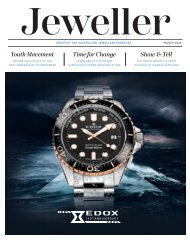

Jeweller - May 2021

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Reset & Refine | CASTING AND REFINING FEATURE<br />

www.morrisandwatson.com<br />

NEW ZEALAND | 0800 500 654<br />

AUSTRALIA | 1800 469 088<br />

INVESTING IN<br />

INNOVATION<br />

Top Tech<br />

L to R: ABC Bullion; Peter W Beck<br />

ABC Refinery is<br />

the benchmark in<br />

Australian ecofriendly<br />

refining.<br />

In <strong>2021</strong>, it invested in<br />

an additional 175kg<br />

acidless separation<br />

refining technology<br />

to service the valueadded<br />

demand”<br />

Chemgold<br />

While electrowinning – the process of separating<br />

metals from impurities – may not have drastically<br />

changed from its discovery in the 1800s, there are<br />

new efficiencies to be had.<br />

“Efficiencies can be gained by good material<br />

management and procedural management,” Beck<br />

adds. “The art of a refiner is to take the timeless<br />

principles of electrowinning and chemistry and by<br />

using the best equipment and practices, to make<br />

the process as efficient as possible.”<br />

There are some exciting developments in this<br />

space. Van Sambeek said Morris & Watson has<br />

invested in more environmentally friendly<br />

processes in order to recover 80 per cent of<br />

the nitric acid from the fume stream before it<br />

reaches the chemical scrubbers.<br />

“This dramatically reduces the workload on<br />

scrubbers, eliminating potential environmental<br />

contaminates and recovers acid that can now be<br />

recycled,” Van Sambeek said.<br />

“We are expanding the use of this technology to<br />

recycle even more chemicals.<br />

“We’ve also invested in a state-of-the-art furnace<br />

for burning sweeps. This world leading furnace<br />

technology results in a cleaner more efficient<br />

use of energy.”<br />

Van Sambeek said these solutions are economically<br />

responsible – both financially prudent and better for<br />

the environment.<br />

“Over the past two years we’ve been upgrading our<br />

refining facility with the latest European technology.<br />

“There are improved processes, reducing<br />

handling of harmful chemicals and a much cleaner<br />

and efficient output. It’s safer for staff and the<br />

environment,” he said.<br />

Meanwhile, Botha says, “ABC Refinery is the largest<br />

independent precious metals refining facility in<br />

Australasia. ABC Refinery is the benchmark in<br />

Australian eco-friendly refining.<br />

“In <strong>2021</strong>, it invested in an additional 175kg acidless<br />

separation (ALS) refining technology to service the<br />

value-added demand.”<br />

He added, “ALS is the world’s most environmentally<br />

safe refining technology and produces no noxious<br />

residue. ABC Refinery is the only Australian<br />

refinery that employs this technology.”<br />

In addition, ABC Refinery’s technology is – uniquely<br />

– accredited by the National Association of<br />

Testing Authorities, International Organization for<br />

Standardization, Commission Électrotechnique<br />

Internationale, Australian Standards and<br />

International Laboratory Accreditation Cooperation.<br />

The Perth Mint has also made strides in<br />

its environmental policy, appointing a chief<br />

sustainability officer and “actively participating” in<br />

the West Australian government’s “carbon neutral<br />

future” strategy.<br />

Technology breakthroughs<br />

in the field of casting are<br />

creating new opportunities<br />

for jewellers, including designs<br />

previously thought to be<br />

impossible”<br />

In addition, Hayes says, “Capital investment at the<br />

Mint’s refinery has amounted to $36 million over<br />

the past 10 years, with $17 million of this being<br />

invested over the last four years.<br />

“Spend has been spread across new equipment,<br />

increased capacity and improved environmental<br />

management.”<br />

He adds, “A new assay laboratory was<br />

commissioned a few years ago, equipped with the<br />

latest state of the art equipment and technology<br />

to ensure its assays and return of metal to<br />

customers is of the highest accuracy.<br />

Additionally, “Automation is regularly adopted<br />

to ensure repetitive or potentially dangerous<br />

tasks are performed by machines, minimising or<br />

eliminating the risk of injury to employees.”<br />

Beyond the human hand<br />

From the design side of jewellery production,<br />

technology breakthroughs in the field of casting<br />

are creating new opportunities for jewellers,<br />

including designs previously thought to be<br />

impossible.<br />

This is being driven by improvements in 3D<br />

printing; a technology that has had a dramatic<br />

effect on the industry over the past 10 years. The<br />

fall in cost of the average 3D printer, alongside<br />

the increasing detail now possible in prints, is<br />

leading to significant achievements.<br />

One example is the ‘arms race’ in breaking the<br />

world record for the most diamonds set in a ring.<br />

Hallmark <strong>Jeweller</strong>s, based in Hyderabad, India,<br />

unveiled ‘The Divine’ in September last year,<br />

which features 7,801 set diamonds, arranged<br />

in a flower design.<br />

However, they did not hold on to the record<br />

very long, with Renani Jewels, from Meerut,<br />

India, displaying ‘Marigold’ just a few months<br />

later, set with 12,638 diamonds – demolishing<br />

the previous record.<br />

These feats have been possible largely thanks<br />

to advances in 3D printing. Imaginarium, an<br />

Indian 3D printing service, played a critical role<br />

in creating the mould from which ‘The Divine’<br />

was cast.<br />

The company is working to push the limits of<br />

what can be achieved in casting, and producing<br />

moulds that would be impossible to do by hand.<br />

“The sheer amount of design freedom that 3D<br />

printing brings with it is incredible, so much<br />

that complexity of a design is no longer a factor<br />

in manufacturing,” Kamlesh Parekh, founder<br />

Imaginarium, recently wrote.<br />

“Designers now have options to experiment<br />

with abstract patterns and shapes that make for<br />

visually striking pieces of jewellery.<br />

“If a designer can produce it on a computer, the<br />

3D printer will print it, no questions asked.”<br />

<strong>Jeweller</strong>s closer to home can take advantage of<br />

more practical and realistic benefits offered by<br />

3D printing, with several casting houses offering<br />

the service.<br />

In October last year Palloys, AGS, PJW, Regentco<br />

Chris Botha<br />

Palloys<br />

[The Perth Mint’s<br />

assay laboratory is<br />

equipped with] the<br />

latest state of the<br />

art equipment and<br />

technology to ensure<br />

its assays and return<br />

of metal to customers<br />

is of the highest<br />

accuracy”<br />

Richard Hayes<br />

The Perth Mint<br />

Over the past two<br />

years we’ve been<br />

upgrading our<br />

refining facility with<br />

the latest European<br />

technology...<br />

It’s safer for staff and<br />

the environment”<br />

Adam Van<br />

Sambeek<br />

Morris & Watson<br />

The sheer amount<br />

of design freedom<br />

that 3D printing<br />

[casting moulds]<br />

brings with it is<br />

incredible, so much<br />

that complexity<br />

of a design is no<br />

longer a factor in<br />

manufacturing”<br />

Kamlesh<br />

Parekh<br />

Imaginarium<br />

and A&E Metals – all part of the Pallion<br />

group of companies – launched a new all in<br />

one platform that allows jewellers to place<br />

customised 3D print orders.<br />

The platform, which took two years to design<br />

and implement, allows jewellers to upload<br />

a CAD file and receive an instant quote for<br />

a finished piece, including everything from<br />

print to mould, casting and finishing.<br />

“The instant quoting for CAD files, casting<br />

from their own mould library, fabricated<br />

metals and diamonds allows jewellers to<br />

enjoy accurate and instant quotes they<br />

can pass onto their customers, giving the<br />

jewellers an instant competitive advantage,”<br />

Alison Habbal, assistant operations manager<br />

– jewellery at Palloys told <strong>Jeweller</strong> at<br />

the time.<br />

Botha adds, “Palloys.com is significantly<br />

outperforming the previous website and has<br />

already exceeded expectations within the<br />

business and industry.<br />

“Palloys’ customers can now order a<br />

customised piece, including certified<br />

diamonds, online and receive them as a<br />

raw cast, semi-finished or fully finished.<br />

“We also offer desprue and tumble options<br />

for castings which have been very popular<br />

since launching the website.<br />

We have seen online orders for the jewellery<br />

division more than double in the new year as<br />

more people adopt the platform.”<br />

Elsewhere, Botha notes that the Palloys<br />

research and development department has<br />

also been working on “direct metal printing<br />

for the bullion and jewellery sector, and<br />

adding subtractive prototyping back into our<br />

manufacturing processes.”<br />

Unstable metal prices have emphasised<br />

the important of efficient and effective<br />

refining, and new technologies are allowing<br />

jewellers to customise pieces to a level that<br />

was previously impossible. Both of these<br />

developments will be important to meet the<br />

needs of customers in <strong>2021</strong> and beyond.<br />

3D Print<br />

& Cast in<br />

Four Days<br />

*STL file(s) must be received by 12pm AEST. Lead time excludes other<br />

casting services and shipping.<br />

More Than Four Decades of Casting<br />

Experience With Service You Can Trust<br />

*<br />

35 | <strong>May</strong> <strong>2021</strong><br />

Refining | Bullion | Fabrication | CAD/CAM | Casting | Chain