XtraBlatt Issue 02-2020

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INFORM<br />

cardanic rotor suspension ensures that the front wheels of<br />

the rotor rise first. On setting down, the rear wheels hit the<br />

ground first so that the tines are always kept off the ground.<br />

TYRE PRESSURE<br />

Don’t miss out on checking tyre pressures. If these don’t<br />

match on all tyres, perfect swathing isn’t possible. Alexander<br />

Esselmann: “Especially when swathers are delivered, the<br />

tyres can have a very high pressure. This stops the implements<br />

moving around on the transport truck, for instance.<br />

But too high pressure in the field reduces shock absorbance.<br />

Resultant bouncing means tines can end-up kicking dirt.<br />

Swather tyres tend to be larger now. 710 wheels can be<br />

ordered for the frame, with up to 18” wheels available for<br />

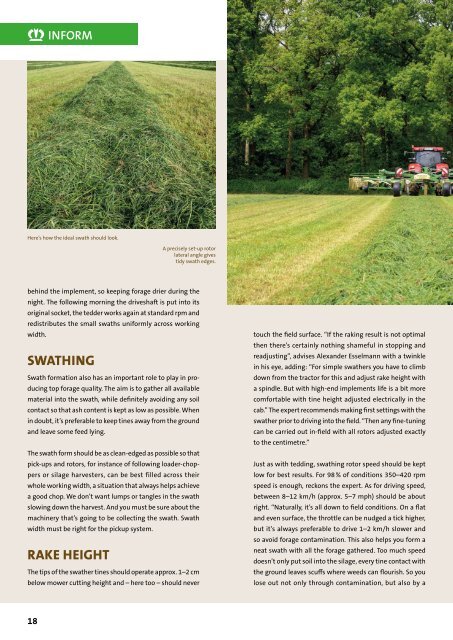

Here’s how the ideal swath should look.<br />

behind the implement, so keeping forage drier during the<br />

night. The following morning the driveshaft is put into its<br />

original socket, the tedder works again at standard rpm and<br />

redistributes the small swaths uniformly across working<br />

width.<br />

SWATHING<br />

Swath formation also has an important role to play in producing<br />

top forage quality. The aim is to gather all available<br />

material into the swath, while definitely avoiding any soil<br />

contact so that ash content is kept as low as possible. When<br />

in doubt, it’s preferable to keep tines away from the ground<br />

and leave some feed lying.<br />

The swath form should be as clean-edged as possible so that<br />

pick-ups and rotors, for instance of following loader-choppers<br />

or silage harvesters, can be best filled across their<br />

whole working width, a situation that always helps achieve<br />

a good chop. We don’t want lumps or tangles in the swath<br />

slowing down the harvest. And you must be sure about the<br />

machinery that’s going to be collecting the swath. Swath<br />

width must be right for the pickup system.<br />

RAKE HEIGHT<br />

A precisely set-up rotor<br />

lateral angle gives<br />

tidy swath edges.<br />

The tips of the swather tines should operate approx. 1–2 cm<br />

below mower cutting height and – here too – should never<br />

touch the field surface. “If the raking result is not optimal<br />

then there’s certainly nothing shameful in stopping and<br />

readjusting”, advises Alexander Esselmann with a twinkle<br />

in his eye, adding: “For simple swathers you have to climb<br />

down from the tractor for this and adjust rake height with<br />

a spindle. But with high-end implements life is a bit more<br />

comfortable with tine height adjusted electrically in the<br />

cab.” The expert recommends making first settings with the<br />

swather prior to driving into the field. “Then any fine-tuning<br />

can be carried out in-field with all rotors adjusted exactly<br />

to the centimetre.”<br />

Just as with tedding, swathing rotor speed should be kept<br />

low for best results. For 98 % of conditions 350–420 rpm<br />

speed is enough, reckons the expert. As for driving speed,<br />

between 8–12 km/h (approx. 5–7 mph) should be about<br />

right. “Naturally, it’s all down to field conditions. On a flat<br />

and even surface, the throttle can be nudged a tick higher,<br />

but it’s always preferable to drive 1–2 km/h slower and<br />

so avoid forage contamination. This also helps you form a<br />

neat swath with all the forage gathered. Too much speed<br />

doesn’t only put soil into the silage, every tine contact with<br />

the ground leaves scuffs where weeds can flourish. So you<br />

lose out not only through contamination, but also by a<br />

poorer regrowth standard for the next cuts”, adds Alexander<br />

Esselmann.<br />

LATERAL ANGLE<br />

A substantial influence on rotor rake performance and swath<br />

formation – the factors affected output of the following harvest<br />

machine – is the angle setting of the rotor (or the front<br />

rotor with multi-rotor machines). This should always slope<br />

down in the direction of the swath. Tines take increasingly<br />

more forage material with them on their way towards the<br />

swath and the weight causes them to bend slightly, thus<br />

altering their height above ground surface. Lateral angle<br />

setting allows this to be compensated for, helping produce<br />

a well-shaped swath with clearly defined edges.<br />

Poor lateral angle setting can usually be seen right away<br />

in the shape of the swath. Material left lying on both sides<br />

is also a sure sign that the angle’s wrong. Adjustment is<br />

simply and rapidly carried out directly on the rear gauge<br />

wheels of each rotor.<br />

All Krone Swadro swathers are equipped with “Jet Effect”<br />

technology: on lifting the implement during operation, the<br />

the rotors. Larger and wider wheels have a bigger contact<br />

area and so help protect the grass sward. The wider the<br />

tyre, the less the ground pressure – and this can make a big<br />

difference, especially in wet ground conditions. Bigger tyres<br />

also avoid feed contamination and protect sward quality in<br />

aftermaths. And the number of wheels per rotor helps too in<br />

preventing field surface damage. With us in Krone, between<br />

four to eight wheels are possible. The more wheels mounted<br />

under the rotor, the more precisely can ground conditions<br />

be adjusted for.”<br />

Rotor suspension settings are dependent on field and<br />

ground conditions too. Not enough free play can lead to<br />

soil compaction or sinking of the rotor support wheels in<br />

wet ground. Here, the rotor suspension movement should<br />

be tendentially eased. If the field surface is very hard, or<br />

steep, suspension travel should be reduced to stop the rotor<br />

“floating” or hopping and leaving forage lying.<br />

Coming in your next <strong>XtraBlatt</strong>: A closer look at actual forage<br />

harvesting. «<br />

Alexander Esselmann:<br />

product specialist for<br />

Krone tedders and swathers.<br />

18 19