Safety, and Operation User's Manual - Tool-Smith

Safety, and Operation User's Manual - Tool-Smith

Safety, and Operation User's Manual - Tool-Smith

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

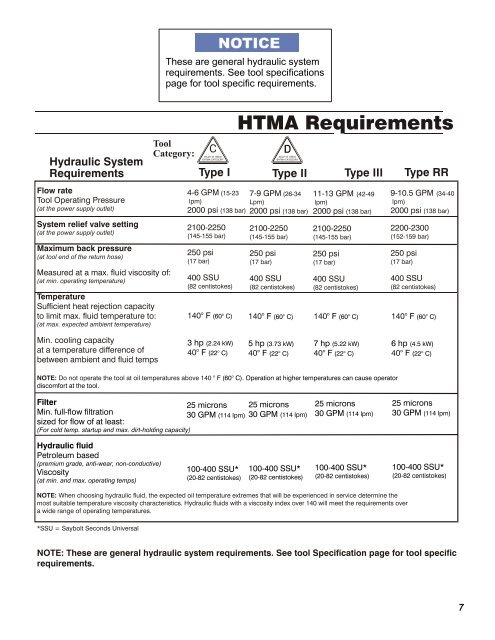

Hydraulic System<br />

Requirements<br />

Flow rate<br />

<strong>Tool</strong> Operating Pressure<br />

(at the power supply outlet)<br />

System relief valve setting<br />

(at the power supply outlet)<br />

Maximum back pressure<br />

(at tool end of the return hose)<br />

Measured at a max. fluid viscosity of:<br />

(at min. operating temperature)<br />

Temperature<br />

Sufficient heat rejection capacity<br />

to limit max. fluid temperature to:<br />

(at max. expected ambient temperature)<br />

Min. cooling capacity<br />

at a temperature difference of<br />

between ambient <strong>and</strong> fluid temps<br />

<strong>Tool</strong><br />

Category:<br />

HTMA Requirements<br />

Type I Type II Type III<br />

NOTE: Do not operate the tool at oil temperatures above 140 ° F (60° C). <strong>Operation</strong> at higher temperatures can cause operator<br />

discomfort at the tool.<br />

Filter<br />

Min. full-flow filtration<br />

sized for flow of at least:<br />

(For cold temp. startup <strong>and</strong> max. dirt-holding capacity)<br />

Hydraulic fluid<br />

Petroleum based<br />

(premium grade, anti-wear, non-conductive)<br />

Viscosity<br />

(at min. <strong>and</strong> max. operating temps)<br />

NOTE: When choosing hydraulic fluid, the expected oil temperature extremes that will be experienced in service determine the<br />

most suitable temperature viscosity characteristics. Hydraulic fluids with a viscosity index over 140 will meet the requirements over<br />

a wide range of operating temperatures.<br />

*SSU = Saybolt Seconds Universal<br />

These are general hydraulic system<br />

requirements. See tool specifications<br />

page for tool specific requirements.<br />

4-6 GPM<br />

lpm)<br />

2000 psi<br />

2100-2250<br />

(145-155 bar)<br />

250 psi<br />

(17 bar)<br />

400 SSU<br />

(82 centistokes)<br />

140°<br />

F<br />

3 hp<br />

40°<br />

F<br />

20Lpm at 138bar<br />

BHTMA CATEGORY<br />

7-9 GPM<br />

(15-23<br />

Lpm)<br />

(138 bar)<br />

(60° C)<br />

(2.24 kW)<br />

(22° C)<br />

25 microns<br />

30 GPM<br />

(114 lpm)<br />

100-400 SSU*<br />

(20-82 centistokes)<br />

2000 psi<br />

2100-2250<br />

(145-155 bar)<br />

250 psi<br />

(17 bar)<br />

400 SSU<br />

NOTE: These are general hydraulic system requirements. See tool Specification page for tool specific<br />

requirements.<br />

(26-34<br />

(82 centistokes)<br />

140°<br />

F<br />

5 hp<br />

40°<br />

F<br />

30Lpm at 138bar<br />

BHTMA CATEGORY<br />

(138 bar)<br />

(60° C)<br />

(3.73 kW)<br />

(22° C)<br />

25 microns<br />

30 GPM<br />

(114 lpm)<br />

100-400 SSU*<br />

(20-82 centistokes)<br />

11-13 GPM<br />

lpm)<br />

2000 psi<br />

2100-2250<br />

(145-155 bar)<br />

250 psi<br />

(17 bar)<br />

400 SSU<br />

(82 centistokes)<br />

140°<br />

F<br />

7 hp<br />

40°<br />

F<br />

(42-49<br />

(138 bar)<br />

(60° C)<br />

(5.22 kW)<br />

(22° C)<br />

25 microns<br />

30 GPM<br />

(114 lpm)<br />

100-400 SSU*<br />

(20-82 centistokes)<br />

9-10.5 GPM<br />

lpm)<br />

2000 psi<br />

2200-2300<br />

(152-159 bar)<br />

250 psi<br />

(17 bar)<br />

140°<br />

F<br />

6 hp<br />

40°<br />

F<br />

Type RR<br />

400 SSU<br />

(82 centistokes)<br />

(60° C)<br />

(4.5 kW)<br />

(22° C)<br />

25 microns<br />

30 GPM<br />

(114 lpm)<br />

100-400 SSU*<br />

(34-40<br />

(138 bar)<br />

(20-82 centistokes)<br />

7