Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

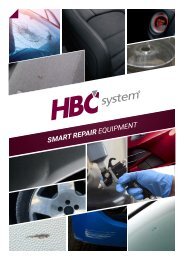

SMART REPAIR EQUIPMENT

A SYSTEM<br />

Fabric & velour<br />

B1 SYSTEM<br />

Plastic, Leather<br />

& Vinyl Repair<br />

B2 SYSTEM<br />

Texture Repair Kit<br />

Part no 00.307<br />

Fabric and velour system A<br />

This system for fabric and velour enables<br />

the repair of upholstery with a finish and<br />

quality sure to attract attention.<br />

As standard we deliver 40 different<br />

fibres, which can be mutually mixed to<br />

match the primary color perfectly.<br />

Subsequently, the pattern is painted on,<br />

and finally the task is impregnated to gain<br />

water and dirt resistance.<br />

Part no. 00.525<br />

Plastic, Leather, and Vinyl System B1<br />

Finding the right kind of adhesive<br />

for each job can often be difficult to<br />

the user. <strong>HBC</strong> system B1 is a system<br />

for the repair of Plastic, Leather<br />

and Vinyl. It makes it possible to<br />

repair hard and flexible plastic, both<br />

interior and exterior parts, bumpers,<br />

dashboards, as well as leather and<br />

vinyl components.<br />

The system contains all the required<br />

tools and adhesive materials to<br />

complete the repair from start to<br />

finish. The adhesive types contained<br />

in the system include among<br />

others specially developed hotmelt<br />

adhesive, chemically activated<br />

adhesives for hard plastics, flexible<br />

and rigid adhesive.<br />

Plastic, Leather, and Vinyl System B1<br />

is complete with cleaners, primers,<br />

and reinforcement material and<br />

the tools, which make it possible to<br />

repair plastic, vinyl and leather parts.<br />

Copy the structure to top off the<br />

repair for a perfect finish!<br />

Part no. 00.816<br />

Texture coat kit System B2<br />

Excellent for repairs of surface<br />

damages in all types of structures.<br />

The world’s most complete texture<br />

system beats everything on the<br />

market.<br />

Including <strong>HBC</strong> System Mouldmaker<br />

- developed to copy all types of<br />

structures.<br />

System B2 includes:<br />

5 different spray textures; coarse,<br />

medium, fine, fine flat, and coarse<br />

flat. 2 types of primers; one clear<br />

thin and one with “sanding” that fills<br />

in the small scratches and glueholes<br />

that often appear in the repair.<br />

Includes<br />

Fabric Protection Shield<br />

Part no. 575

B3 SYSTEM<br />

Vinyl Plastic Leather<br />

Color Mixing<br />

B4 SYSTEM<br />

Leather and<br />

Plastic Sprays<br />

B6 SYSTEM<br />

Plastic Welding System<br />

Part no. 00.826<br />

System B3 Aqua - Color mixing system<br />

Base colors for mixing of plastic-,<br />

leather and vinyl colors. The complete<br />

dye-to-match system for all kinds<br />

of soft, hard, and flexible materials<br />

such as leather, fabric, vinyl, plastic,<br />

and glass fiber. The standard system<br />

includes color swatch, gloss system,<br />

mixing book (formulas), primers,<br />

additives etc.<br />

Available as both solvent based and<br />

water based. All dyes and glosses gain<br />

a permanency that makes this system<br />

indispensable for service mechanics<br />

working with the repair of plastics or<br />

with maintenance jobs on furniture,<br />

cars, lorries, etc.<br />

Handheld Color Matching Tool provides<br />

a powerful, versatile way to find an<br />

exact match for any interior<br />

sample.<br />

Part no. 00.460<br />

Spray color system B4<br />

Dye to match system, spray B4<br />

With the B4 dye to match system<br />

we offer a wide variety of aerosols<br />

for the coloring of leather, fabrics,<br />

vinyl, plastic and glass fiber - and<br />

all other soft, hard, and flexible<br />

materials.<br />

Standard colors serial “30” Plastic<br />

and vinyl coat:<br />

Part no. 00.308<br />

Trolley mobile<br />

This fully equipped SMART Repair<br />

Trolley from <strong>HBC</strong> system is developed<br />

for the high-end SMART Repair<br />

specialist.<br />

It includes all necessary systems to<br />

make the most standard high-end<br />

interior repairs in the SMART Repair<br />

business.<br />

All necessary tools are included;<br />

airbrush, mini scale, caulking gun, etc.<br />

Part no. 40.000<br />

Plastic welding kit B6<br />

CAPSURE<br />

Part no. 913

Spot /Paint<br />

Repair Systems<br />

Chipfix produces a deep fill,<br />

quick shine, fast dry repair<br />

and refinish within minutes.<br />

Chipfix System<br />

For the repair of scratches and or<br />

stonechips on all types of vehicles<br />

Chipfix from <strong>HBC</strong> system provides for the first time a<br />

stand-alone system and fast, low cost option for the<br />

repair of stone-chips and minor paint damage, scuffs<br />

and scratches on motor vehicles.<br />

Combining unique new technology with specialist<br />

training Chipfix produces a deep fill, quick shine,<br />

fast dry repair and refinish within minutes.<br />

The system allows deeper stone chip<br />

damage to be built upon to achieve the<br />

desired level of fill and make the repair<br />

optically almost undetectable.<br />

Part no. 1100<br />

Chipfix System<br />

Currently 16 1K colour range available<br />

Including silver tinters.<br />

Chip Fix system is a 1K system with huge<br />

benefits over existing systems available.<br />

» Super durable<br />

» High build for quicker results<br />

» High gloss levels<br />

» Very fast drying<br />

» Polish-able system<br />

» High opacity<br />

» Can be sprayed or touched in with a brush<br />

» UV Durable<br />

» No shrinkage<br />

» Easy to match colours<br />

» No fillers or primers required<br />

» Does not contain isocyanates

C<br />

Chipfix - Spot Repair<br />

Spot Repair system<br />

Mix every color of car paint with maximum accuracy. The<br />

system is built up from approximately 75 colors covering<br />

everything from mother-of-pearl, metallic, and other<br />

effect-dyes. Carry out normal spray-jobs with a maximum<br />

finish through exercise. Or spray the paint directly on small<br />

scratches and stone chips and remove excess paint with a<br />

remover.<br />

Part no. 534<br />

Spot repair system<br />

C<br />

PAINT COLOUR MATCHING SOFTWARE - grants you direct access to<br />

our entire mixing formula database. Access and download is included<br />

with the system. Launch the software and fill in the relevant fields<br />

in the clearly structured user interface, and the requested mixing<br />

formula will appear on the screen within a wink of an eye - and it’s<br />

fast and easy to use. The database contains over 200.000 mixing formulas,<br />

giving access to more than 100.000 colours. It even provides<br />

variants of the requested colour for badly oxidized or aging paint.<br />

The Colour Match Software is updated two times a year at no additional<br />

cost and contains all the MSDS information and safety data<br />

sheets for all paint chemicals and toners.

Spot /Paint<br />

Repair Systems<br />

UV-A1<br />

Spot Repair system<br />

» Extremely fast curing times for improved repair times<br />

» Tried and tested new system delivers improved efficiency and<br />

profitability<br />

» Can be used on all types of materials in and outside the vehicle<br />

» Fewer preparation steps<br />

» Less waste product<br />

» Low material usage<br />

» Increased productivity and profitability<br />

» No mixing required<br />

33<br />

» Safe UVA curing with no health & safety risk<br />

» Also available for the first time in Aerosol format<br />

MINUTES<br />

SPOT REPAIR!<br />

A Spot repair from start till finish within 33 minutes including<br />

curing time, even if the repair needs filler! It sounds too good<br />

to be true, but this is now achievable with the NEW and unique<br />

<strong>HBC</strong> UV-A1 Spot repair system.<br />

Traditional Spot repairs can take between<br />

45-60 minutes, excluding curing time.<br />

Larger repairs which need filling can take<br />

even longer!<br />

Fast, clean, easy to use and safe<br />

for either aerosol or spraygun.<br />

UV-A1 Spot Repair System<br />

Part no. 19000<br />

Complete System includes<br />

1K UV-A1 Clearcoat cures within 3-4 min.<br />

1K UV-A1 Thinner for blending<br />

1K UV-A1 Filler cures within 3-4 min.<br />

1K UV-A1 Filler-Primer cures within 3-4 min.<br />

UV-A1 Ultraviolet refinishing lamp

C<br />

Spot Repair - Glasscoat<br />

GlassCoat<br />

Paint Protection<br />

<strong>HBC</strong> System now offers a revolutionary new technology called<br />

GlassCoat. It is a ceramic glass resin, that when applied to<br />

your paint provides a permanent bond that protects and<br />

guarantees your vehicle’s finish from environmental conditions<br />

not covered by the manufacturer’s warranty.<br />

GlassCoat is a clear liquid that is applied to the clearcoat of<br />

your vehicle. Unlike traditional waxes and sealants that simply<br />

“coat the surface”, GlassCoat polymerizes and crosslinks onto<br />

the surface of the clear-coat. The end result is a clear and<br />

extremely durable ceramic film that adheres so strongly to the<br />

surface that not even organic solvents can remove it.<br />

n<br />

r<br />

7YEAR<br />

PROTECTION *<br />

YEAR<br />

GUARANTEE *<br />

GlassCoat<br />

YEAR<br />

Easy to apply paint protection<br />

REPAIR<br />

which protects paint finishes<br />

GUARANTEE against damage * from machine Warranty car *<br />

washes, acid rain and bird lyme for<br />

up to a 7 year period!<br />

Part no. 570 GlassCoat<br />

Available with<br />

570-1 ClassCoat Applicator Sponge<br />

570-2 Clay Bar – 100 grams

Windscreen<br />

Repair / Removal<br />

Part no. 617G6<br />

Windscreen repair system D Pro G6<br />

» the fastest most efficient glass<br />

repair system available in the<br />

windscreen repair business.<br />

Windscreen<br />

Repair System<br />

The <strong>HBC</strong> system D has been developed to carry<br />

out quality repairs on laminated car windows.<br />

The technology allows you to seal the window,<br />

restore the original strength of thewindow, make<br />

the windscreen optically clear all over, and to<br />

prevent the fracture point from becoming a<br />

weak spot. This revolutionary system is specially<br />

designed for professionals and is your guarantee<br />

for top quality windscreen repairs with a<br />

minimum of time consumption.<br />

» No heating required<br />

» Higher vacuum<br />

» Simple repair process<br />

» Lower risk of breaking<br />

the windscreen<br />

» Even faster repair time<br />

NEW<br />

FASTEST<br />

LED UV LAMP<br />

AVAILABLE<br />

Part no. 714-LED<br />

UV LED lamp w/ rechargeable battery<br />

Curing time<br />

30 seconds<br />

Curing time 30 seconds or less<br />

Rechargeable Li-ion battery<br />

Battery indicator for recharge<br />

Safety UV control; Turns off when removed<br />

from windscreen<br />

USB recharging cable included<br />

CE approved<br />

Strong suction cups<br />

Automatic countdown for curing time<br />

Light weight (Only 278 grams)<br />

Does not generate heat

D<br />

Windscreen repair & removal<br />

Windscreen Cutting System<br />

The windscreen cutting system from <strong>HBC</strong> system is used to remove gluedin<br />

windscreens from vehicles without using cutting blades or metal wire.<br />

As the tool is powered using a rechargeable electric screwdriver (not<br />

included as part of the kit), it does not require much expenditure of<br />

force.<br />

In order to cut through the adhesive bead around the windscreen,<br />

the kit makes use of the specially designed high-tensile cutting wire<br />

(Part no. 623). This removal wire has a cutting performance that is<br />

similar to standard metal cutting cords, but is so soft and flexible that<br />

it avoids any damage to the paintwork of the vehicle.<br />

Part no. 622<br />

Windscreen Cutting System<br />

» The tool is constructed in such a way that the tool only<br />

needs to be repositioned four times to remove the<br />

windscreen and the tool does not need to be modified<br />

during the process.<br />

» Time-saving<br />

» Can be operated by one person<br />

» Powered by electric screwdriver<br />

» Simple and quick operation<br />

» Where permissible the interior fittings<br />

can remain in place<br />

» Avoids any damage to the paint and<br />

body work of the vehicle<br />

» No re-spray necessary<br />

» Clean, even cut<br />

» Reduced risk of injury to the installer

Headlight<br />

Restoration System<br />

2 component<br />

formula<br />

Part no. 609<br />

Headlight Repair System<br />

Headlight Repair System<br />

Many vehicles on the road today have yellowed and cloudy<br />

headlights due to UV light damage as well as wear and tear from<br />

weather and road debris. The results is not only poor vehicle<br />

appearance and reduced reselling value but it also compromises<br />

safety.<br />

The headlight repair system from <strong>HBC</strong> Smart Repairs offers a<br />

fast and easy way to restore the clarity to headlight lenses<br />

that have become dull over time, at a fraction of the cost of<br />

replacement.<br />

Consisting of a special two-component finish with<br />

excellent characteristics of resistance and adherence<br />

to polycarbonate-base plastic materials. The raw<br />

materials used do not prejudice the polycarbonate’s<br />

mechanical resistance (cracking), but protect it from<br />

the otherwise inevitable yellowing.<br />

the perfect start<br />

to an excellent finish<br />

YEAR<br />

*<br />

YEAR<br />

REPAIR<br />

*<br />

GUARANTEE * GUARANTEE * Warranty *<br />

* <strong>HBC</strong> System guarantees that headlights restored with our Headlight Repair System<br />

maintain clarity for at least five years. Provided all instructions have been followed

D<br />

Headlight restoration<br />

UV Protective<br />

Headlight coating<br />

in a ready-to-use Aerosol, no mixing required<br />

The aerosol contains 400 ml. of UV coating suitable for all types of<br />

headlights made of polycarbonate, incl. halogen, LED and Xenon lights.<br />

» Ready to use aerosol, no mixing required<br />

» Suitable for all types of polycarbonate headlights;<br />

Halogen, LED, Xenon<br />

» Fast drying time; 15 min. at 20 degrees Celsius<br />

Part no. 621 UV-Protective Coating Aerosol<br />

the perfect start<br />

to an excellent finish<br />

caravan<br />

repair<br />

7YEAR<br />

PROTECTION *<br />

YEAR<br />

GUARANTEE *<br />

YEAR<br />

REPAIR<br />

GUARANTEE *<br />

*<br />

W<br />

* <strong>HBC</strong> System guarantees that headlights restored with the UV-Protective Coating remain<br />

clear for one year. Provided all instructions have been followed.

Alloy wheel<br />

Restoration Systems<br />

Painted Alloy wheel<br />

Repair System<br />

Part no. 532<br />

The E3 Alloy Wheel Repair System effectively repairs<br />

kerbed, scratched or corroded alloy wheels at a very<br />

low cost per repair.<br />

The system is complete with fillers and aerosol colours<br />

for the repair of most common wheel types. After the<br />

application of colour, a thick layer of clearcoat is added<br />

to attain the perfect finish.<br />

-----------------------------------------------------------------------<br />

PAINTED ALLOY WHEELS – The most common finish is a painted<br />

wheel which comes in a wide variety of designs. Painted wheels are<br />

sprayed or powder coated. The process of painting a wheel consists<br />

of prepping the wheel, priming, painting and applying a clear coat,<br />

which seals the finish against corrosion.<br />

Alloy wheel Paint System<br />

INTRODUCING THE 4TH GENERATION AND MOST ADVANCED,<br />

EASY TO USE ALLOY WHEEL PAINT SYSTEM ON THE MARKET!<br />

The <strong>HBC</strong> alloy wheel paint System is a must for anyone<br />

looking to produce a factory finish repair - first time!<br />

Part no. 998 Wheel paint system

E<br />

Alloy wheel restoration<br />

Polished Alloy wheel<br />

Repair System<br />

Part no. 551<br />

With the E3 Alloy wheel repair system, for polished alloy wheels<br />

you can effectively repair kerbed, scratched or corroded alloy<br />

wheels at a very low cost per repair.<br />

The system is complete with sanding equipment, polishing<br />

compounds, cleaner and clear coat for the perfect finish.<br />

-----------------------------------------------------------------------------<br />

POLISHED ALLOY WHEELS are the most difficult of all wheel styles to<br />

identify. They are generally very expensive and are constructed of the<br />

highest quality material. Some polished finishes resemble painted finishes<br />

while others resemble chrome. Polished wheels have a lighter look and<br />

may not be clear-coated. Polished wheels that are not clear-coated have<br />

a much higher luster but they require a great deal of maintenance. You<br />

will never see a metallic sparkle on polished wheels when viewed in bright<br />

sunlight. A polished wheel closely resembles silverware.<br />

<strong>HBC</strong> system is introducing the latest water-based paint system for refinishing alloy wheels. Packaged in a<br />

mobile trolley solution. The most advanced, easy to use wheel paint system on the market! Designed<br />

in conjunction with vehicle manufacturers the system provides: Original factory matched colours<br />

including all leading manufacturers such as Ford , VW/AUDI, Mercedes, Honda, Porsche etc.<br />

With the system you can repair many kinds of smaller scratches, parking<br />

damaged and other kind of damaged on polished high gloss<br />

aluminum wheels, aluminum frames on<br />

motorbikes, and other aluminum parts.<br />

» 4th Gen. Water Borne technology. Using the latest world wide available pigments and resins of the highest quality.<br />

» Excellent technology. Shake and pour technology with no need for stirring, saving time for the operator.<br />

» Fast drying. Offers increased in productivity and greater material durability, saving time and increasing profitability.<br />

» Fully compliant. Meets the needs & requirements of the latest environmental legislation.<br />

» Superb opacity. Less coats required to achieve full colour reproduction, due to high quality and concentration of pigments.<br />

» Aerosols are Toulene Free which is a major advantage in terms of Health & Safety as Toulene is carcinogenic.

PPATENTED CARAVAN REPAIR SYSTEM<br />

ATENTED CARAVAN REPAIR SYSTEM<br />

Caravan & Mobile home<br />

Repair Systems<br />

Caravan Repair System<br />

With the <strong>HBC</strong> Caravan Repair System for the first time panels on caravans,<br />

motorhomes and trailers can be restored to their original condition,<br />

quickly and cost-effectively. <strong>HBC</strong> system has successfully designed<br />

& developed a specialist repair system which has been rigorously<br />

tested and now features a world-wide patent.<br />

Part no. 513<br />

Caravan system E1<br />

Traditionally damaged panels (normally the whole side of the<br />

vehicle), would have to be replaced which is hugely expensive<br />

and very time consuming for the insurer, repairer and owner.<br />

Now specially designed vacuum equipment, templates and<br />

unique mouldmaker provide a perfect match to original smooth<br />

or contoured surfaces. This system is capable of repairing major<br />

damage on aluminium panels.

E<br />

Caravan repair<br />

Caravan<br />

Repair Trolleys<br />

The new Caravan Trolley<br />

is the ultimate high-end<br />

workshop solution for the<br />

Caravan repairer.<br />

Caravan Trolley Master<br />

(Part no. 652)<br />

Trolley Content :<br />

E : Complete Caravan Repair System<br />

E : Caravan Spot Repair System<br />

E : Upgrade-System E<br />

B6 : Plastic Welding System<br />

H : Ozon - Air Cleaning System<br />

Caravan Trolley Standard<br />

(Part no. 651)<br />

Content :<br />

E : Complete Caravan Repair System<br />

E : Caravan Spot Repair System<br />

E : Upgrade-System E<br />

The Smart Repair Trolley is flexible and is simply a<br />

must for workshops that require efficiency, flexibility<br />

and mobility and contains all the needed tools and<br />

equipment to make a high-end Caravan repair.<br />

Packed in a strong, lockable, steel cabinet on wheels<br />

which makes it very easy to move around in the<br />

workshop area.

PDR Paintless<br />

Dent Removal Systems<br />

G8 system<br />

Part no. 398 / Complete System G Mini 8 Kit<br />

G14 system<br />

Part no. 399 / Complete System G Basic 14 Kit<br />

G8<br />

G14<br />

G30 system<br />

Part no. 400 / G Premium, 30 tools, accessories and transport box<br />

G30

G<br />

Paintless dent removal<br />

Part no. 17.400 Dent Repair Mini Kit<br />

The Dent Repair Mini Kit is perfect for removal of minor dents.<br />

Part no. 13.985<br />

Magnetic Get Started System<br />

The training of eye-hand<br />

coordination is one of the most<br />

difficult exercises during the<br />

training Paintless Dent Repair<br />

(PDR). Trainees often spend<br />

several hours or days before they<br />

can find the exact location of the<br />

tip of the tool.<br />

Part no. 13999<br />

Magnetic PDR Tool

G61 Master System<br />

Part no. 700 / G Master, 51 tools, accessories and 2 transport boxes<br />

G51

G<br />

Paintless dent removal<br />

Adjustable PDR tools<br />

Multi adjustable handles<br />

The multi adjustable handles allow the technician to<br />

quickly change the working position angle. Just one<br />

simple click, and the tool is ready to operate in the new<br />

angle. The steel is our standard specially heat treated,<br />

8 mm, durable stainless steel.<br />

Type 2<br />

L:450 mm. D:8 mm Part no. 498<br />

L:620 mm. D:8 mm Part no. 499<br />

Type 3<br />

L:450 mm.D:8 mm Part no. 500<br />

L: 620 mmD:8 mm Part no. 501<br />

Type 1<br />

L:520 mm. D 8 mm.<br />

Part no. 497<br />

Lift handle<br />

Twist handle<br />

Click in position<br />

497 PDR Door tool, type 1, 570mm<br />

498 PDR Door tool, type 2, 490mm<br />

499 PDR Door tool, type 2, 660mm<br />

500 PDR Door tool, type 3, 475mm<br />

501 PDR Door tool, type 3, 620mm<br />

502 Adjustable door tool kit<br />

497 + 498 + 500

Electro-Magnetic<br />

Dent Removal System<br />

Part no. 17500<br />

the cleanest and fastest way<br />

for fixing hail dents, door dings<br />

and other minor soft dents.<br />

The new Electro-Magnetic Dent Removal System with a custom<br />

designed Dent pulling inductor is ideal for repairing small soft dents<br />

on the car body without retouching the paint.<br />

Unlike traditional PDR tools, there is no need to meticulously<br />

massage dents from the back of vehicle panels, in hard-to-reach<br />

areas, or areas difficult to get behind.<br />

Induction heating is the highest tech method for<br />

removing soft dents. The result is a clean dent repair in<br />

a fraction of the time compared to a conventional PDR<br />

tool. The system can be used in all mechanical repair and<br />

auto body repair facilities.<br />

Part no. 17500<br />

Electro-Magnetic Dent Removal System

WIRELESS LED<br />

13928 LED Dent lamp 12v<br />

Wireless with rechargeable lithium<br />

battery w/ suction-cup and flexible<br />

“gooseneck”.<br />

LED<br />

13923 LED Dent Lamp<br />

(white/yellow) 12v w/ suctioncup<br />

and flexible “gooseneck”<br />

LED<br />

FLUORESCENT<br />

13443-1<br />

LED Dent Lamp w/ 3 LED strips<br />

(white and yellow) 12v<br />

Portable stand w/ locking wheels<br />

CHROME<br />

13443<br />

Fluorescent Dent Lamp 12v<br />

Portable stand w/ locking wheels<br />

CHROME

A System B1 System B2 System B3 System<br />

Fabric repair<br />

Plastic repair<br />

Leather repair<br />

Vinyl repair<br />

Bumper repair<br />

Texture repair system for repair<br />

of damages in the surface of<br />

plastic, leather and vinyl.<br />

Plastic paint mixing<br />

Vinyl paint mixing<br />

Leather paint mixing<br />

Leather Coat<br />

“10” leather coat aerosols<br />

Fabric Coat<br />

“20” Fabric coat aerosols<br />

B4 System<br />

“30” Plastic coat aerosols<br />

G Dentlifter<br />

E System<br />

Caravan repair<br />

system<br />

B5 System<br />

Leather Care<br />

system<br />

E Painted Rim System<br />

E Polished Rim System<br />

B6 Plastic Welding<br />

System<br />

B Mini Bumper<br />

Bumper repair system<br />

B Mini Plastic<br />

Hard plastic repair<br />

Trolley Mobile<br />

Trolley L<br />

Trolley XL<br />

PDR Trolley Prof<br />

Systems in trolley<br />

Systems in trolley<br />

Systems in trolley<br />

Systems in trolley<br />

A<br />

B3<br />

A<br />

B3<br />

A<br />

B4<br />

Slidehammer Kit<br />

B1<br />

B4<br />

B1<br />

B4<br />

B1<br />

E3<br />

G30 - PDR kit<br />

B2<br />

B2<br />

E3<br />

B2<br />

D Pro G6<br />

B3

C System<br />

Car paint, spot repair<br />

C Chipfix System<br />

Chipfix, spot repair<br />

D System<br />

D Pro G6<br />

Windscreen and crack<br />

repair system<br />

Complete Smart Repair Range<br />

F Scanning System<br />

Plastic,leather & vinyl<br />

scanning system<br />

H System<br />

Air cleaning system<br />

D System<br />

Windscreen<br />

Cutting system<br />

D Headlight Repair<br />

G8 system G14 system G30 system Slidehammer system<br />

Dent repair starter - G Mini 8<br />

Dent repair semi - G Basic 14<br />

Dent repair profi.- G Premium 30<br />

Dent repair glueing<br />

system<br />

Trolley XXL<br />

Systems in trolley<br />

Trolley Premium<br />

Systems in trolley<br />

Trolley Master<br />

Systems in trolley<br />

A<br />

B4<br />

A<br />

B4<br />

A<br />

B4<br />

B1<br />

E3<br />

B1<br />

E3<br />

B1<br />

E3<br />

B2<br />

D Pro G6<br />

B2<br />

D Pro G6<br />

B2<br />

D Pro G6<br />

B3<br />

C<br />

B3<br />

C<br />

B3<br />

C<br />

Slidehammer Kit<br />

Slidehammer Kit<br />

G30 - PDR kit<br />

G30 - PDR kit<br />

D - Headlight System<br />

H - Air Cleaning

Smart Repair<br />

Training<br />

Getting started<br />

Training is a vital part of your new smart repair equipment and<br />

training is a crucial factor to make sure that you achieve all the<br />

advantages and possibilities that the tools offer.<br />

Our international Smart Repair and PDR training academies are<br />

centrally located in Europe and Asia. We also have several official<br />

partners spread across the globe offering <strong>HBC</strong> standardised Smart<br />

Repair training. For more details on your nearest <strong>HBC</strong> training<br />

provider please visit our website:<br />

www.hbc-system.com > training > booking<br />

www.smartrepair-training.<br />

www.hbc-system.com<br />

www.smartrepairtools.com<br />

www.smartreparatursystem.de<br />

www.dassmartreparatur.de<br />

www.facebook.com/hbcsystems<br />

youtube.com/HenrikBro<strong>HBC</strong>system<br />

get started online<br />

www.hbc-system.com<br />

videos, guides, news ...<br />

Copyright 2000-2020- <strong>HBC</strong> SYSTEM All rights reserved <strong>HBC</strong> system Smarttool Production. Subject to omissions and alterations.<br />

www.hbc-system.com<br />

info@hbc-system.com<br />

Tel. +45 7022 7070<br />

<strong>HBC</strong> system<br />

<strong>HBC</strong> system / Corporate headquarters<br />

Hobrovej 963<br />

DK9530 Støvring<br />

Denmark<br />

Tel.: +45 7022 7070<br />

info@hbc-system.com<br />

<strong>HBC</strong> System Germany<br />

<strong>HBC</strong> System Deutschland<br />

Lise-Meitner-Str. 1 – 7<br />

D-24223 Schwentinental bei Kiel<br />

Deutschland<br />

Tel.: + 49 43190499891<br />

verkauf@hbc-system.com