed with a<br />

moisture sensor, which automatically shuts<br />

off the machine when clothes are dry.<br />

This will save energy and reduce<br />

wear and tear on your clothes<br />

caused by over-drying<br />

SUMMER <strong>2021</strong> | 5

around the district<br />

TRANSFORMER TRANSFERS<br />

Loup has been busy transferring transformers around the<br />

District this spring and summer.<br />

A new, larger 56 MVA transformer was installed at the<br />

substation near the Columbus Powerhouse in late spring.<br />

This replaced a 37 MVA transformer which was moved to<br />

Schuyler to replace a 28 MVA transformer there. In turn, that<br />

transformer will be moved to Creston later this year and the<br />

Creston transformer will move to Petersburg.<br />

All this work ensures that our communities have transformers<br />

large enough to meet their growing needs.<br />

Right: The smaller 28 MVA transformer north of Schuyler was<br />

moved out using a hydraulic jack and slide system in April.<br />

Transformers are typically moved with cranes, but that’s not<br />

possible at Schuyler due to overhead structures.<br />

Barnhart Crane helped to move the transformers.<br />

The 37 MVA transformer weighed 107,000 pounds.<br />

VEHICLE DAY AT AG PARK<br />

It was a great day for the first graders at Vehicle Day at Ag Park on May 11!<br />

Loup employees Beau Schommer and Tommy Wemhoff described<br />

their jobs as linemen and answered questions about the bucket truck<br />

on display. The event was hosted by the Columbus Area Chamber of<br />

Commerce.<br />

6 | GENERATOR

SETTLING BASIN SUNRISE<br />

John Fritzges shot this sunrise photo at<br />

the Genoa Headworks in May. Fritzges is<br />

a Dredge/Canal Maintenance Technician<br />

for Loup Power District.<br />

ADDING POLES ALONG 38TH STREET<br />

The Columbus crew added extra poles along 38th street just south of the<br />

hospital in May. Decreasing the span between the poles reduces slack in<br />

the lines and reduces the possibility for outages during wind and storms.<br />

The new poles are also five feet taller to help with clearance and slack.<br />

SUMMER <strong>2021</strong> | 7

POWER LINE SAFETY:<br />

look up and look out<br />

A farmer near Columbus hit this power pole<br />

in June and the power lines fell on his tractor.<br />

He is lucky to be alive and uninjured.<br />

Farming equipment has become<br />

larger and more advanced over time.<br />

While these welcome improvements<br />

help farmers cover more ground in<br />

less time, taller equipment and longer<br />

extensions can bring added challenges<br />

around power lines.<br />

Loup urges everyone working in<br />

the agricultural field to be alert to the<br />

dangers of working near overhead<br />

power lines, poles and other electrical<br />

equipment.<br />

CODY CONRADY’S STORY<br />

It was Cody Conrady’s next-to-last<br />

day as an assistant manager for an ag<br />

fertilizer company in Illinois. They were<br />

understaffed that day, and Conrady<br />

jumped in the truck to get ahead of the<br />

sprayer. Once the sprayer was in position,<br />

he hopped out to fill the tank with<br />

fertilizer.<br />

Neither he nor his coworker inside<br />

the cab were aware that the sprayer<br />

boom had either made contact or gotten<br />

too close to a power line.<br />

When 7,400 volts of electricity traveled<br />

through the boom, it electrified the<br />

equipment and ground. Unfortunately,<br />

the unyielding stray voltage considered<br />

his body as part of its electrical path to<br />

ground.<br />

In the minutes and hours that<br />

followed, Conrady was brought back<br />

to life, rushed to a local hospital, and<br />

transferred to a trauma center. That was<br />

the starting point of a very long and<br />

arduous road to recovery that included<br />

surgeries, rehab, and prosthetics.<br />

HINDSIGHT IS 20/20: CODY’S ADVICE<br />

When working near power lines,<br />

“pay attention a little more,” Conrady<br />

advises. “Keep an eye on your<br />

surroundings. Just take an extra second<br />

to look at things, to see how your situation<br />

is going to unfold."<br />

These days, he drives by fields<br />

buzzing with activity and wonders if<br />

others see what he sees — if they realize<br />

the potential dangers of getting too<br />

close to power lines.<br />

His wife, Bailey, says this type of<br />

accident could happen to anyone.<br />

Unintended contact happened in an<br />

instant, but its impact lives on long after<br />

an accident.<br />

“We knew life wasn’t going to be<br />

the same," she said. “We knew that the<br />

‘normal’ before was not going to be the<br />

‘normal’ after.”<br />

FOLLOW THE 10-FOOT DISTANCE RULE<br />

To stay safe around overhead power<br />

lines, follow safe work practices at all<br />

times to help prevent serious and even<br />

deadly accidents.<br />

Start by making sure everyone<br />

knows to maintain a minimum 10-foot<br />

clearance from power lines.<br />

This 10-foot rule applies not only to<br />

the area underneath the power line, but<br />

to the full 360 degrees around it. Electricity<br />

can change paths if direct contact<br />

is made. It can also happen when<br />

someone or something gets too close to<br />

a power line and the current jumps, also<br />

known as arcing.<br />

— from SafeElectricity.org<br />

AG ELECTRICAL SAFETY TIPS<br />

• If your machinery or vehicle comes in contact with<br />

a power line, do not get out of the cab because you<br />

could be electrocuted. Instead, stay where you are<br />

and call 9-1-1 to dispatch the utility to deenergize<br />

the power.<br />

• If it is not safe to stay in the cab due to fire or smoke,<br />

make a solid, clean jump with both feet landing at<br />

the same time. Hop away as far as you can with feet<br />

together.<br />

• If you come across an accident or incident near a<br />

downed power line, alert individuals (from at least<br />

50 feet away) to stay in the cab or vehicle as long<br />

as there is no imminent danger. Stay back and call<br />

9-1-1.<br />

• Teach anyone working with or for you (including<br />

family members and seasonal employees) about<br />

power line awareness and proper clearance<br />

distance.<br />

• When working around power lines, always use a<br />

spotter, who has a broader vantage point than the<br />

person in the cab.<br />

• Visually inspect overhead lines. If a wire is hanging<br />

too low, don’t try to move it. Call your electric utility<br />

for assistance.<br />

• Lower extensions to the lowest setting when<br />

moving loads.<br />

• Simply coming too close to a power line while<br />

working is dangerous as electricity can arc to<br />

conducting material or objects, such as a ladder,<br />

pole, or truck. Remember, non-metallic materials<br />

such as lumber, tree limbs, tires, ropes, and hay will<br />

conduct electricity depending on dampness, dust,<br />

and dirt contamination.<br />

• When guy wires (a grounded wire used to stabilize<br />

utility poles) are broken, these normally neutral<br />

wires can become dangerous. If you hit a guy wire<br />

and break it, stay away and call your utility.<br />

8 | GENERATOR

SUMMER <strong>2021</strong> | 9

employee notes<br />

MATT SWACKHAMER<br />

Supervisor of Information Services<br />

Matt Swackhamer<br />

joined Loup in 2001<br />

as Supervisor of<br />

Information Systems<br />

at the Columbus<br />

General Office and<br />

continues in that<br />

position today.<br />

As Supervisor of<br />

Information Systems<br />

his responsibilities<br />

include managing<br />

all of the District’s<br />

computers and communications<br />

systems.<br />

Swackhamer is a graduate of Bad<br />

Axe High School in Bad Axe, Mich. He<br />

attended Western Michigan University<br />

in Kalamazoo, Mich., where he earned<br />

a Bachelor of Science degree with<br />

a major in Computer Science and a<br />

minor in Mathematics and Electrical<br />

Engineering.<br />

DAN STRONG<br />

Maintenance Technician<br />

Dan Strong of<br />

Genoa joined Loup<br />

in 1986 as a Maintenance<br />

Man at the<br />

Genoa Headworks.<br />

He was promoted to<br />

his current position<br />

of Maintenance<br />

Technician in 1988.<br />

As a Maintenance<br />

Technician, Strong’s<br />

responsibilities<br />

include maintaining<br />

and servicing vehicles and equipment<br />

at the Genoa Headworks. He<br />

also troubleshoots the electrical<br />

and mechanical components of the<br />

District’s dredge, the Pawnee II.<br />

Strong is a graduate of Genoa High<br />

School. He and his wife, Janice, are<br />

the parents of two children: Brandy and<br />

Brian.<br />

He also has five grandchildren — Hannah,<br />

Garrison, Marshall, Grady, and<br />

Grant.<br />

10 | GENERATOR<br />

20 YEARS<br />

35 YEARS<br />

DALE GASPER<br />

Columbus Division Superintendent<br />

Dale Gasper joined<br />

Loup in 1986 as an<br />

Apprentice Lineman<br />

at the Humphrey<br />

Office. Later that<br />

year he was promoted<br />

to Lineman.<br />

He transferred to the<br />

Columbus Service<br />

Center in 1989, and<br />

was promoted to<br />

Journeyman Lineman<br />

the following<br />

year.<br />

In 2012, Gasper was promoted to Line<br />

Foreman at the Columbus Service<br />

Center and was named Columbus Division<br />

Superintendent at the Columbus<br />

Service Center in 2014.<br />

As Division Superintendent, Gasper<br />

oversees the construction, operation,<br />

and maintenance of the electric system<br />

in the Columbus Division, including<br />

Columbus, Duncan, Platte Center,<br />

Richland, Clarkson, and Howells. He<br />

supervises the Columbus line and<br />

service crews, working with local<br />

contractors, and handling customer<br />

contacts regarding new service.<br />

Gasper is a native of Lindsay and a<br />

graduate of Newman Grove High<br />

School. He earned an Associate of<br />

Applied Science Degree in Utility Line<br />

from Northeast Community College in<br />

Norfolk.<br />

Gasper and his wife, Nancy, are the<br />

parents of three sons: Casey, Jesse,<br />

and Jaime.<br />

MARK HANEL<br />

Shop & Transportation Superintendent<br />

Mark Hanel joined<br />

Loup in 2011 as Automotive/Equipment<br />

Mechanic for the<br />

Shop and Transportation<br />

Department<br />

at the Columbus<br />

Service Center.<br />

He transferred to<br />

Machinist/Welder in<br />

2017.<br />

He was promoted to<br />

35 YEARS<br />

10 YEARS<br />

Shop & Transportation Superintendent<br />

in 2020.<br />

In this role, Hanel provides leadership,<br />

supervision, and guidance to all shop<br />

personnel. His team is responsible for<br />

inspecting, maintaining, and repairing<br />

District vehicles and equipment. He<br />

also advises management on standards<br />

and specifications for vehicle<br />

purchases for the District’s fleet.<br />

Hanel is a native of Clarkson and<br />

earned an Associates of Applied<br />

Science Degree in Automotive Technology<br />

from Northeast Community<br />

College in Norfolk.<br />

He and his wife, Rhonda, have three<br />

children: Carter, Chloe, and Grant.<br />

TOM WOOD<br />

Line Foreman<br />

Tom Wood joined<br />

Loup in 1991 as<br />

Apprentice Lineman<br />

at Fullerton.<br />

He was promoted<br />

to Lineman in 1993<br />

and to Journeyman<br />

Lineman in 1997. In<br />

2005, Wood was<br />

promoted to Line<br />

Foreman in the<br />

Fullerton Division.<br />

30 YEARS<br />

As Line Foreman,<br />

Wood is in charge of the construction<br />

and maintenance of Loup’s electrical<br />

transmission and distribution system in<br />

the Fullerton Division.<br />

This division includes the communities<br />

of Fullerton, Belgrade, St. Edward,<br />

Cedar Rapids, Primrose, Genoa, and<br />

Monroe.<br />

Wood is a graduate of Abraham<br />

Lincoln High School in Council Bluffs.<br />

He earned an Associate of Applied<br />

Science Degree in General Studies<br />

with an emphasis in Business from Iowa<br />

Western Community College.<br />

He earned an Associate of Applied<br />

Science Degree in Utility Line from<br />

Northeast Community College in<br />

Norfolk.<br />

He and his wife, Jennifer, have two<br />

children: Paige and Tate.

DAN HELLBUSCH<br />

Vice President of Operations<br />

Dan Hellbusch<br />

joined Loup in 1986<br />

as an Apprentice<br />

Lineman at the<br />

Columbus Service<br />

Center. Later that<br />

year he was promoted<br />

to Lineman<br />

and he was named<br />

St. Edward Local<br />

Superintendent in<br />

1989.<br />

In 1994, he was<br />

promoted to Columbus Division Superintendent<br />

based out of the Columbus<br />

Service Center. Hellbusch was promoted<br />

to his current position of Vice<br />

President of Operations based out of<br />

the Columbus General Office in 2014.<br />

As Vice President of Operations,<br />

Hellbusch’s responsibilities involve<br />

overseeing all the operations of<br />

Loup’s Operations and Hydro Divisions<br />

throughout the District’s service<br />

territory. These operations activities<br />

include construction, operation, and<br />

maintenance of the District’s electrical<br />

transmission and distribution system;<br />

hydro generation facilities; the Loup<br />

Power Canal; and all district recreation<br />

facilities.<br />

Hellbusch is a graduate of Fullerton<br />

High School and received his lineman<br />

training at Northeast Community<br />

College in Norfolk. He and his wife,<br />

Annette, have three children: Cody,<br />

Maggie, and Lauran.<br />

ANGELL ROBAK<br />

Admin Assistant to the President/CEO<br />

Angell Robak<br />

joined Loup in 2001<br />

as Cashier at the<br />

Columbus General<br />

Office. She was<br />

promoted to Administrative<br />

Assistant<br />

for the Engineering<br />

Department in 2005.<br />

In 2014, she was<br />

promoted to her<br />

current position<br />

of Administrative<br />

35 YEARS<br />

20 YEARS<br />

Assistant to the President/CEO.<br />

The Administrative Assistant to the<br />

President/CEO is also the Assistant<br />

Secretary to the Board of Directors.<br />

Duties and responsibilities of this<br />

position include providing administrative<br />

support for the District’s Executive<br />

office, compiling materials for Board<br />

meetings, recording and filing minutes<br />

for Board meetings, and maintaining<br />

corporate files.<br />

Robak was born in Detroit, Mich.<br />

She also lived in Humphrey before<br />

moving to Columbus. Robak is a<br />

graduate of Columbus High School<br />

and attended Central Community<br />

College–Columbus.<br />

She and her husband, John, are the<br />

parents of four grown children: Cory,<br />

Matt, Kaitlyn, and Kelcey. They have<br />

three grandchildren: Ike, Claire, and<br />

Rose.<br />

KEVIN SEIER<br />

Meter, Relay and Equipment Technician<br />

Seier joined Loup<br />

Power District<br />

in 2016 as a<br />

Plant Operator<br />

at the Columbus<br />

Powerhouse.<br />

He was promoted<br />

to Meter, Relay and<br />

Equipment Technician<br />

in 2018.<br />

5 YEARS<br />

Seier is part of a<br />

team that is responsible<br />

for installation and maintenance<br />

of substation power equipment.<br />

The team’s duties include operating<br />

equipment that switches electric power<br />

between substations and transmission<br />

lines, relay maintenance and testing,<br />

and designing substation control<br />

wiring.<br />

He is a graduate of Twin River High<br />

School in Genoa and earned an Associate<br />

of Applied Science Degree<br />

in Electro-Mechanical Technology<br />

from Northeast Community College in<br />

Norfolk. He and his wife, Kara, are the<br />

parents of two daughters, Rossi and<br />

Kimber.<br />

JIM BOGUS<br />

Accounting Supervisor<br />

Jim Bogus joined<br />

Loup in 2011 as<br />

Chief Accountant. In<br />

2015, he transferred<br />

to his current position<br />

of Accounting<br />

Supervisor at the<br />

Columbus General<br />

Office.<br />

His responsibilities<br />

include a variety of technical and<br />

administrative accounting work; oversight<br />

of property insurance; purchases<br />

of supplies, materials, and equipment;<br />

approval of purchase orders and the<br />

material bidding process; processing<br />

of work orders; and general liability<br />

concerns.<br />

Bogus is a graduate of Columbus High<br />

School. He has a Bachelor’s Degree in<br />

Business Administration/Accounting<br />

from the University of Nebraska-Lincoln<br />

and earned his CPA in 1982.<br />

Bogus and his wife, Deb, are the<br />

parents of two married children: Kyle<br />

(Ngan) Bogus, and Kara (Brad) Florian.<br />

Kara and Brad have one daughter,<br />

Leah.<br />

MATT ROSNO<br />

Maintenance Technician<br />

Matt Rosno of<br />

Genoa joined Loup<br />

Power District as a<br />

Maintenance Technician<br />

at the Genoa<br />

Headworks in April.<br />

10 YEARS<br />

Rosno is responsible<br />

for maintaining District<br />

parks, facilities,<br />

and equipment<br />

in the hydraulic<br />

WELCOME<br />

operations of the<br />

District. He will also<br />

assist the Dredge/Maintenance Canal<br />

Technicians and serve on the dredge<br />

during the dredging season.<br />

Rosno is a graduate of Twin River High<br />

School. He is certified in ATV Personal<br />

Water Craft Repair and Automotive<br />

Mechanic. He previously worked for<br />

Bryan’s Repair as a mechanic.<br />

SUMMER <strong>2021</strong> | 11

employee notes<br />

JUSTIN SHANLE<br />

Meter, Relay, and Equipment Tech II<br />

Justin Shanle of Columbus joined Loup<br />

Power District as Drafting Technician in<br />

2020. He was promoted to Meter, Relay,<br />

and Equipment Tech II in November 2020.<br />

DEB PETCHE<br />

Customer Service Representative<br />

Debra Petsche of Petersburg joined<br />

Loup Power District as a Customer<br />

Service Representative in the Albion<br />

and Fullerton offices in 2020.<br />

Shanle installs, tests, switches, and<br />

maintains substation and line equipment.<br />

He also operates SCADA and load<br />

control systems.<br />

Shanle is a graduate of Scotus Central<br />

Catholic High School. He earned a degree in Electromechanical<br />

Technology from Southeast Community College in Milford.<br />

Quarterly lease<br />

payments total<br />

$1.5 million<br />

Loup Power District officials delivered<br />

lease payments totaling more than $1.5<br />

million to area communities in May.<br />

Each of these communities owns their<br />

electric distribution systems. These<br />

payments compensate them for the use<br />

of those systems for the first quarter of<br />

<strong>2021</strong>. Communities use the funds for a<br />

variety of public projects.<br />

The payments were:<br />

Petsche’s responsibilities include greeting<br />

customers; processing payments;<br />

setting up, transferring, or closing<br />

service; taking service calls; and preparing<br />

reports.<br />

1 YEAR 1 YEAR<br />

Petsche and her husband, Bob, have three children — Amanda<br />

(Travis) Ray, Travis (Jill) Petsche, and Eric (Tori) Petsche. They<br />

also have nine grandchildren.<br />

Columbus $1,140,254.52<br />

Platte Center $14,173.01<br />

Monroe $13,875.23<br />

Tarnov $1,834.15<br />

Creston $8,364.98<br />

Humphrey $25,330.83<br />

Lindsay $56,186.31<br />

Cornlea $2,185.69<br />

Newman Grove $22,641.72<br />

Duncan $20,575.10<br />

Fullerton $36,367.22<br />

Genoa $29,087.55<br />

Belgrade $4,282.93<br />

Richland $3,388.84<br />

Howells $24,572.56<br />

Leigh $18,368.54<br />

Clarkson $21,451.47<br />

Albion $56,370.60<br />

Primrose $1,862.21<br />

Petersburg $11,333.16<br />

St. Edward $20,743.11<br />

Total $1,533,249.73<br />

2020 SUMMER EMPLOYEES<br />

L to R: Elijah Norman, Fullerton; Kyle Kemper, Albion; Travis Stanley, Columbus; Grant<br />

Ohnemus, Columbus; Evan Sliva, Columbus; Bradley Schindel, Columbus. Not pictured:<br />

Tim Tannehill, Columbus<br />

Elijah, Kyle, Travis and Evan are working as TPT Linemen. Grant and Tim are TPT<br />

Maintenance Men for the Hydro Department. Bradley is working as a TPT Engineering Tech.<br />

ENERGY EFFICIENCY TIP<br />

When shopping for new light bulbs, know<br />

the difference between lumens and watts.<br />

Lumens measure the amount of light produced<br />

by the bulb. Watts measure energy consumption.<br />

Energy-saving LEDs come in a variety of colors<br />

and brightness levels and last 15-25 times<br />

longer than incandescent bulbs.<br />

12 | GENERATOR

NEW!<br />

Electric Mower<br />

INCENTIVE<br />

GO ELECTRIC<br />

& GET A 10% INCENTIVE<br />

Gasless, but not gutless. Quiet, but not shy. This is not your<br />

grandfather’s battery powered mower. Advances in battery<br />

technology have come a long way in recent years. More<br />

power is now being packed into batteries so your mower<br />

can easily deliver a knock-out punch to your lawn.<br />

Maybe it is time to consider upgrading your conventional,<br />

gas-burning mower with a new electric or battery-powered<br />

option.<br />

LOWER ENERGY COSTS<br />

Depending on how often you mow, electric-powered<br />

mowers will cost about $15 per year in electricity.<br />

Gas mowers use about $30 of<br />

$<br />

gasoline.<br />

LESS MAINTENANCE<br />

No sparkplugs, air filters, fuel filters,<br />

or oil change.<br />

FOLLOW THESE EASY STEPS:<br />

• Obtain an EnergyWise SM application form<br />

at your local Loup office or online at loup.com.<br />

• Purchase your choice of a new battery-powered or<br />

corded electric mower. Chargers and additional battery<br />

purchases are available for the incentive at the time of<br />

the initial mower purchase. However, taxes, delivery/<br />

shipping, and set up costs are not.<br />

• Complete the application and return it to Loup<br />

with a copy of your proof of purchase.<br />

Mowers must be new — not used, previously owned, or factory<br />

reconditioned. Riding, walk-behind, and robotic mowers are<br />

eligible for the incentive.<br />

$ $<br />

$<br />

QUIETER OPERATION<br />

Electric mowers create up to 75 decibels of<br />

sound, which is similar to a washing machine.<br />

Gasoline mowers can exceed 95 decibels, which<br />

is comparable to a motorcycle on the highway.<br />

GREG BADSTIEBER<br />

402-562-5718 ■ badstieber@loup.com<br />

ECO-FRIENDLY<br />

No toxic gas emissions including nitrogen<br />

oxides, airborne particulates, carbon monoxide<br />

and carbon dioxide.<br />

The EnergyWise SM program is offered in conjunction<br />

with Nebraska Public Power District.<br />

SUMMER <strong>2021</strong> | 13

BRADEN SHARMAN<br />

Fullerton High School<br />

—<br />

Plans: Graphic Art at Wayne State College<br />

Son of Les and Natalie Sharman,<br />

Customer Service Representative<br />

AARON LANGEMEIER<br />

Schuyler Central High School<br />

—<br />

Plans: Exercise Science at Midland University;<br />

Midland Warriors Basketball Team<br />

Son of Kerri and Chris Langemeier,<br />

Board of Directors<br />

BRADY SOKOL<br />

Northeast Community College<br />

—<br />

Associate of Applied Science –<br />

Precision Agriculture<br />

Works at Mitchell Equipment in Humphrey<br />

Son of Joan and Scott Sokol,<br />

Albion Division Superintendent<br />

JAXSON JONES<br />

Twin River High School<br />

—<br />

Plans: Welding at Central Community<br />

College-Columbus<br />

Son of Debbie and Jack Jones,<br />

Dredge Operator<br />

14 | GENERATOR<br />

KELCEY ROBAK<br />

Marist College (Poughkeepsie, NY)<br />

—<br />

Master of Science<br />

in Physician Assistant Studies<br />

Daughter of John and Angell Robak,<br />

Administrative Assistant to the President/CEO<br />

AIDEN CROMWELL<br />

Central Community College–Columbus<br />

—<br />

Associate Degree in Applied Science<br />

– Mechatronics<br />

Works at ADM as a Instrumentational Technician<br />

Son of John and Shari Cromwell,<br />

Lead Customer Service Representative

KEATON ZAREK<br />

Twin River High School<br />

—<br />

Plans: Utility Line at Northeast<br />

Community College<br />

Son of Nichole and Andy Zarek,<br />

Headgates Operator<br />

MICHAEL GASPER<br />

Scotus Central High School<br />

—<br />

Plans: Aviation at the University of Nebraska<br />

at Omaha<br />

Son of Greg and Cindy Gasper,<br />

Customer Service Representative<br />

JARED DUREN<br />

University of Nebraska-Lincoln<br />

—<br />

Master of Science in Civil Engineering<br />

Special Emphasis in Structural Engineering<br />

Will Work at Kiewit Corporation<br />

as a Structural Engineer<br />

MADISON CERV<br />

Wayne State College: Master's Degree in School Counseling PK-12<br />

Daughter of Adam and Ann Cerv; Granddaughter of Sharon and Robert Cerv, Board of Directors<br />

Son of Lisa and Todd Duren,<br />

Vice President of Corporate Services<br />

Area students earn scholarships<br />

LINKAGES SCHOLARSHIPS<br />

Linkages Scholarships were awarded to four students in the <strong>2021</strong><br />

graduating class at Columbus High School.<br />

The Linkages Program is a nationally recognized program that supports<br />

high schools offering a quality program of engineering and technology<br />

courses. The Columbus Economic Council, Loup Power District, and local<br />

businesses provide support for the program.<br />

The students qualified for the Linkages Scholarship by taking<br />

engineering and technical courses. The scholarship can be used<br />

at each student’s college of choice.<br />

The <strong>2021</strong> Linkages Scholarships were awarded to Logan Brown,<br />

Alexander Larson, Ethan Macken, and Chase Paczosa.<br />

The following local sponsors provided important financial support to this<br />

year’s program: Behlen Mfg. Co., Central Confinement Services (CCS),<br />

Columbus Bank, Columbus Community Hospital, Duo Lift Manufacturing<br />

Company, Pillen Family Farms, Pinnacle Bank, SIDUMP’R, Superior<br />

industries, TORIN Products, Inc., and Valmont Newmark.<br />

Since its beginning in 2004, the Linkages Program has awarded 202<br />

scholarships totaling $63,675.<br />

LOUP POWER DISTRICT SCHOLARSHIPS<br />

Loup Power District has awarded scholarships to 11<br />

area students who are attending Central Community<br />

College-Columbus this fall.<br />

Loup Power District scholarships are awarded to<br />

high school seniors living in Boone, Colfax, Nance,<br />

and Platte Counties and portions of Madison<br />

County.<br />

Selection is based on academic achievement,<br />

employment and school activities, quality of the<br />

personal statement, application completeness and<br />

recommendations.<br />

Scholarships were awarded to: Columbus High<br />

School — Mason Dahlke and Libby Wurdeman;<br />

Columbus Bible Baptist — Tiffany Wright; Lakeview<br />

High School — Alison Loseke; Fullerton High School<br />

— Luke Foland; Leigh High School — Alicia Holmberg;<br />

Schuyler High School — Ailyn Adame and<br />

Alejandra Castro; St. Edward High School — Jennifer<br />

Sutton; Twin River High School — Jaxson Jones and<br />

Sydnei Kemper.<br />

SUMMER <strong>2021</strong> | 15

2404 15th Street | PO Box 988<br />

Columbus, NE 68602-0988<br />

Have you seen<br />

these ads?<br />

While most people know what solar panels<br />

are, many aren’t aware of the complexity of<br />

setting up a complete solar power system or<br />

understanding the actual return on investment.<br />

Give us a call to learn more. We can provide<br />

an assessment on the proper project size,<br />

estimated costs and return on investment,<br />

best practices for installation, and advice<br />

on selecting a reliable solar developer.<br />

Thinking about solar?<br />

Give Loup Power District a call FIRST!<br />

LOWER YOUR<br />

MONTHLY<br />

ELECTRIC BILL<br />

Find out how much<br />

you can save today!<br />

SEE IF YOU QUALIFY >><br />

Nebraska homeowners are eligible for<br />

solar panel program with great savings!<br />

Go Green. Go Solar.<br />

SAVE MONEY!<br />

Install Solar Panels.