Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

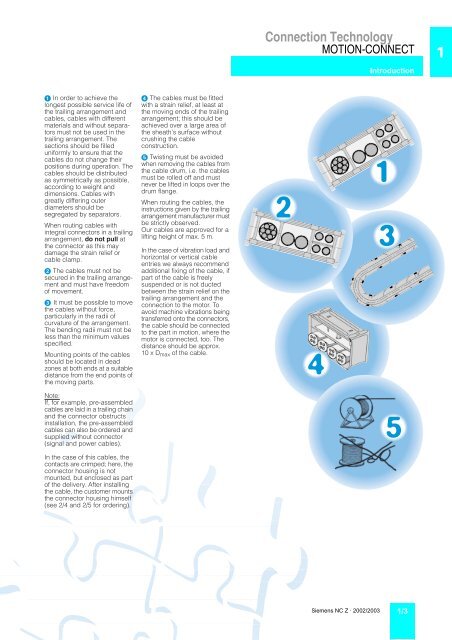

a In order to achieve the<br />

longest possible service life of<br />

the trailing arrangement and<br />

cables, cables with different<br />

materials and without separators<br />

must not be used in the<br />

trailing arrangement. The<br />

sections should be filled<br />

uniformly to ensure that the<br />

cables do not change their<br />

positions during operation. The<br />

cables should be distributed<br />

as symmetrically as possible,<br />

according to weight and<br />

dimensions. <strong>Cables</strong> with<br />

greatly differing outer<br />

diameters should be<br />

segregated by separators.<br />

When routing cables with<br />

integral connectors in a trailing<br />

arrangement, do not pull at<br />

the connector as this may<br />

damage the strain relief or<br />

cable clamp.<br />

s The cables must not be<br />

secured in the trailing arrangement<br />

and must have freedom<br />

of movement.<br />

d It must be possible to move<br />

the cables without force,<br />

particularly in the radii of<br />

curvature of the arrangement.<br />

The bending radii must not be<br />

less than the minimum values<br />

specified.<br />

Mounting points of the cables<br />

should be located in dead<br />

zones at both ends at a suitable<br />

distance from the end points of<br />

the moving parts.<br />

Note:<br />

If, for example, pre-<strong>assembled</strong><br />

cables are laid in a trailing chain<br />

and the connector obstructs<br />

installation, the pre-<strong>assembled</strong><br />

cables can also be ordered and<br />

supplied without connector<br />

(signal and power cables).<br />

In the case of this cables, the<br />

contacts are crimped; here, the<br />

connector housing is not<br />

mounted, but enclosed as part<br />

of the delivery. After installing<br />

the cable, the customer mounts<br />

the connector housing himself<br />

(see 2/4 and 2/5 for ordering).<br />

f The cables must be fitted<br />

with a strain relief, at least at<br />

the moving ends of the trailing<br />

arrangement; this should be<br />

achieved over a large area of<br />

the sheath’s surface without<br />

crushing the cable<br />

construction.<br />

g Twisting must be avoided<br />

when removing the cables from<br />

the cable drum, i.e. the cables<br />

must be rolled off and must<br />

never be lifted in loops over the<br />

drum flange.<br />

When routing the cables, the<br />

instructions given by the trailing<br />

arrangement manufacturer must<br />

be strictly observed.<br />

Our cables are approved for a<br />

lifting height of max. 5 m.<br />

In the case of vibration load and<br />

horizontal or vertical cable<br />

entries we always recommend<br />

additional fixing of the cable, if<br />

part of the cable is freely<br />

suspended or is not ducted<br />

between the strain relief on the<br />

trailing arrangement and the<br />

connection to the motor. To<br />

avoid machine vibrations being<br />

transferred onto the connectors,<br />

the cable should be connected<br />

to the part in motion, where the<br />

motor is connected, too. The<br />

distance should be approx.<br />

10 x Dmax of the cable.<br />

Connection Technology<br />

MOTION-CONNECT<br />

Siemens NC Z · 2002/2003<br />

Introduction<br />

1/3<br />

1