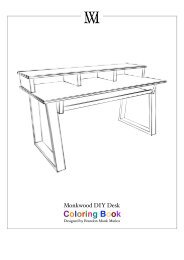

Monkwood DIY Desk Plans BETA version

Here's an 'as is' DIY desk with supplies and dimensions and some instructions. Fill in the blanks creatively and or consult a woodworker to create your own until full version is released. My client building schedule has been very intense and I have less help in the shop these days due to COVID. I aim to keep chipping away at these plans for release3 in the new year. For those who would like to get started I have made these BETA plans available. Thanks for your patience and interest in this project! Sincerely, Monk Please tag you pics with #monkwoodDIYdesk

Here's an 'as is' DIY desk with supplies and dimensions and some instructions. Fill in the blanks creatively and or consult a woodworker to create your own until full version is released.

My client building schedule has been very intense and I have less help in the shop these days due to COVID. I aim to keep chipping away at these plans for release3 in the new year.

For those who would like to get started I have made these BETA plans available.

Thanks for your patience and interest in this project!

Sincerely,

Monk

Please tag you pics with #monkwoodDIYdesk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Monkwood</strong> <strong>DIY</strong> <strong>Desk</strong>:<br />

Designed by Brandon Monk Muñoz // Built by You<br />

monkwoodstudio.com<br />

(<strong>BETA</strong> Version)

Table of Contents<br />

3 Why Build a Studio <strong>Desk</strong>?<br />

4 Style & Method<br />

5 Notes on Safety<br />

6 Tools & Equipment<br />

10 Model A // 61 key - 3 rack bays<br />

11 - dimensions & diagrams<br />

11 - materials & supplies<br />

11 - cutting tops & shelving<br />

12 - cutting under frame parts<br />

13 - bases<br />

14 - finishing<br />

15 - assembly<br />

16 Model B // 88 key - 2 split rack bays<br />

11 - dimensions<br />

11 - materials & supplies<br />

11 - cutting tops & shelving<br />

12 - cutting under frame parts<br />

13 - bases<br />

14 - finishing<br />

15 - assembly<br />

22 Model Z (custom configuration)<br />

23 - notes on hardwood<br />

24 - notes on sit/stand bases<br />

25 - notes on future editions and upgrades<br />

25 Example Photos<br />

26 #<strong>Monkwood</strong><strong>DIY</strong>desk Community<br />

@ reddit.com/monkwooddiydesk

Why Build a Studio <strong>Desk</strong>?<br />

A desk can be much more than a wooden rectangle that holds up your stuff. A well built<br />

studio desk can organize your creative tools and help you focus your skills and ideas<br />

into a unified workflow that unlocks your potential to alter your current reality for the<br />

better. Or, it can simply be a very nice place to shoot some emails.<br />

However you decide to use your studio desk, you’ll soon experience the benefit of<br />

having a versatile space to work on what’s important to you. Now you won’t waste time<br />

setting up your gear whenever you get inspired or start feeling cable chaos fatigue when<br />

10 hours into an all night session. A designated space to create will allow you to pick up<br />

wherever you left off and begin to gain some real traction towards your goals and<br />

aspirations.<br />

I’m not suggesting a studio desk will magically make your life better. Yet, if built and<br />

used with sincere intent, it can definitely help open up many new possibilities for you.<br />

I’ve built over 250 desks for all sorts of creative professionals. Whether they were a full<br />

time composer/producer or a lawyer by day and synth lord by night - each of my clients<br />

has an innate desire to manifest their ideas into material form - no matter what.<br />

If that sounds anything like you, then I believe you have what it takes to make this<br />

<strong>DIY</strong> desk and then go on to do great things with it...<br />

You got this!<br />

Brandon Monk Muñoz

Style & Method<br />

These plans are intended for the first time woodworker with minimal tools, time,<br />

space and money to work with. If you can build a skate ramp, you can build this. The<br />

building style is inspired by the old school, use what you got in the garage method I<br />

watched my grandfather employ during my childhood. With only a few tools and<br />

some scrap wood he could build a doghouse that could survive the apocalypse.<br />

My aim is to help you create a beautiful and long lasting piece of furniture with<br />

common materials and very simple construction methods. In these plans I combine<br />

strength and accessibility of ‘skateramp joinery’ with the attention to detail I've<br />

learned over 20 years of furniture making.<br />

You are also welcome to seek assistance from an experienced craftsperson in your area<br />

if needed or preferred. Those with more experience and resources can enhance the<br />

design with alternate joinery and hardwood materials to make it even better.<br />

I see the #<strong>Monkwood</strong><strong>DIY</strong>desk as a long term and evolving project. I will add more<br />

details and options to the plans in the days to come. I look forward to seeing the<br />

many different <strong>version</strong>s that will come out of these plans.<br />

Treat it like a flexible recipe which can be adapted to fit your specific taste and needs.<br />

The desk can be made in a weekend, but if you have the time and space, I recommend<br />

giving it about a week so you can hone in and give each step of the process your full<br />

attention and focus. If you only have a small window to work with, just give it your all,<br />

don’t rush or get too mad at mistakes. They are a part of every learning process.

Notes on Safety<br />

(post in a visible area as you build)<br />

__________________________________________________________________________<br />

• Build Sober<br />

• Don’t Rush<br />

• Wear Eye Protection + Dust Mask<br />

• Measure Twice, Cut Once<br />

• Don’t Make Cuts in Awkward Positions<br />

• Let Blades Spin Fully Before Cutting<br />

• Don’t Video Yourself While Making Cuts<br />

• Organize Your Power Cables<br />

• Unplug Your Tools When Not in Use<br />

• Put Oily rags in Water Bucket After Use<br />

• Clean Work Area Frequently<br />

• Don’t Get Too Mad at Your Mistakes

Tools & Equipment:<br />

Use all tools with care and respect. If borrowing any from neighbors or friends please return<br />

them promptly, cleaned and in good condition. I also recommend requesting the help of those<br />

with building experience for any part of the process you may need assistance with.<br />

__________________________________________________________________________<br />

Essential//<br />

• miter saw or handsaw with miter box<br />

• #2 pencil / silver color pencil / sharpie<br />

• tape measure<br />

• combination square<br />

• hammer<br />

• power drill<br />

• stubby phillips screwdriver<br />

• #2 phillips / 1/8” pilot bit / counter sink bit<br />

• worktable on sawhorses or 4 x 8 - 3/4 ply or<br />

insulation foam on ground<br />

• extension chord<br />

• 3” paint brush<br />

• water bucket or large quart cup<br />

• cloth rags<br />

• first aid kit (place in plain sight to help stay alert)<br />

• sanding stick*<br />

Recommended//<br />

• circular saw ‘skil saw’ (if cutting<br />

your own ply)<br />

• orbital sander or regular square<br />

• 48” metal T-square or straight edge<br />

• router with 1/4” round over bit<br />

• small hand plane<br />

• nail gun with 2” and 2.5” nails**<br />

• Kreg pocket hole system**<br />

* Instructions how to make in finishing section<br />

** You can substitute wood screw and hammered finish<br />

nails with these tools

Model A // 61 key Studio <strong>Desk</strong>

Model A // Materials & Supplies:<br />

This shopping list is based on readily available and cost effective construction materials. You are<br />

welcome to substitute certain items for others, such as hardwood tops instead of ply. However,<br />

you will need to adapt the plans to suite your material preferences.<br />

This list also includes additional pieces of wood for a possible mistake cuts and scrap wood to<br />

use for assembly and finish purposes. If using Kreg Jig or nail gun you’ll need to get the<br />

equivalent screws/nails needed.<br />

__________________________________________________________________________<br />

Wood//<br />

1 4 x 8 ft sheet 3/4” (18mm) plywood (construction or furniture grade)<br />

1 4 x 8 ft sheet of 3/4” (18mm) ply or insulation foam (for cutting assembly work top)<br />

3 2 x 6 - 8ft (245cm)<br />

3 2 x 4 - 10ft (305cm) - or 4 @ 8ft long<br />

3 1 x 2 - 8ft (245cm) fir, pine or poplar<br />

Building Supplies//<br />

Choose the driest and straightest pieces you can find!<br />

2 14” (356mm) or 16” metal drawer slides<br />

(Accuride 3832 or equivalent - regular not soft close or push!)<br />

4 A35z Simpson Strong Tie mounting brackets<br />

(or large door hinges)<br />

25 box of #6 - 2” (50mm) coarse drywall or wood screws<br />

25 box of #8 - 2.5” (64mm) coarse drywall or wood<br />

screws<br />

50 box of #8 - 5/8” (16mm) pan head screws<br />

25 box of 2” (50mm) finish nails<br />

1 small bottle of wood glue (ex: Titebond 2)<br />

Finish Supplies//<br />

3 sheets each of 80/120/220 grit sandpaper<br />

5 80 grit paper for sander<br />

1 quart (946ml) clear top coat finish<br />

(water based recommended on ply)<br />

1 quart (946ml) wood stain or paint<br />

1 beeswax and or orange oil<br />

4 felt pads for bases<br />

1 small wood filler<br />

1 plastic or fabric drop cloth

Cutting Tops and Shelving:<br />

You can cut the main panels with a circular saw or even a handsaw if needed. You can also<br />

show this page to someone who can operate the sheet cutting panel saw which can be found at<br />

many large supply stores like Home Depot or B&Q. They can make the main cross cuts for<br />

you if you ask them nicely. Tips help too.<br />

__________________________________________________________________________<br />

Before cutting ply, look and see which side looks the<br />

best and use that for your desk top and top shelf<br />

1. Measure and mark ply from left edge at 66”<br />

2. Measure and mark ply from left edge at 81”<br />

3. Measure and mark ply from left edge at 91”<br />

4. Use T-square or straight edge to draw a line<br />

across the whole sheet with a sharpie<br />

5. Cut on the line at 91”<br />

6. Cut on the line at 81”<br />

7. Cut on the line at 66”<br />

8. Measure and mark a line at 33” lengthwise<br />

across the large 66” x 48 piece<br />

9. Cut across the line

Cutting Parts:<br />

Use the straightest and driest pieces of wood you can find for the under-frame and bases to<br />

avoid any assembly issues from warped wood. Cut rack shelf partitions from the same piece<br />

of wood to insure it is the same width as it can vary slightly from piece to piece.<br />

Always keep your holding hand AWAY from the cutting area.<br />

1. Cut 2 pieces of 2x6 at 31.5” (main side frame panels)<br />

2. Cut 10 degree angles on both ends of each. (make cure<br />

they face correctly like a v.<br />

3. Cut 4 pieces of 2x6 at 14” (rack shelf)<br />

4. Cut 1 piece of 2x4 at 48” (support beam)<br />

5. Cut 2 pieces of 1x2 at 48’ (hidden shelf rails)<br />

6. Cut 1 piece of 1x2 at 47 7/8” (sliding shelf front rail)<br />

7. Cut 1 piece of 1x2 at 47” (sliding shelf back rail)

Sanding and Finishing:<br />

I recommend pre-finishing the pieces before assembly as it it easier to work on in pieces +<br />

way less messy. It also allows for different tones for the parts and tops as shown in the<br />

example pieces. Always use adequate floor covering as to not anger your landlord. Things<br />

splatter no matter how careful you are.<br />

The Sanding Stick:<br />

A useful shaping and sanding tool for this project and beyond.<br />

I recommend making at least a couple.<br />

1. Cut 1x2 off cut at 11”<br />

2. Fold and cut 1 sheet of sandpaper in half lengthwise<br />

3. Apply spray adhesive or school glue to back of sandpaper<br />

4. Line up edge of paper with long edge of wood and wrap around<br />

5. Use hands to press on sandpaper until fully adhered<br />

Shaping and Sanding:<br />

Rough to smooth. Don’t rush or skip paper grits. It’ll all shows up in the end...<br />

1. Use router or sanding stick around to round the<br />

top edge of your desktop and top shelf piece.<br />

2. Use router or sanding stick to round the front and<br />

back edges of rack shelf partitions.<br />

3. Use router or sanding stick to round the front/<br />

back and bottom edge of the underframe side panels<br />

4. Use sanding stick to tame any remaining sharp -<br />

fresh cut edges and corners of the plywood shelving<br />

and underframe parts.<br />

5. Use sander or hand with 120/150 grit to smooth<br />

out the edges you just sanded with 80grit.<br />

6. Use sander or hand with 120/150 grit to smooth all<br />

flat surfaces of the panels and parts

Finishing:<br />

A million ways to chase a cat. Here’s just a few...<br />

Paint Sample Wood Stain:<br />

A cheap way to get wood to look any color you want.<br />

1. Mix one 8oz (237ml) sample per quart (1L) of water<br />

2. Stir well<br />

3. test on off cuts till you get the right ratio for you<br />

4. add more water if too dark/opaque<br />

Brushing on Finish:<br />

Use brush to apply water based paint or stain. Use rag or small bristle brush to apply oil<br />

stain. Always put oily rags in water bucker after use for fire safety.<br />

1. Paint or stain top panels desired color with brush<br />

2. Paint or stain underframe parts desired color<br />

3. Paint or stain 2x4’s for bases desired color (can<br />

do this before or after making cuts - see Base<br />

section for more info)<br />

4. Lightly sand with 220<br />

5. Apply clear water based finish<br />

6. Sand with used 220 and add another coat if<br />

desired. I recommend 2 or 3 coats of clear for the<br />

desktop.<br />

7. Add second coat on tops

Cutting Bases:<br />

2x4 material for bases can be pre finished before cutting or afterward. I pre-finished them<br />

in the example desks as its easier to brush upon the whole plank. Either way, I recommend<br />

cutting the 4 parts from a single 10ft - 2x4 for wood consistency. I cut pieces in order like I<br />

would a grain wrapped box. Make a smaller practice piece if you have extra wood.<br />

You can also make these a simpler rectangle if your miter saw or box doesn’t go past 45 deg.<br />

__________________________________________________________________________<br />

1. Set your miter saw to 0 deg and cut following<br />

pieces from long 8-10ft 2x4 starting from the right.<br />

2. Cut 1st piece at 29.5” then label 1a w/ pencil<br />

3. Cut 2nd piece at 30” then label 1b (bottom)<br />

4. Cut 3rd piece at 29.5” then label 1c (side)<br />

5. Cut 4th piece at 20.5” then label 1d (top)<br />

6. Repeat above cuts for for other base,<br />

labeling 2a - 2b - 2c - 2d in the same manner.<br />

7. Arrange Base 1 on your worktop next to you in<br />

the way with will be assembled (fig 3.)<br />

8. Draw a mark on each end indicating which<br />

direction the cut will be made. Then draw a 40 to the<br />

top cuts and a 50 to the bottom ones. This will help<br />

you keep track of each cut.<br />

On the following cuts I recommend making 2 cuts per<br />

miter. One to get close to the edge and the second to<br />

go right up to the the edge. If using a handsaw miter<br />

box just make one cut on the edge.<br />

9. Set miter saw to 40deg and make the 4 cuts on<br />

the top miters you labeled accordingly.<br />

10. Set miter saw to 50deg and make the 4 cuts on<br />

the top miters you labeled accordingly.<br />

11. Check cuts with measuring tape and dry<br />

assemble on worktop to see if they fit together well.<br />

12. Repeat the above steps with Base 2

Assembling Bases:<br />

Use the tape trick method for gluing up the base parts and reinforcing with screws after glue dries.<br />

_________________________________________________________________________<br />

1. Layout 4 pieces for left Base 1 on long work top<br />

or foam board. Place them in consecutive order from<br />

end to end with outside facing up.<br />

2. Use painters tape or duct tape to connect ends<br />

3. Flip over carefully<br />

4. Add glue to miters and spread evenly<br />

5. Gently lift up parts to meet together<br />

6. Attach tape to remaining end<br />

7. Wipe and let dry for 2-3hours<br />

8. Drill 2 pilot holes on each miter angle. entering<br />

from top and bottom of base. Use optional<br />

countersink after for cleaner screw entry.<br />

9. Use #8 x 2in screws in each pilot hole. 2 per<br />

angle - 8 per base.<br />

10. Drill 8 evenly spaced pilot holes to to trapezoid<br />

piece of the bases. Then Countersink.<br />

11. Sand and touch up finish on miter angles and<br />

ends<br />

12. Repeat the above steps with right Base 2

Assembling Underframe:<br />

We employ a simple skate ramp style method with screws or nail gun.<br />

You can adapt to dowels, pocket holes or dominoes if preferred.<br />

_________________________________________________________________________<br />

1. Designate which side frame pieces are left and<br />

right and mark them on the top side. L and R<br />

2. Lay side frames on worktop with inside facing up.<br />

3. Use measuring tape and combo square to mark<br />

layout points and pilot hole marking accorning to<br />

digram above. (Will include more specific instructions<br />

in <strong>version</strong> 1.0)<br />

4. Drill pilot holes for support beam and hidden shelf.<br />

add countersink on outside<br />

5. Set combo square to 7/8” (22ml) and mark a line<br />

on the bottom inside front of side piece for aligning<br />

the drawer slides. front of slide should be 2” from<br />

front and 29.5” from back for both left and right<br />

slides.<br />

6. Take out shelf piece of drawer slide by pulling<br />

plastic tab. (see slides instructions for more details)<br />

7. Attach frame portion of slide to the left and right<br />

side frames.<br />

8. Place left and right side frames upside down on<br />

worktop with insides facing eachother.<br />

9. Attach 2x4 support beam angle using 2 - #8 x<br />

2.5” screws though pilot holes on each side.

10. cut 2 pieces of 2x6 @ 4.5” long for assembly<br />

supports for hidden shelf. (cut them off of a scrap<br />

piece no shorter than 14” for safety!)<br />

11. Lay 4.5” cut off on each side where the hidden<br />

shelf will be.<br />

12. Place hidden shelf on top of scrap supports<br />

and line up to markings.<br />

13. Screws into side frame using #8 x 2.5” wood<br />

screws. (3 screws pers side - 6 total). Use a clamp<br />

if needed to hold in place.<br />

14. Attach front and back 1x2 rails onto hidden<br />

shelf using nail gun or 1.5” brad finish nails.<br />

15. Take out shelf piece of drawer slide by pulling<br />

plastic tab. (see slides instructions for more details)<br />

16. Attach frame portion of slide to the left and<br />

right side frames.<br />

17. Place left and right side frames upside down<br />

on worktop with insides facing eachother.<br />

18. Attach 2x4 support beam angle using 2 - #8 x<br />

2.5” screws though pilot holes on each side.<br />

19. Drill 8 evenly spaced pilot holes to to trapezoid<br />

piece of the bases. Then Countersink.<br />

11. Sand and touch up finish on miter angles and<br />

ends

Model B - 88key // Materials & Supplies:<br />

This shopping list is based on readily available and cost effective construction materials. You are<br />

welcome to substitute certain items for others, such as hardwood tops instead of ply. However,<br />

you will need to adapt the plans to suite your material preferences.<br />

This list also includes additional pieces of wood for a possible mistake cuts and scrap wood to<br />

use for assembly and finish purposes. If using Kreg Jig or nail gun you’ll need to get the<br />

equivalent screws/nails needed.<br />

__________________________________________________________________________<br />

Wood//<br />

1 4 x 8 ft sheet 3/4” (18mm) plywood (construction or furniture grade)<br />

1 4 x 8 ft sheet of 3/4” (18mm) ply or insulation foam (for cutting assembly work top)<br />

2 2 x 8 - 8ft (245cm)<br />

2 2 x 6 - 8ft (245cm)<br />

3 2 x 4 - 10ft (305cm) - or 4 @ 8ft long (245cm)<br />

3 1 x 2 - 8ft (245cm) fir, pine or poplar<br />

Building Supplies//<br />

Choose the driest and straightest pieces you can find!<br />

2 14” (356mm) or 16” metal drawer slides<br />

(Accuride 3832 or equivalent - regular not soft close or push!)<br />

4 A35z Simpson Strong Tie mounting brackets<br />

(or large 3” door hinges)<br />

25 box of #6 - 2” (50mm) coarse drywall or wood screws<br />

25 box of #8 - 2.5” (64mm) coarse drywall or wood<br />

screws<br />

50 box of #8 - 5/8” (16mm) pan head screws<br />

25 box of 2” (50mm) finish nails<br />

1 small bottle of wood glue (ex: Titebond 2)<br />

Finish Supplies//<br />

3 sheets each of 80/120/220 grit sandpaper<br />

5 80 grit paper for sander<br />

1 quart (946ml) clear top coat finish<br />

(water based recommended on ply)<br />

1 quart (946ml) wood stain or paint<br />

1 beeswax and or orange oil<br />

4 felt pads for bases<br />

1 small wood filler<br />

1 plastic or fabric drop cloth

Model B // 88 key Studio <strong>Desk</strong>